Automatic welding device

A driving device and automatic technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as uneven surface, difficult welding joints for automatic welding, and affecting welding quality, so as to maintain beauty and reduce manual welding skills Requirements and production costs, and the effect of improving operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

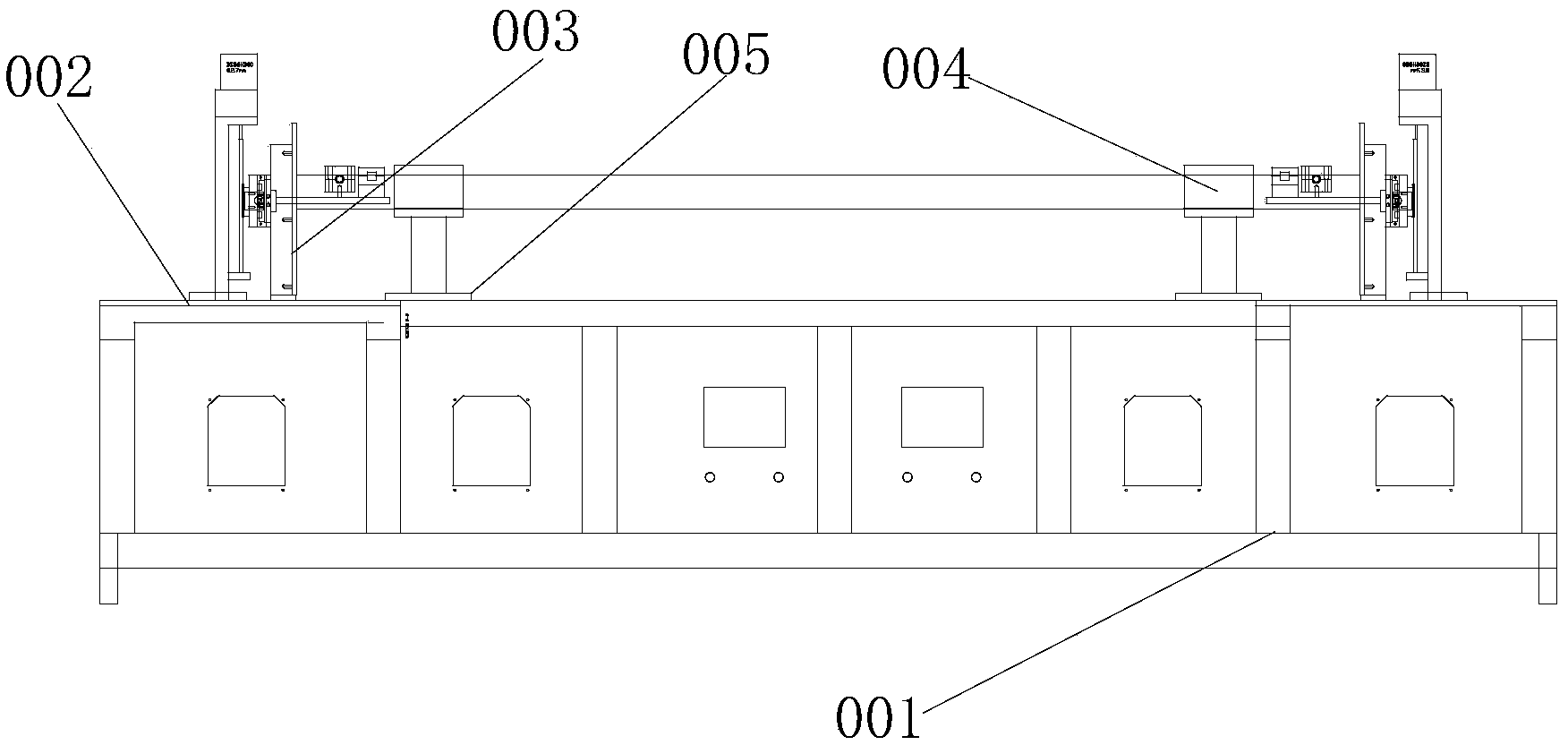

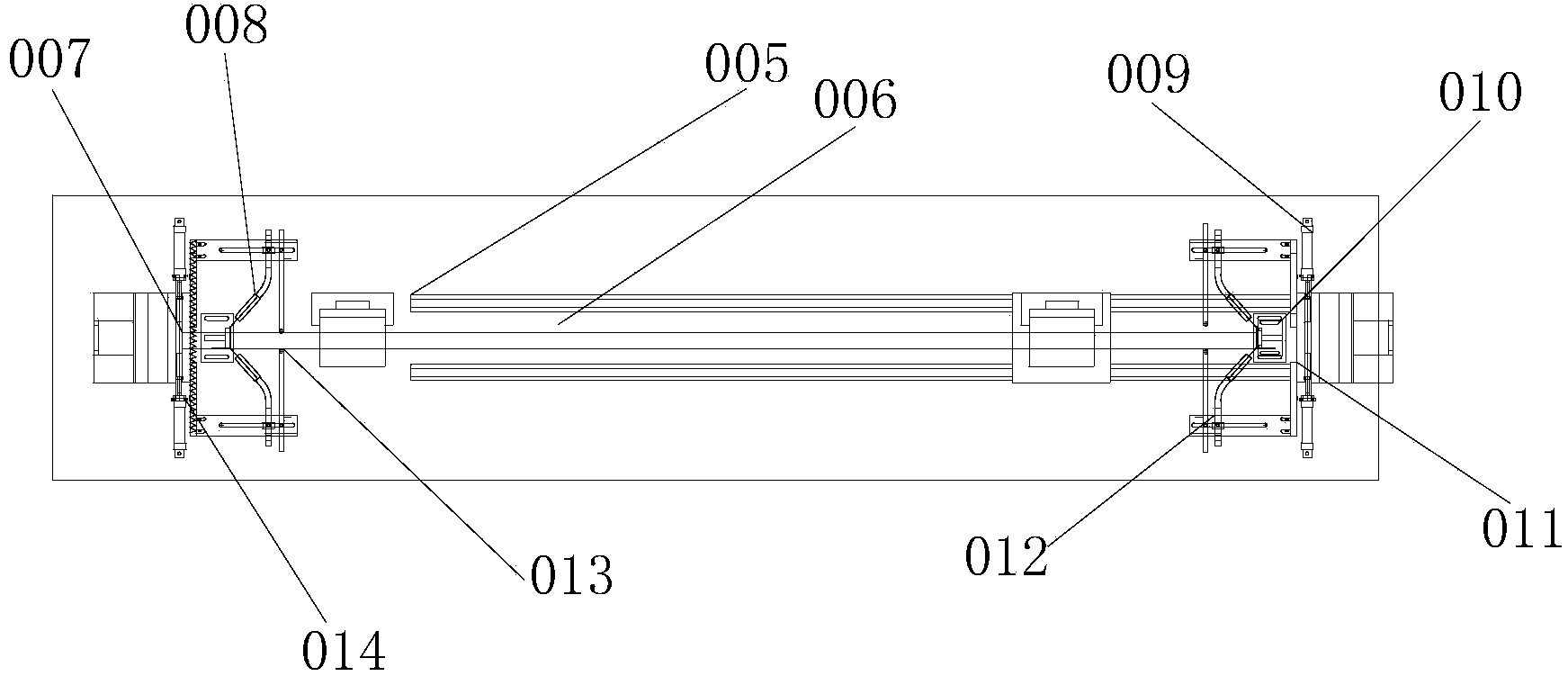

[0021] Such as figure 1 and figure 2 As shown, the automatic welding device in this embodiment includes a mechanism body, which is composed of a cabinet 001 and a workbench 002 arranged on the cabinet 001, and the left and right ends of the workbench 002 are respectively provided with welding stations 003 , a transmission mechanism 004 is set between the welding stations 003, the transmission mechanism 004 is composed of a sprocket set 005 and a moving beam 006 for mutual transmission, and the welding station 003 is composed of multiple sets of welding adjustment mechanisms 007 and welding torches 008, The welding adjustment mechanism 007 includes a driving device 009, a clamping device 010 and a fixing device 011, and the welding adjusting mechanism 007 realizes automatic adjustment under the driving of the driving device 009 through the clamping device 010 and the fixing device 011, so as to ensure that the welding parts Adjustable contact with the welding torch 008, satis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com