Soft precious alloy foil strip active loading mechanism

A precious alloy and foil strip technology, which is applied in the field of active feeding mechanism of soft precious alloy foil and strip, can solve problems such as long contact or extrusion exposure time, large volume, heavy volume, and hidden dangers to personal safety, etc. Achieve the effects of improving production efficiency and production instruction requirements, reducing adverse effects on quality, and reducing production flow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

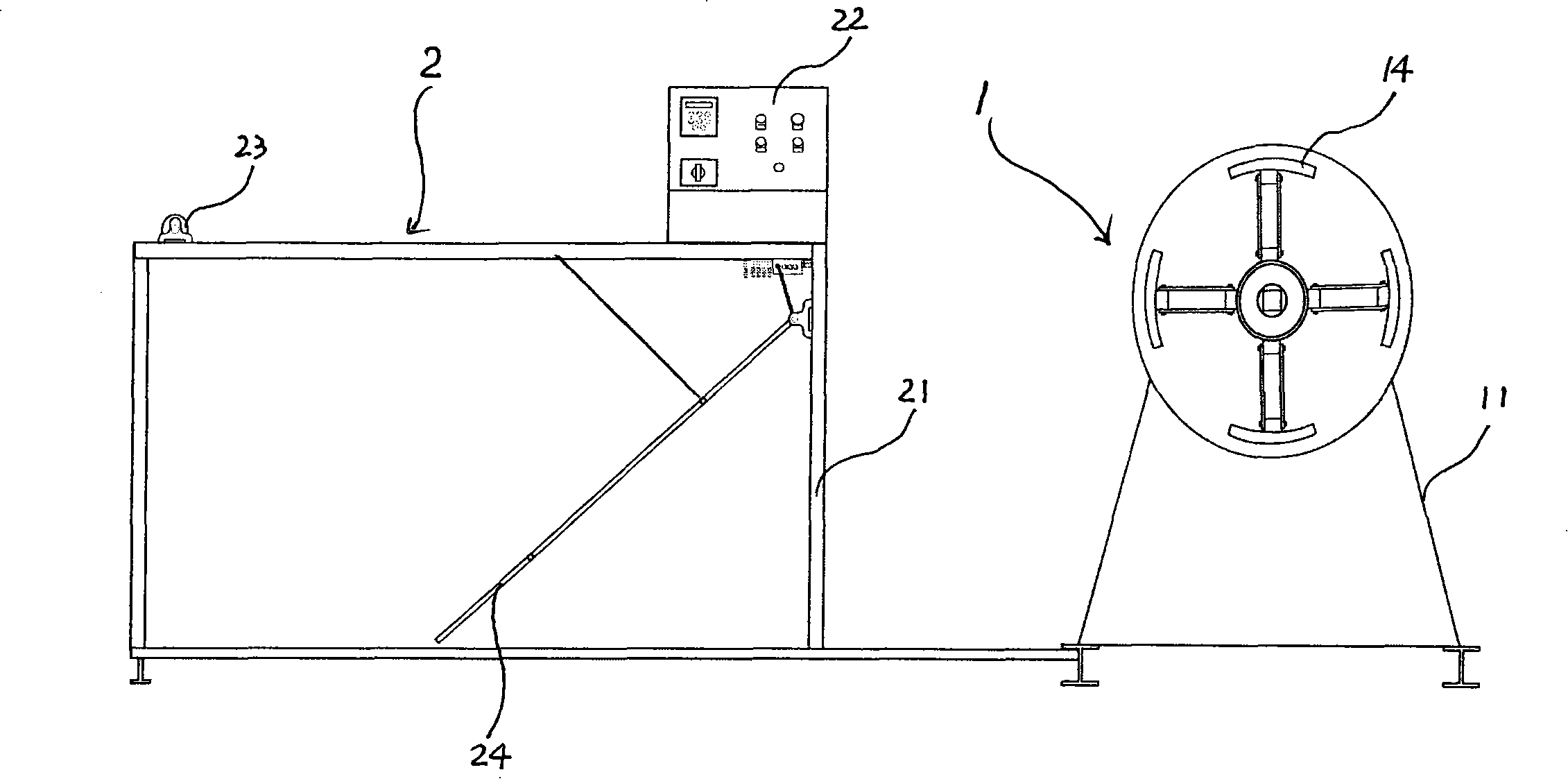

[0030] see figure 1 , referring to the remaining figures, the active feeding mechanism for the soft precious alloy foil strip of the present invention includes a feeding mechanism 1 and a feeding control mechanism 2 arranged front and back.

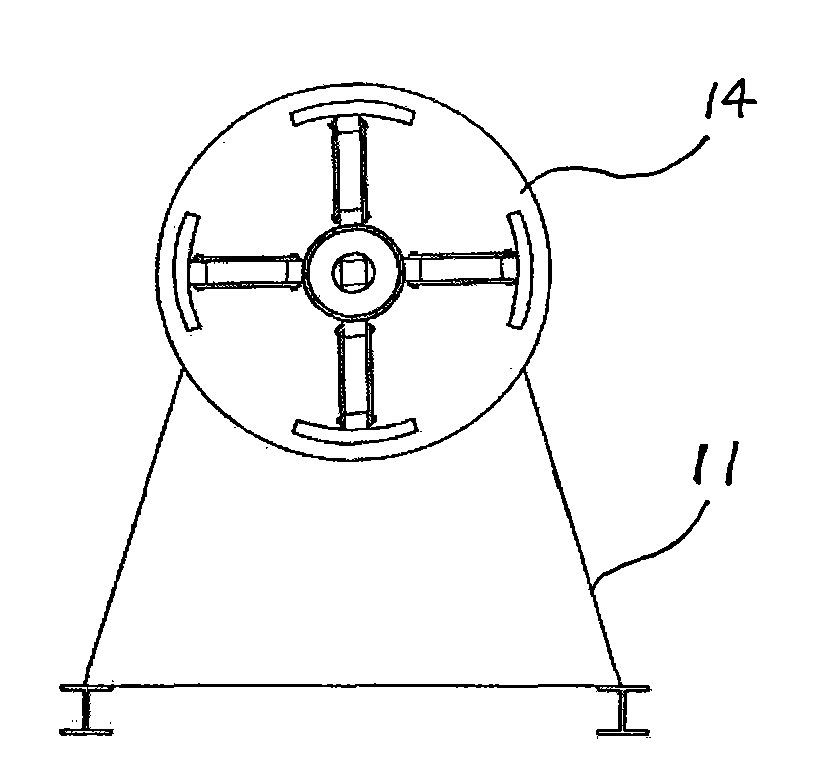

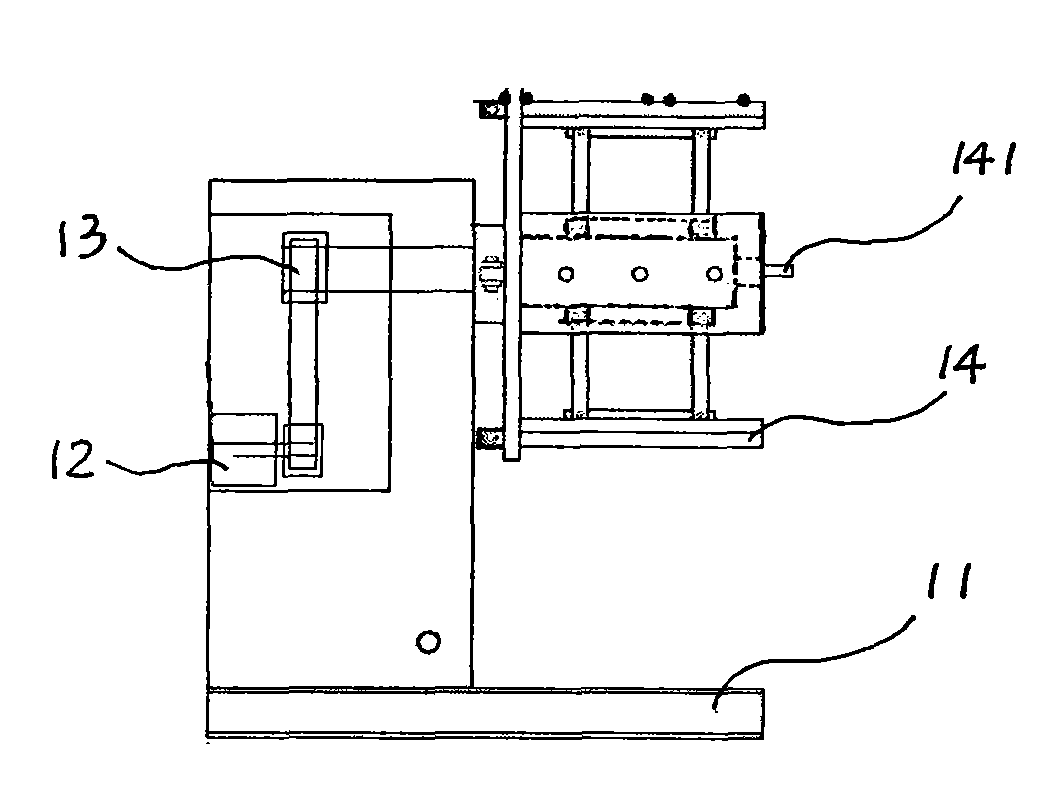

[0031] see figure 2 , image 3 , Figure 4 , the feeding mechanism 1 in the present invention comprises a base 11, a feeding motor 12 installed on the base, a transmission mechanism 13, and a roll holder 14 connected to the transmission mechanism, the shaft of the roll holder is composed of two needle rollers Bearings are fixed on the base. The material roll fixing frame is a material support sleeve structure with adjustable outer diameter, and a support sleeve adjustment rod 141 for adjusting its outer diameter is arranged in the material support sleeve structure, and its outer diameter can be adjusted according to the different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com