Automatically controlled food ice coating device and control method thereof

A food and controller technology, applied in the fields of food preservation, food freezing, food science, etc., can solve the problems of reducing the efficiency of ice wrapping, difficult to turn over, reducing the speed of ice wrapping processing, etc., to prevent the appearance and color change and taste change, improve The effect of controllable conveying speed and ice thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with embodiment, further illustrate the present invention.

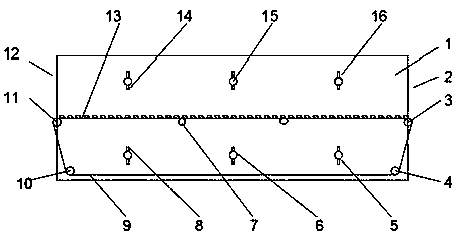

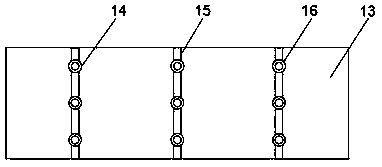

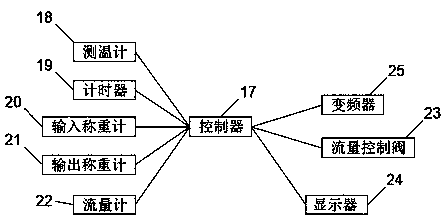

[0044] combine Figure 1-Figure 3 It can be seen that an automatically controlled food ice wrapping device of the present invention includes an ice wrapping chamber 1, a food input mechanism, a food output mechanism, a monitoring and control system that cooperate with the ice wrapping chamber 1, and the ice wrapping chamber 1 One end is the feed end 2, and the other end is the discharge end 12. The wrapping room is provided with a conveying mechanism and a water spray mechanism. The conveying mechanism is provided with a rotating roller and a wire mesh conveyor belt. Above and directly below are respectively equipped with upper water spray mechanism 16, lower water spray mechanism 5, upper water spray mechanism 16, lower water spray mechanism 5 are respectively provided with upper water spray pipe 15, lower water spray pipe 6, upper water spray pipe 15. The lower water spray pipe 6 is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com