Method and device for carrying out non-contact measuring and positioning on surface temperature of rotating blades

A technology for rotating blades and surface temperature, which is applied in the field of measuring and positioning methods and devices for realizing the above method, can solve problems such as inability to temperature positioning, and achieve the effects of high sensitivity, low response time requirements, and convenient replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

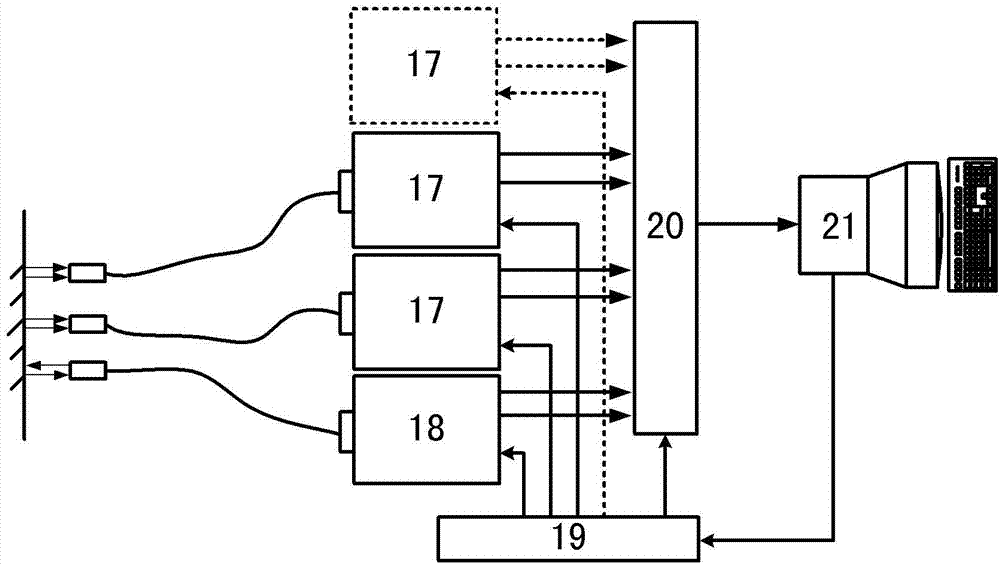

[0038] The invention can measure the surface temperature of the high-speed rotating blade at high temperature, and obtain the specific distribution position of the blade surface temperature, provide necessary data for the blade shape and cooling structure design of the rotating blade, and can monitor the temperature change characteristics on-line in real time, advance Prevent serious failures such as blade ablation in gas turbines in operation.

[0039] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

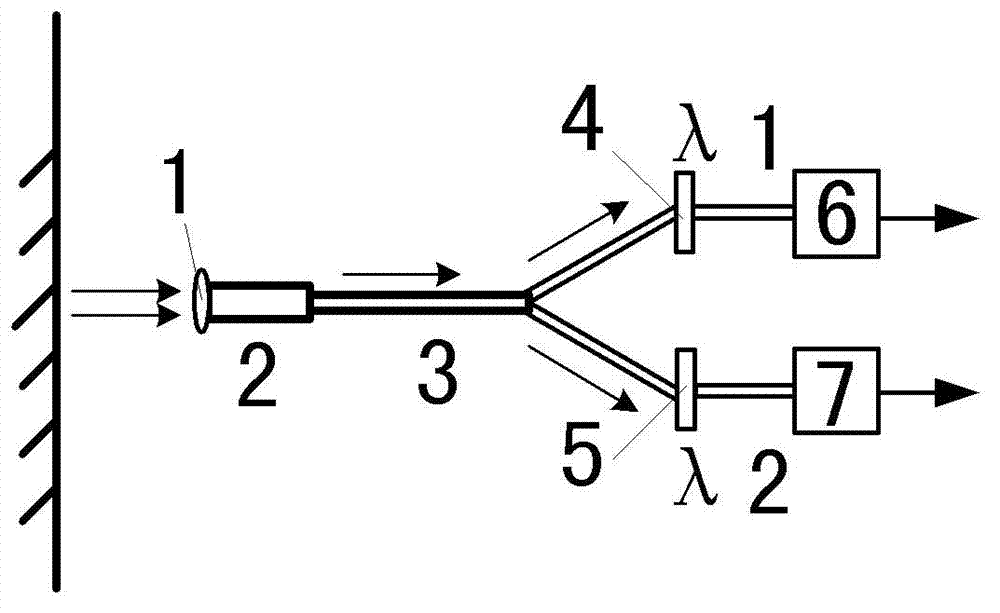

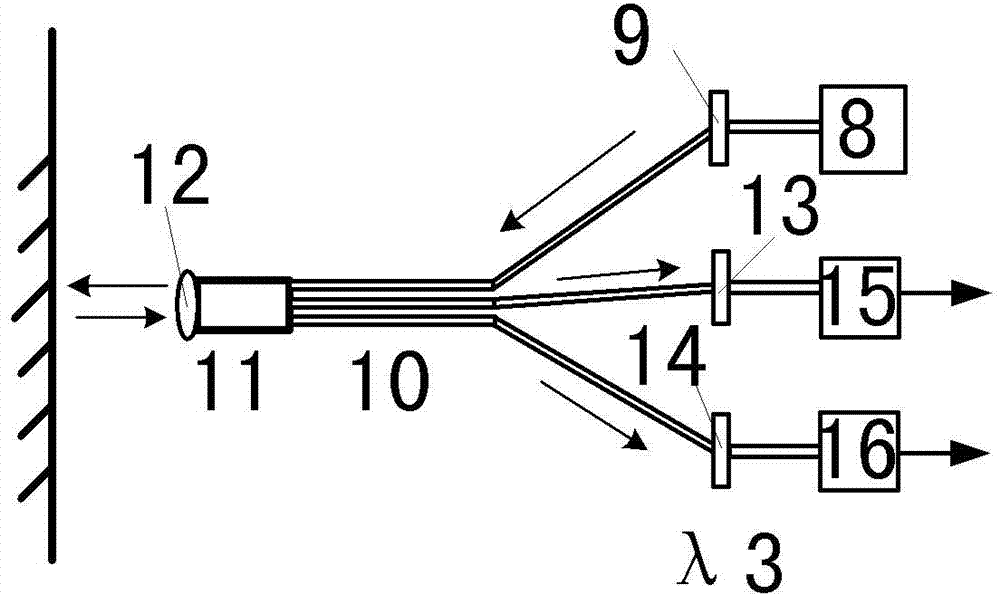

[0040] figure 1 It is a working principle diagram of the optical fiber colorimetric temperature measurement system 17 in the present invention. The radiated light energy of the high-temperature components enters the optical fiber bundle 3 after passing through the lens 1 and the optical fiber temperature probe 2, and then the optical fiber bundle is divided into two paths, respectively using optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com