Production of autoclaved aerated building block material with crystal calcarea lime to partially partial substitute unslacked lime and method thereof

A technology of autoclaved gas filling and quicklime, which is applied to ceramic products, climate sustainability, and other household appliances, etc., can solve the problems of dust consumption of large power resources, coal resources and land resources, etc., to reduce adverse effects, The effect of improving quality and avoiding calcium-silicon reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

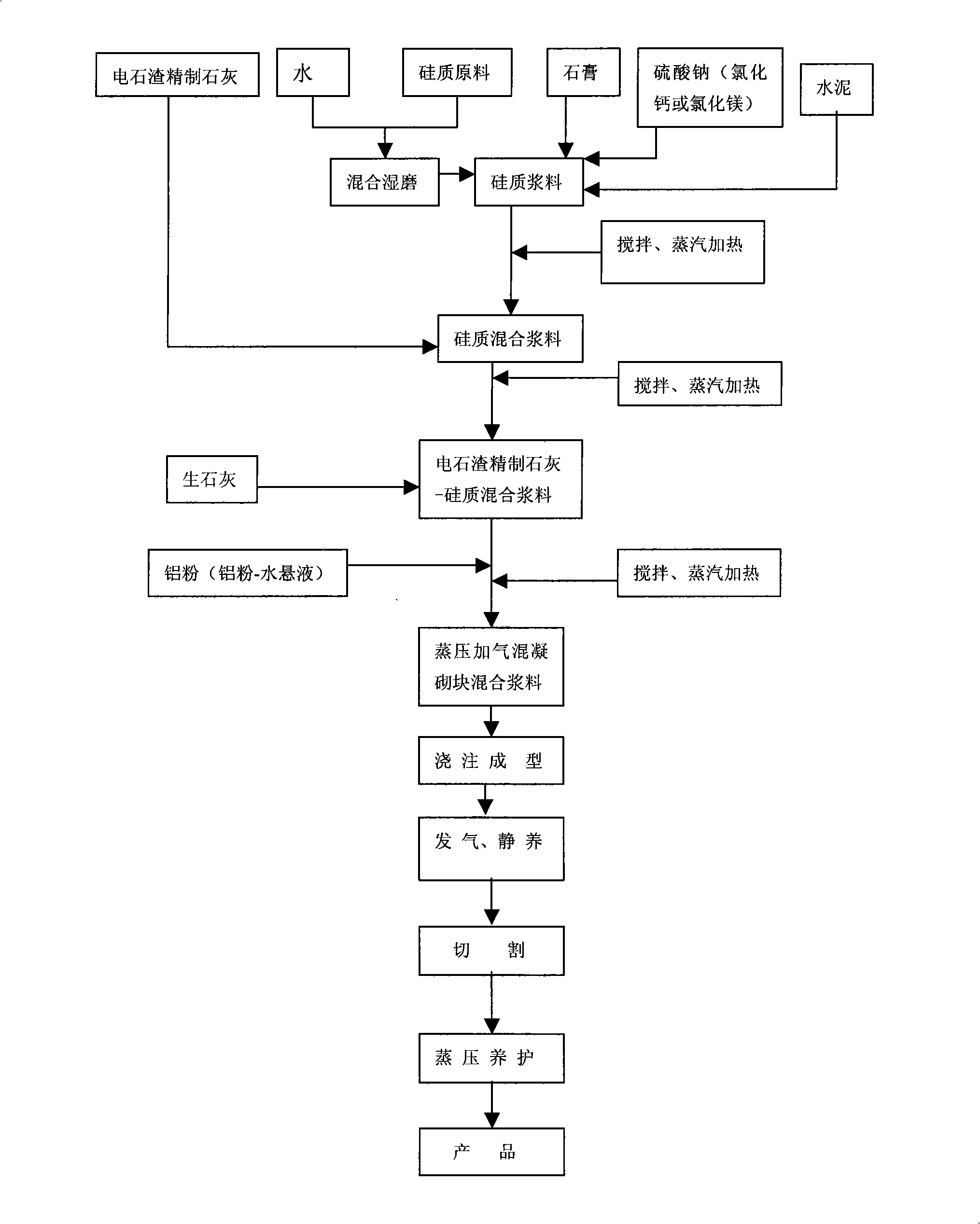

[0023] Combined with the flow chart, the present invention uses calcium carbide slag refined crystalline lime to partially replace unslaked lime to prepare autoclaved aerated block material and its method, and the production operation is carried out according to the following process steps:

[0024] 1. Material selection: The moisture content of refined crystal lime with carbide slag is 30.0% by mass, the mass percentage of calcium hydroxide is 66.0%, and the mass percentage of calcium oxide in quicklime is 82.0%; the mass percentage of silicon dioxide in fly ash The percentage content is 61.0%, the mass percentage content of alumina is 27.5%, the mass percentage content of calcium oxide is 4.5%, the mass percentage content of iron oxide is 3.0%; ordinary portland cement.

[0025]2. Add fly ash and water into a ball mill for wet grinding in a mass percentage of fly ash: water at a ratio of 57:43, control the particle fineness, and more tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com