Self-propelled trolley conveying line polling device

A self-propelled trolley and conveyor line technology, applied in conveyors, measuring devices, mechanical conveyors, etc., can solve the problems of high labor intensity of workers, slopes on the track, unsafe, etc., to improve working conditions, good inspection effects, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

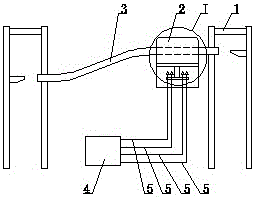

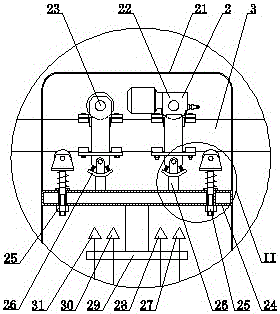

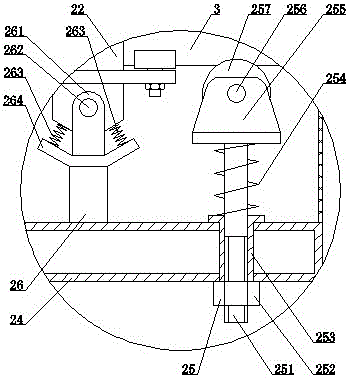

[0009] see Figure 1 to Figure 3 , the present invention includes an auxiliary beam 1 and a track 3, the track 3 is mounted on the auxiliary beam 1, and also includes an inspection trolley 2, and the inspection trolley 2 includes a transparent outer cover 21, a main vehicle 22, an auxiliary vehicle 23, an equalizing beam 24. Laser anti-collision sensor 27, temperature sensor 28, sensor support 29, combustible gas sensor 30, camera 31, control center 4, signal line 5, two equalizing beam stabilizing devices 25 and two car body stabilizing devices 26, all Described each equalizing beam stabilizing device 25 comprises guide rod 251, nut 252, guide sleeve 253, large compression spring 254, roller seat 255, roller rotating shaft 256 and roller 257, and described guide sleeve 253 is contained in the hole of equalizing beam 24, The roller 257 is installed on the roller seat 255 through the roller rotating shaft 256, the upper end of the guide rod 251 is welded on the bottom surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com