Methods and systems for rapid thermal processing

A high-temperature processing and fast technology, applied in the manufacture of furnaces, electrical components, semiconductors/solid-state devices, etc., can solve the deformation of the wafer, it is difficult to adjust the relative position of the heating unit and the wafer, and it is difficult to achieve uniform temperature distribution on the surface of the wafer And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below, together with the accompanying drawings, and are described in detail as follows:

[0018] Since heat conduction is related to the pattern if the pattern on the front side of the semiconductor substrate faces the heat source, it is best to prevent the pattern from being directly irradiated by the heat radiation generated by the heat source.

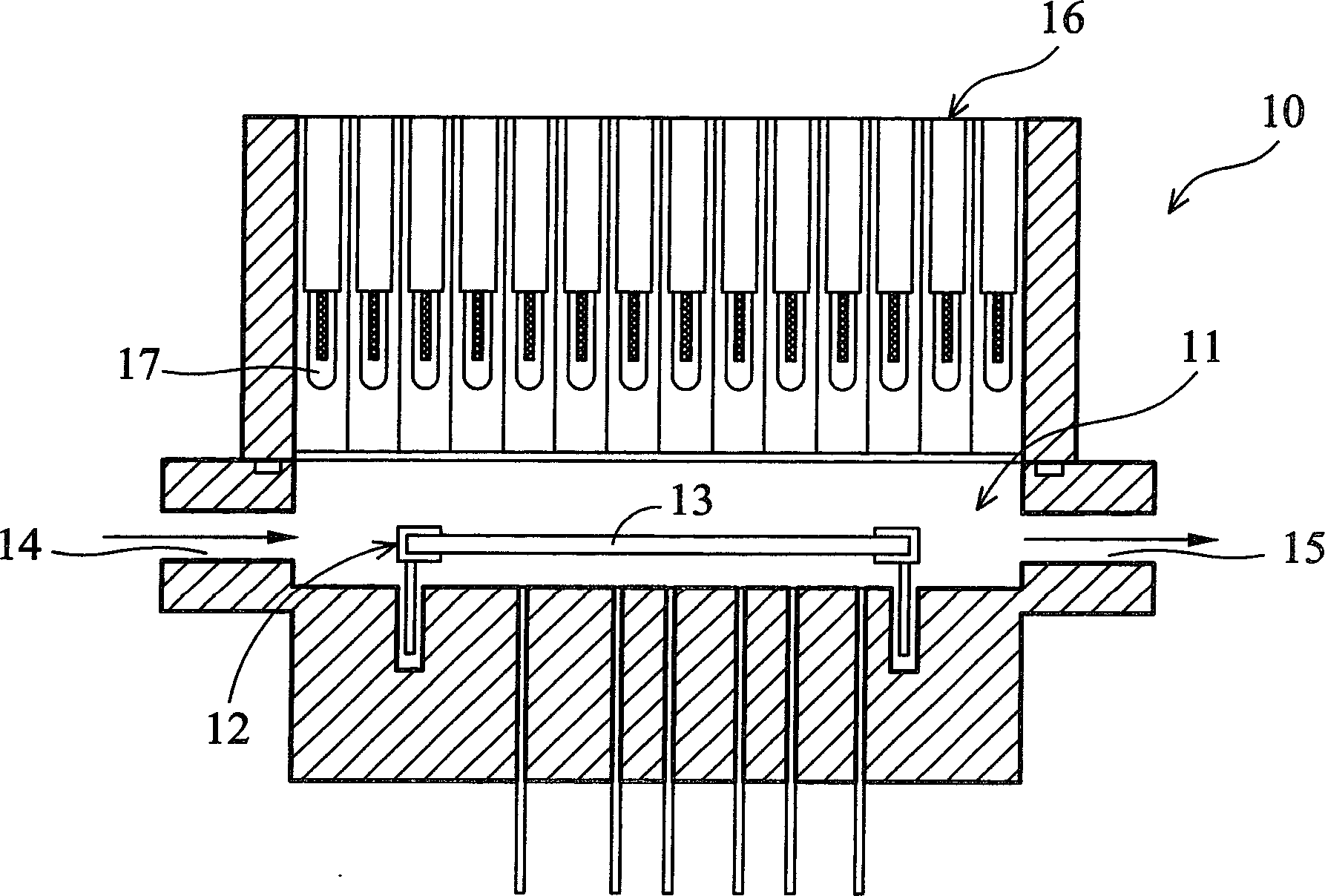

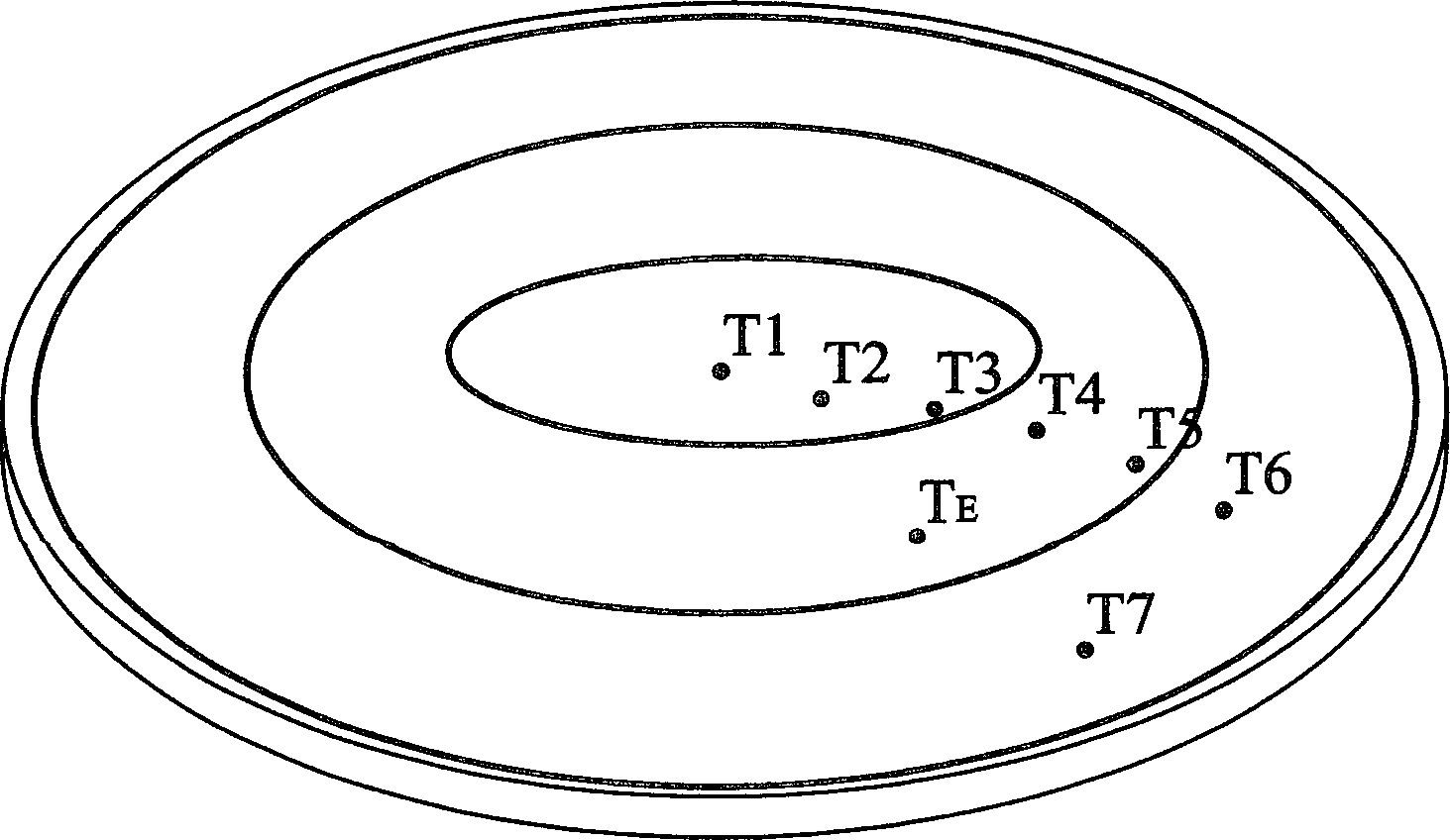

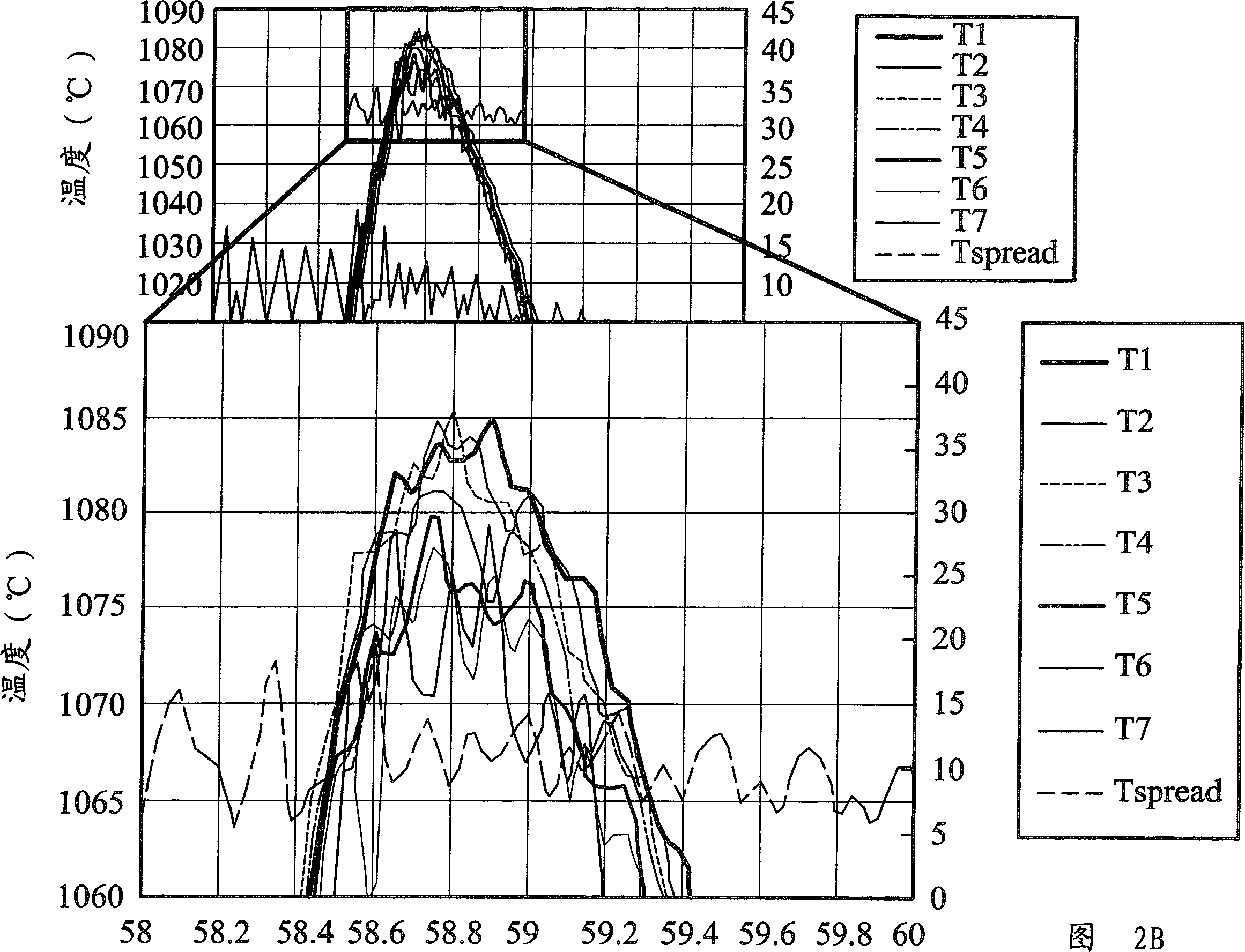

[0019] The present invention provides methods and systems for rapid high temperature processing of semiconductor substrates. In some embodiments of the present invention, the radiant heat energy is directed to the back side of the semiconductor substrate, while the front side of the semiconductor substrate is not irradiated by the radiant heat energy, so the pattern on the front side of the semiconductor substrate will not affect the uniformity of heat flow. Since t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com