Patents

Literature

98results about How to "Does not affect uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

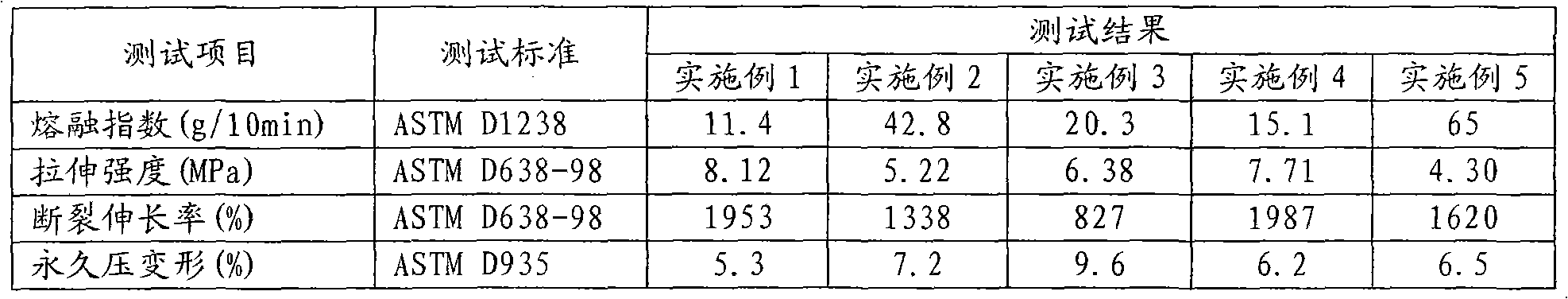

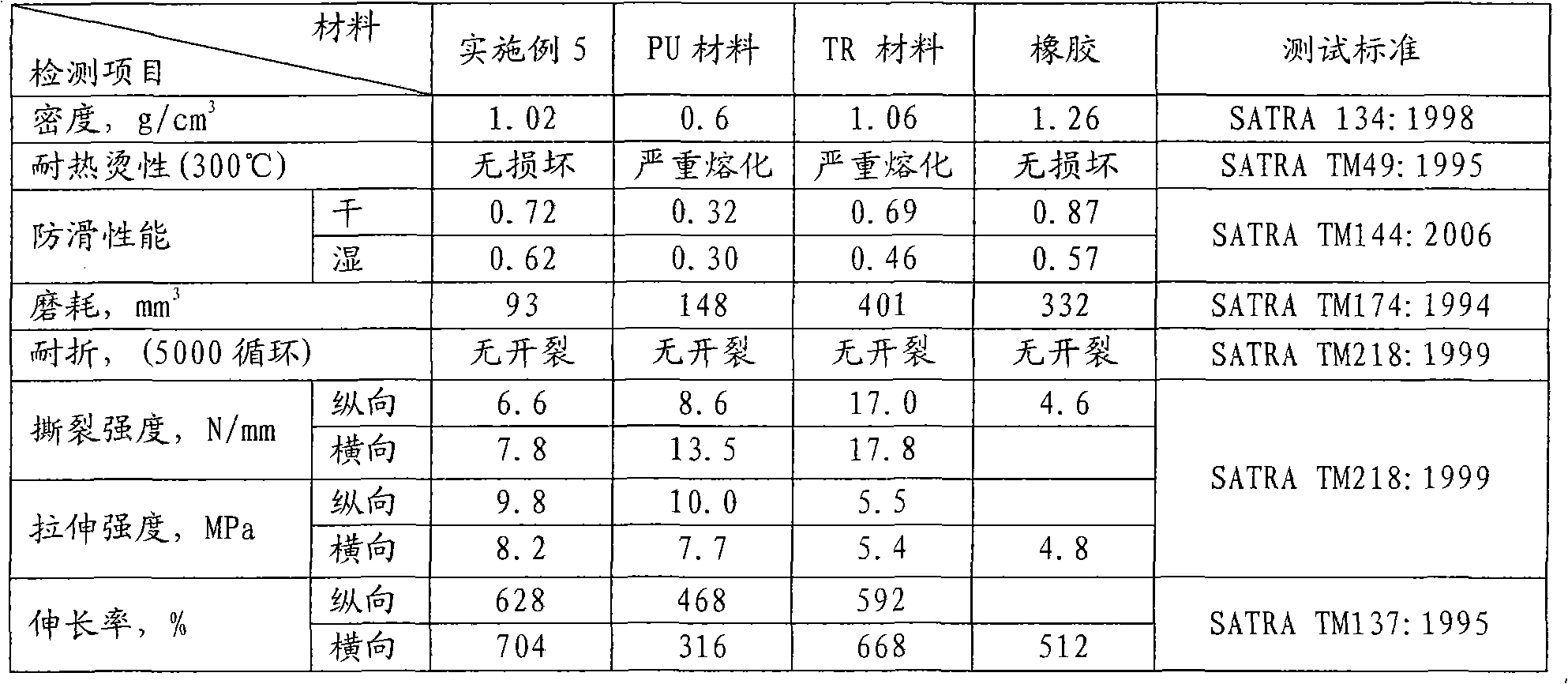

Cross-linked rubber composition, application thereof, rubber grains prepared by cross-linked rubber composition, preparation method and injection method of rubber grains

InactiveCN101624461ASmall molecular weightImprove liquiditySolesOvergarmentsCross-linkPolymer science

The invention relates to a cross-linked rubber composition, the application thereof, rubber grains prepared by the cross-linked rubber composition, a preparation method and an injection molding method of the rubber grains. The cross-linked rubber composition at least comprises a styrene-butadiene copolymer, a rubber softening agent, a flow modifying agent and a peroxide vulcanizing agent; the cross-linked rubber composition is suitable for preparing rubber products and can be prepared into non-cross-linked rubber grains below the temperature of 80 DEG C; and the rubber grains are formed by banburying, milling, extruding and granulating. The rubber composition and the rubber grains can be directly molded by injection, have good flow property, can be vulcanized in a later period and can be preserved at room temperature. Compared with the prior art, the rubber grains can be directly molded by injection, rubber particles are not easy to self-vulcanize, the vulcanization speed is easy to control, the rubber grains have no need to be stored at low temperature, and the like.

Owner:陈友明

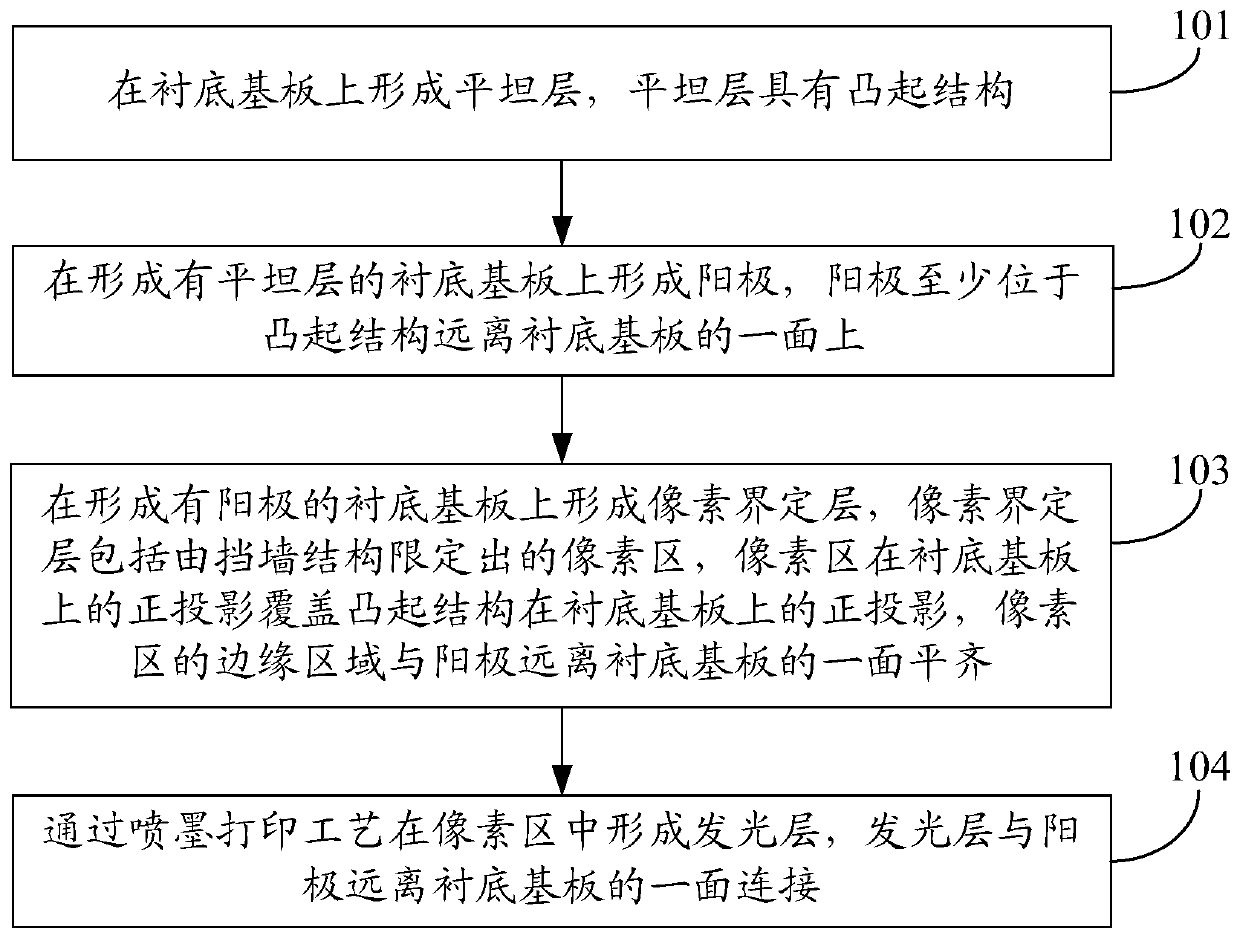

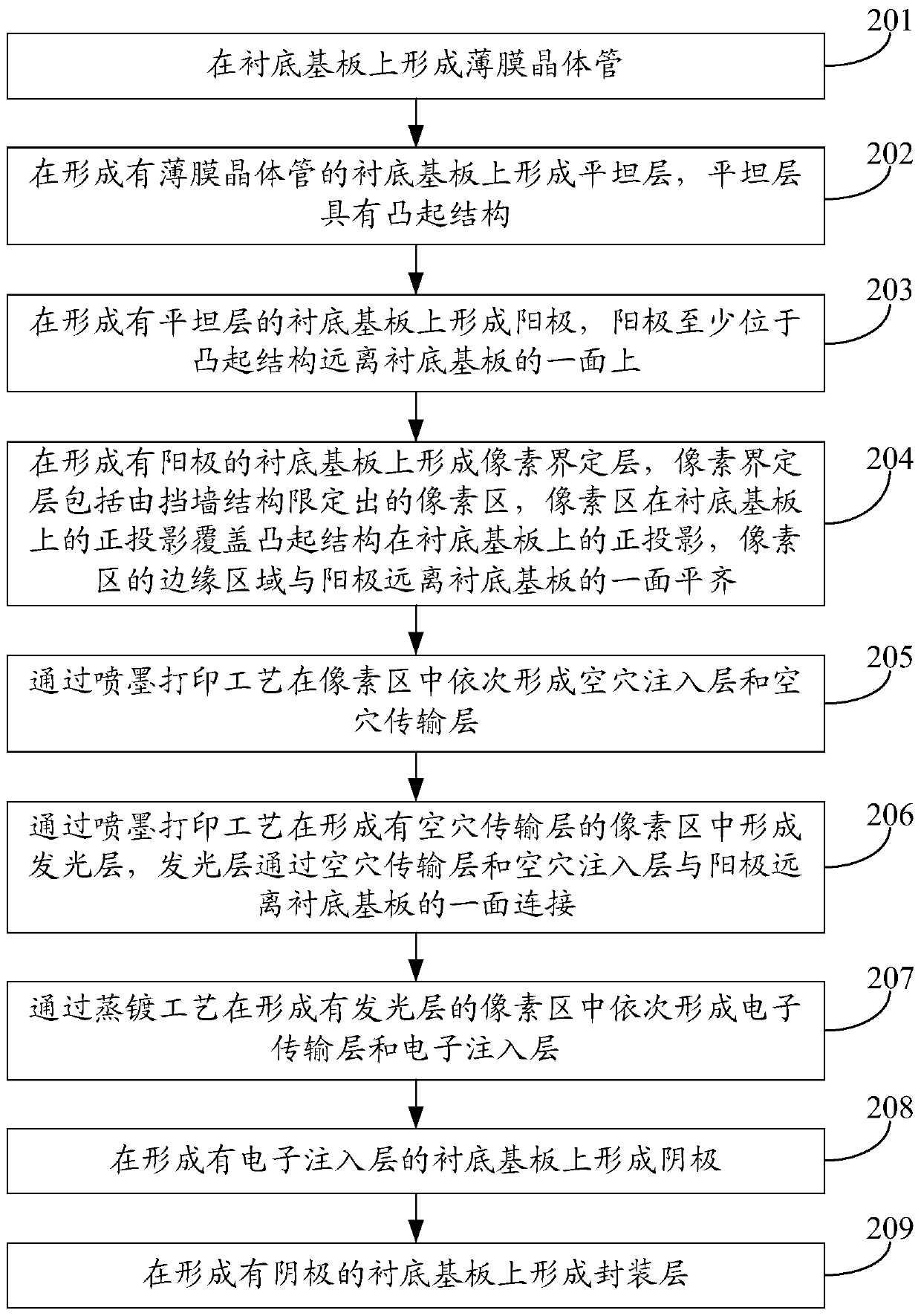

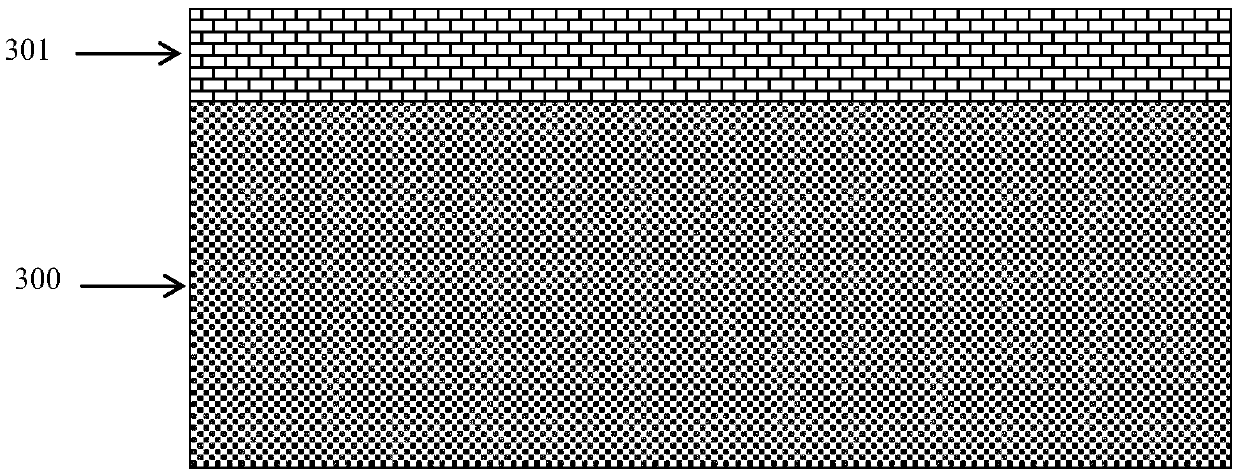

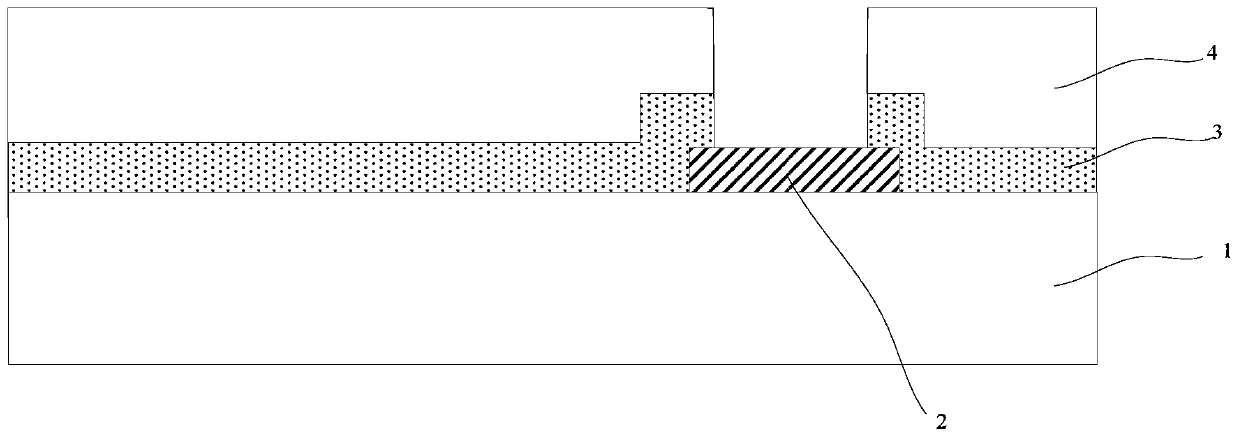

Display substrate, manufacturing method thereof, and display device

InactiveCN109950292AImprove the uniformity of luminous brightnessDoes not affect uniformitySolid-state devicesSemiconductor devicesDisplay deviceOptoelectronics

The invention discloses a display substrate, a manufacturing method thereof and a display device, and belongs to the technical field of the display. The method comprises a step of forming a flat layeron a base substrate, wherein the flat layer has a protruding structure, a step of forming an anode on the base substrate on which the flat layer is formed, wherein the anode is at least on a side ofthe protruding structure away from the base substrate, a step of forming a pixel defining layer on the base substrate on which the anode is formed, wherein the pixel defining layer comprises a pixel region defined by a retaining wall structure, the orthographic projection of the pixel region on the base substrate covers the orthographic projection of the protruding structure on the base substrate,and an edge region of the pixel region is level with one side of the anode away from the base substrate, and a step of forming a light-emitting layer in the pixel region by an inkjet printing process, wherein the light-emitting layer is connected to the side of the anode away from the base substrate. According to the invention, the problem that the uniformity of the light-emitting luminance of the light-emitting layer is poor is solved, and the uniformity of the light-emitting luminance of the light-emitting layer is improved. The invention is used for manufacturing the display substrate.

Owner:BOE TECH GRP CO LTD

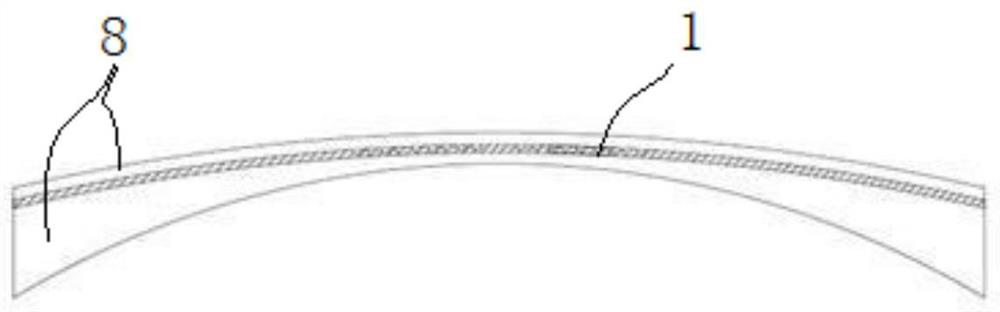

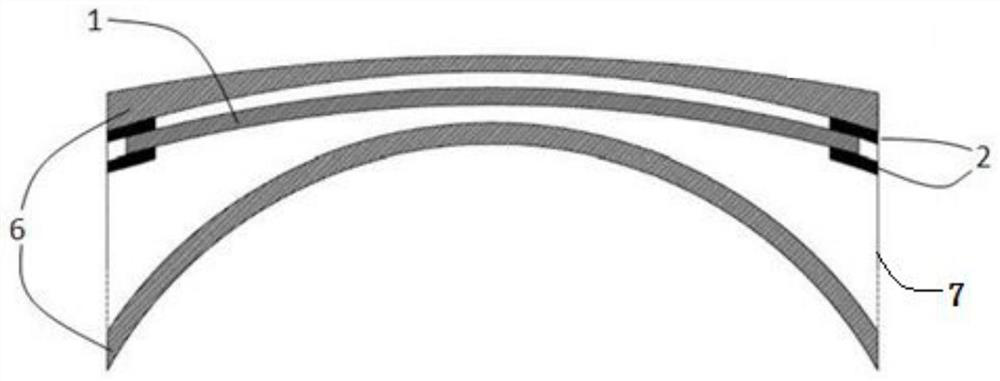

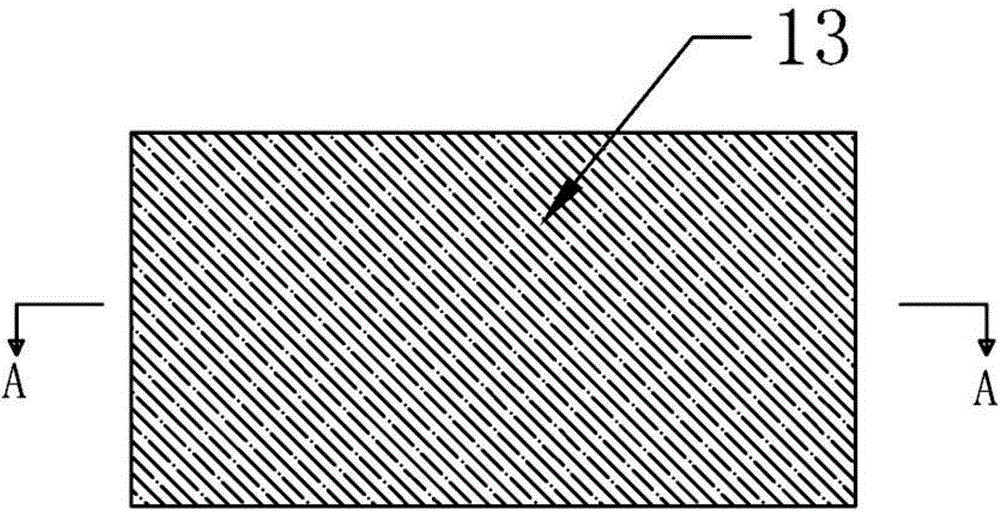

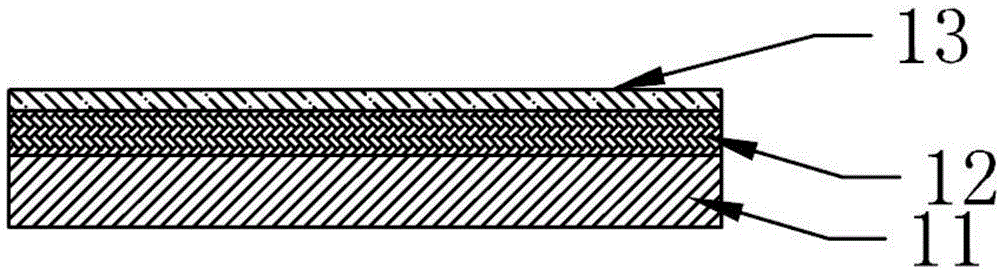

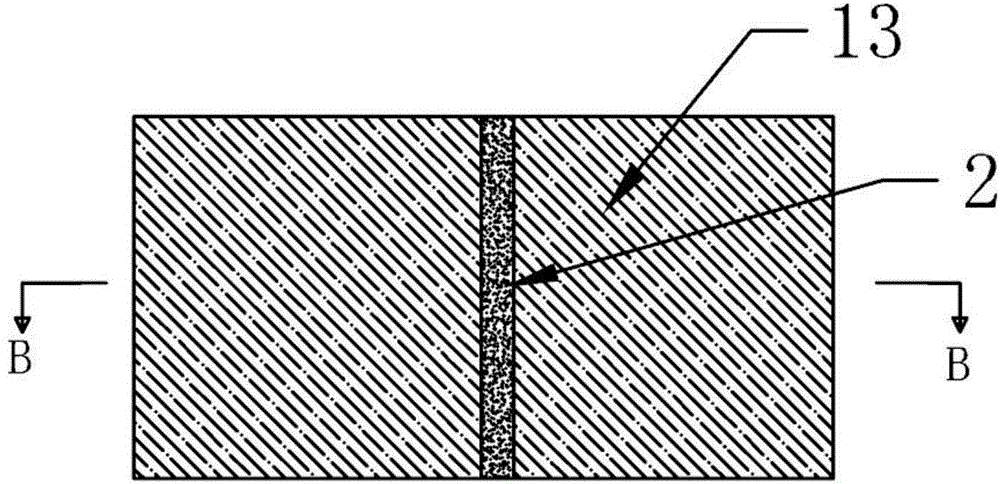

Lens for slowing down myopia deepening and preparation method thereof

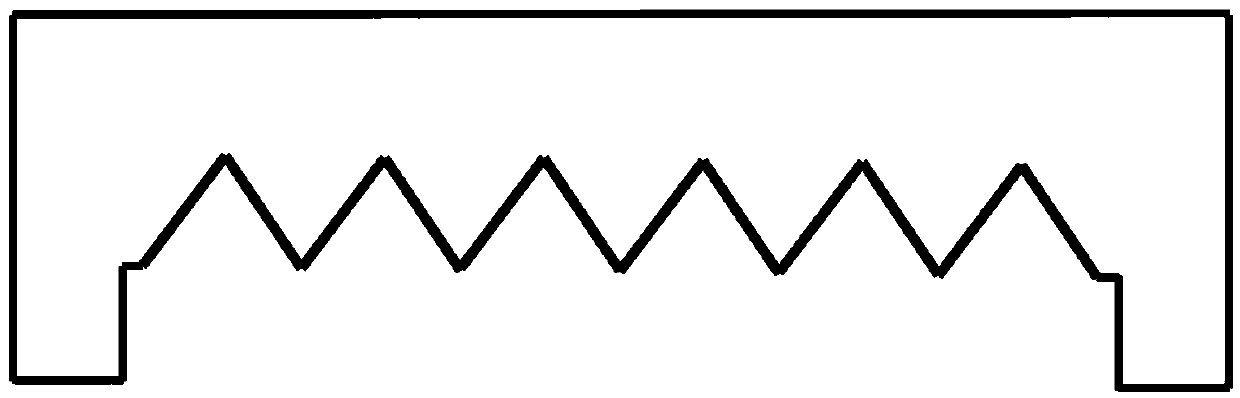

PendingCN111796436APlay the role of myopia prevention and controlDoes not affect uniformitySpectales/gogglesOptical articlesOphthalmologyPlastic film

The invention relates to a lens for slowing down myopia deepening. The lens comprises two layers of resin monomers and an optical plastic film arranged between the two layers of resin monomers, wherein the optical plastic film sequentially comprises a central flat light area, an out-of-focus refraction area and an external flat light area from inside to outside, and the out-of-focus refraction area is a discontinuous out-of-focus refraction area. According to the invention, the optical plastic film is used for preparing the functional film with the defocusing effect; the functional film is arranged in the middle of the resin lens, so that the lens can still play a role in myopia prevention and control; in addition, tiny bulges do not exist on the surface of the lens, the uniformity of hardening and film coating is not influenced in the subsequent hardening and film coating processes, and the lens is simpler and more thorough to clean when being worn in daily life.

Owner:JIANGSU MINGYUE PHOTOELECTRICS TECH

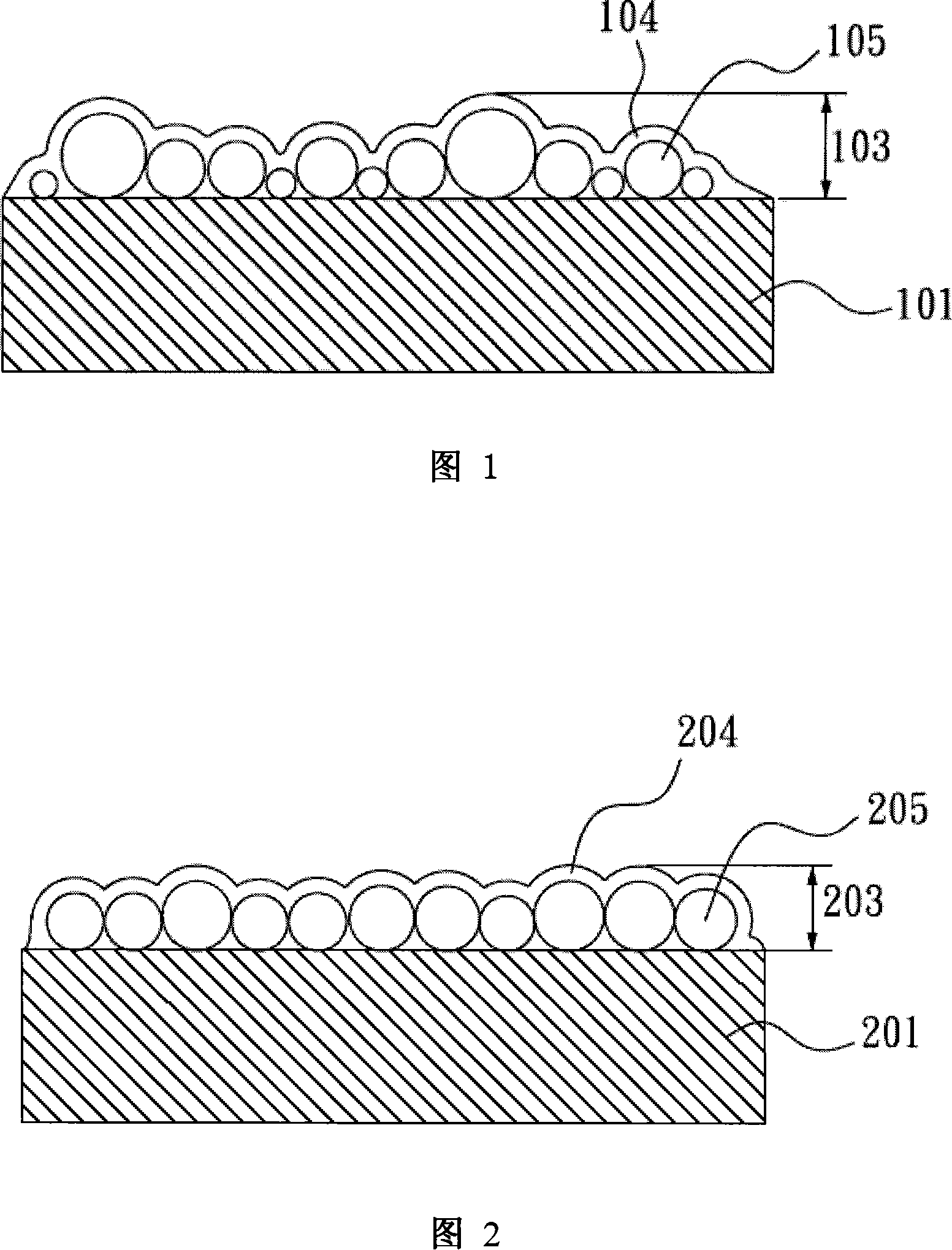

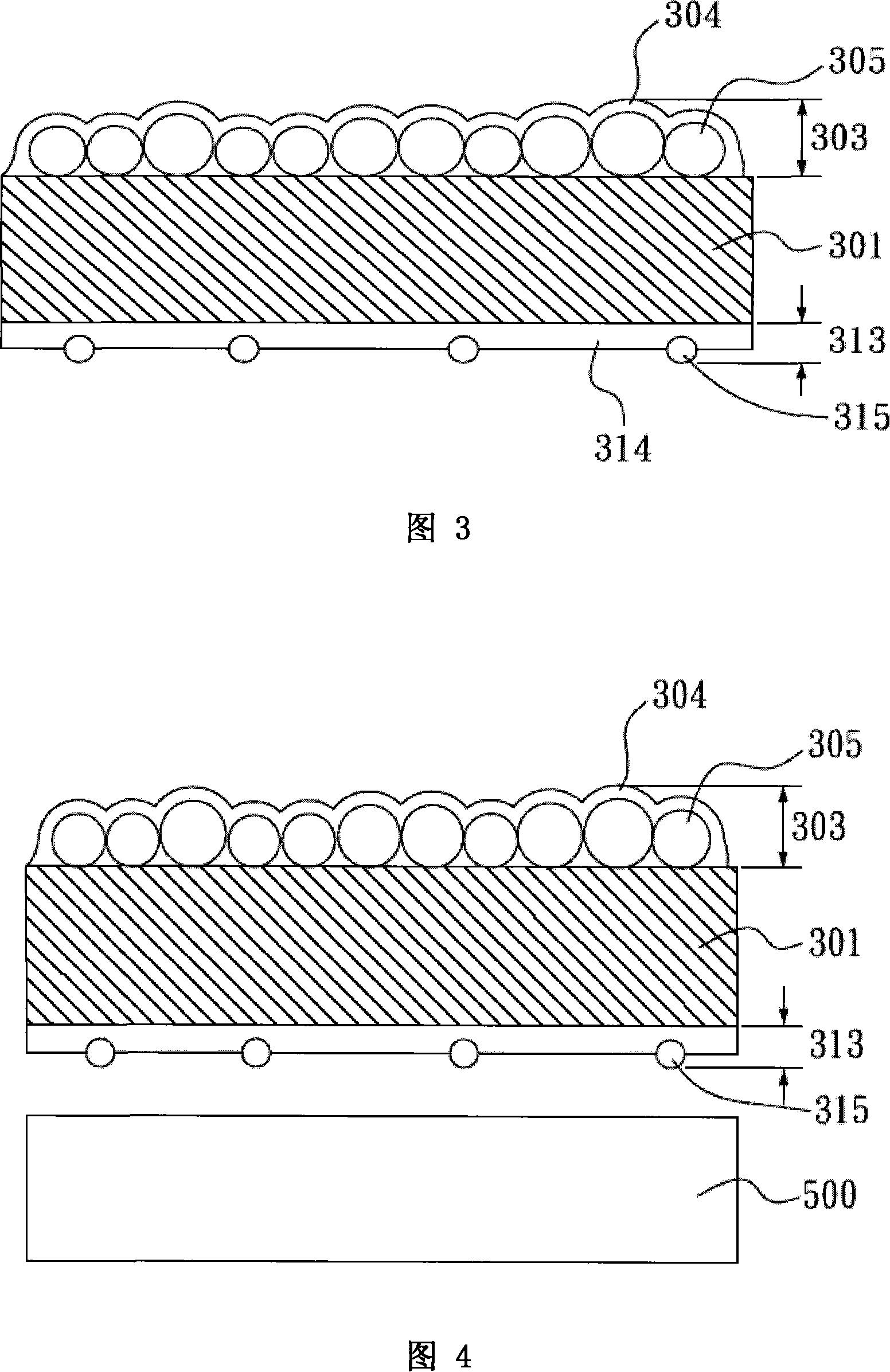

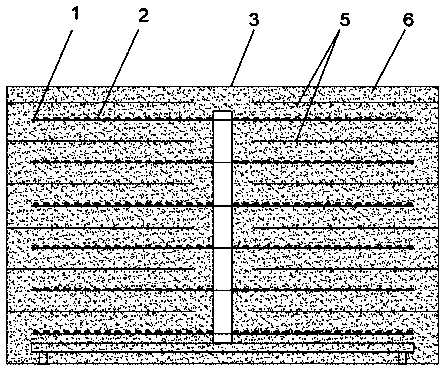

Optical thin film with resin coating containing narrow particle size distributed organic particle

InactiveCN101153926AImprove diffusivityIncrease brightnessDiffusing elementsNon-linear opticsConvex structurePrill

The invention provides an optics film, wherein, at least one surface of base material is provided with a resin coating with concave and convex structure. The coating comprises an organic grain and a cement, wherein, the organic grain is polyacrylic acid ester resin which is polymerized by an acrylic acid ester monomer with at least one single functional base and an acrylic acid ester monomer with at least one multiple functional base and the weight occupying 30 percent to 70 percent of total weight of polymerization monomer. The organic grain has single and average grain diameter. The grain diameter distribution fall within in around 30 percent of average grain diameter. Furthermore, the organic grain relative to solid shape part quantity of the cement is that each of 100 weight part of the solid shape part of the cement contains 110 to 360 weight part organic grain. The optics film has good light diffusion effect for ray and avoids extreme diffusion of scattering of light which complies with light diffusion efficiency requirement and has excellent brightness to use the light source effectively as the diffusion film of various LCD panel backlighting moulds.

Owner:长兴光学材料(苏州)有限公司

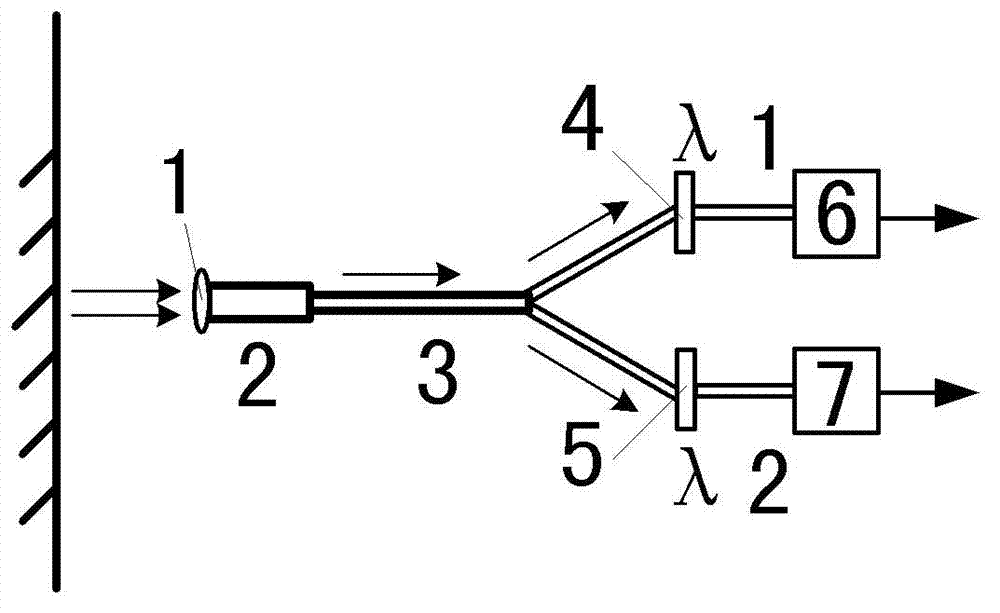

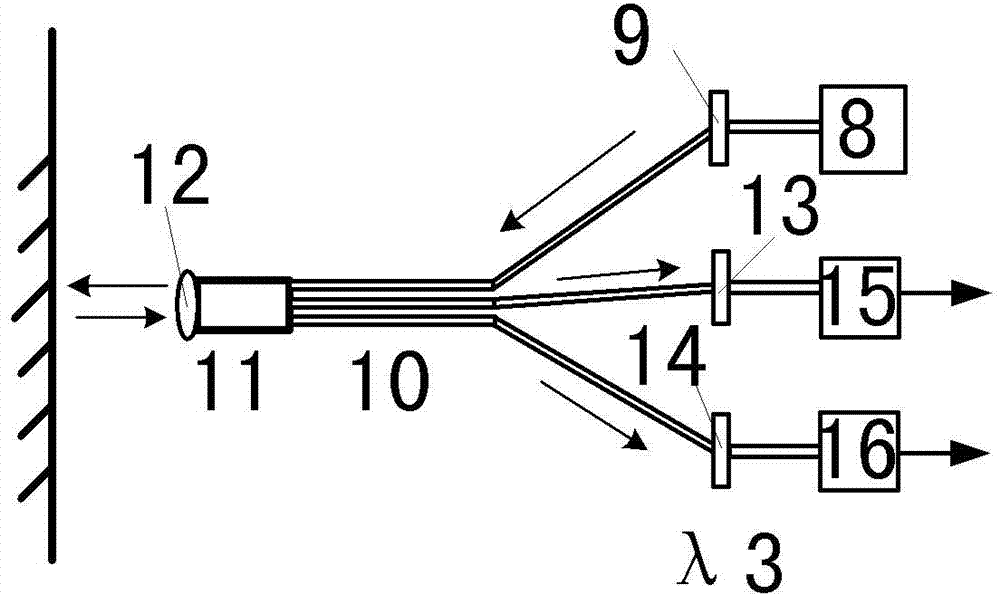

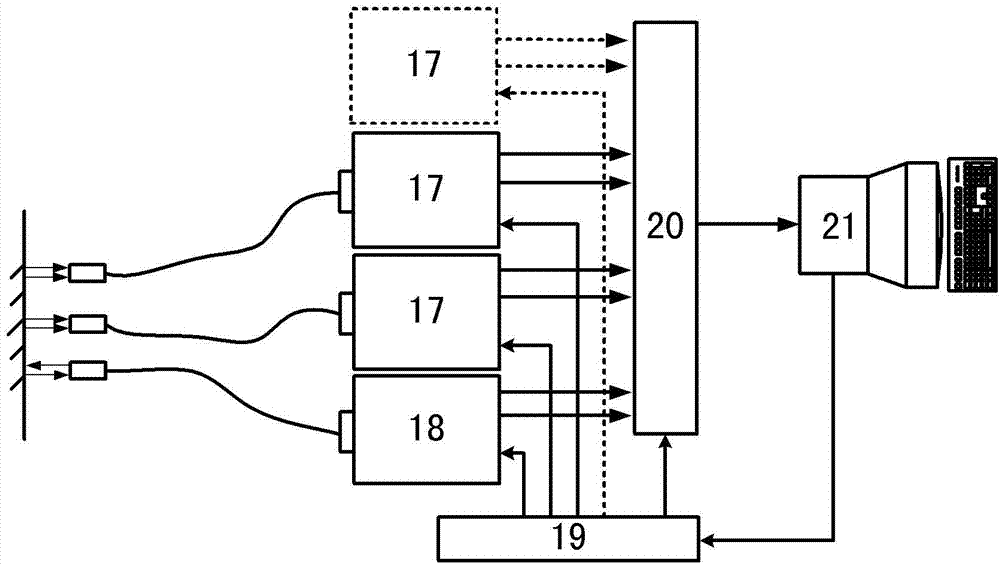

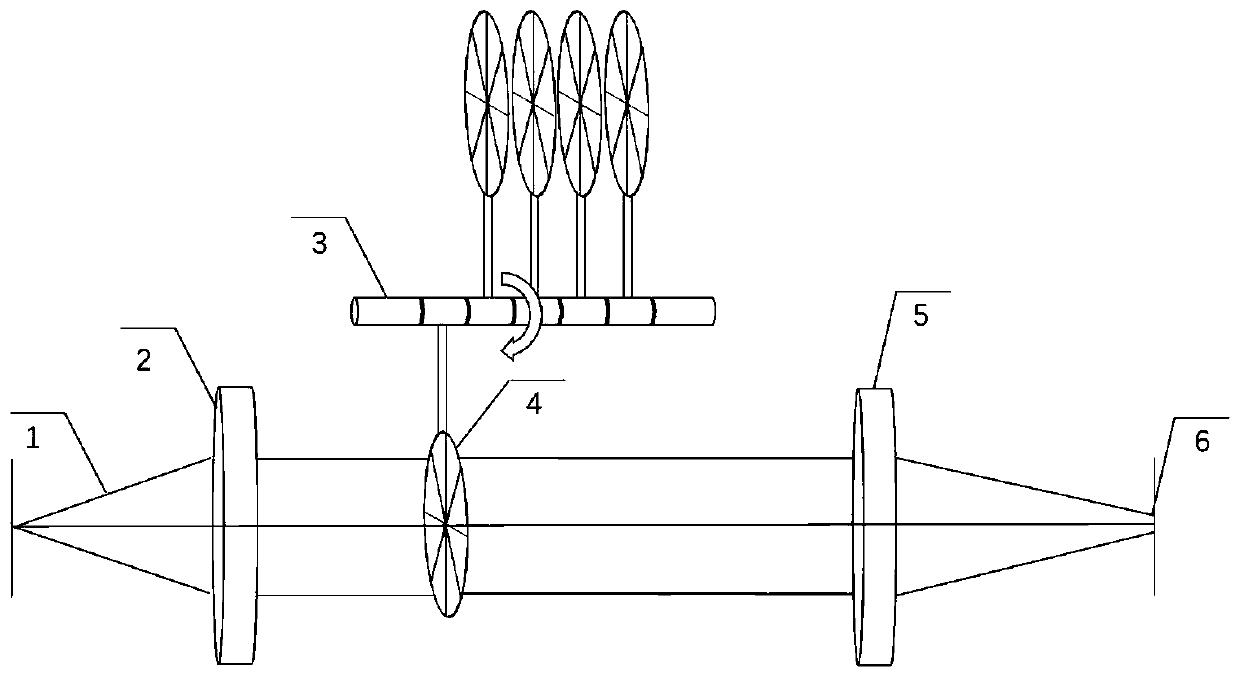

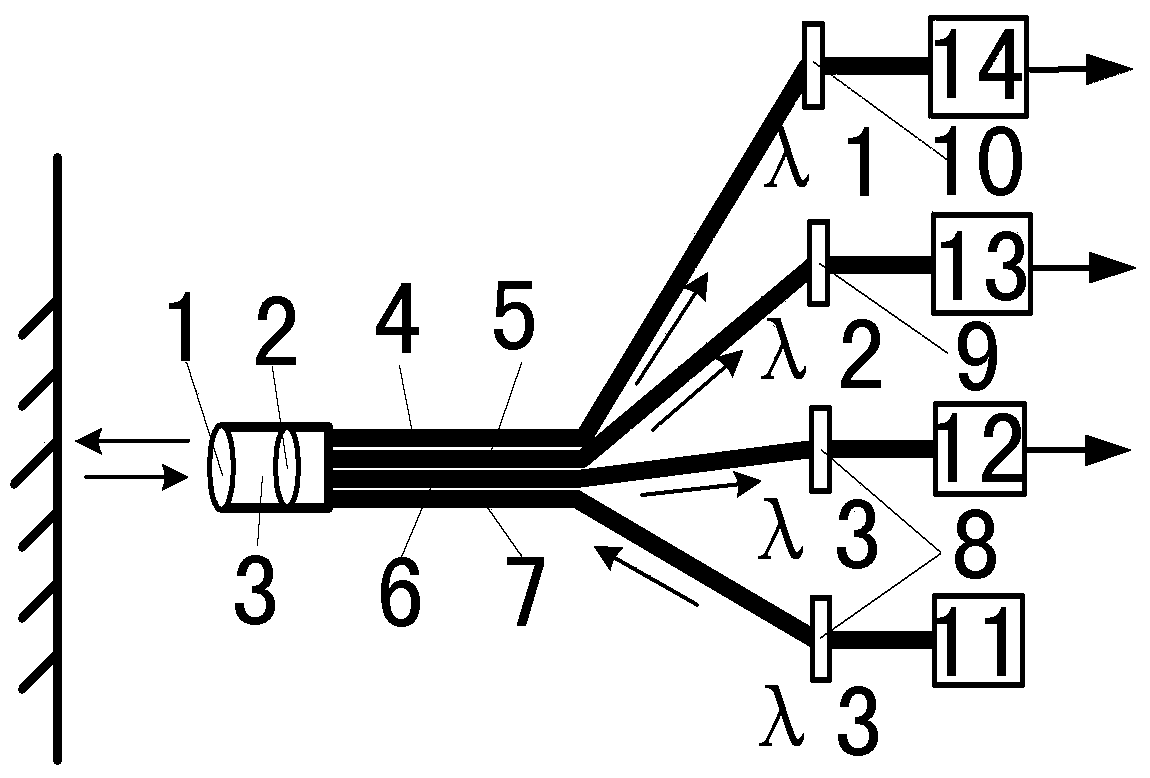

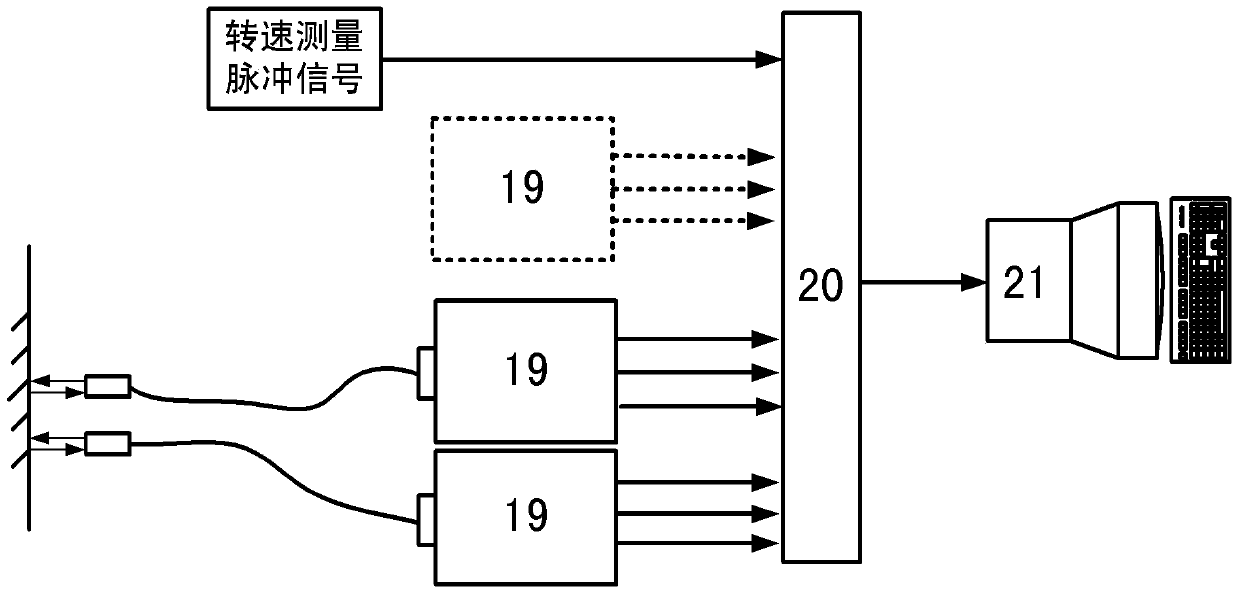

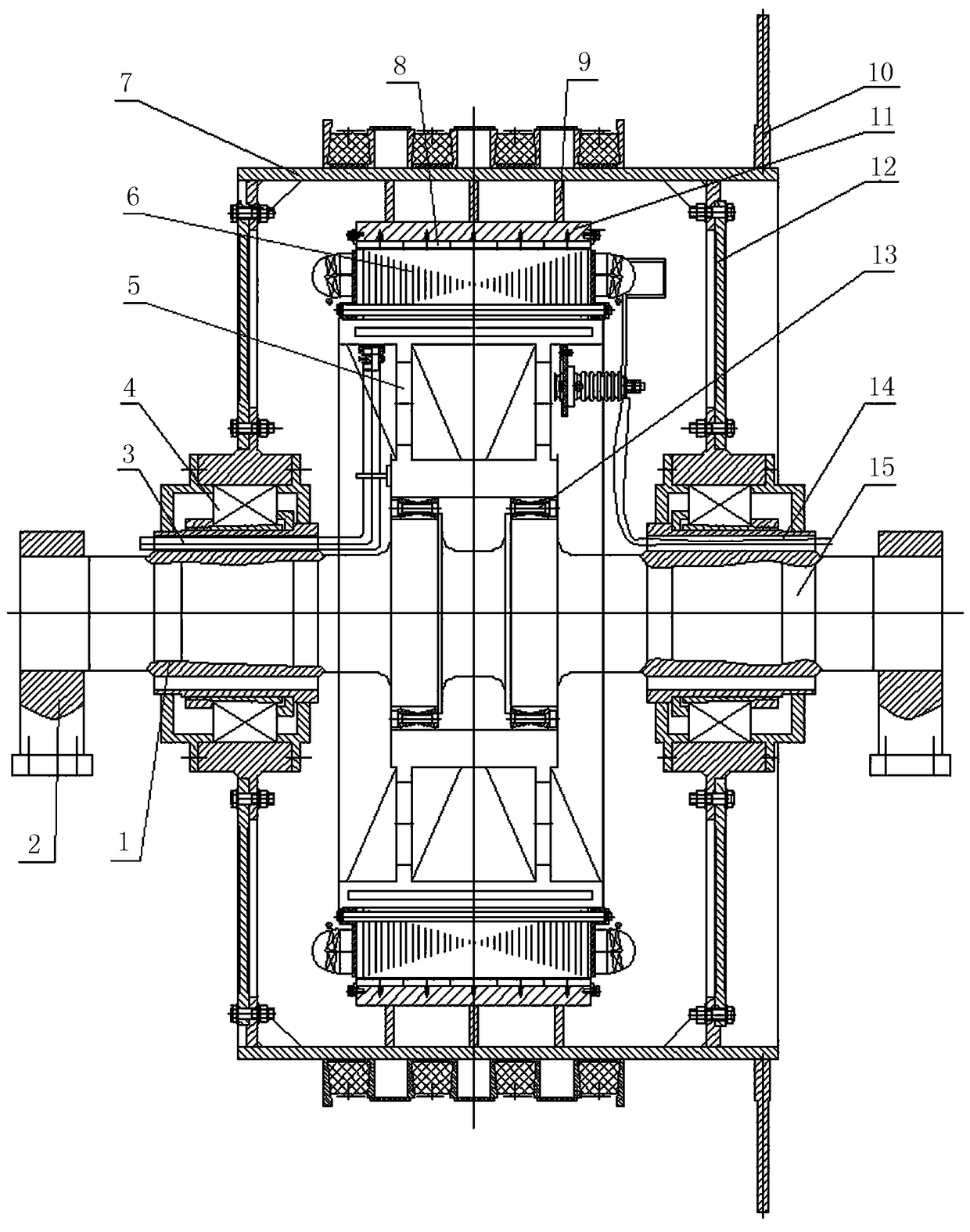

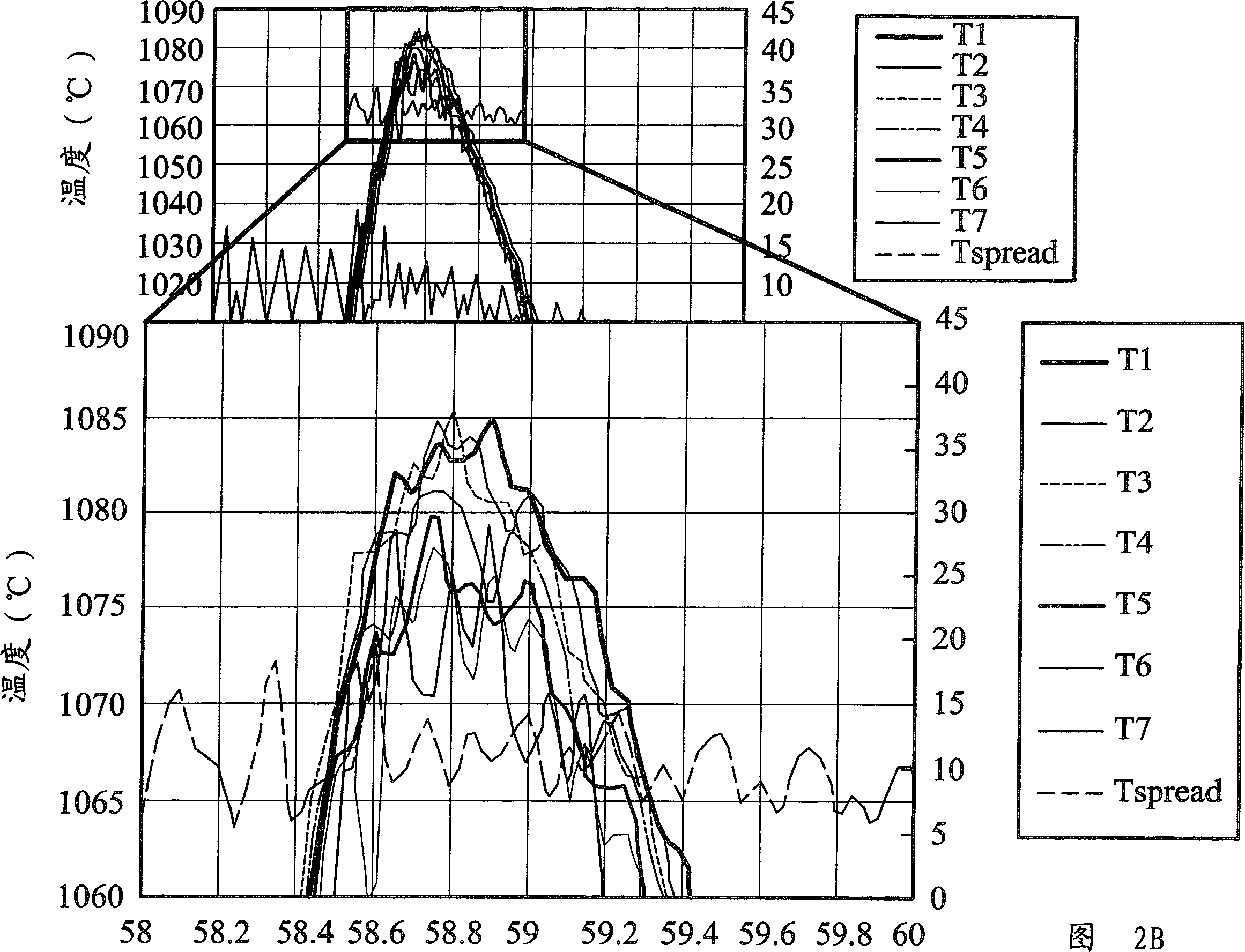

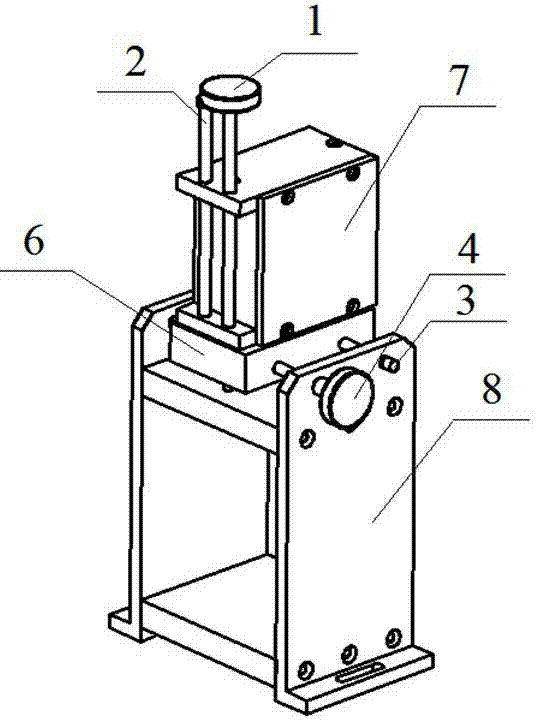

Method and device for carrying out non-contact measuring and positioning on surface temperature of rotating blades

ActiveCN102967377ADoes not affect distributionDoes not affect uniformityRadiation pyrometryUsing optical meansRelative displacementThermodynamics

The invention discloses a device for carrying out non-contact measuring and positioning on the surface temperature of rotating blades. The device mainly comprises an optical-fiber colorimetric temperature measuring system and a reflection-compensated optical-fiber displacement measuring system, wherein the optical-fiber colorimetric temperature measuring system is used for measuring the surface temperature of a rotating blade, and the reflection-compensated optical-fiber displacement measuring system is used for measuring the relative displacement variation information of the rotating blade; and the optical-fiber colorimetric temperature measuring system and the reflection-compensated optical-fiber displacement measuring system are respectively connected with a synchronous / asynchronous trigger device and a data acquisition instrument, the synchronous / asynchronous trigger device is connected to the data acquisition instrument, and the synchronous / asynchronous trigger device and the data acquisition instrument are connected with a computer. The invention also discloses a method for carrying out measuring and positioning by using the device. According to the invention, the surface temperature of a high-speed rotating blade can be measured at a high temperature, and the specific distribution position of surface temperature of the blade can be obtained, therefore, necessary data is provided for designs of the blade profile and cooling structure of the rotating blade, the temperature change characteristics can be monitored in real time online, and serious faults such as blade ablation possibly occurring in combustion gas turbines in the process of running can be prevented in advance.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

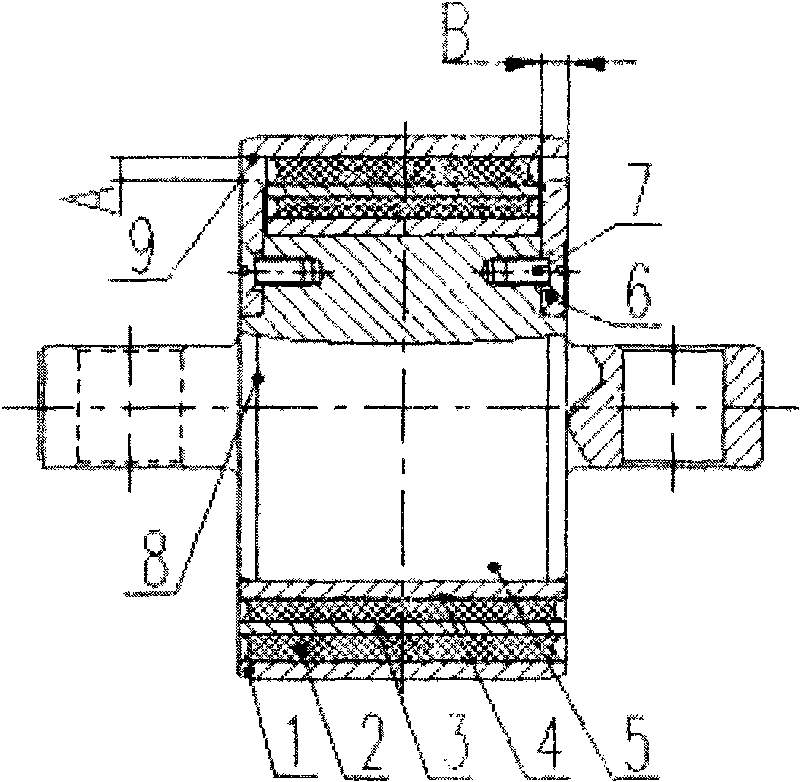

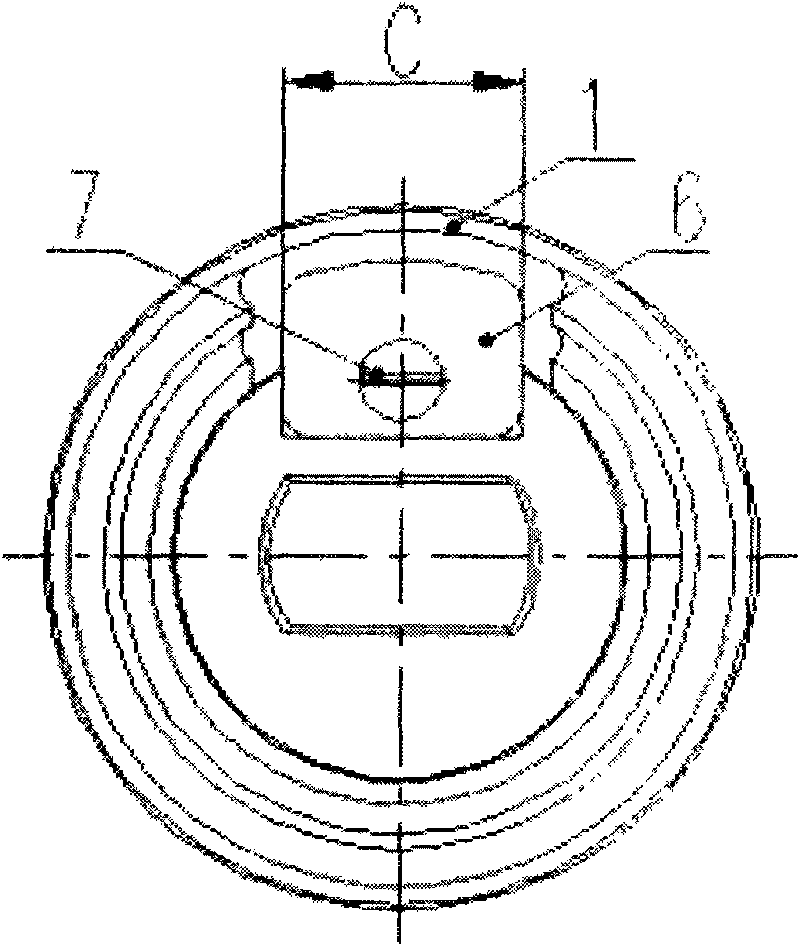

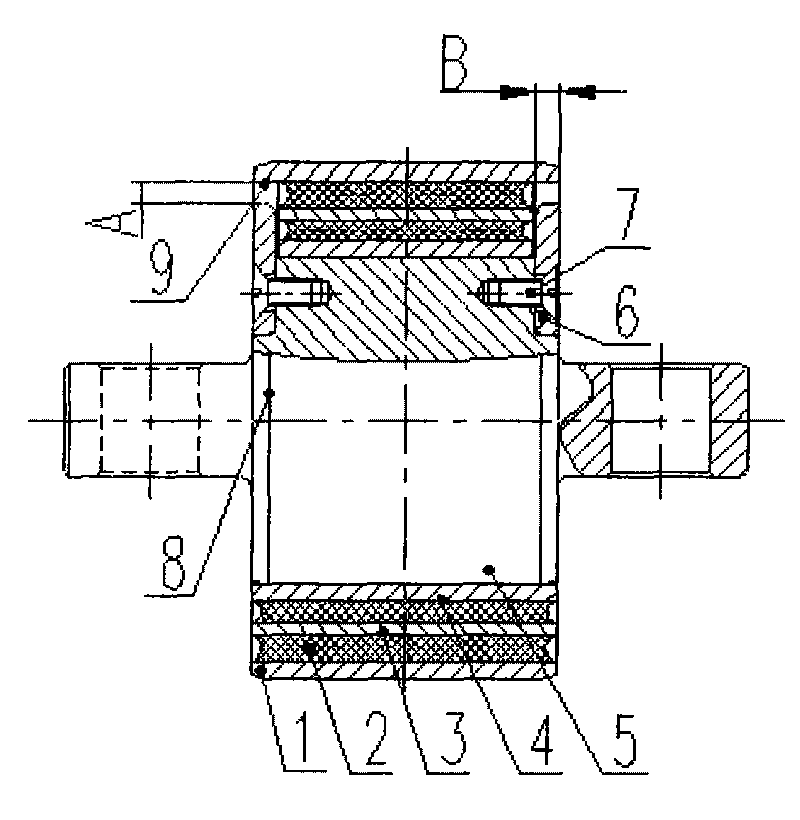

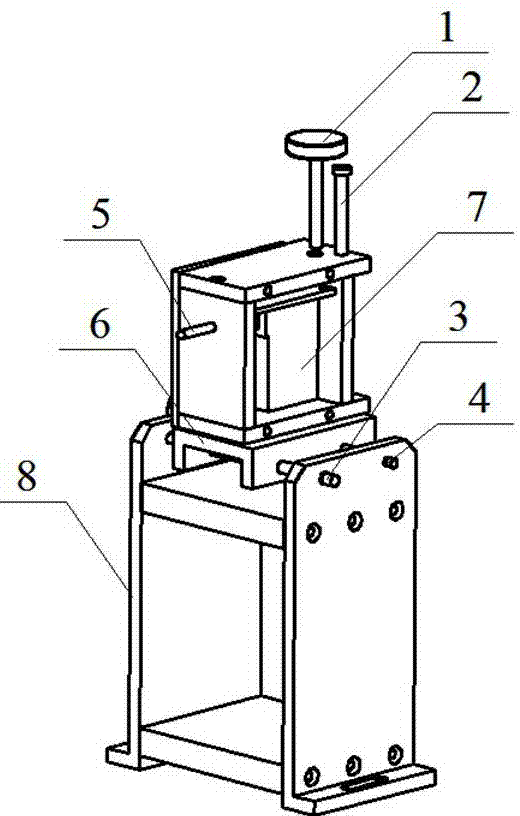

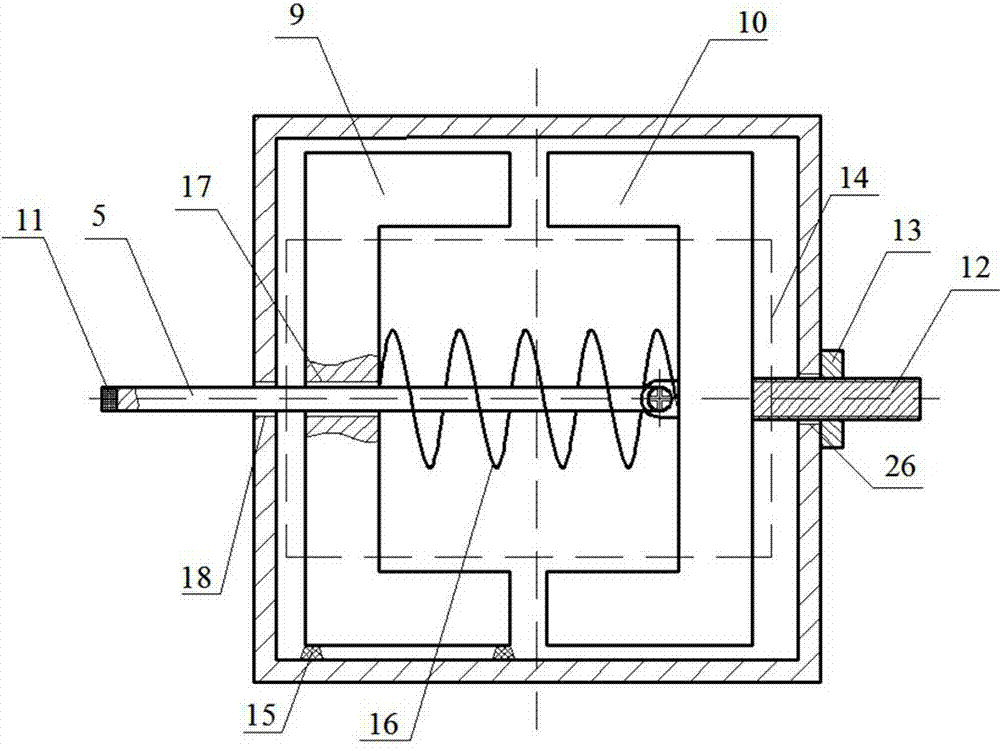

Rubber-metal spherical hinge provided with hard stop catch on end face

ActiveCN101694233ADoes not affect uniformityGuaranteed uniformityElastic dampersRelative displacementCompound a

The invention relates to radial limiting method and device of a spherical hinge. A hard stop catch is placed on the end face of a core shaft and is installed at two end faces of an elastic vibration damping part of the core shaft of the spherical hinge through a fastener after the spherical hinge is manufactured, and a radial gap is ensured to be left between the top of the hard stop catch and an outer sleeve of the elastic vibration damping part. When radially moving relative to the hard stop catch to exceed the gap, the outer sleeve of the elastic vibration damping part is limited. The spherical hinge comprises the core shaft and the elastic vibration damping part, wherein the elastic vibration damping part is a rubber-metal composite element which is formed by compounding a metal outer sleeve, a metal inner sleeve, an interlayer and elastic rubber; a rubber part is integrally vulcanized with the metal outer sleeve and the metal inner sleeve together; a radial hard stop catch is arranged on the inner face of the outer sleeve end of an elastic part; the radial hard stop catch of the spherical hinge is installed on two end faces of the core shaft close to the elastic vibration damping part; and a gap exists between the radial hard stop catch of the spherical hinge and the inner surface of the outer sleeve of the elastic part. The invention can prevent the outer sleeve and the core shaft of the spherical hinge from generating larger relative displacement when a rubber layer is damaged.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

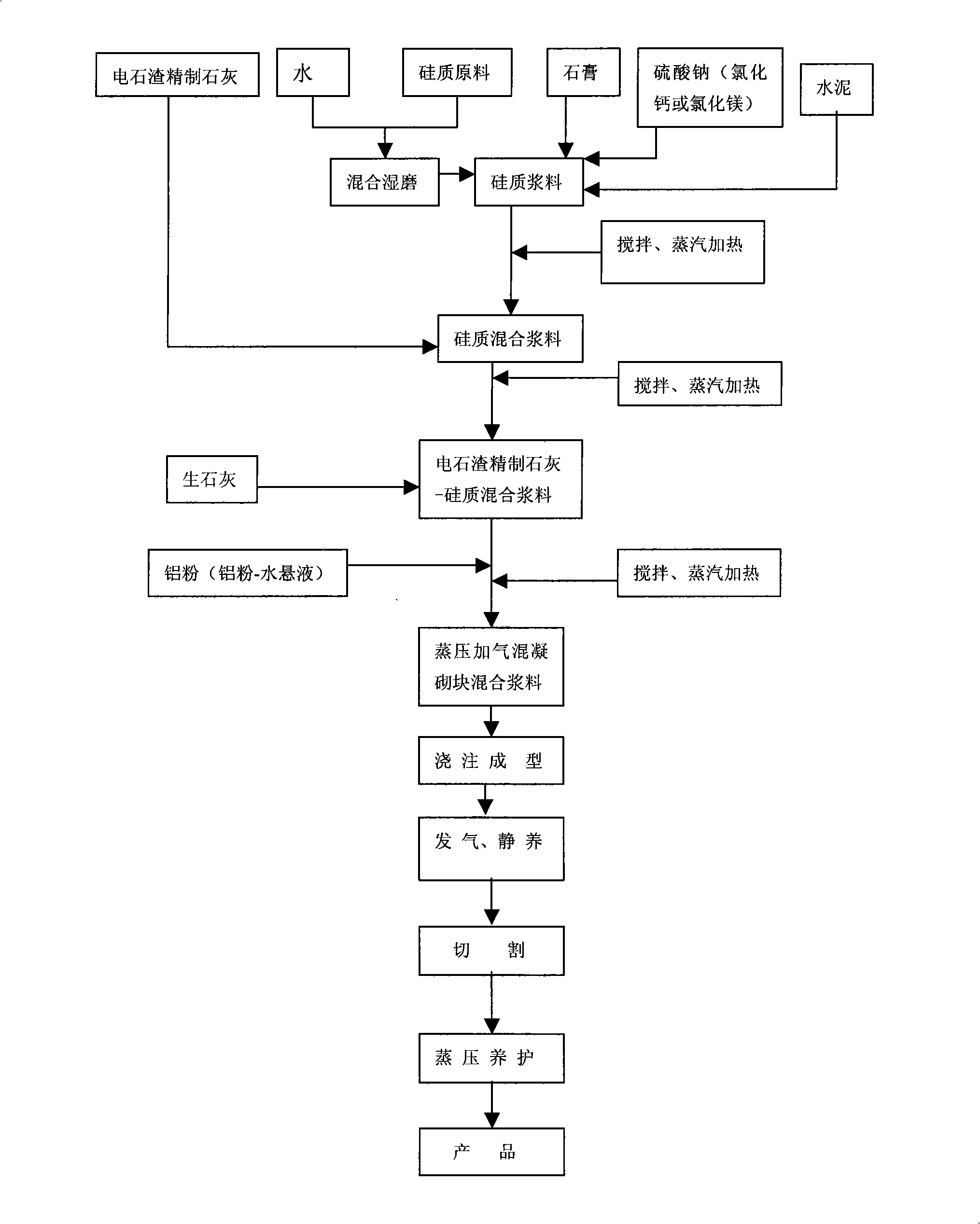

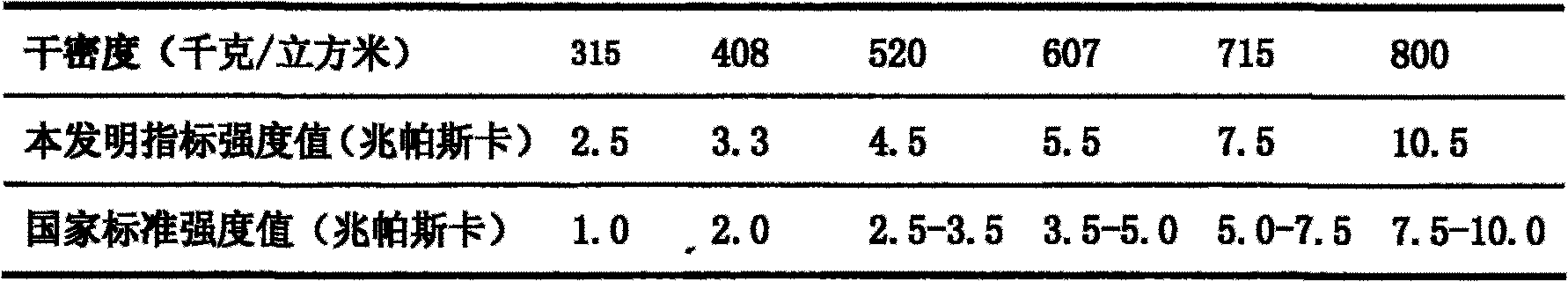

Production of autoclaved aerated building block material with crystal calcarea lime to partially partial substitute unslacked lime and method thereof

InactiveCN101244912AReduce adverse effects on qualityReduce calcium carbonateSolid waste managementCeramicwareWet grindingImpurity

The invention relates to a refining electric stone ballast that is the preparation of autoclaved and aerated block material by using crystal lime parts to substitute quick lime parts and a method thereof; wherein, siliceous material pulp is obtained by wet grinding the mixture of material with silicon and water; siliceous mixing material pulp is obtained by adding additive agent and cement into the material pulp, which are mixed for 2.0 to 10.0 minutes and heated to 40.0 to 45.0 DEG C; crystal lime and quick lime are added into the siliceous material pulp and are mixed; gas former is then added and mixed for 30.0 to 50.0 seconds; steam aerated block casting material pulp is obtained and is gas emitted, statically stopped, cut, autoclaved and formed. By adopting the direct adoption electric stone ballast of crystal lime, calcium carbonate, unburned carbon and other impurities are decreased, and the quality of autoclaved and aerated block is improved; by first adopting wet grinding siliceous material and then adding electric stone ballast cement process, parts of quick cement can be substituted markedly and production cost can be reduced; the autoclaved and aerated block prepared by the technique is energy-saving, light in quality, and high in strength.

Owner:汤建新 +2

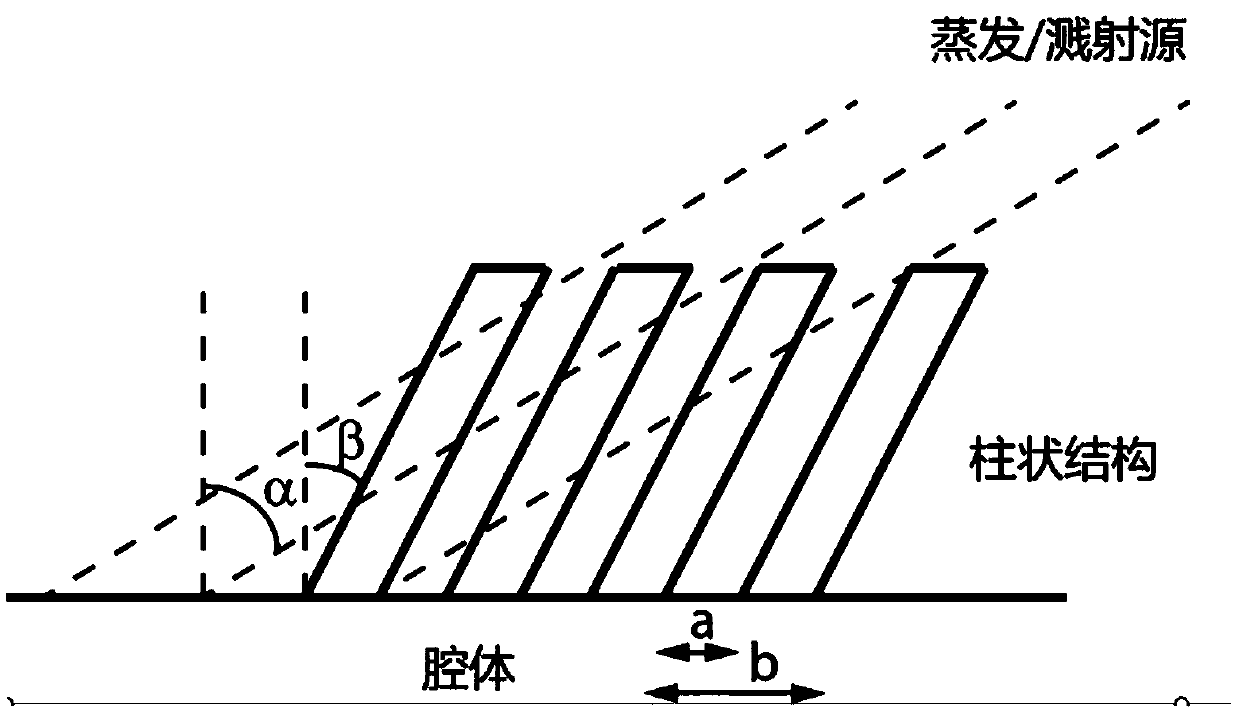

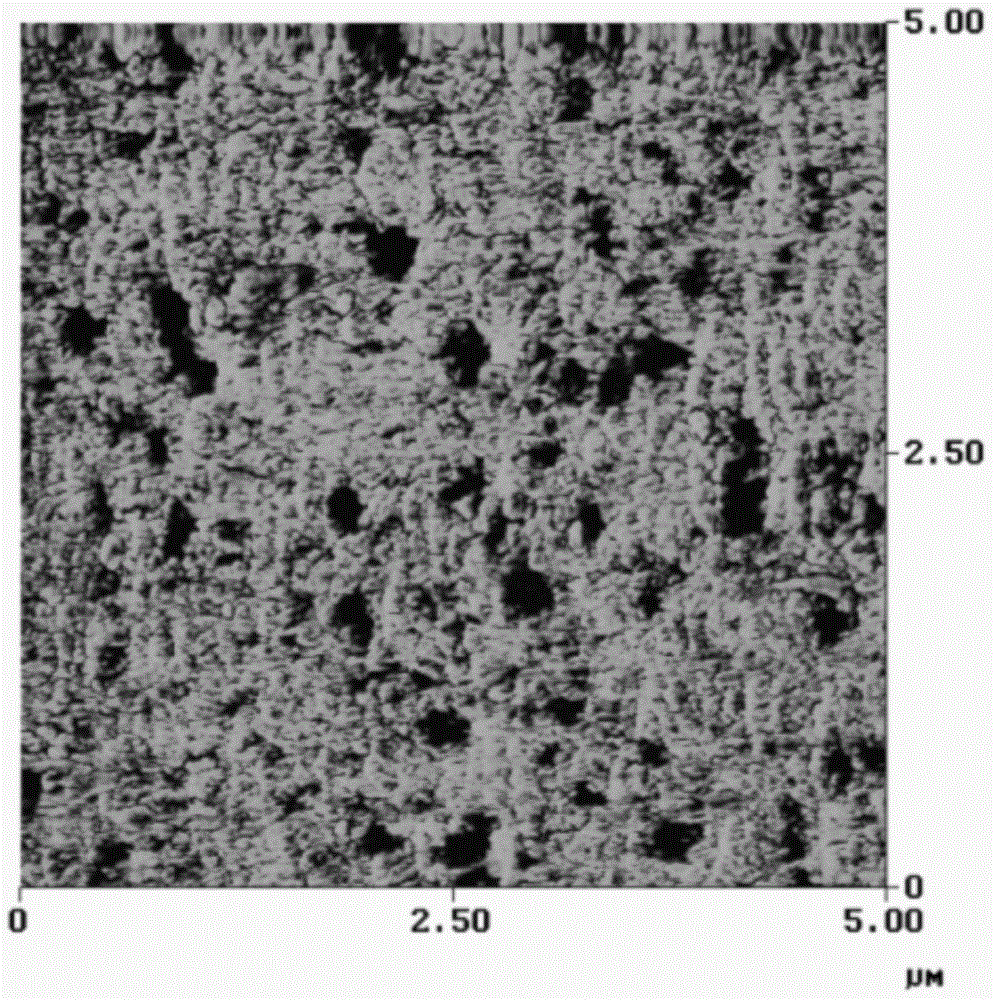

Non-evapotranspiration type thin film getter and preparation method thereof

InactiveCN109680249AExtended service lifeLarge specific surface areaDispersed particle separationVacuum evaporation coatingGetterMicrostructure

The invention discloses a non-evapotranspiration type thin film getter and a preparation method of the non-evapotranspiration type thin film getter. The preparation method comprises the steps that target materials are deposited in a packaging cavity in a single-layer or multi-layer mode by adopting an evaporation or magnetron sputtering way; and during deposition, the packaging cavity or an evaporation source / target material is inclined, and therefore a thin film with an inclined and separated nanocolumn microstructure is obtained in the packaging cavity. The invention further provides the non-evapotranspiration type thin film getter prepared by the preparation method. By means of the preparation method, the columnar porous thin film getter with the large specific surface area can be obtained, gas can be more easily dispersed, and therefore the getting capacity of the thin film getter can be increased.

Owner:SUZHOU UNIV

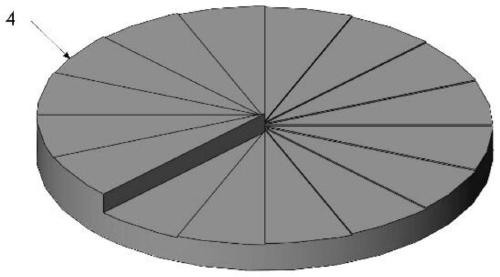

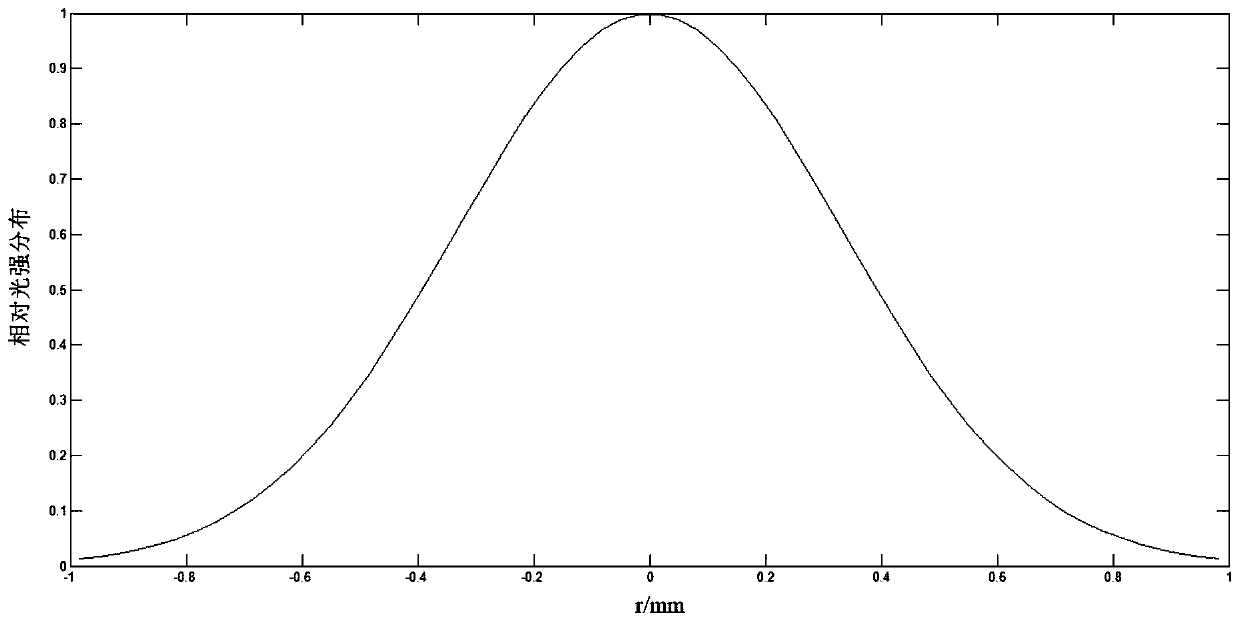

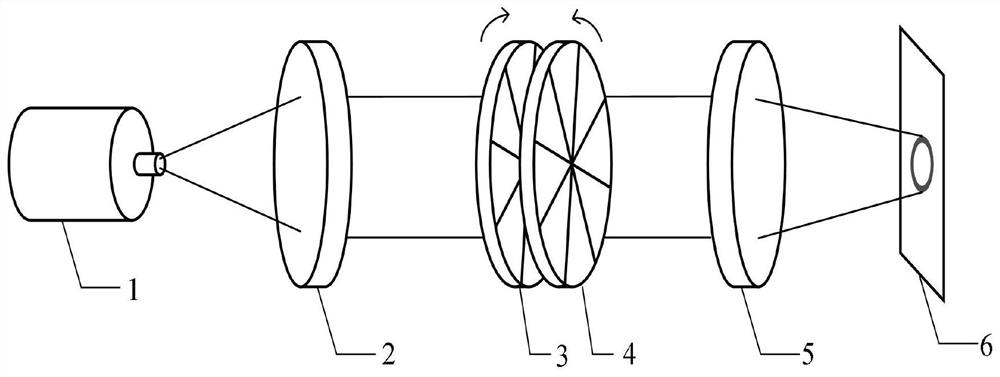

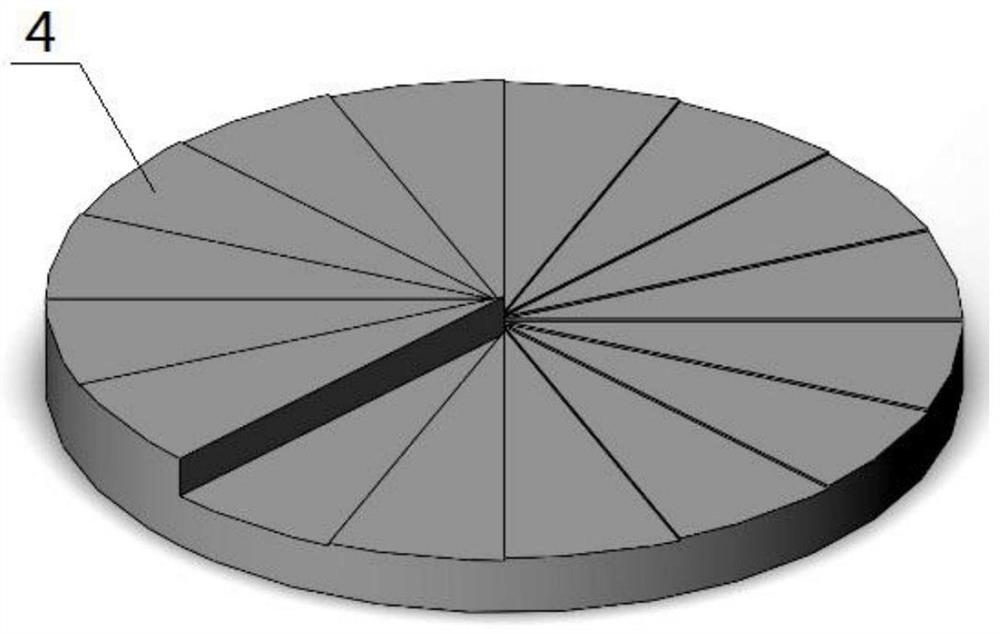

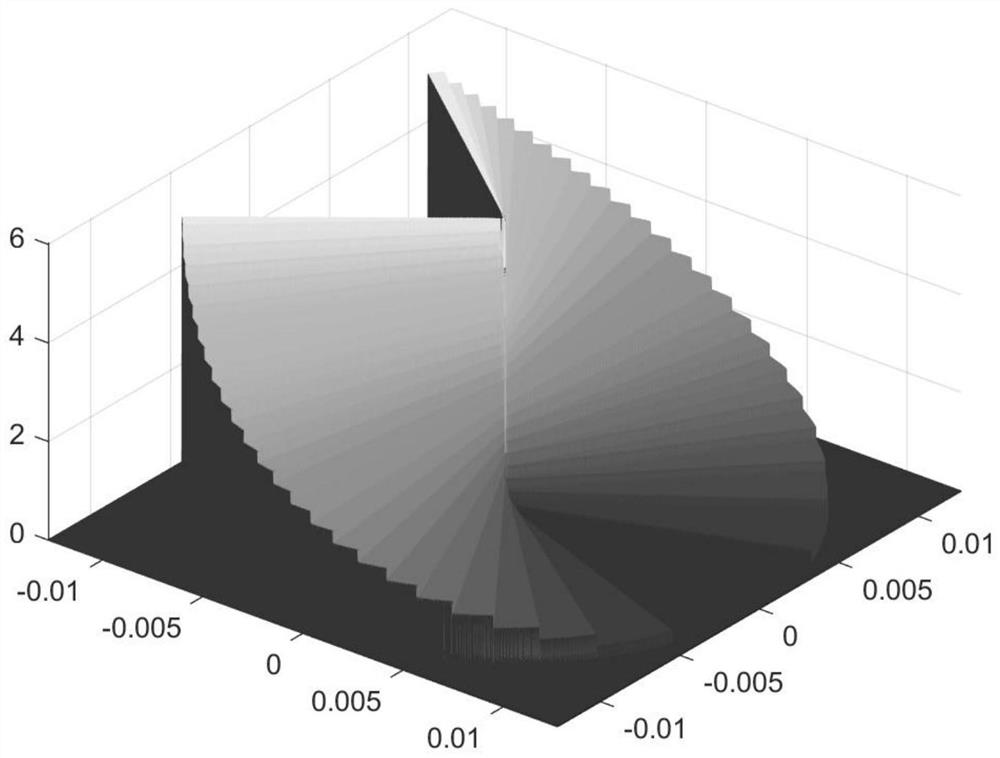

Optical system of annular light spot

PendingCN111338089AEasy to implementHigh edge energyLaser beam welding apparatusOptical elementsOptical pathEngineering

The invention belongs to the field of laser processing, and discloses an annular light spot optical system. The system comprises a collimation unit, a phase modulation unit and a focusing unit which are sequentially arranged along a light path. The phase modulation unit comprises at least one spiral phase plate positioned in the light path; a laser beam can be added with a spiral phase factor to realize phase modulation through a spiral phase plate in an optical path, so the energy distribution of the laser beam is changed into annular distribution. Furthermore, the spiral phase plates can bearranged on the rotating shaft, and the states in the light path and outside the light path are switched by rotating around the rotating shaft, so variable annular light spots can be realized by switching the spiral phase plates. By improving the components of the optical system and the matching action mode among the components, the annular light spot with concentrated energy distribution at the edge, larger diameter and longer focal depth can be obtained, the size of the light spot is further adjustable, and the optical system is suitable for various laser processing fields such as laser cutting and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

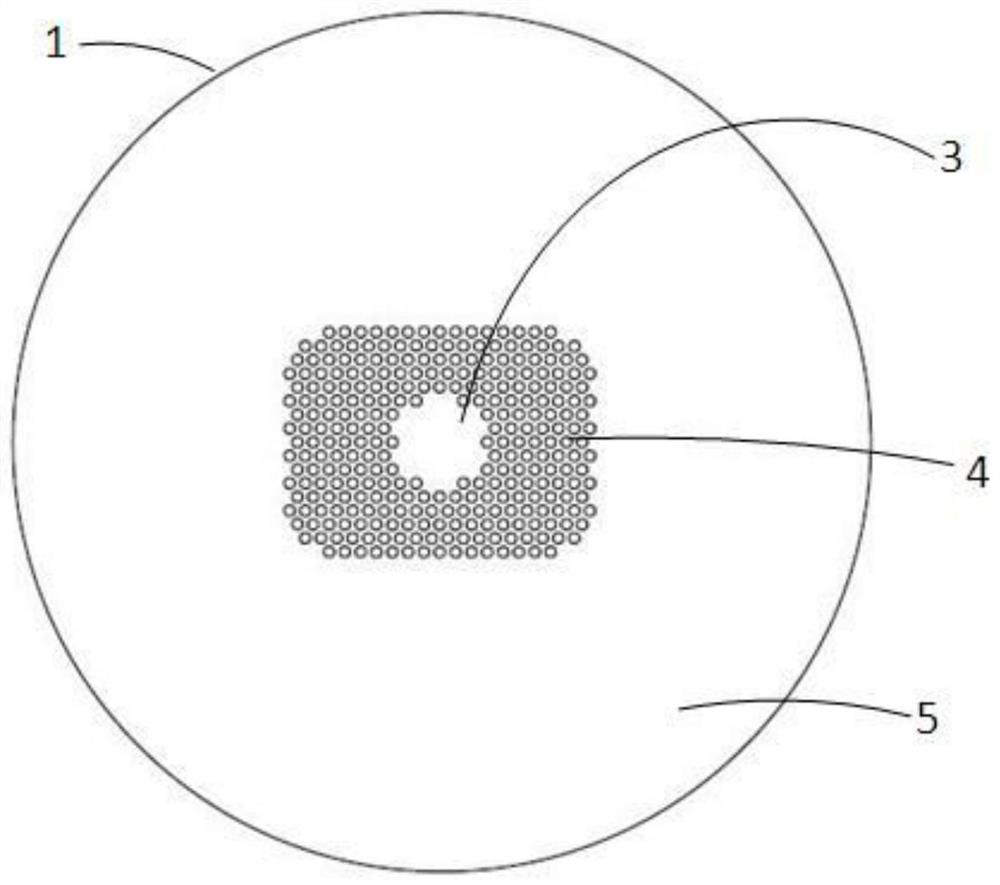

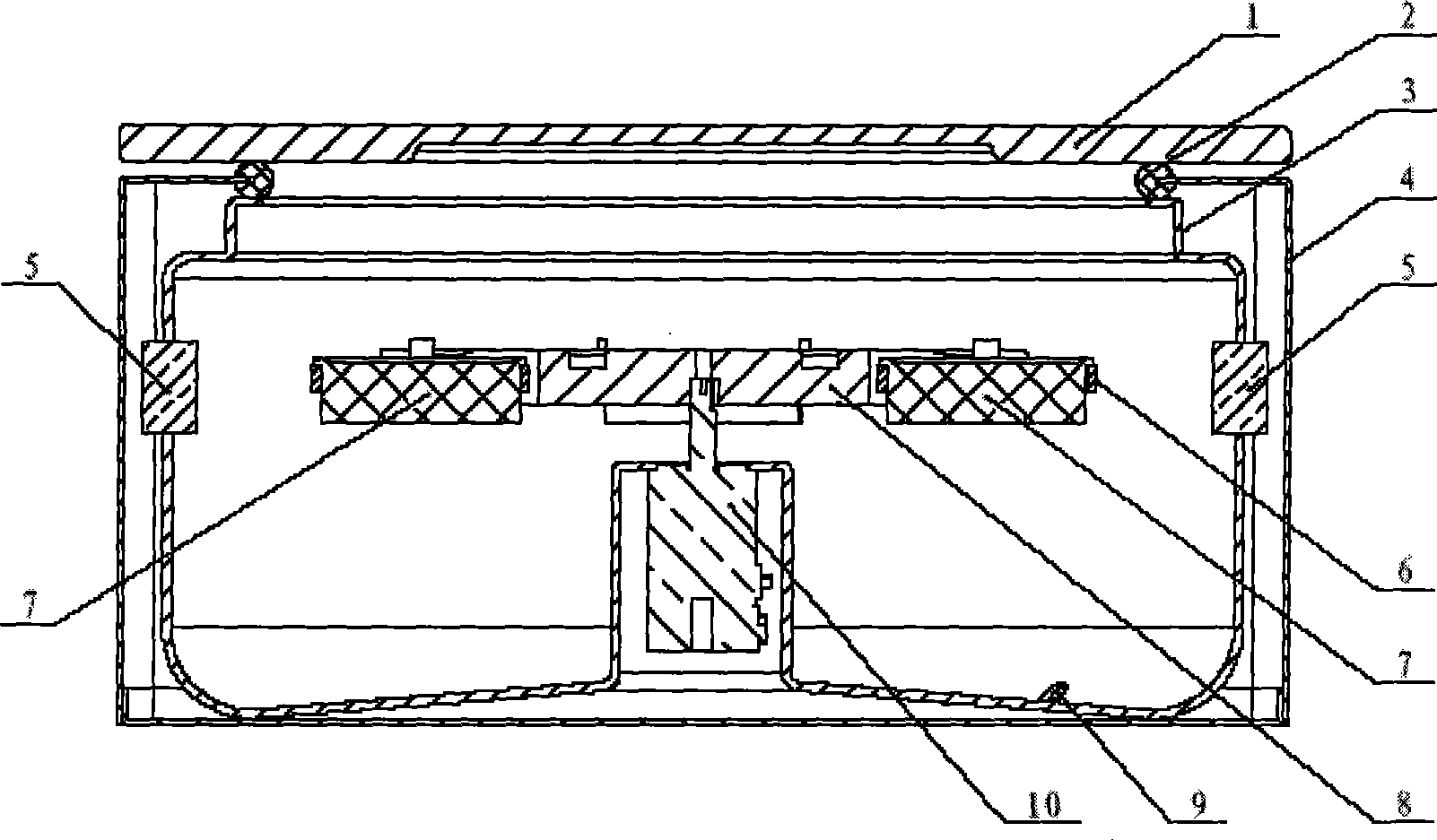

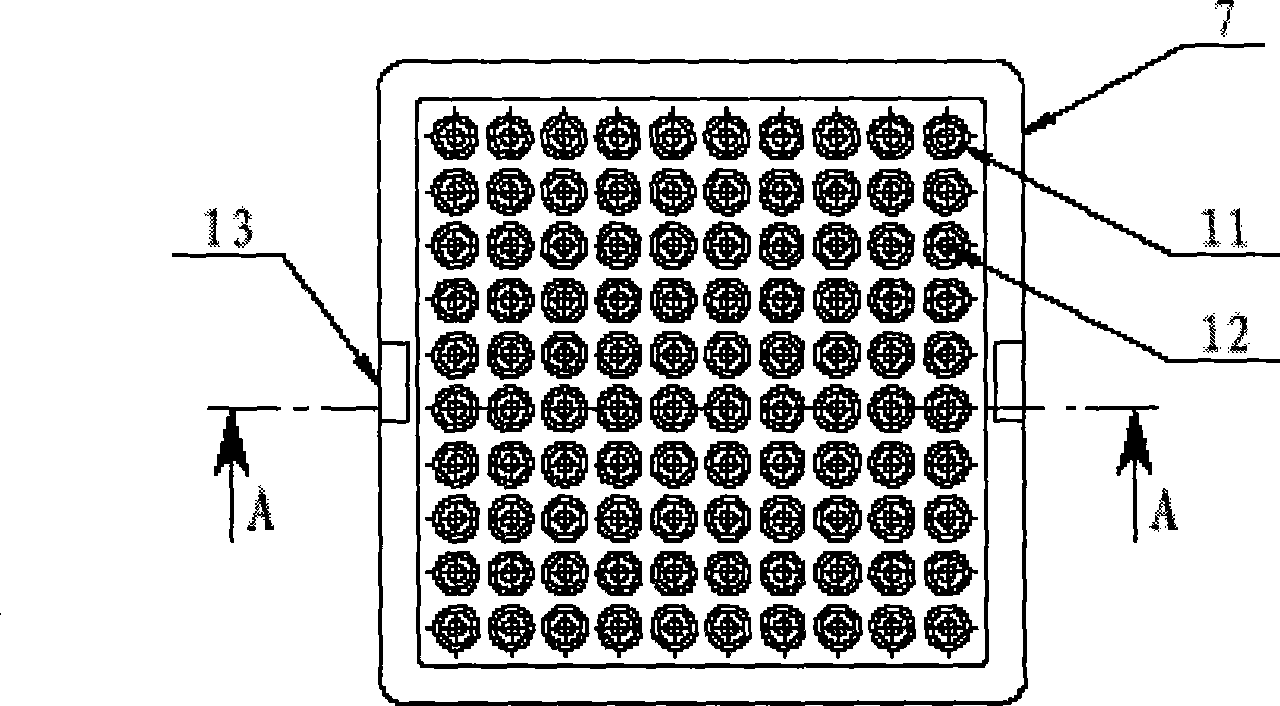

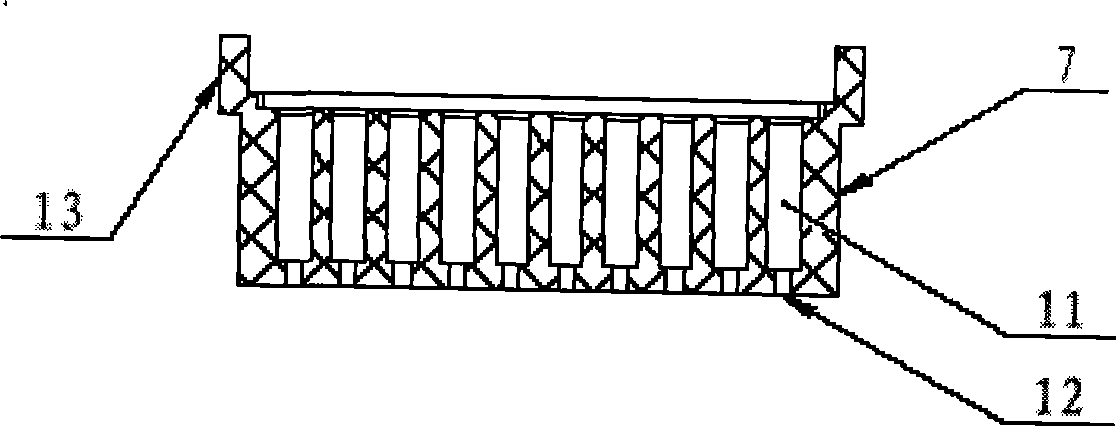

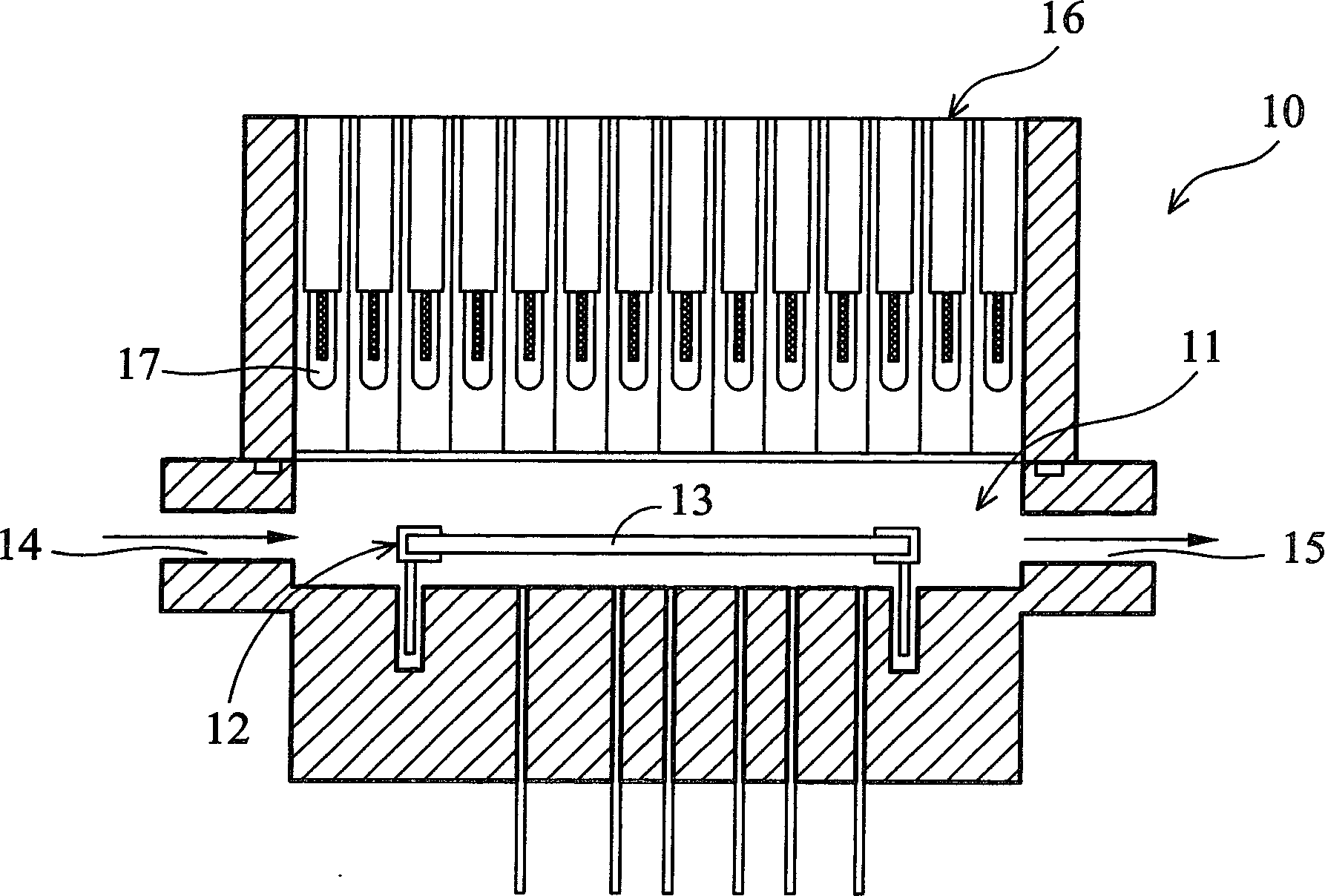

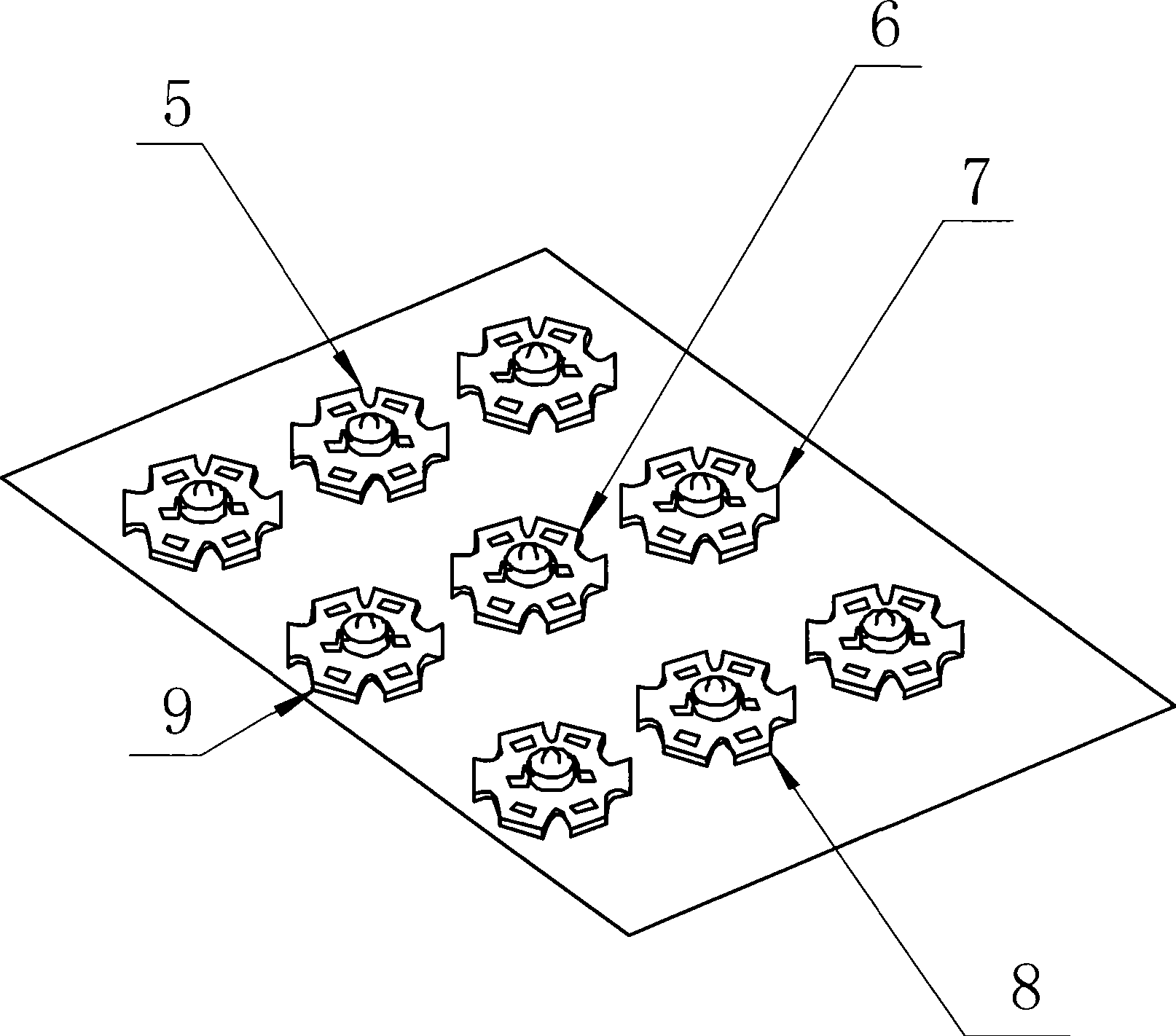

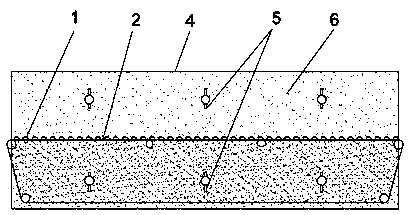

Method and tool for drying hard substrate biological chips

ActiveCN101435655AKeep dryAchieve dryingDrying machines with non-progressive movementsTemperature controlEngineering

The invention discloses a method for drying a hard-substrate biological chip and a drying tool thereof. The method comprises the following technical proposal: (1) the chip drying tool is started; temperature is set between 22 and 37 DEG C and is balanced for 8 to 15 minutes; (2) the hard-substrate biological chip is put to a mould of the drying tool; the centrifugal rotational speed is between 2,000 and 5,000 rmp; and the hard-substrate biological chip is subjected to centrifugal rotation for 5 to 40 minutes. The chip drying tool used in the method for drying the hard-substrate biological chip comprises a shell, an inner liner and a top cover; a motor is arranged between the shell and the inner liner; a rotating shaft of the motor runs through the liner wall of the inner liner, and extends into a chamber of the inner liner; the rotating shaft of the motor is connected with a rotary arm; two ends of the rotary arm are connected with a mould bracket respectively; a mould is arranged on each mould bracket; the mould is provided with densely distributed macropores; and the macropores run through the bottom of the mould through small pylomes running through the bottom. The periphery of the inner liner is provided with a temperature control module. Through the chip drying tool and the matched mould, the drying method utilizes centrifugal force to firstly fully throw closed liquid remained on the surface of the chip off the chip and fully evaporate less moisture remained on the surface of the chip under the centrifugal vacuum environment in order that the chip achieves the drying effect.

Owner:江苏三联生物工程股份有限公司

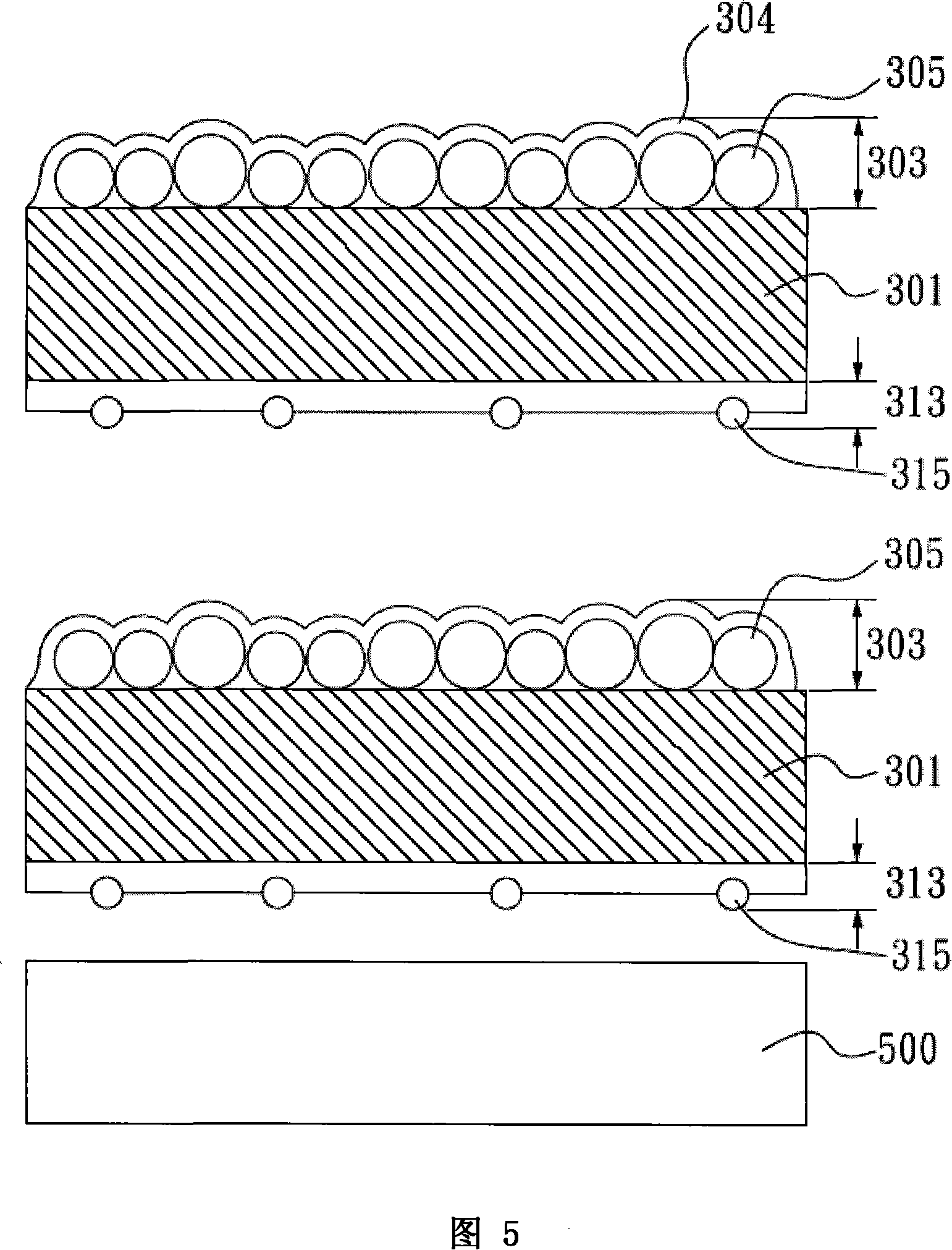

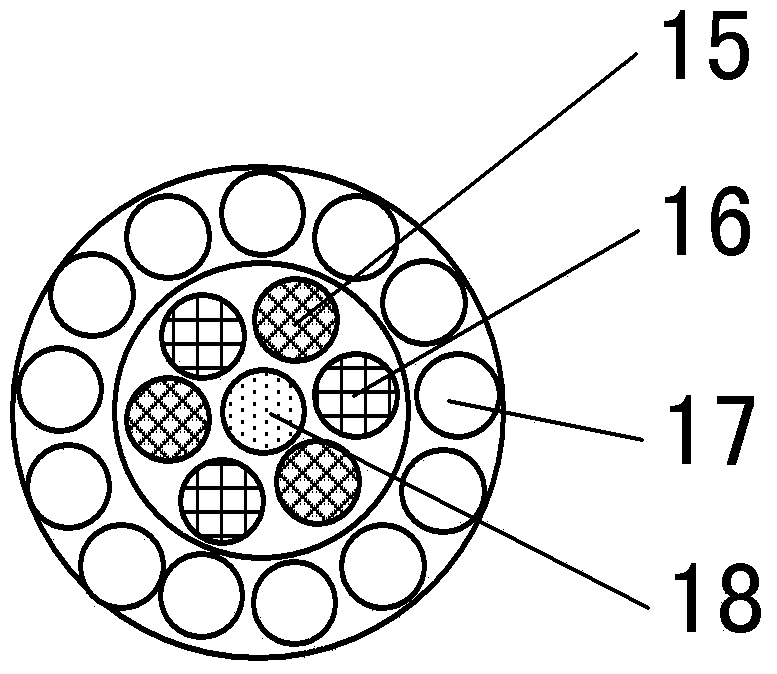

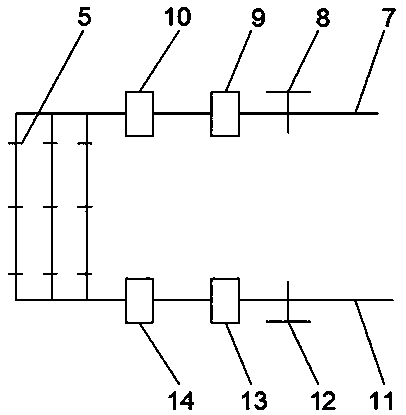

Optical fiber device and measuring method for turbine blade surface temperature distribution measuring

InactiveCN104006899AHigh sensitivityEasy maintenance and replacementThermometers using physical/chemical changesOptical pathColor temperature

An optical fiber device for turbine blade surface temperature distribution measuring comprises an optical fiber probe, a lens set is arranged in the optical fiber probe, the lens set and the optical fiber probe are connected to four optical fiber bundles, a double-color temperature measuring system for measuring the temperature of the surface of a turbine blade is formed by the first optical fiber bundle and the second optical fiber bundle, and a reflection type displacement measuring system for measuring position information of the turbine blade is formed by the third optical fiber bundle and the fourth optical fiber bundle. The optical fiber bundles respectively correspond to one optical filter. The light paths of the first optical fiber bundle, the second optical fiber bundle and the third optical fiber are respectively provided with one photovoltaic conversion part, and the light path of the fourth optical fiber is provided with an illuminating source. The double-color temperature measuring system and the reflection type displacement measuring system are connected with a data collecting instrument which is connected with a remote monitoring system through the network. The optical fiber device can measure the temperature of the surface of the turbine blade rotating at a high speed, the temperature changing characters can be monitored online in real time, and the serious failures such as probable blade ablation in an operating combustion gas turbine are prevented in advance.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

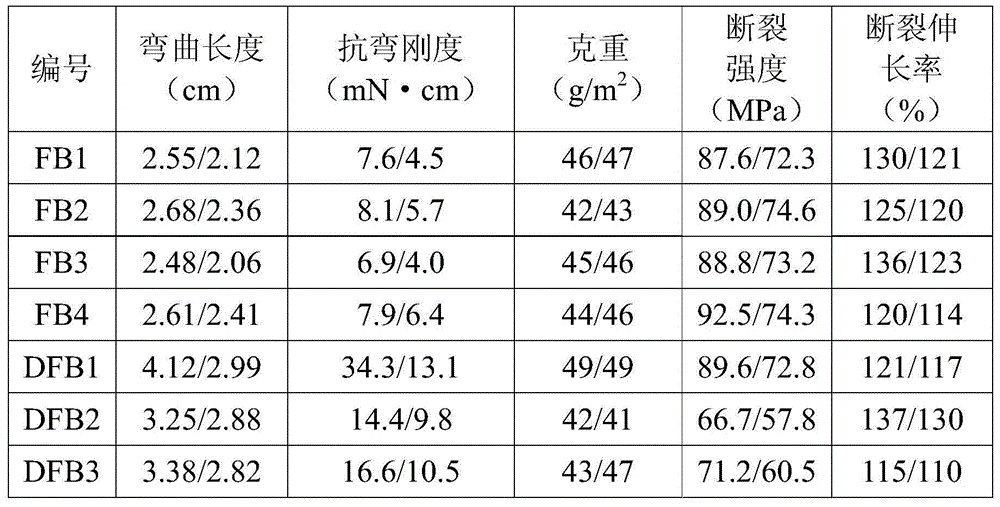

Non-woven fabric raw material and preparation method thereof, and preparation method of non-woven fabric

ActiveCN105623074AImprove spinnabilityDoes not affect uniformityNon-woven fabricsBulk chemical productionPolymer scienceNonwoven fabric

The invention discloses a non-woven fabric raw material and a preparation method thereof, and a preparation method of a non-woven fabric; the non-woven fabric raw material contains a polypropylene composition and a nucleating agent; the polypropylene composition contains 40-70 wt.% of crystalline polypropylene A and 30-60 wt.% of an ethylene-propylene elastic copolymer B, wherein at the temperature of 230 DEG C and the pressure of 2.16 kg, the ratio of the melt index of the polypropylene composition to the melt index of the crystalline polypropylene A is 0.7-1.3; with the total weight of the polypropylene composition as a benchmark, the content of the nucleating agent is 200-2000 ppm. The non-woven fabric raw material has good spinnability, and the prepared non-woven fabric has the advantages of comfortable sense of touch, softness, good mechanical performance, high strength and high flexibility.

Owner:CHINA PETROLEUM & CHEM CORP +1

Permanent magnet direct-driven internally-mounted-type elevator

InactiveCN108313857AStructural Design ImplementationSave construction areaMine liftsElectricityPower factor

The invention relates to the field of mine elevators, in particular to a permanent magnet direct-driven internally-mounted-type elevator. The permanent magnet direct-driven internally-mounted-type elevator comprises a spindle and a winding drum rotatably arranged on the spindle. A stator coil is fixedly arranged on the position, corresponding to the winding drum, of the spindle along the outer circumference of the spindle, a permanent magnet used for being matched with the stator coil is arranged on the inner wall of the winding drum along the inner circumference of the winding drum, and the outer circumference of the winding drum is used for coiling of a steel wire rope of the elevator. The permanent magnet direct-driven internally-mounted-type elevator has the advantages that the efficiency is high, energy and electricity saving are achieved, the power factor is high, the motor structure is simple, reliability is high, the size is small, the power density is high, the starting torqueis large, noise is small, and the temperature is low.

Owner:CITIC HEAVY INDUSTRIES CO LTD

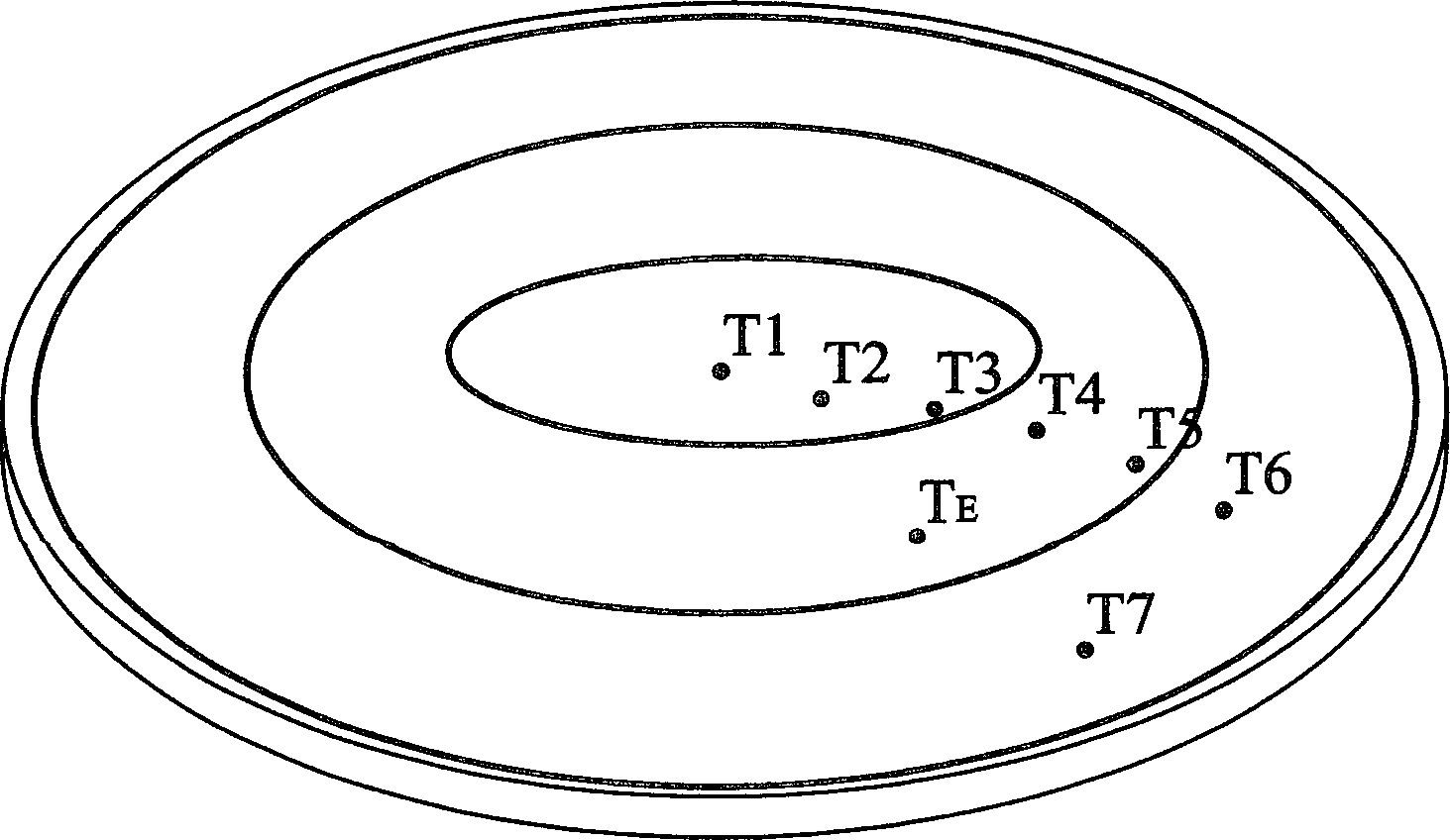

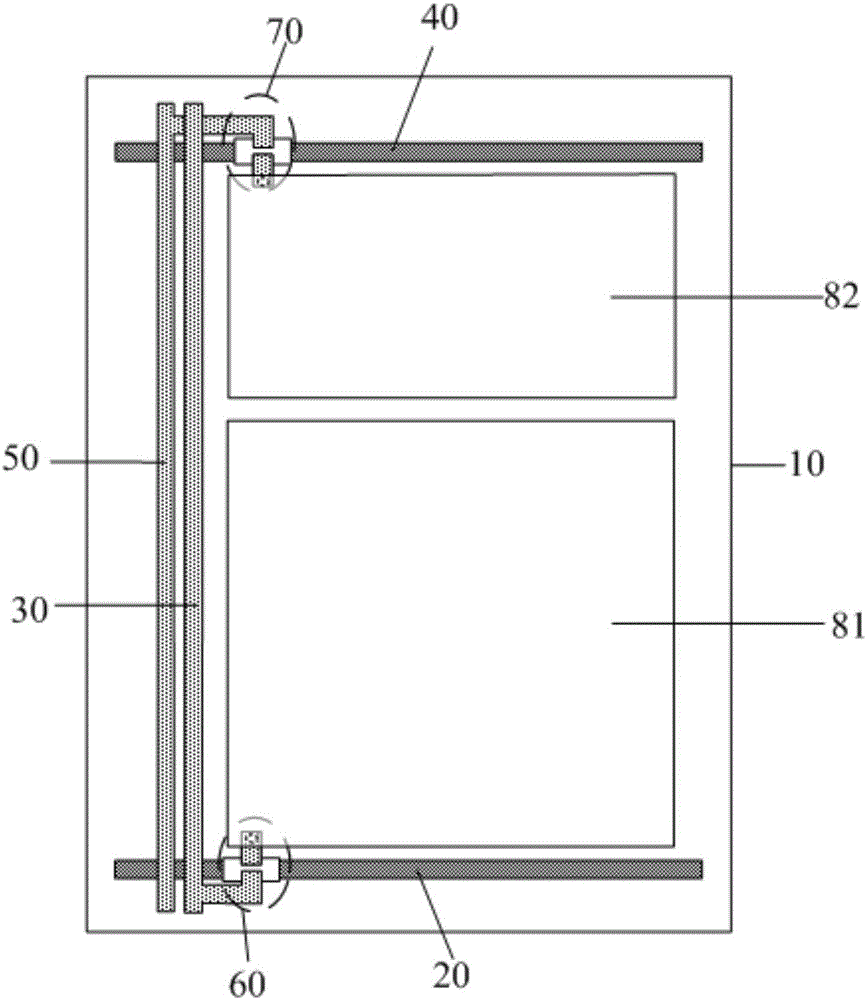

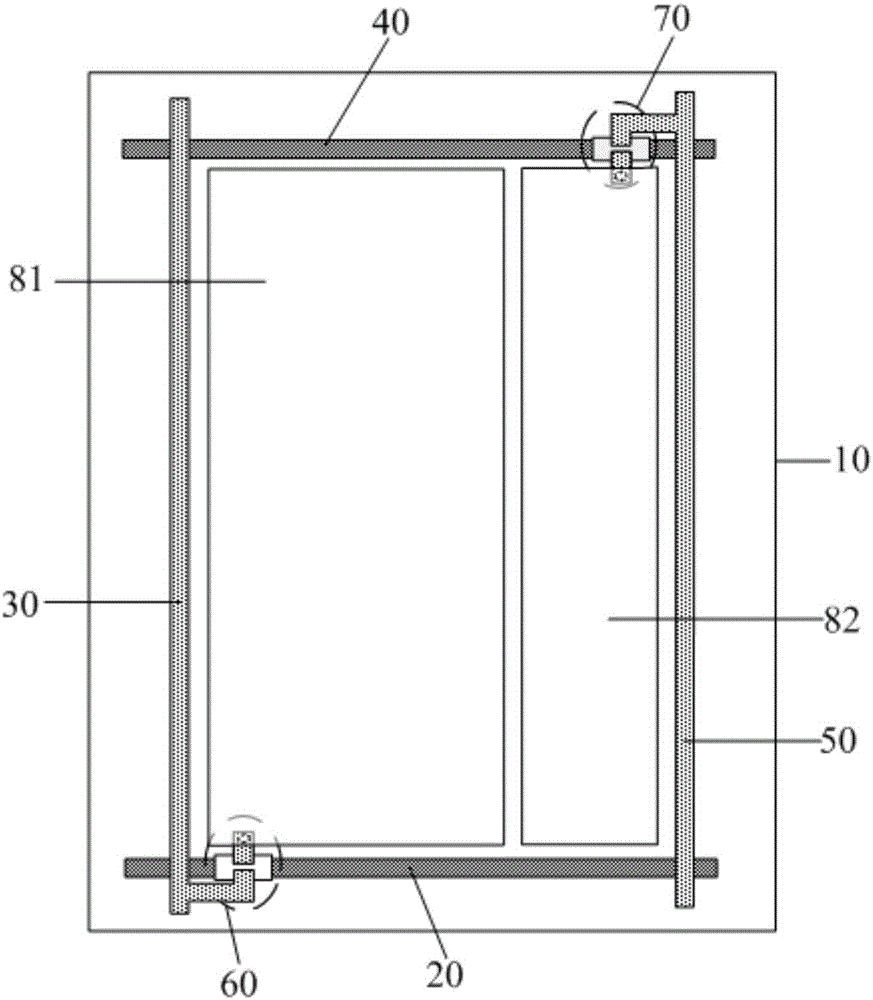

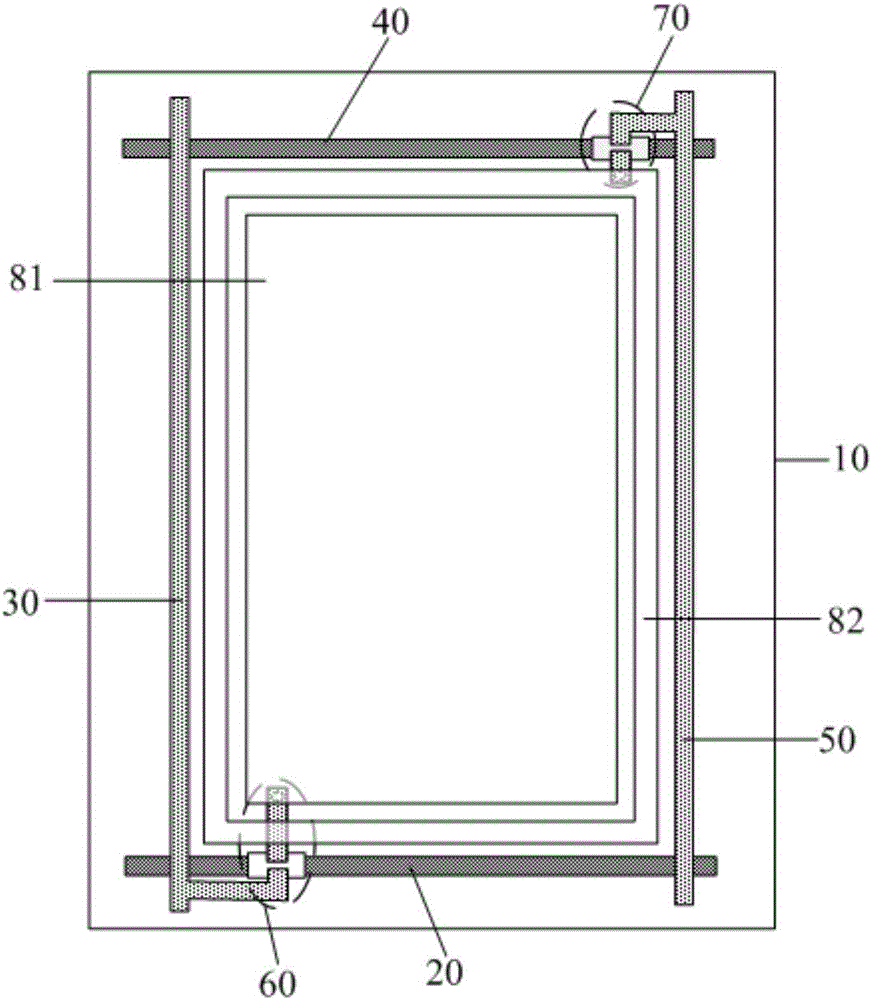

Methods and systems for rapid thermal processing

InactiveCN1734716ADoes not affect uniformityAccurate measurementCharge supportsSemiconductor/solid-state device manufacturingHeat flowEngineering

Methods for rapid thermal processing of semiconductor substrates are provided. An exemplary method comprises directing radiant heat energy emitted from a heat source toward a backside surface of the semiconductor substrate. Systems for rapid thermal processing also are provided. The effect of the invention is that the heat energy emitted from the heat source is lead to the back of the semiconductor substrate, and the front of the semiconductor is not radiated by the heat energy, so patterns of the front of the semiconductor substrate do not influence evenness of heat flowing, alternatively, a pyrometer is arranged on the front of the semiconductor substrate because the heat source is not set in the front of the semiconductor substrate, by this the real temperature of the front of the semiconductor substrate is exactly measured, and radiation heat energy emitted from the individually heating lamp tube of the heat source is real-time controlled.

Owner:TAIWAN SEMICON MFG CO LTD

Array substrate, display device and driving method thereof

InactiveCN106842745AImprove reliabilityRealize display luminescenceStatic indicating devicesNon-linear opticsDisplay deviceEngineering

The invention provides an array substrate, a display device and a driving method thereof and relates to the technical field of touch display. Voltage uniformity and reliability of the display device can be improved. The array substrate comprises a substrate, a grid line and a data line, wherein the grid line and the data line are arranged on the substrate. The grid line and the data line limit a sub-pixel in a cross mode. The sub-pixel comprises a first thin film transistor, a second thin film transistor, a first transparent electrode and a second transparent electrode. A grid of the first thin film transistor is electrically connected with the grid line, a source is electrically connected with the data line, and a drain is electrically connected with the first transparent electrode; a grid of the second thin film transistor is electrically connected with a touch scanning line, a source is electrically connected with a touch lead, and a drain is electrically connected with the second transparent electrode. The first transparent electrode and the second transparent electrode are insulating, and orthographic projections of the first transparent electrode and the second transparent electrode on the substrate are not overlapped.

Owner:BOE TECH GRP CO LTD +1

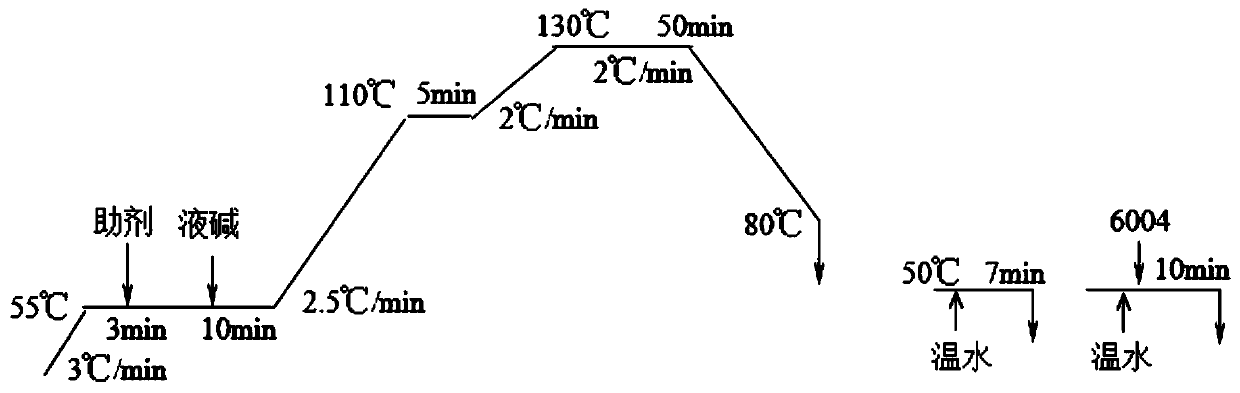

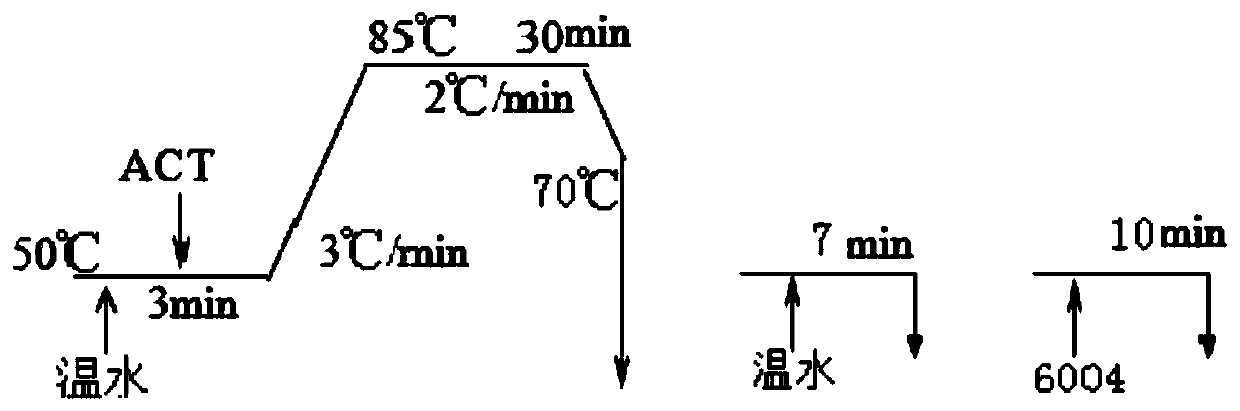

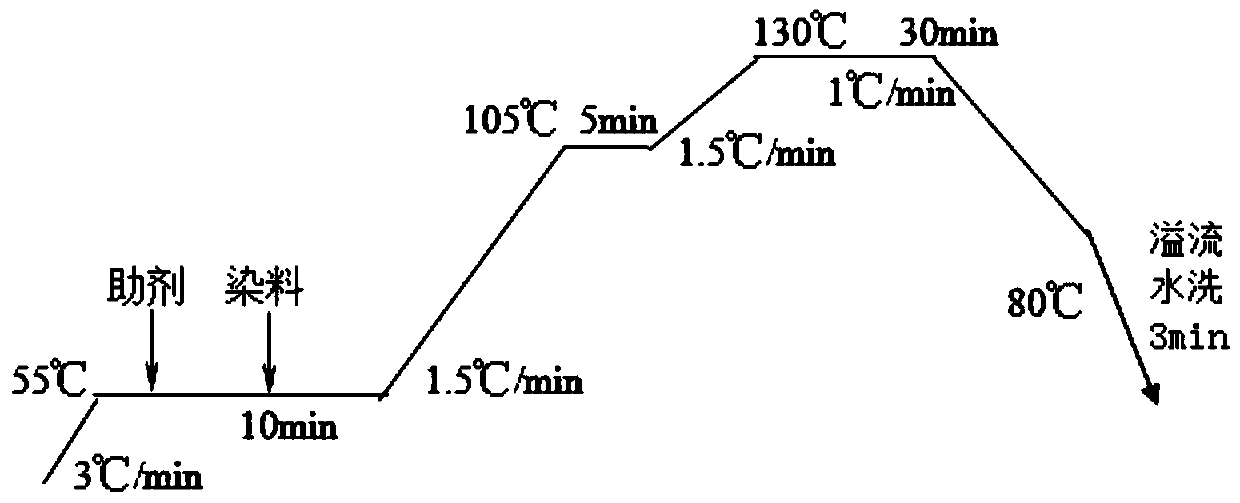

Comfortable permanent moisture absorption and quick drying polyester knitted fabric and making method thereof

InactiveCN109944089AGuaranteed whitenessGuaranteed qualityWeft knittingDyeing processPolyesterMoisture absorption

The invention relates to a comfortable permanent moisture absorption and quick drying polyester knitted fabric and a making method thereof, and belongs to the technical field of textile dyeing and finishing processes. The making method of the comfortable permanent moisture absorption and quick drying polyester knitted fabric includes the steps of gray cloth weaving, pre-treatment opening one-bathtreatment, dyeing, primary reduction washing, neutralizing, secondary reduction washing, cotton dyeing, post-treatment drying and sizing. Fiber of the obtained fabric has a large number of microporousstructures and can discharge a large amount of sweat generated by the human body out of the outer layer of clothes through micropores and accelerate the volatilization of sweat, so that the wearing comfort of the fabric is improved, the rigidity of polyester is reduced, the softness of the polyester fabric is improved, the polar light on the surface of the polyester fiber is eliminated, the handfeel and appearance of the polyester fabric are closer to those of natural fiber, and thus the comfort of the fabric is further improved.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Topology-number-adjustable vortex light beam generation device, system and method

The invention discloses a topology-number-adjustable vortex light beam generation device, system and method. The topology-number-adjustable vortex light beam generation device comprises two spiral phase mirrors, wherein the phases of the two spiral phase mirrors are respectively set as A[theta]2 and -A[theta]2, the two spiral phase mirrors are sequentially disposed on an optical path, and the topological number of the obtained vortex light beam is increased by 1 by increasing the angle difference of the two spiral phase mirrors. According to the invention, after passing through the device, a laser beam can be added with a spiral phase factor to realize phase modulation, so that the energy distribution of the laser beam is changed into annular distribution; the topological number of the obtained vortex beam is adjusted by rotating one or two spiral phase mirrors to control the angle difference of the two spiral phase mirrors so as to realize an annular light spot with an adjustable size; and a group of spiral phase mirrors with second-order nonlinear spiral structures are designed and superposed to generate vortex light beams with adjustable topological numbers, so that annular light spots with concentrated energy distribution at the edge, larger diameter, longer focal depth and adjustable size are formed.

Owner:武汉先河激光技术有限公司

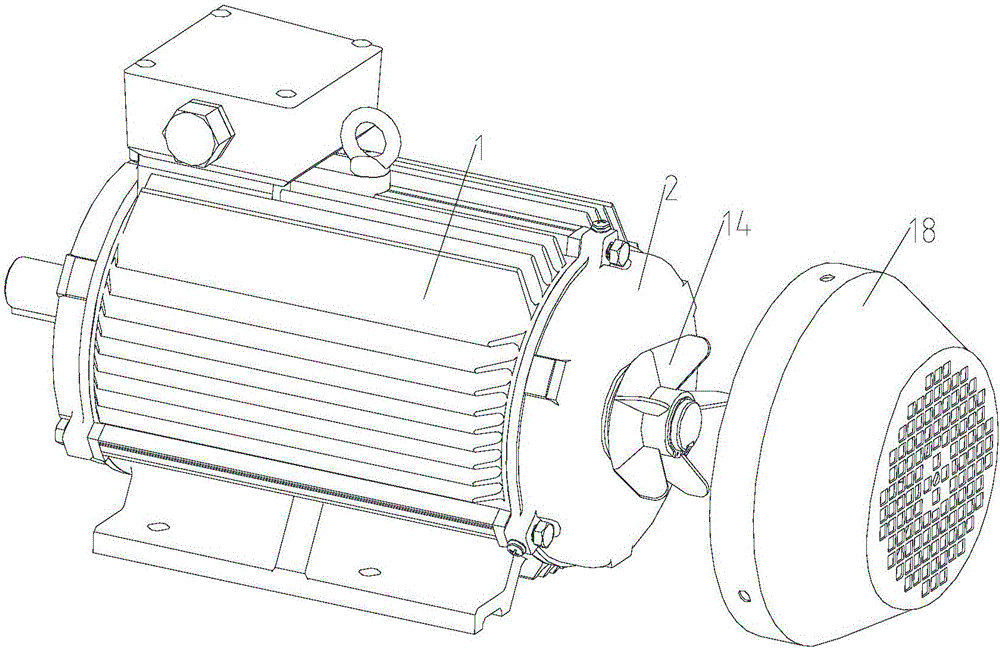

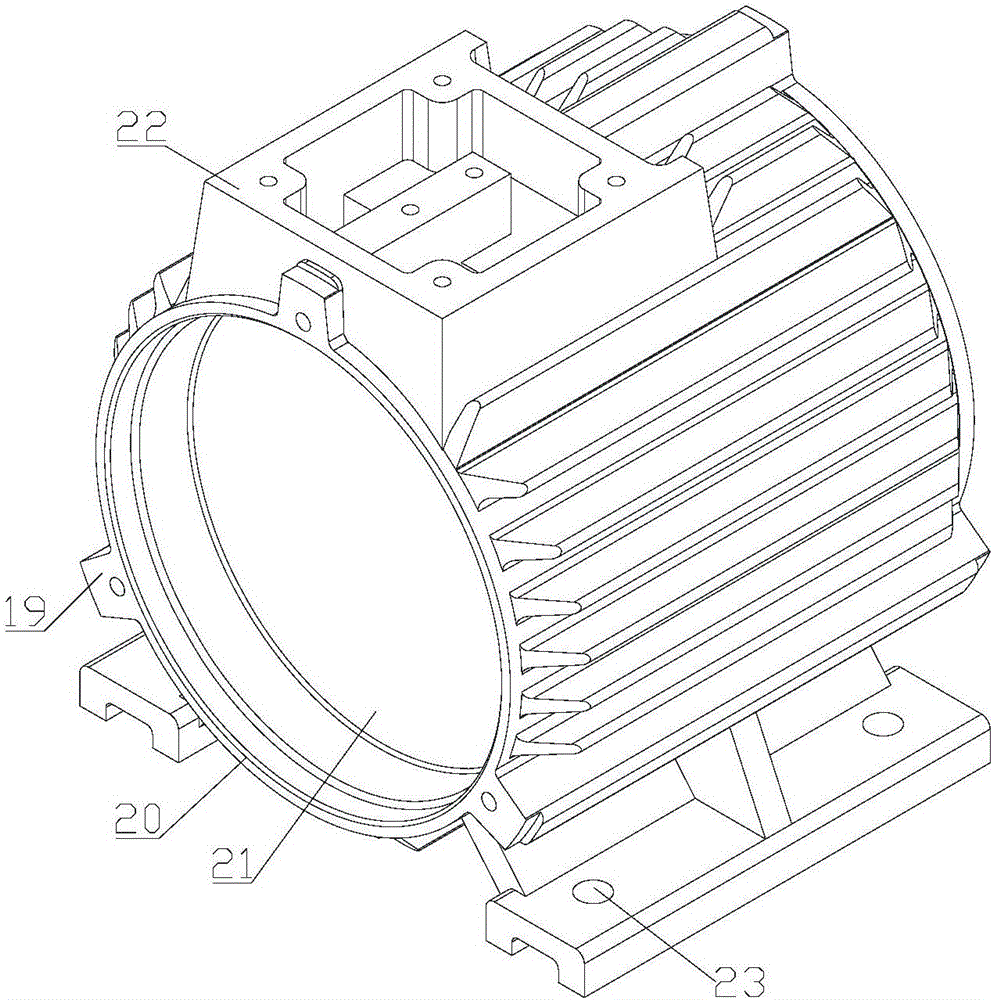

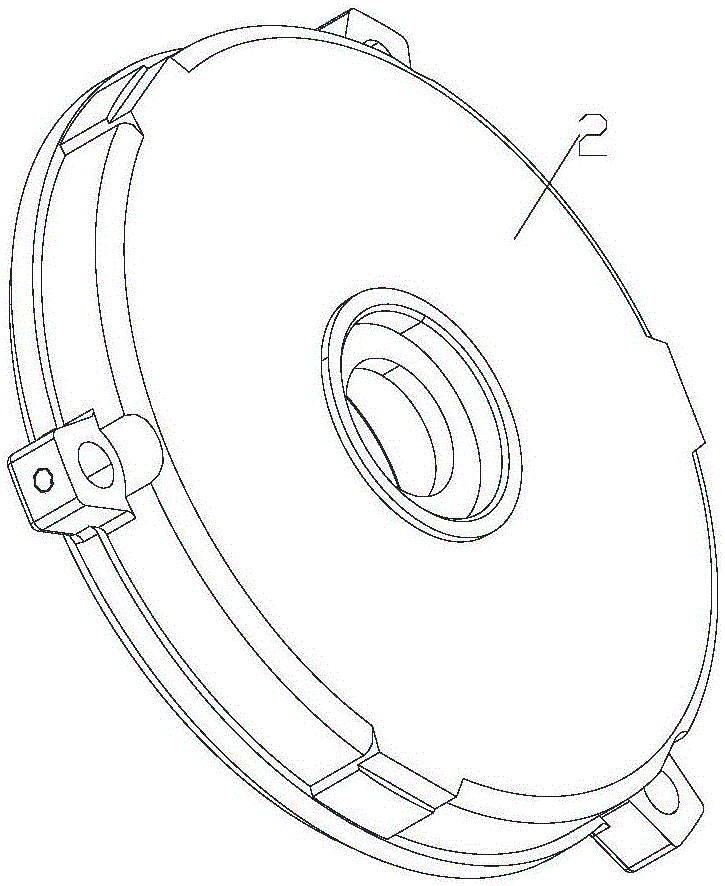

Motor base and motor

PendingCN106685125AImprove coaxialityDoes not affect uniformityManufacturing dynamo-electric machinesSupports/enclosures/casingsNoise controlPosition error

The invention discloses a motor base and a motor. The motor base comprises a hollow base body and an end cover, wherein the end cover is arranged at a first end of the base body, and the base body and the end cover are integratedly formed. With the adoption of the integrated base body, the coaxiality of the whole machine is favorably improved, form and position error accumulation caused by different processing references is reduced, the gas uniformity of the motor cannot be affected, and noise control is facilitated.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Borax oxide remover for internal surface of hot continuous rolled steel pipe and method for preparing same

A borax oxide remover for an internal surface of a hot continuous rolled steel pipe and a method for preparing the same belong to the technical field of hot continuous rolled steel pipes. The oxide remover comprises the following components of 53-58% of borax, 30-35% of sodium sulfate, 10-15% of reducing agent and 1-2% of fluxing agent according to mass percent content; and the maximum granularity of each component is less than or equal to 20 meshes. The preparation process of the borax oxide remover comprises the following steps of: preparing the reducing agent (sodium stearate), drying the borax, adding the fluxing agent and mixing together for granulating and screening, and then preparing the borax oxide remover. The method for preparing the borax oxide remover has the advantages that the problems of melt aggregation, high moisture content, poor blowing homogeneity and the like in the hot continuous rolling process can be solved; the quality of the internal surface of the steel pipe can be improved; the requirements on hot continuous rolling are met; and the method is moderate in cost, high in cost performance and suitable for population and application in the metallurgical field.

Owner:BAOTOU HERUN METALLURGICAL LUBRICATION MATERIALS

Preparation method of cutting-free rice and wheat straws by alkaline cooking through vertical digester

InactiveCN103194923AQuality improvementGood filterabilityPretreatment with water/steamPretreatment with alkaline reacting compoundsBlack liquorSulfate

The invention provides a preparation method of straw pulp by alkaline cooking through a vertical digester without straw cutting. The preparation method comprises the steps of: washing cutting-free straw raw materials, and putting the straw raw materials into the vertical digester; adding a hot alkali solution, and carrying out liquor circulation cooking by using a conventional sulfate method or caustic soda anthraquinone method; when lignin released by the straw raw materials reaches 80-90% by cooking, discharging free black liquor, supplementing a part of an alkali solution for continuous liquor circulation to the cooking temperature, stopping the liquor circulation, and preserving heat until the cooking is finished; and performing conventional pulp washing, so as to obtain unbleached pulp, and conveying the obtained black liquor to an alkali recovery system. According to the preparation method, the straw materials are not cut, and the liquor circulation is unobstructed and the straw materials are uniformly cooked into the pulp in the vertical digester by utilizing good appearance and maintained characteristics of the straw materials before pulping, so that on the premise of ensuring the quality of cooking, the solid matter concentration of the black liquor can be up to more than 12%, the raw material stock loss can be reduced by about 5%, the cooking capability of unit digester volume can be improved by about 10%, the pulp yield and the viscosity are improved by different degrees, and the level of efficient, energy-saving and clean production of the straw pulp is improved significantly.

Owner:KUNMING UNIV OF SCI & TECH

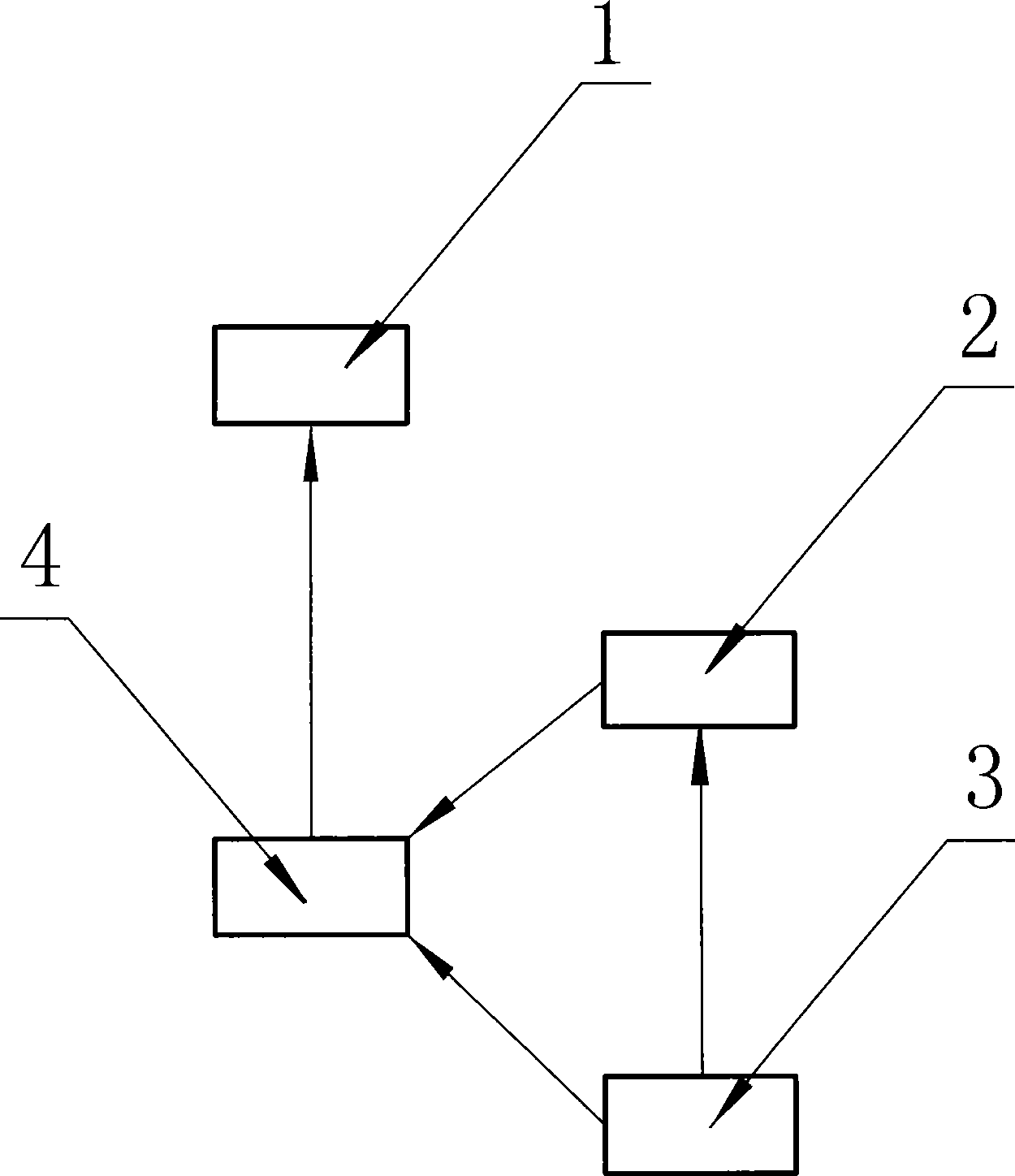

Control circuit for high brightness LED lamp

InactiveCN101363599AControl brightnessDoes not affect uniformityPoint-like light sourceElectric circuit arrangementsOptical ModuleEngineering

The invention discloses a control circuit of a high brightness LED lamp, which comprises an optical module of the high brightness LED, a driving circuit of the high brightness LED and a high brightness LED lamp that consists of sequentially connected switch powers; the high brightness LED lamp is provided with a high brightness LED driving control circuit, which is convenient to control the brightness of LED illuminating equipment, satisfy the energy-saving requirement that the brightness is halved during the off-peak period without influencing the light distribution uniformity; the control circuit of the high brightness LED lamp can be widely used in the LED illuminating equipment such as high brightness LED street lamps, high brightness LED projectors, etc.

Owner:朱敬华

Production method of film solar cell and electro-deposition device thereof

ActiveCN105206703AReduce dead areaAvoid occupyingFinal product manufactureSemiconductor devicesElectrical isolationElectricity

The invention provides a production method of a film solar cell. A first groove is filled with a substance identical with an absorption layer, and the substance of the absorption layer is a semiconductor; the vacancy of a long-strip-shaped contact electrode is directly filled with a substance identical with a back electrode, and the direct contact resistance between the back electrode and the absorption layer is very large, so that no influenced are caused to serial connection of solar cell units; and that is to say, the film solar cell does not need to be filled by an electrical-isolation substance, the electrical-isolation substance does not participate in photoelectric conversion, and the area of a dead area is reduced, so that the occupation of the solar cell by the electrical-isolation substance is avoided, and the photoelectric conversion area of the solar cell is increased. In addition, when the used contact electrode is the long-strip-shaped contact electrode, the long-strip-shaped contact electrode is removed after electro-deposition, then a long-strip-shaped contact electrode vacancy is obtained, and the original groove etching process is omitted, so that the wastes of production materials are reduced, the processes are saved, and the production cost is further lowered.

Owner:BEIJING HI TECH WEALTH INVESTMENT DEV

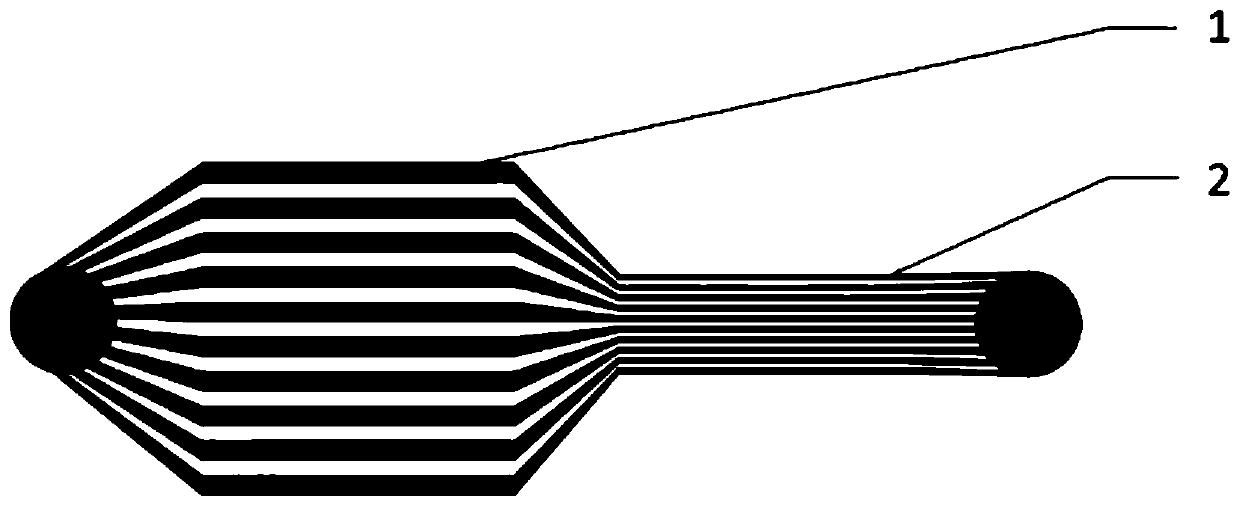

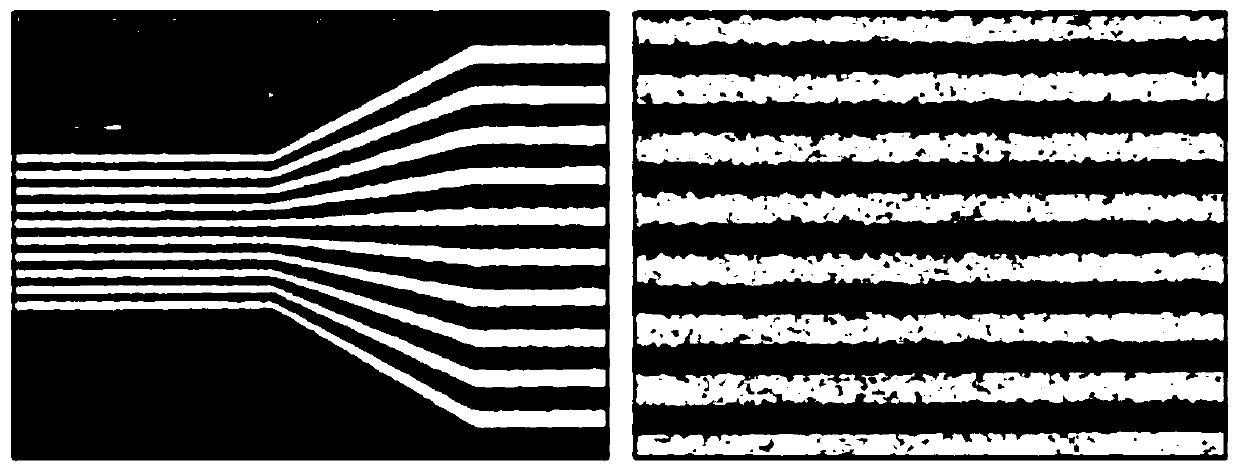

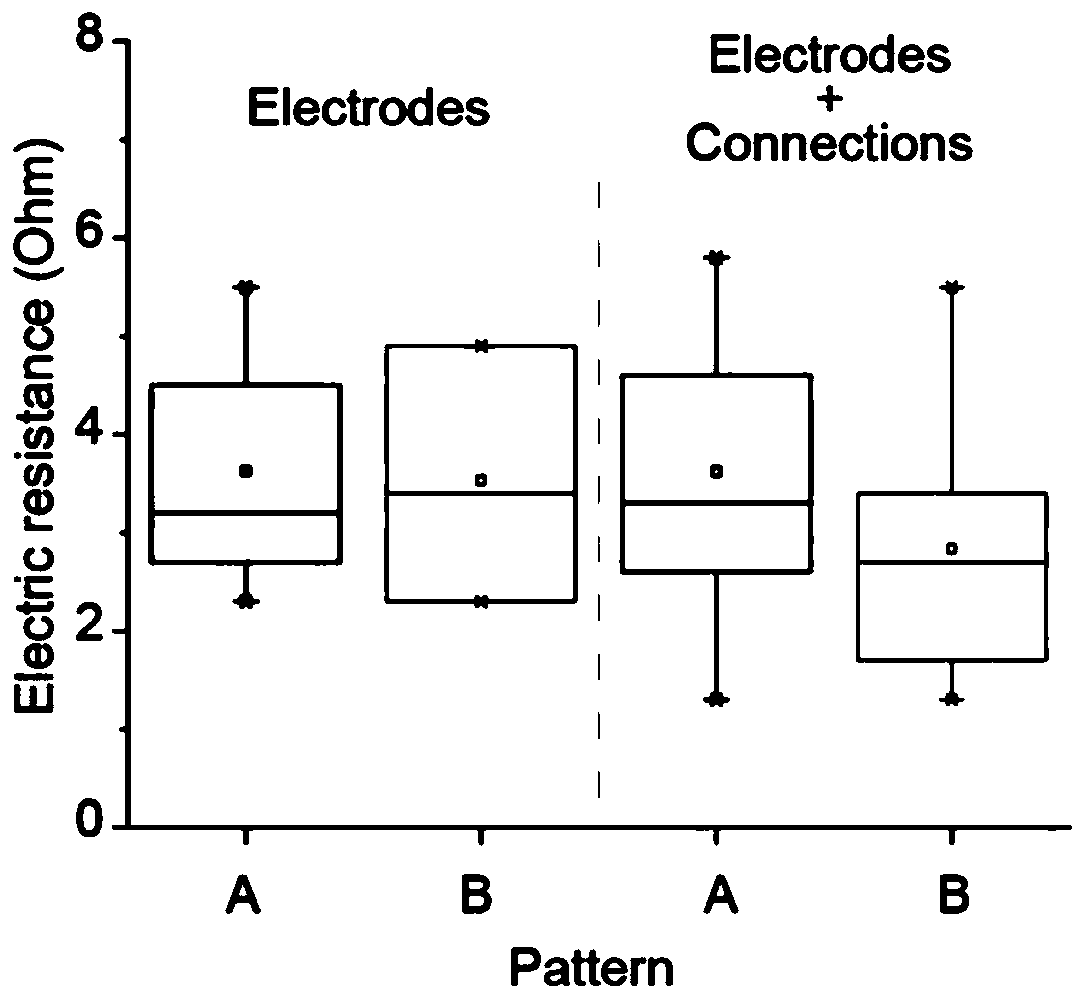

Flexible array microelectrode manufacturing method

ActiveCN110146114AIncrease distribution densityImprove flexibilityConverting sensor output electrically/magneticallyPlasma treatmentIon

The invention discloses a flexible array microelectrode manufacturing method. The method adopts a viscous flexible substrate, uses a high-conductivity material as an electrode material, and adopts a micro-electrode coating technology based on soft lithography to achieve a sub-millimeter size and below. . The method comprises the following steps of making a mould with an electrode pattern; punchingat circular positions of two ends of a channel of the electrode pattern by using a puncher; putting the punched mould into an ion bonding machine, making the channel face upwardly during placing, vacuumizing and carrying out plasma treatment; mixing conductive ink and diluent, then placing in an ultrasonic cleaning machine to carry out ultrasonic concussion and mix uniformly, and injecting the diluted conductive ink from one end of a hole with a needle and an injection syringe having the same size with the puncher in the second step till that a channel is filled with the conductive ink; and after reheating, tearing the mould from the viscous flexible substrate, and cutting two head portions with the hole of the viscous flexible substrate, and leaving only an electrode portion and a wiringportion. Flexibility is ensured and simultaneously low cost and a high resolution are realized.

Owner:HEBEI UNIV OF TECH

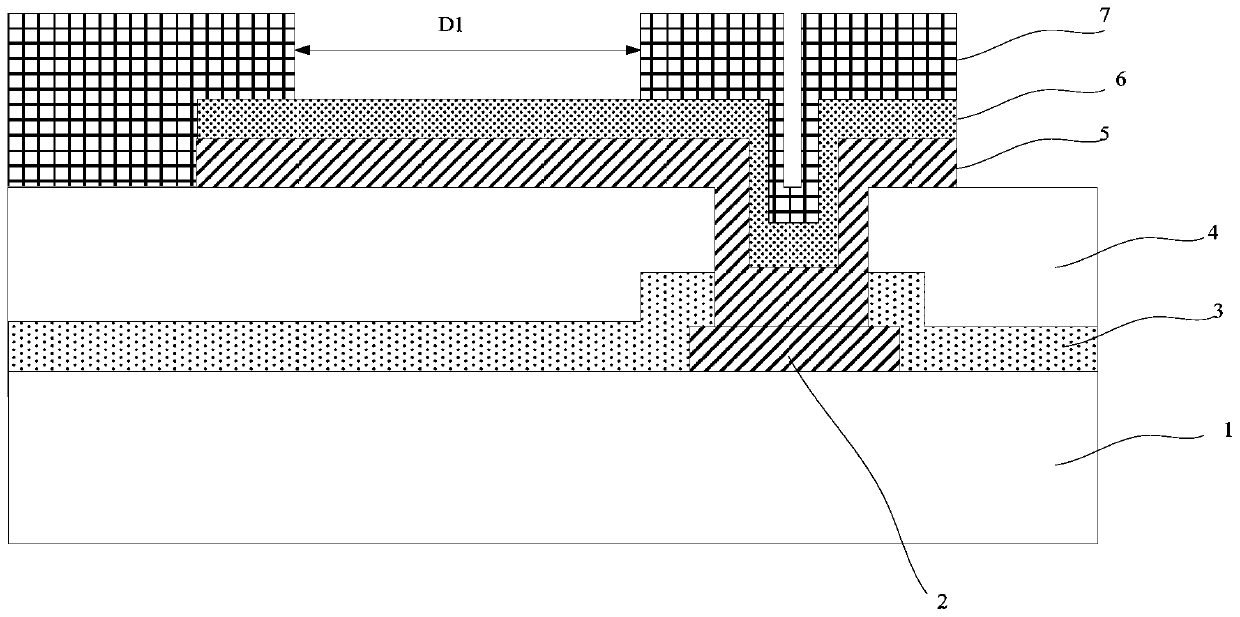

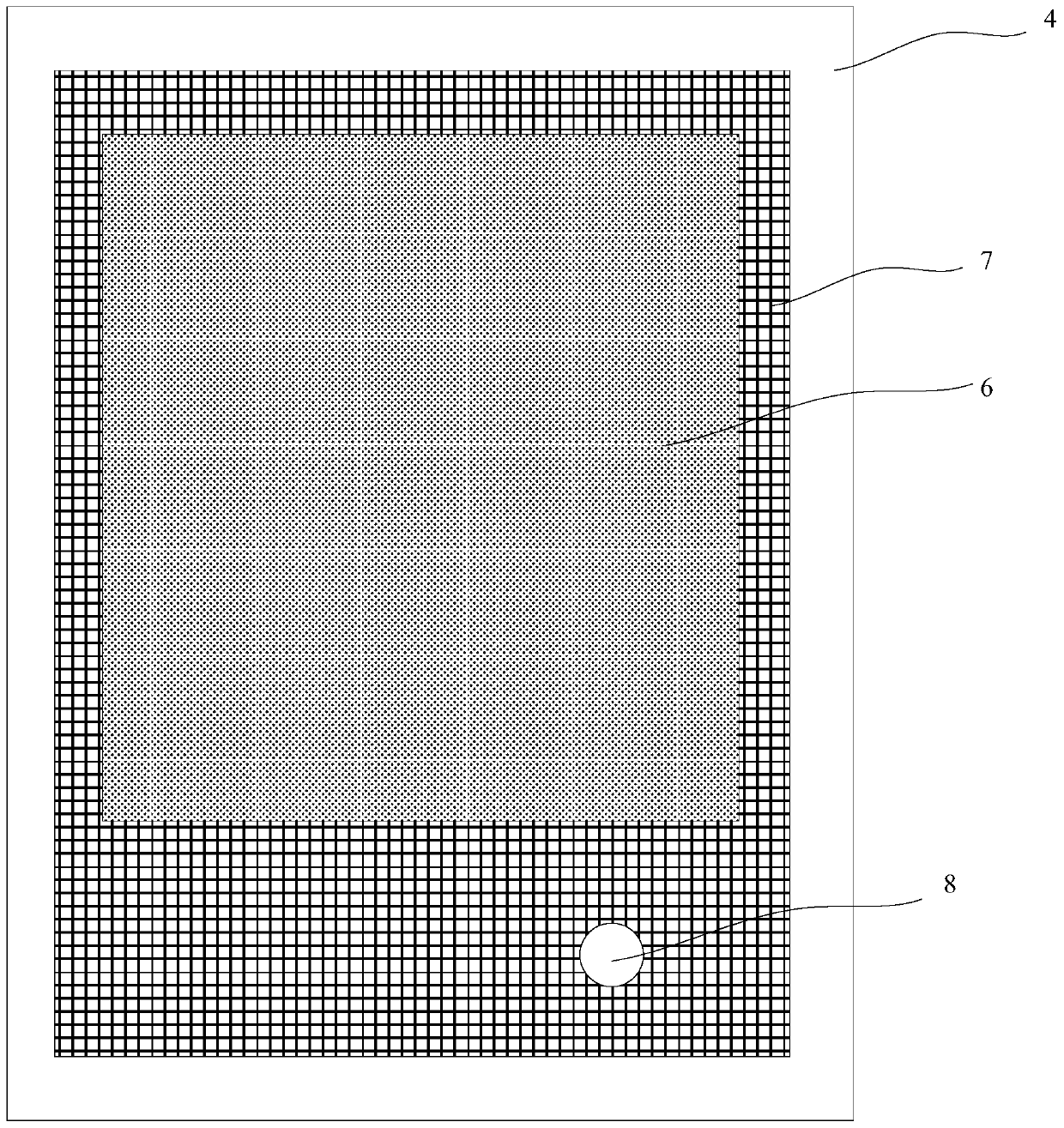

OLED display substrate, manufacturing method thereof and display device

InactiveCN111244326ADoes not affect uniformityIncrease the areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

The invention provides an OLED display substrate, a manufacturing method thereof and a display device, and belongs to the technical field of display. The OLED display substrate comprises a driving thin film transistor, an anode, a light-emitting layer and a cathode which are located on a substrate body. An insulating layer is arranged between the anode and the driving thin film transistor in a spaced mode, the anode is connected with an output electrode of the driving thin film transistor through an anode via hole penetrating through the insulating layer, and the segment difference of the surface of the side, away from the underlayer substrate, of the anode is smaller than a threshold value. According to the technical scheme of the invention, the pixel aperture opening ratio of an OLED display product can be improved.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

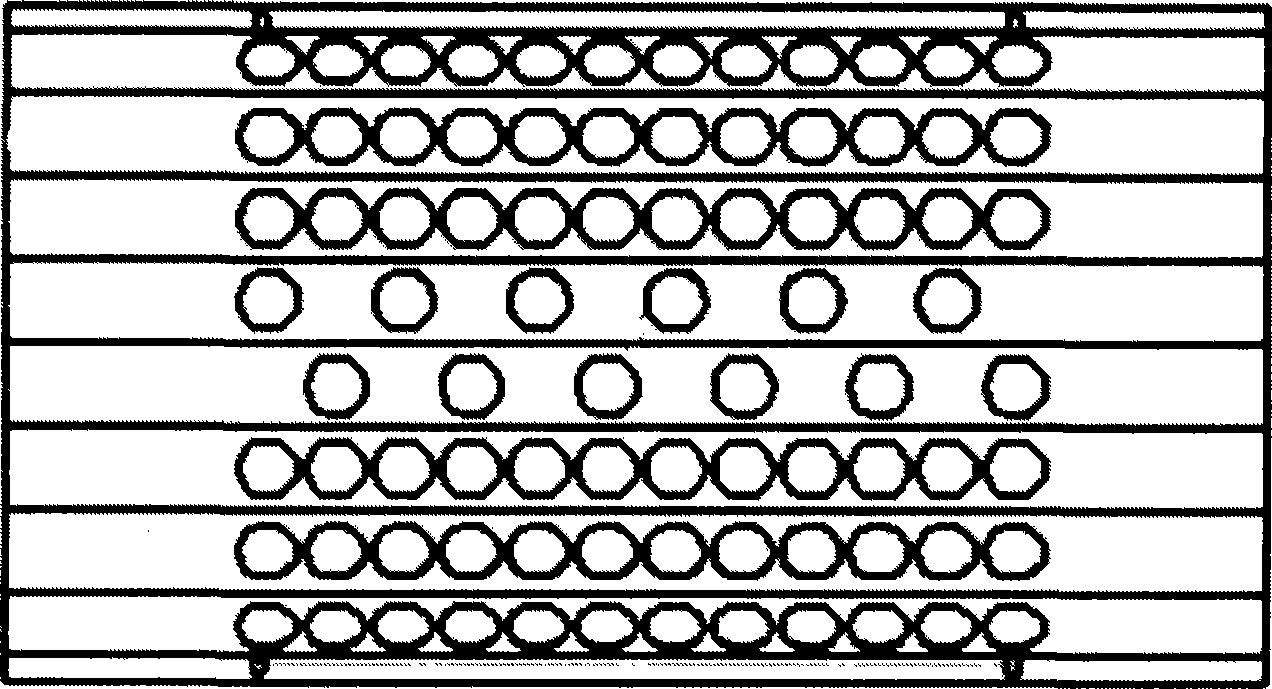

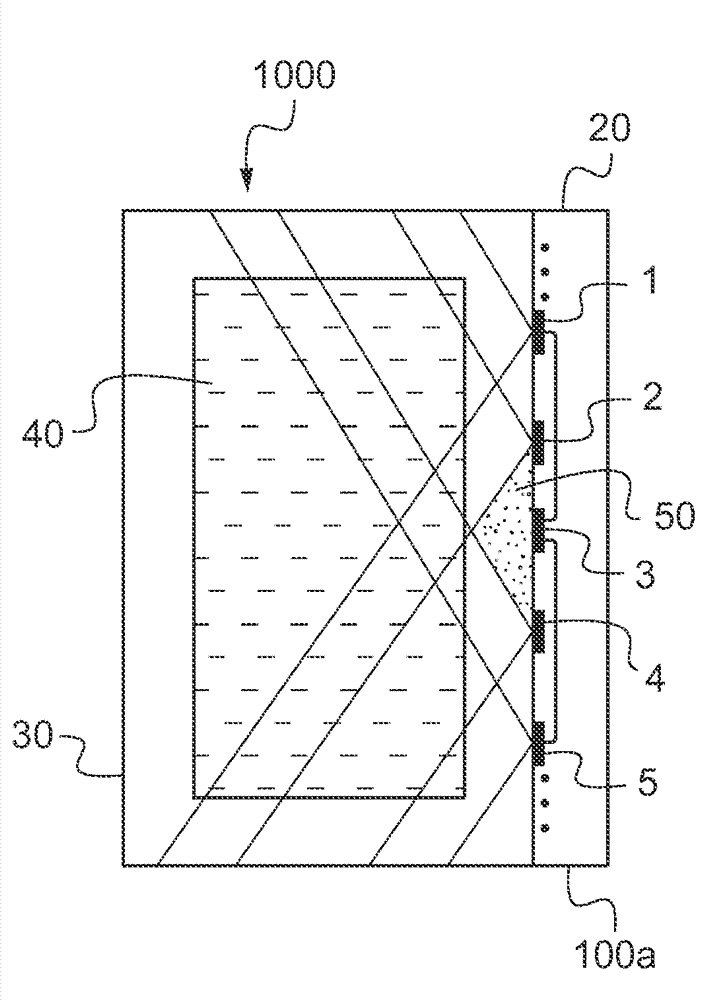

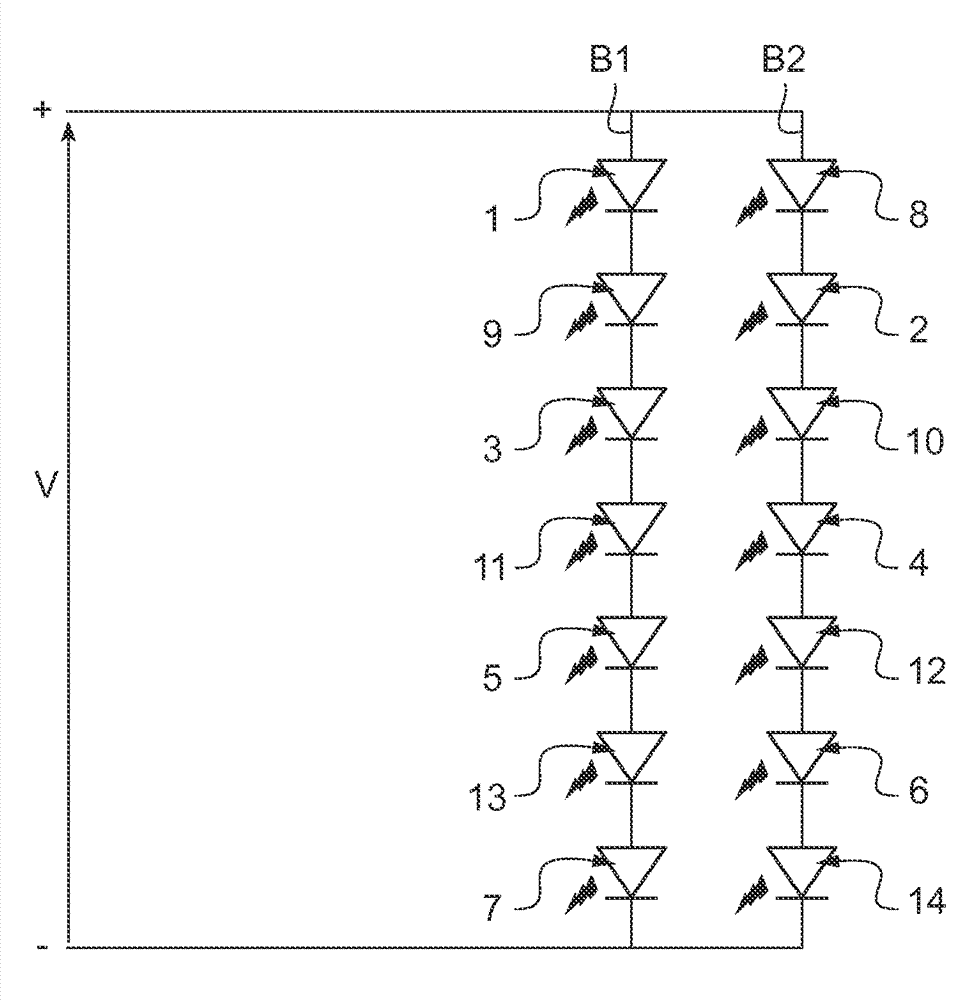

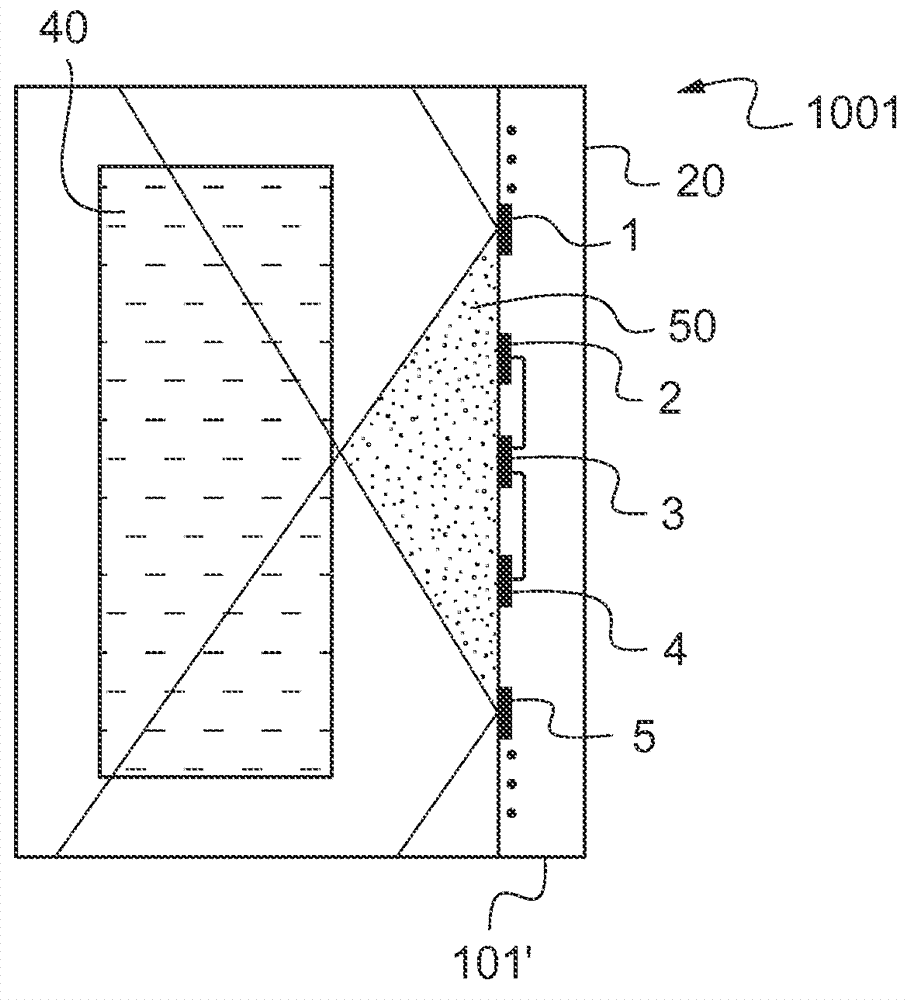

Module comprising light-emitting diodes and illuminated glazing including such a diode module

InactiveCN103493591ADoes not affect uniformityFreedom of choiceElectrical apparatusElectroluminescent light sourcesElectricityLight-emitting diode

The invention relates to a module comprising light-emitting diodes (100) and including a printed circuit card (20) bearing diodes (1 to 12) connected in a series / parallel electrical circuit comprising multiple circuit branches (B1 to B4) powered by a common electricity supply (V), each branch comprising two peripheral diodes and, optionally, at least one internal diode. At least one of the multi-diode branches comprises at least one internal reference diode, the two diodes closest to the reference diode belonging to branches other than the multi-diode branch. And / or at least one of the dual-diode branches comprises two peripheral reference diodes and the closest diode on the printed circuit card is a diode belonging to a branch other than the dual-diode branch. The invention also relates to illuminated glazing including such a module.

Owner:SAINT-GOBAIN GLASS FRANCE

Environment-friendly lubricating grease with high lubricating property and preparation method thereof

ActiveCN109536260AImprove the lubrication effectReduce pollutionLubricant compositionCalcium silicateLithium hydroxide

The invention discloses environment-friendly lubricating grease with high lubricating property. The environment-friendly lubricating grease is prepared from the following raw materials in parts by weight: 85 parts of base oil, 20 parts of 12-hydroxystearic acid, 8 parts of lithium hydroxide powder, 1 part of a complex heat stabilizer, 0.4 part of an auxiliary heat stabilizer, 0.5 part of carboxymethyl cellulose, 1 part of sodium dodecyl sulfate, 1 part of sodium dodecyl benzene sulfonate, 0.3 part of an antioxidant, 0.3 part of graphite and 0.3 part of glycerinum, wherein the base oil is prepared from epoxidized soybean oil and chlorinated paraffin in the mass ratio is 7:3 through mixing; the complex heat stabilizer is prepared from peanut oil and tea tree oil in the mass ratio is 2:1; theauxiliary heat stabilizer is prepared from calcium silicate, zinc oxide and aluminum oxide in the mass ratio is 3:2:2. The invention also provides a preparation method of the environment-friendly lubricating grease with the high lubricating property. The environment-friendly lubricating grease disclosed by the invention has very high lubricating property, is good in biodegradability and has smallpollution to environment.

Owner:统一石油化工有限公司

Non-woven fabric for water purification and preparation method thereof

ActiveCN114516677AImprove hydrophilicityImprove water purification abilityWater/sewage treatment bu osmosis/dialysisSustainable biological treatmentPolymer scienceSodium phosphates

The invention provides a non-woven fabric for water purification and a preparation method thereof.The preparation method includes the steps that chitosan serves as a raw material and is modified through lactose acylation to obtain modified chitosan, then under the action of sodium polyphosphate, a cross-linking reaction is conducted to obtain modified chitosan microspheres, then polypropylene and the modified chitosan microspheres are mixed, and the non-woven fabric for water purification is obtained. Preparing a non-woven fabric gray fabric through a melt-blowing process; preparing a suspension from the nano activated carbon, and carrying out dipping treatment on the non-woven fabric grey cloth by utilizing the suspension under a continuous flow condition to obtain a pretreated non-woven fabric; and carrying out surface modification on the pretreated non-woven fabric by using acrylic acid to obtain the non-woven fabric. The non-woven fabric is good in hydrophilicity, high in water filtering precision and good in water purification effect.

Owner:CHTC JIAHUA NONWOVEN CO LTD

Impulsive knock microsphere bouncing device

InactiveCN104841614AReduce exposureReduce collisionLiquid surface applicatorsCoatingsMicrosphereEngineering

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Ice wrapping method for foods

PendingCN111406874APrevent changes in appearance, color and tasteIncreased ice delivery speedFood freezingFood preservationFood qualityEngineering

The present invention discloses an ice wrapping method for foods. The method comprises the following steps of (1) enabling the temperature of the quickly frozen foods to be -18 DEG C or below; (2) flatly spreading the quickly frozen foods and putting the quickly frozen foods on a silk screen-shaped supporting surface in a single-layer manner; (3) arranging a closed ice wrapping chamber or a semi-closed ice wrapping chamber, and enabling aerial fog to be uniformly distributed in the closed ice wrapping chamber or the semi-closed ice wrapping chamber by a two-fluid atomization nozzle; (4) conveying the quickly frozen foods arranged in a layer shape into an ice wrapping environment, enabling the aerial fog in the ice wrapping environment to be solidified on the surfaces of the low-temperaturequickly frozen foods to form small ice crystal particles, and forming protective ice layers which cover the quickly frozen foods on the surfaces of the quickly frozen foods; and (5) conveying the ice-wrapped foods to outside from the interior of the closed ice wrapping chamber or the semi-closed ice wrapping chamber. According to the method, in the ice wrapping process, the quickly frozen foods do not need to be turned over, so that the collision and friction between the foods are reduced, the appearance, color and taste change of the foods is prevented, the ice layer thickness of the quicklyfrozen foods subjected to ice wrapping is controllable, and the food quality is improved.

Owner:山东达信农牧科技股份有限公司

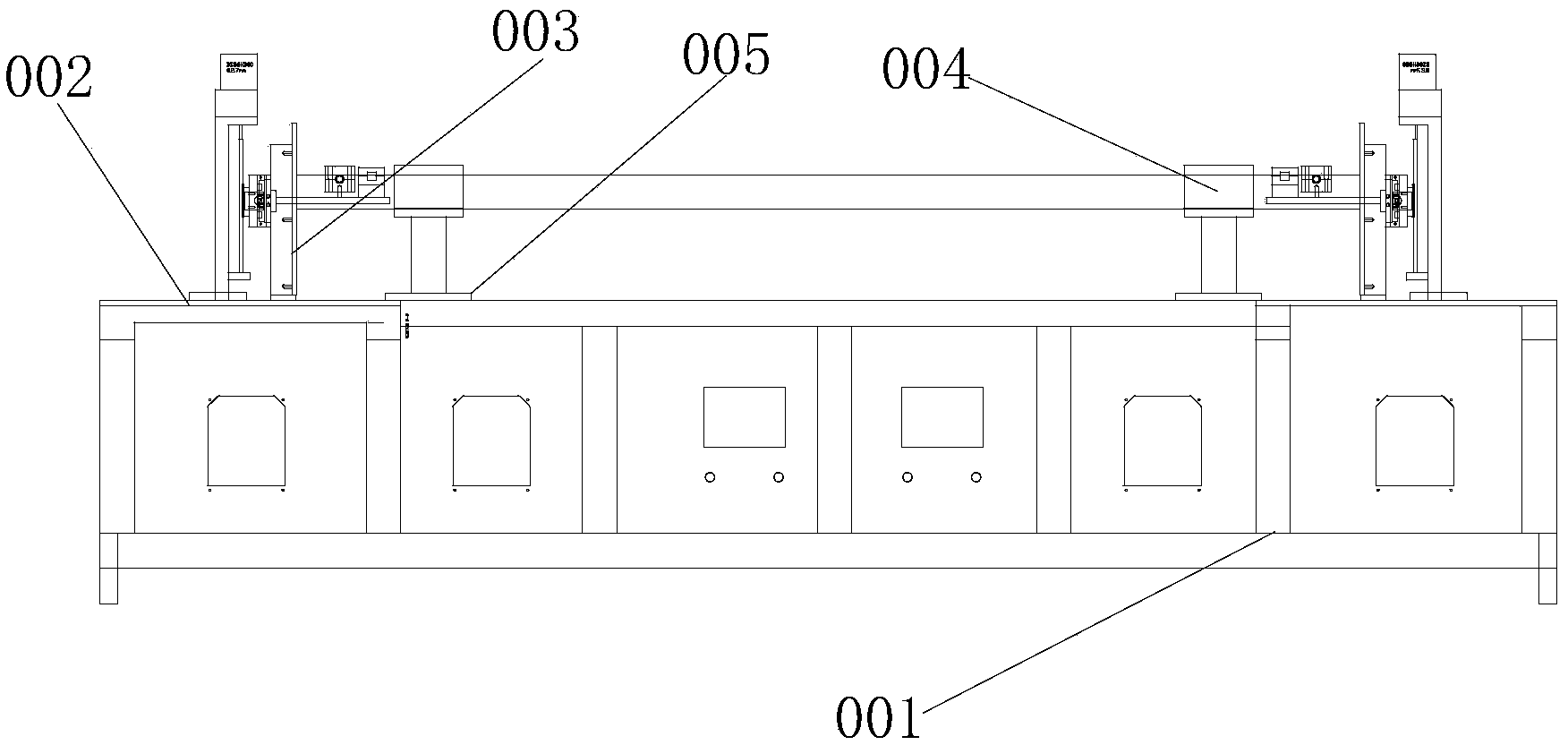

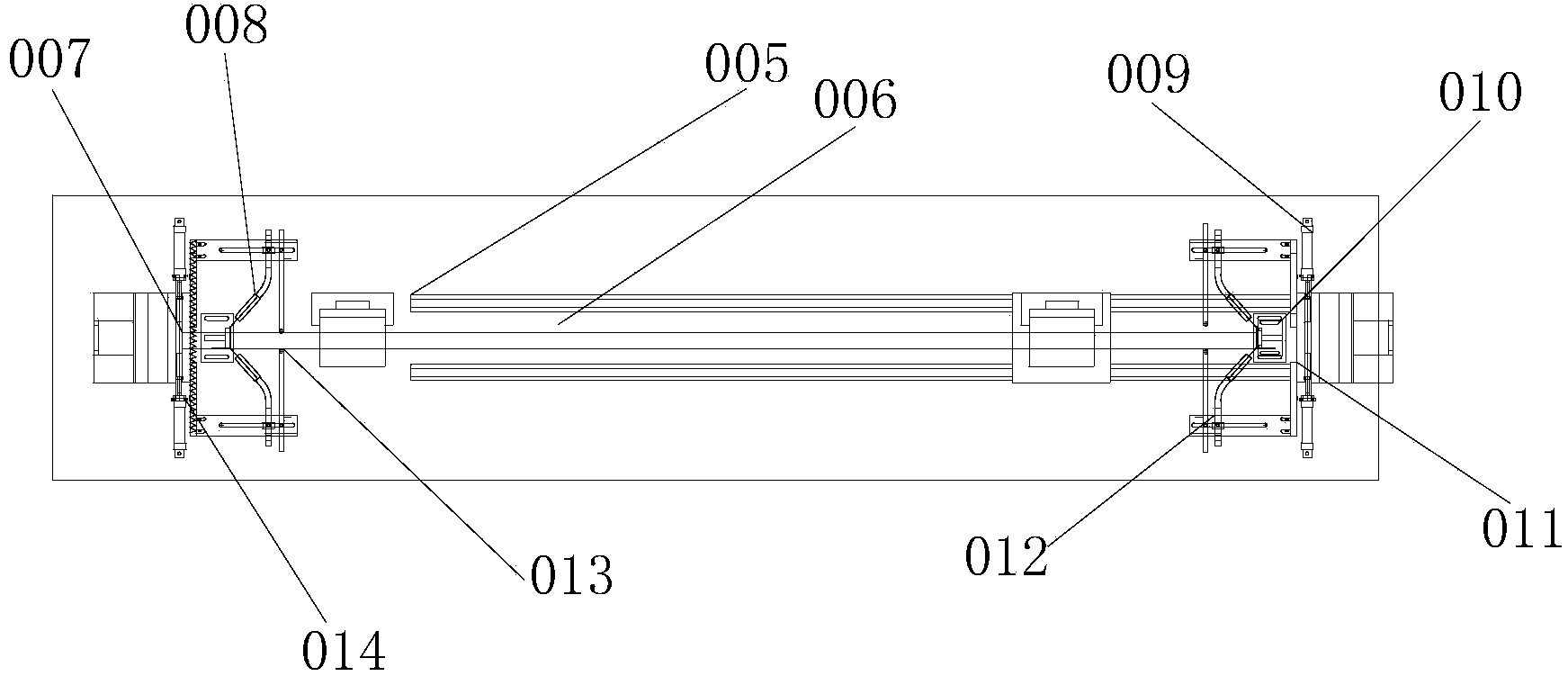

Automatic welding device

InactiveCN103909367AImprove operational flexibilityDoes not affect uniformityWelding/cutting auxillary devicesAuxillary welding devicesSprocketEngineering

The invention discloses an automatic welding device which comprises a mechanism body. The body comprises a equipment cabinet and a workbench disposed on the equipment cabinet. Welding stations are respectively disposed at the left and the right ends of the workbench. A transmission mechanism is disposed between the welding stations. The transmission mechanism comprises sprocket groups in mutual transmission and a moving crossbeam. Each welding station comprises multiple groups of welding adjusting mechanisms and a welding gun. Each welding adjusting mechanism comprises a drive device, a clamping device and a fixing device, the welding adjusting mechanism is driven by the drive device to achieve automatic adjusting by the aid of the clamping device and fixing device, and accordingly adjustable contact of a to-be-welded part and the welding gun is guaranteed, and sufficient welding of various to-be-welded parts with irregular surfaces. The automatic welding device has the advantages that an integrated welding adjusting and control mode is achieved, welding intervals are automatically adjusted according to the irregular welding points of the to-be-welded parts, two-end control of the intervals between the welding guns and the to-be-welded parts is achieved, and omnibearing automatic adjusting and control type welding of different welding surfaces of different shapes is achieved.

Owner:东莞市道滘和茂机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com