Ice wrapping method for foods

A technology for food and quick-frozen food, applied in the fields of food preservation, food freezing, food science, etc., can solve the problems of reducing the efficiency of ice wrapping, affecting the appearance and taste of products, and reducing the speed of ice wrapping, so as to prevent the appearance and color from changing and taste. Change, ensure product taste and nutrition, and improve the effect of ice wrapping conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with embodiment, further illustrate the present invention.

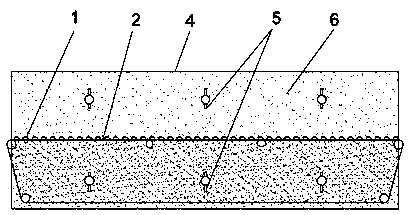

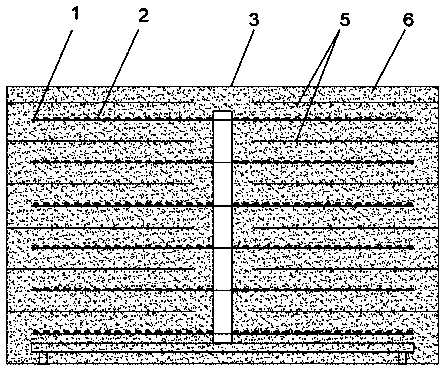

[0052] see figure 1 , figure 2 It can be seen that the ice coating method of a kind of food of the present invention comprises the following steps:

[0053] (1) Quick-frozen food 1. Quick-freeze the produced food so that the temperature of the quick-frozen food is below -18°C;

[0054] (2) The quick-frozen food 1 is arranged in layers, and the quick-frozen food 1 is placed in a single layer on the wire mesh support surface 2;

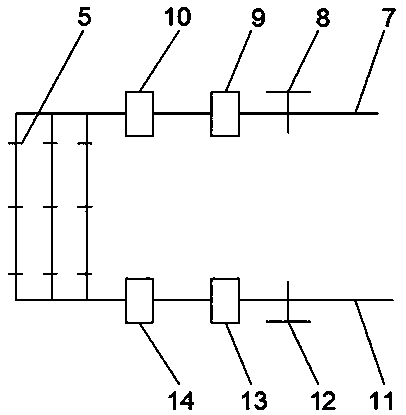

[0055] (3) Setting up the ice-wrapping environment, set up a closed ice-wrapping chamber 3 or a semi-closed ice-wrapping chamber 4, and set a two-fluid atomizing nozzle 5 in the closed ice-wrapping chamber 3 or semi-closed ice-wrapping chamber 4, and pass through The water supply control pipeline and the air supply control pipeline deliver water and air to the two ports of the two-fluid atomizing nozzle 5 respectively, and use the two-fluid atomizing nozzle 5 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com