Portable low-voltage electromagnetism riveter

An electromagnetic riveting gun, portable technology, applied in the field of machining, can solve the problems of high flexibility of riveting process, poor opening of the operating environment, inflexible operation, etc. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

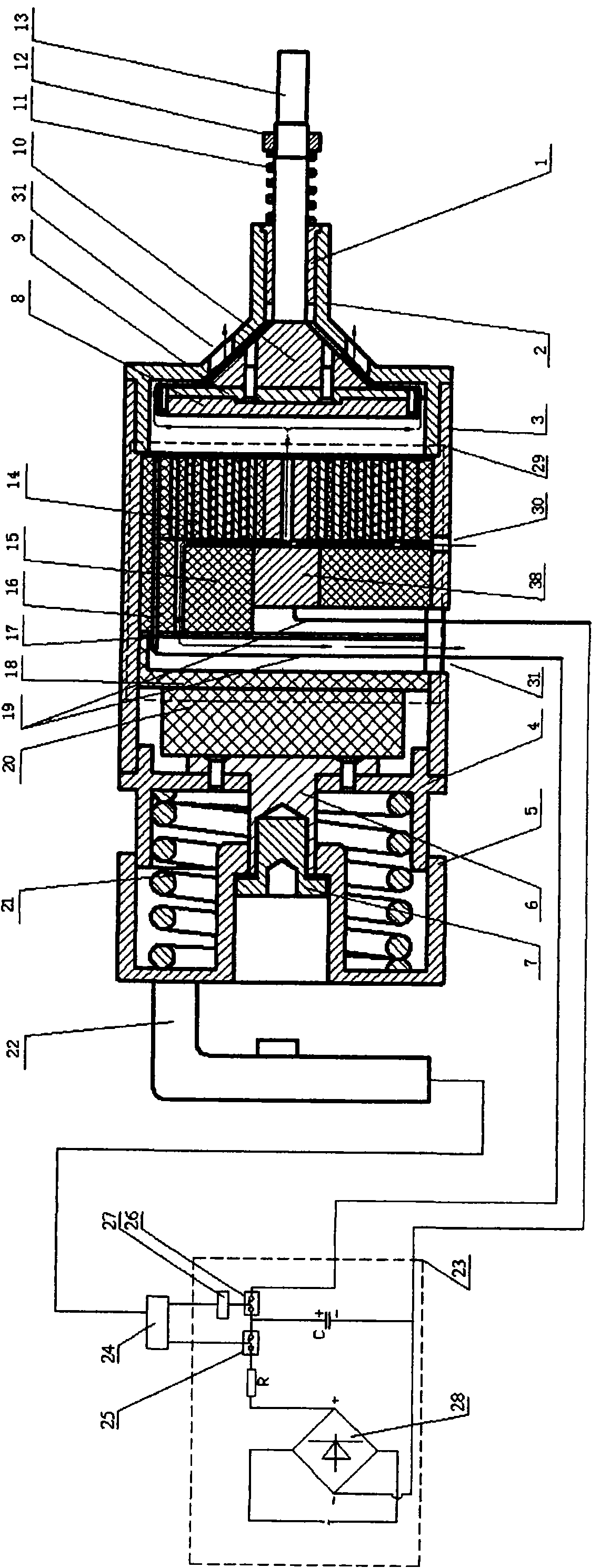

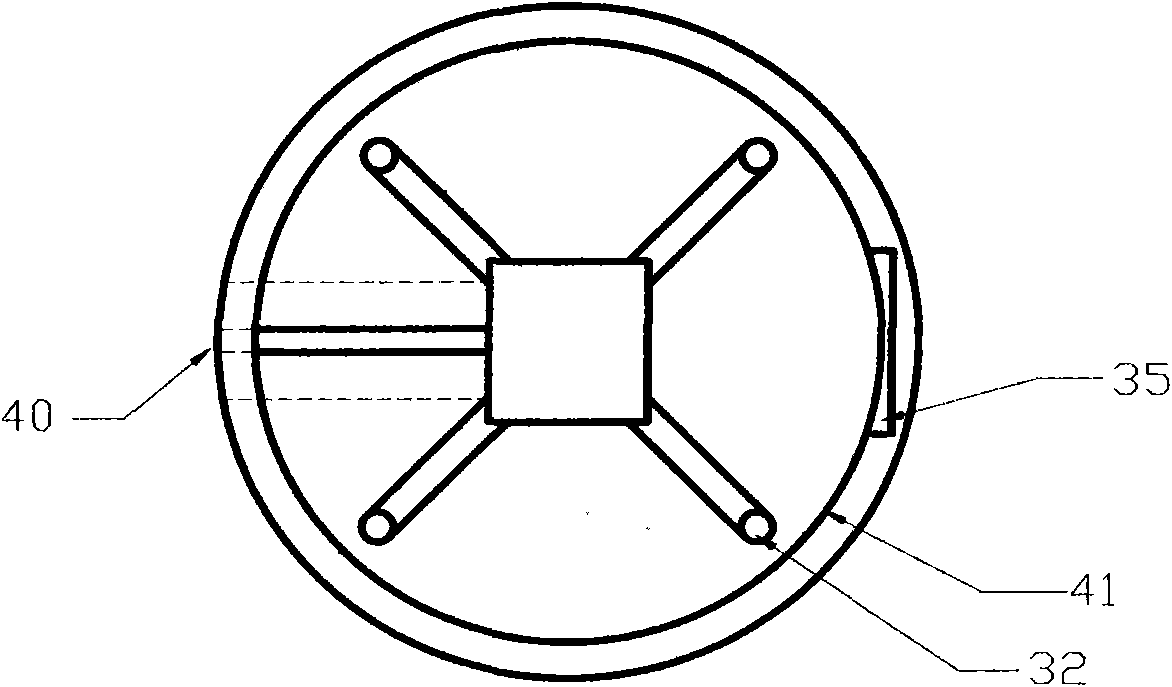

[0032] The principle block diagram of the electromagnetic riveting equipment including the portable electromagnetic riveting gun proposed by the present invention is as follows: figure 1 As shown, the structures of the coil bobbin 15 and the coil center terminal 38 are respectively shown in figure 2 with Figure 4. Wherein the electromagnetic riveting gun that the present invention proposes is mainly by coil 29, driver plate 8, amplifier 10, punch 13, damping rubber 20, damping spring 21 and by front cover 2, gun barrel 3, back cover 4, spring slideway 5 and rear cover flange 6 and other parts constitute.

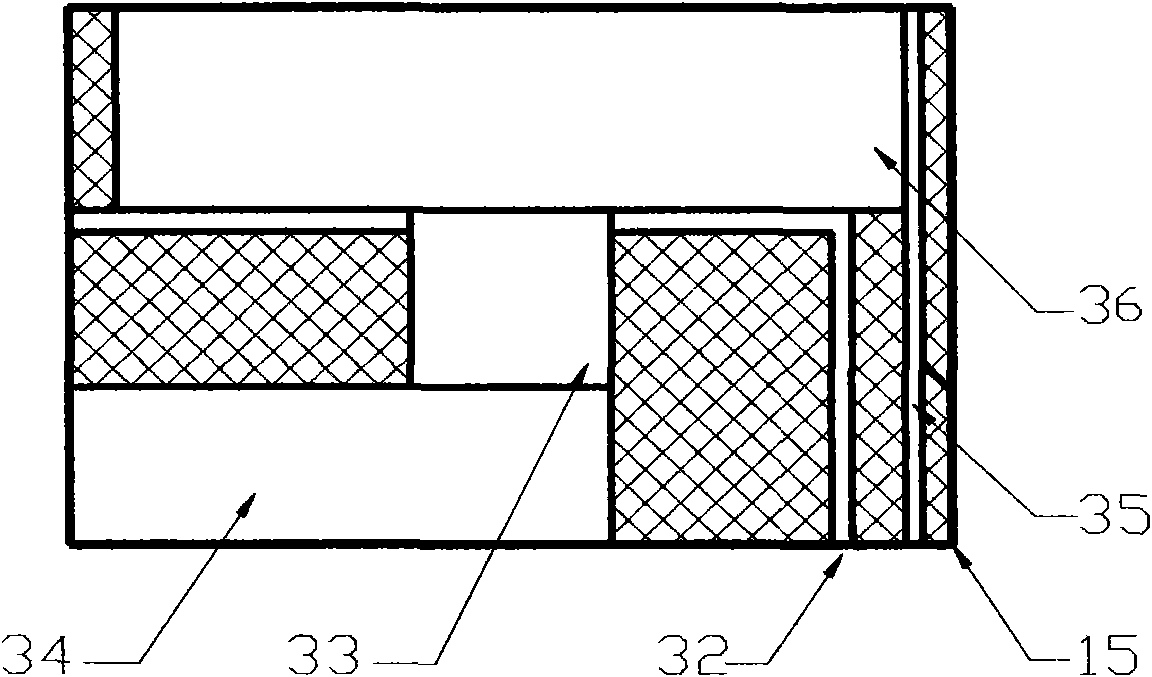

[0033] (1) The central terminal 38 is fixedly connected to the copper strip 14 . The copper strip 14 is embedded into the space 36 of the coil frame 15 , and the outer turns of the copper strip 14 are in contact with the inner surface 41 of the space 36 . Edge post 16 passes through channel 35 and connects to power lead 19 . The side surface 37 of the rectangular end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com