Electromagnetic oil sprayer

A technology of electromagnetic and solenoid valves, applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve problems such as high cracks, hardening of the outer surface, and the influence of the distribution of magnetic force lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

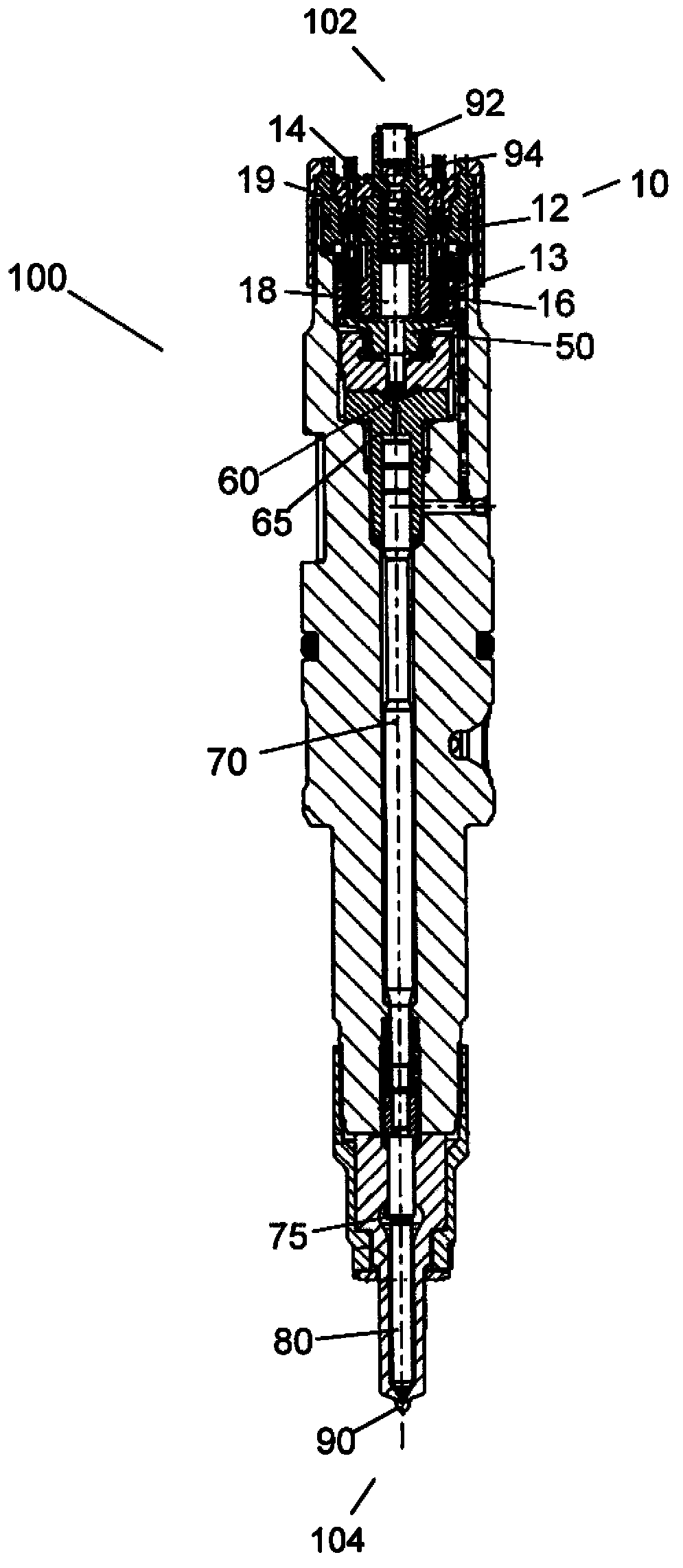

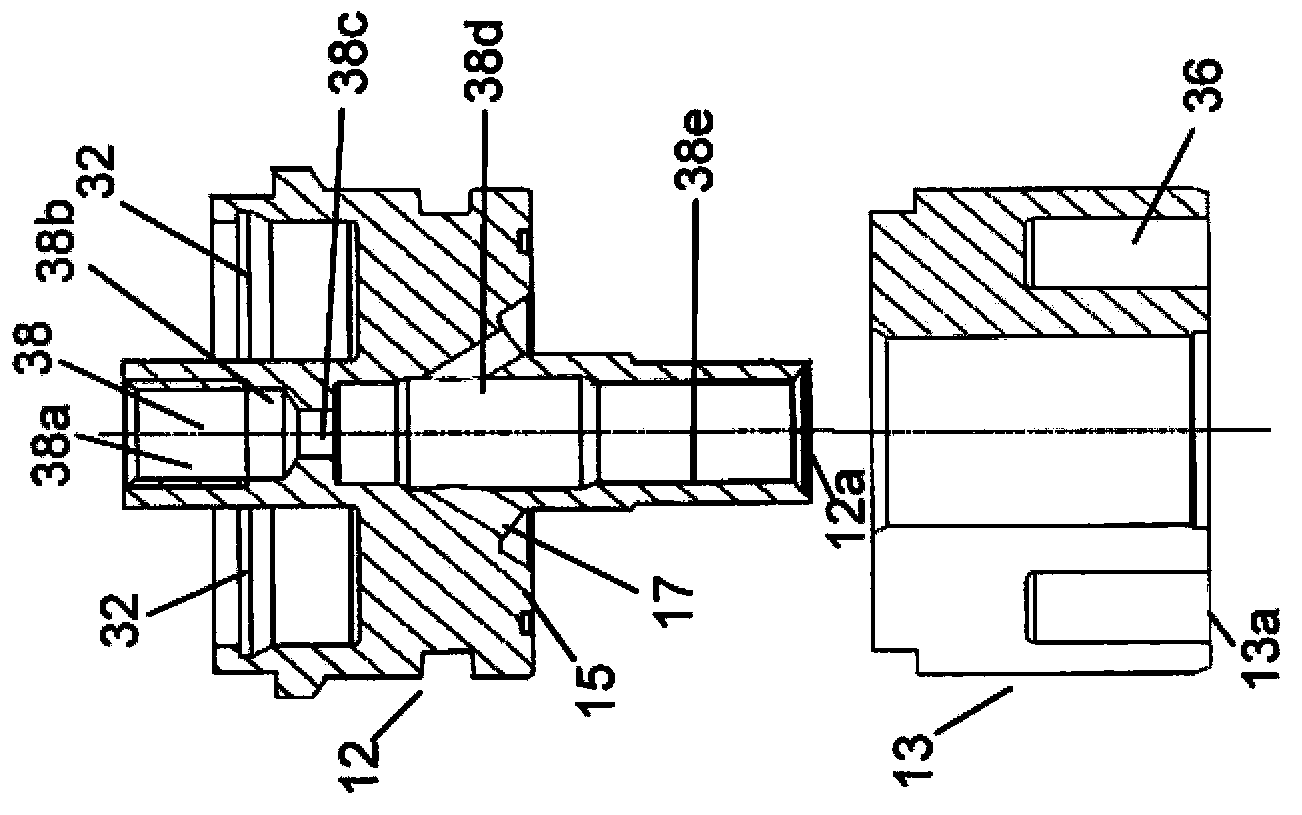

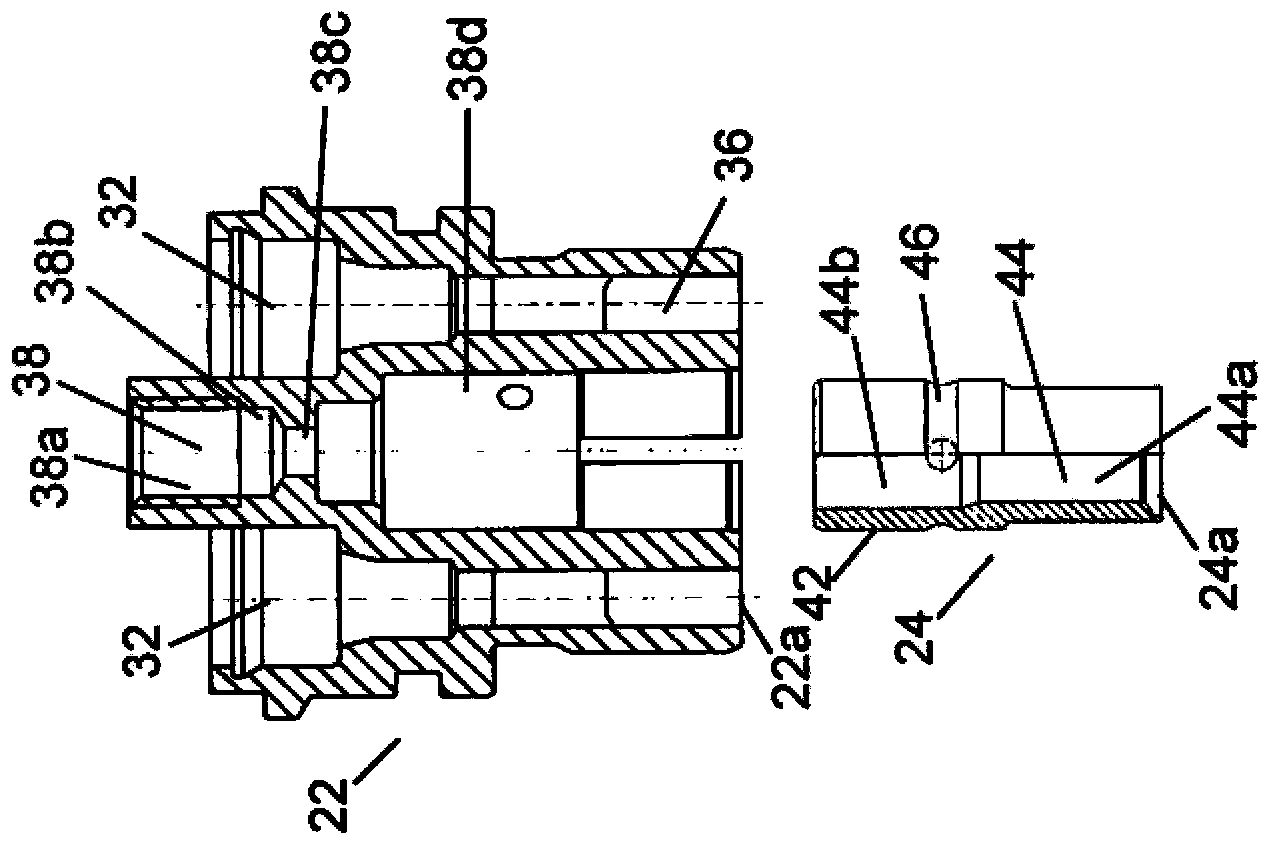

[0036] The inventive point of the present invention lies in the improved structure of the solenoid valve control assembly of the electromagnetic fuel injector, which meets the requirements of making the magnetic core relatively soft and making the inner surface of the guide armature shaft wear-resistant.

[0037] According to one aspect of the present invention, in the electromagnetic valve control assembly of the electromagnetic fuel injector, the magnetic core, that is, the part accommodating the electromagnetic coil in the prior art, is formed as one part with the electromagnetic housing. The electromagnetic housing according to the invention differs from prior art electromagnetic housings that accommodate a movable member and a return spring. The electromagnetic housing according to the invention is made of a relatively soft metal material, for example, a steel material with a hardness below 400 HV10, which may be unhardened or only slightly hardened steel material. This s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com