Optical fiber device and measuring method for turbine blade surface temperature distribution measuring

A technology of turbine blade and surface temperature, applied in the field of optical fiber devices, can solve the problems of short service life, easy falling off, and potential safety hazards of sensors, and achieve the effects of convenient replacement and maintenance, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

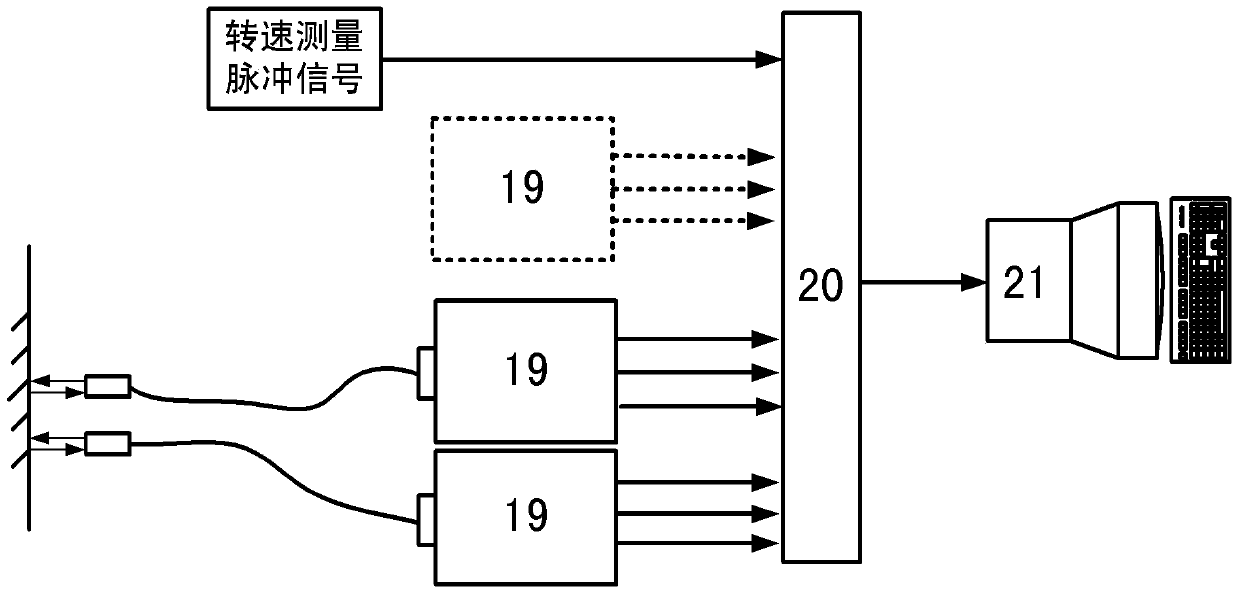

[0043] The invention can measure the surface temperature of the high-speed rotating turbine blade at high temperature, and obtain the specific distribution position of the blade surface temperature, provide necessary data for the design of the blade shape of the turbine blade and its cooling structure, and at the same time obtain the thermal barrier coating on the surface of the turbine blade It can also monitor the temperature change online in real time, so as to prevent serious faults such as blade ablation in the running gas turbine in advance.

[0044] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

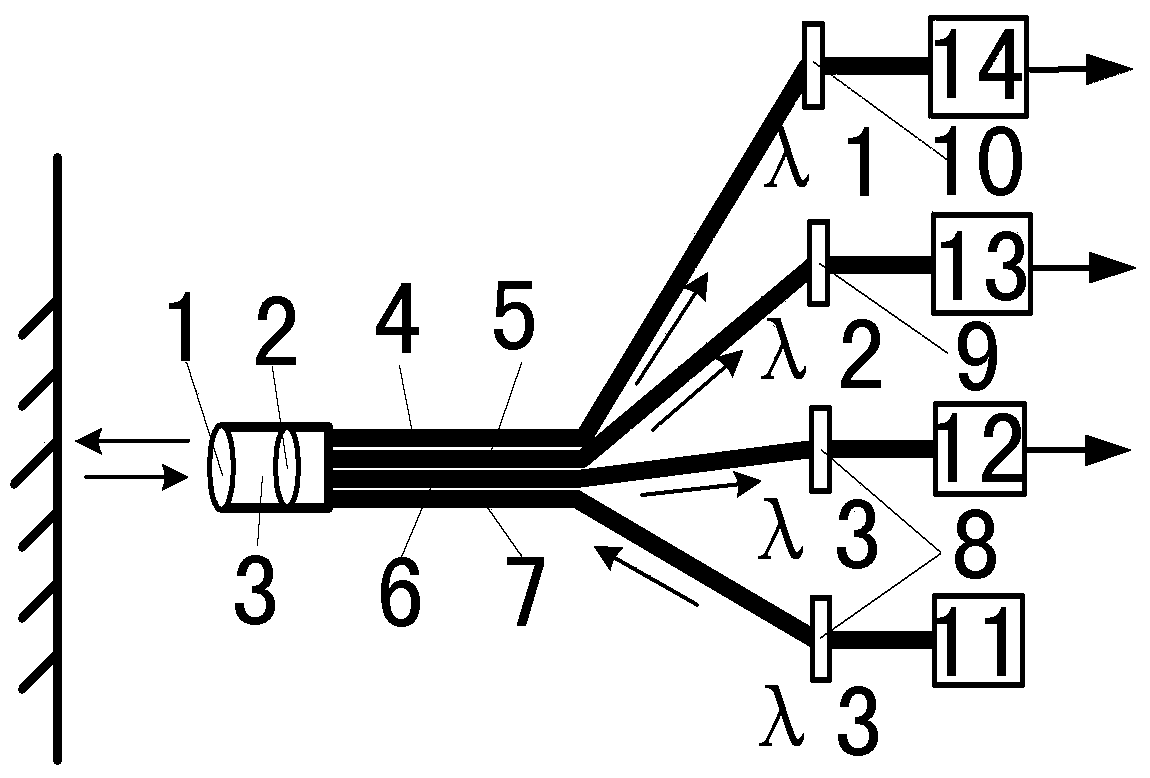

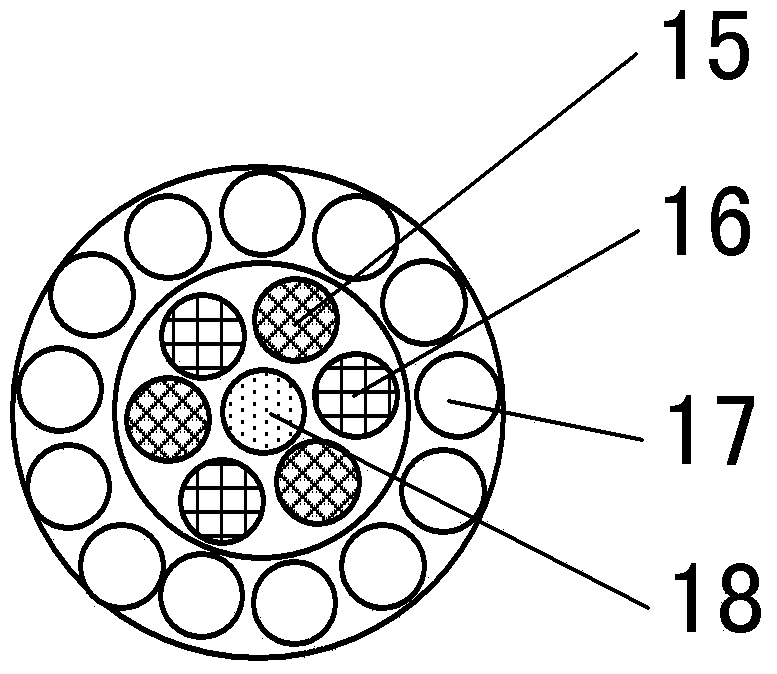

[0045] figure 1 It is the optical path and circuit working principle diagram of the optical fiber measurement system 19 in the present invention. During the optical fiber two-color temperature measurement process, the radiation spectral energy of the high-temperature components enters the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com