Patents

Literature

51results about How to "Accelerate escape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

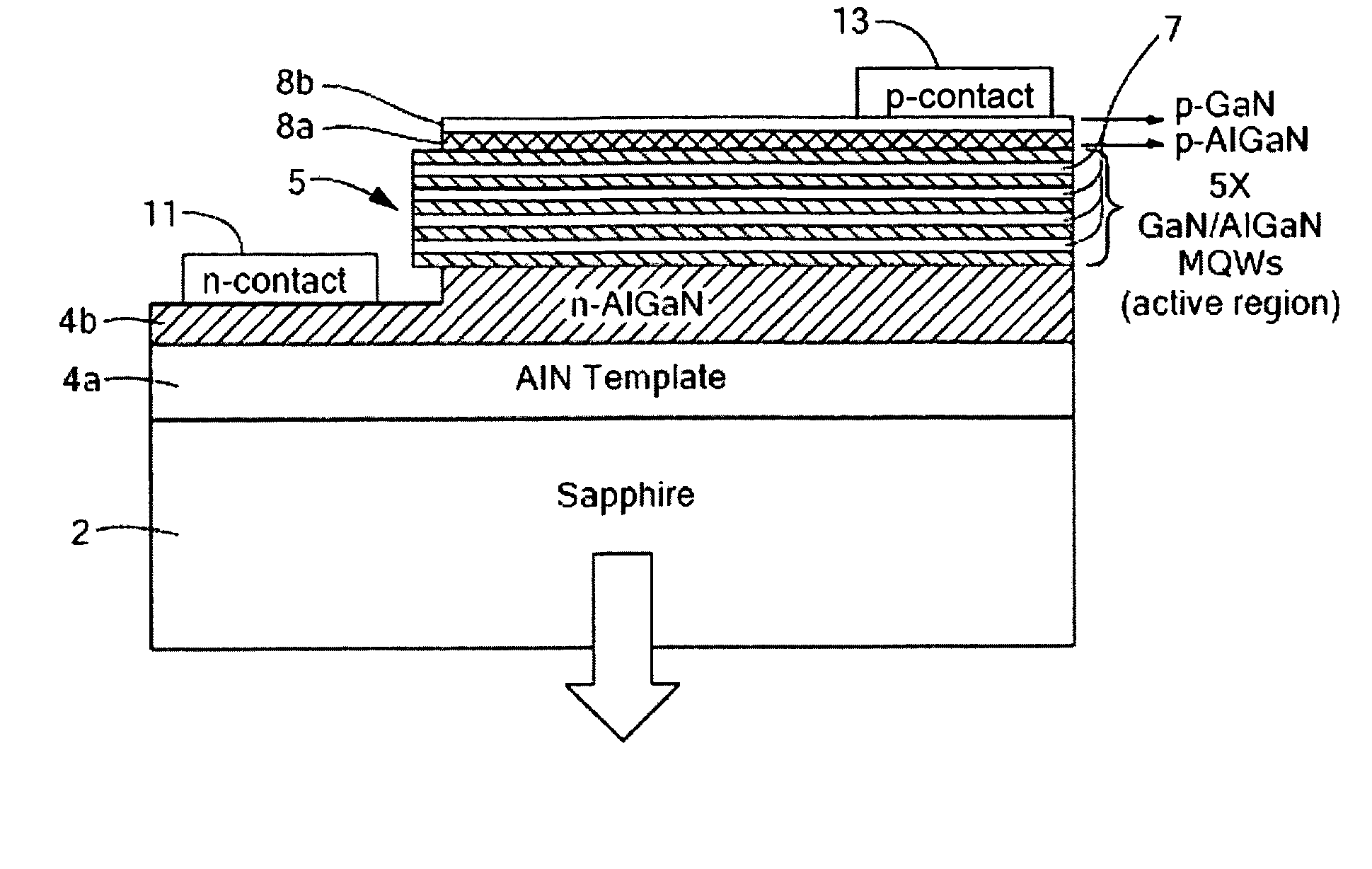

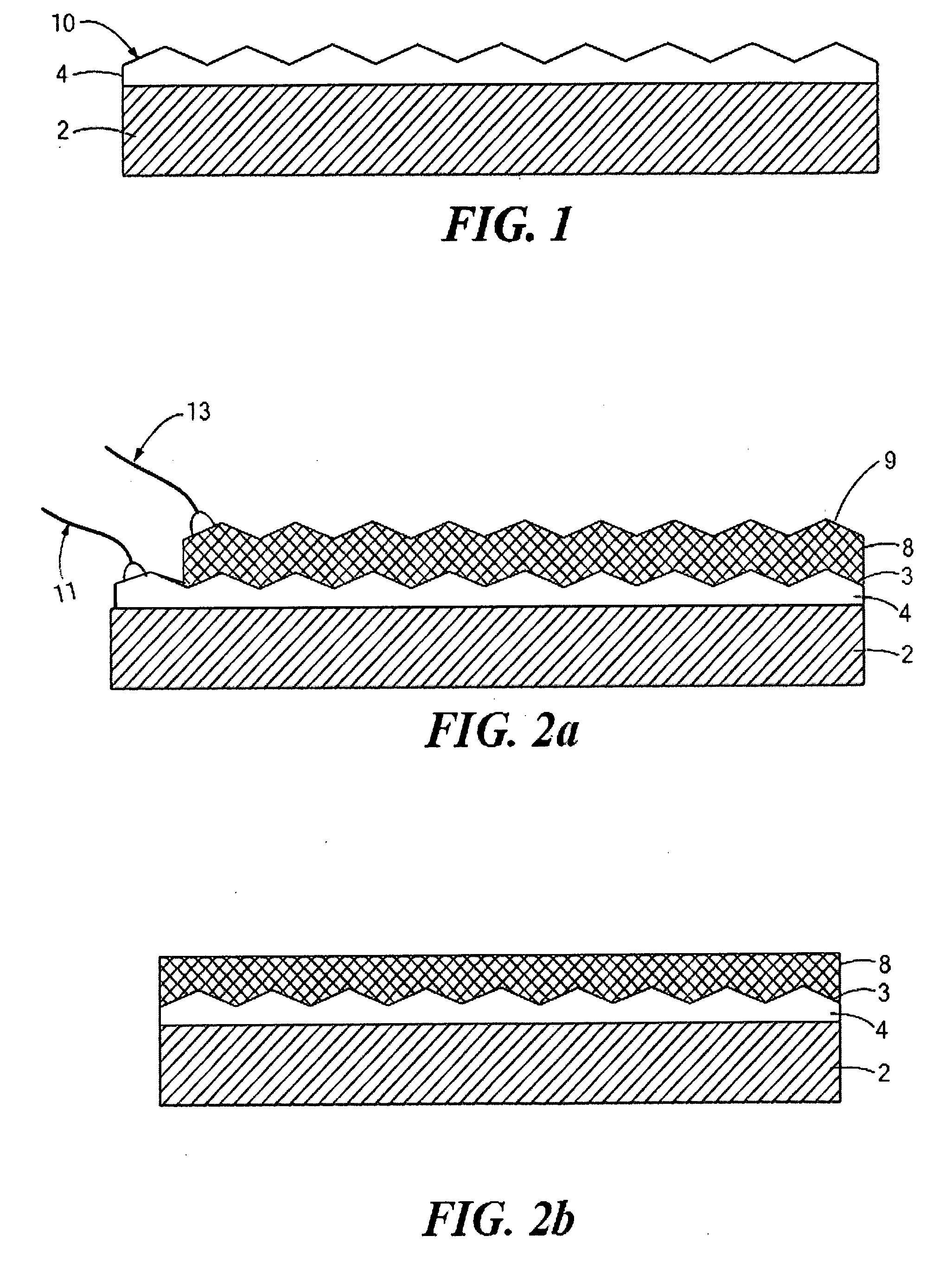

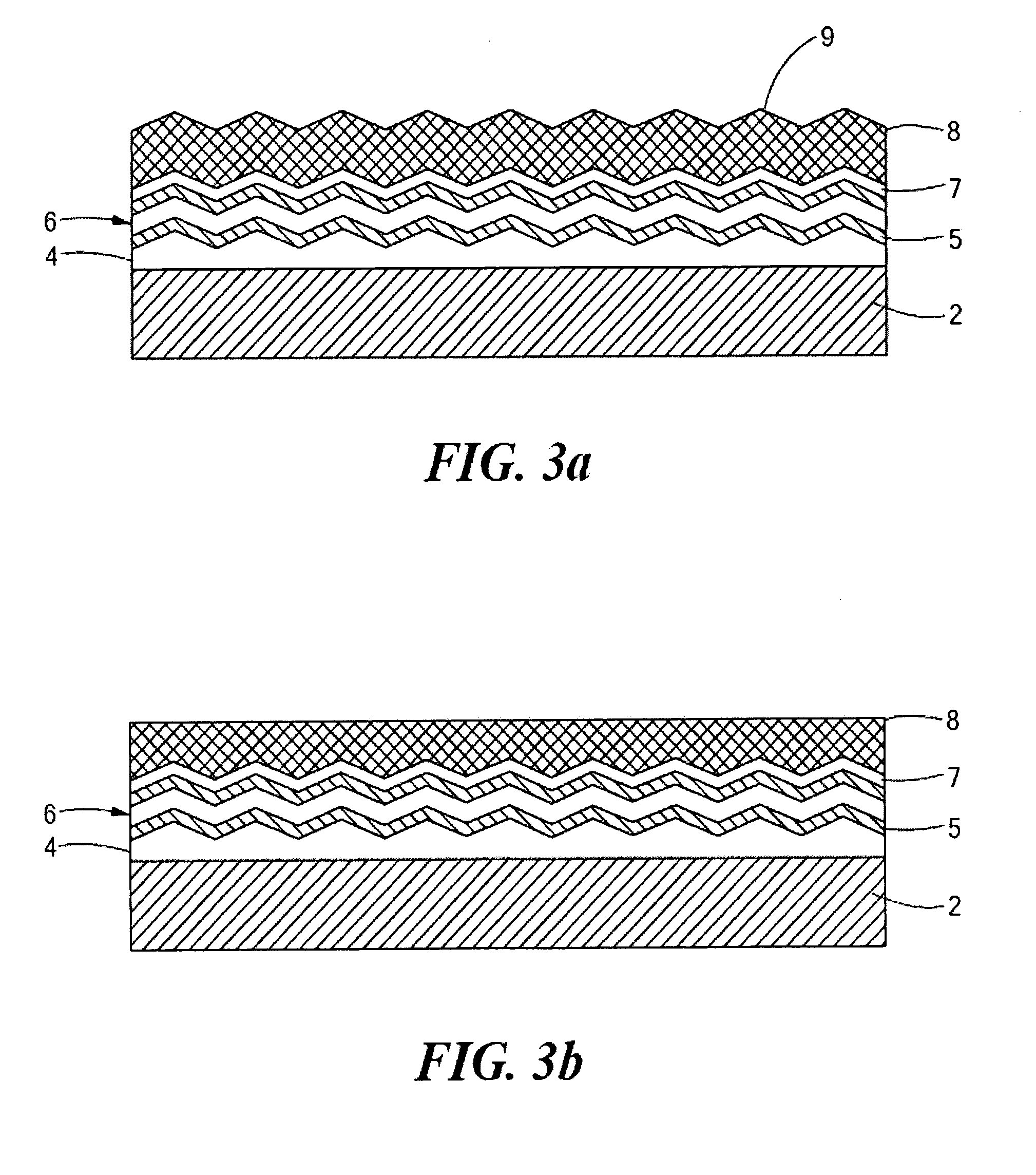

Optical devices featuring textured semiconductor layers

ActiveUS20070120141A1Accelerate escapeLight extraction efficiencySolid-state devicesNanoopticsQuantum efficiencyPhosphor

A semiconductor sensor, solar cell or emitter, or a precursor therefor, has a substrate and one or more textured semiconductor layers deposited onto the substrate. The textured layers enhance light extraction or absorption. Texturing in the region of multiple quantum wells greatly enhances internal quantum efficiency if the semiconductor is polar and the quantum wells are grown along the polar direction. Electroluminescence of LEDs of the invention is dichromatic, and results in variable color LEDs, including white LEDs, without the use of phosphor.

Owner:TRUSTEES OF BOSTON UNIV

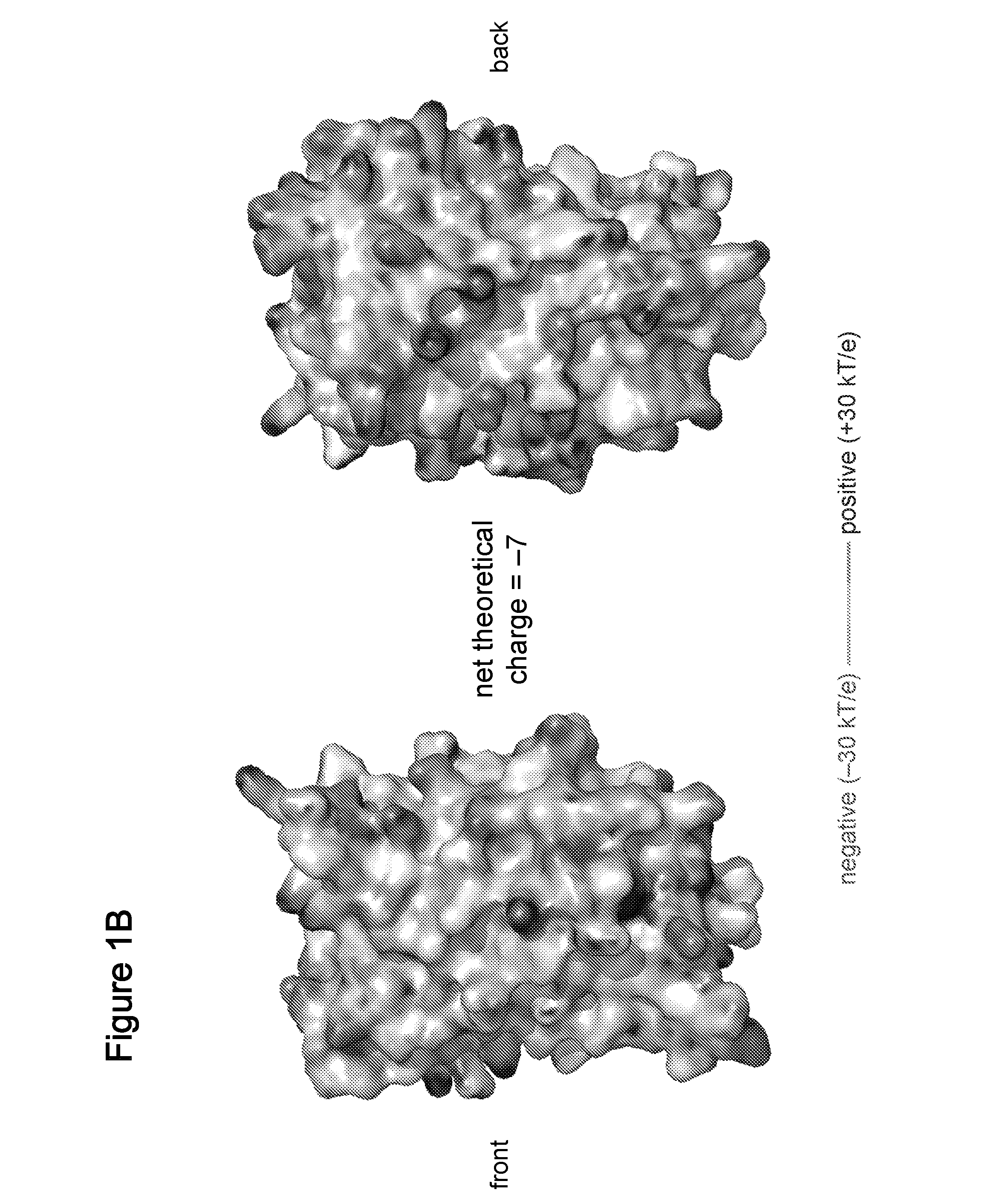

Supercharged proteins for cell penetration

InactiveUS20110112040A1Improved cell penetrationReduce biological activityMicrobiological testing/measurementSaccharide peptide ingredientsInfective disorderDisease cause

Compositions, systems and related methods for delivering a supercharged protein or a complex of a supercharged protein and therapeutic agent (e g, nucleic acid, peptide, small molecule) to cells are disclosed. Superpositively charged proteins may be associated with nucleic acids (which typically have a net negative charge) via electrostatic interactions. The systems and methods may involve altering the primary sequence of a protein in order to “supercharge” the protein (e g, to generate a superpositively-charged protein). The compositions may be used to treat proliferative diseases, infectious diseases, cardiovascular diseases, inborn errors in metabolism, genetic diseases, etc.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

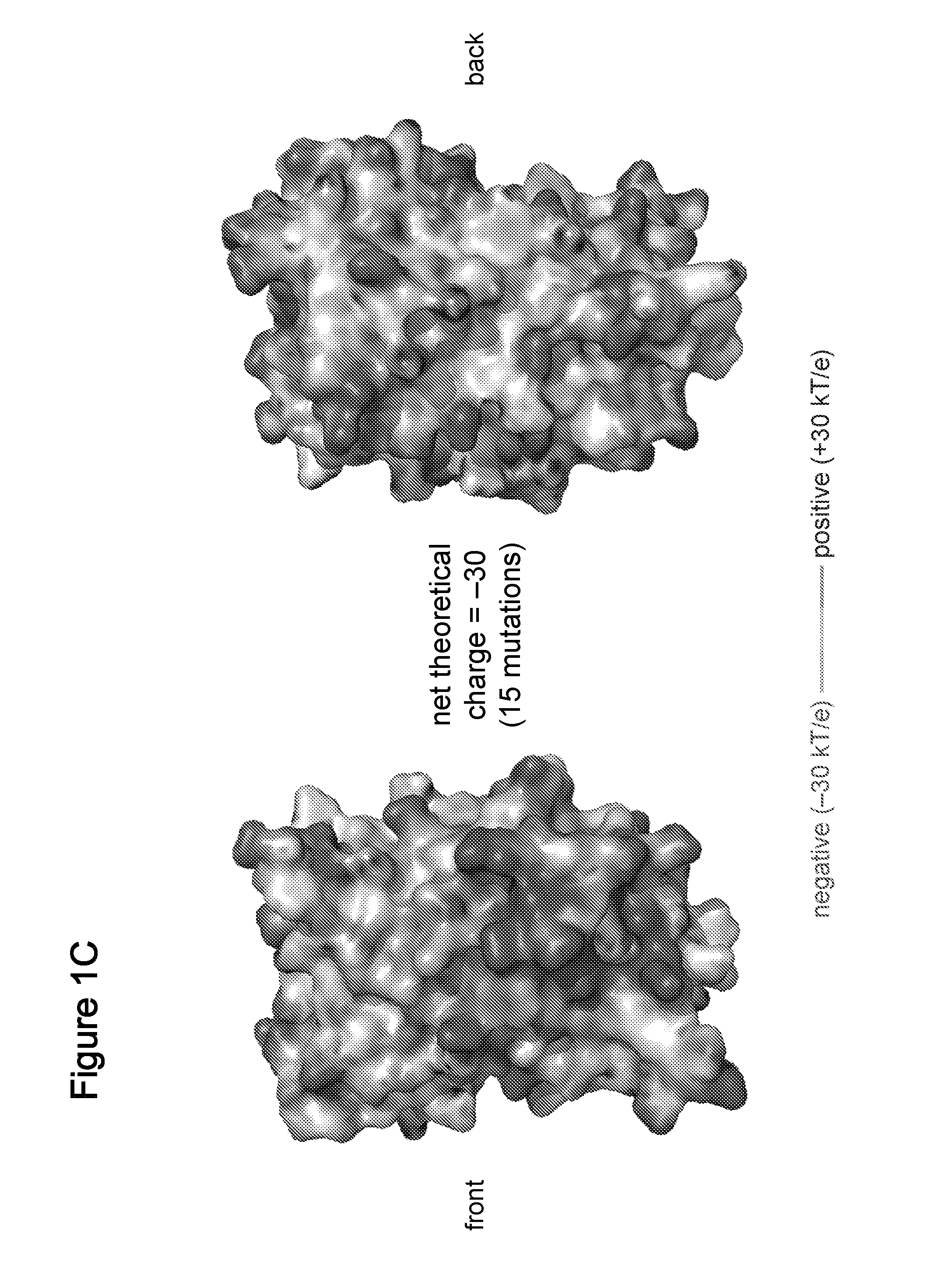

Organic electrolyte, method for extracting non-metallic inclusions from steel and electrolyzer

InactiveCN103898596AAvoid erosionFacilitates ion migrationElectrolysis componentsPreparing sample for investigationSurface-active agentsPlastic bag

The invention discloses an organic electrolyte comprising the following components in percentage by weight: 2%-5% of lithium chloride, 5%-8% of gamma-butyrolactone, 2%-5% of ethylene glycol, 0.1%-10% of phenyl surface active agent and balance of absolute ethyl alcohol. The invention also discloses a method for extracting non-metallic inclusions from steel. The method comprises the following steps: preparing the electrolyte, sleeving a microporous cellulose acetate plastic bag on the periphery of a steel sample to electrolyze the steel sample, and separating the inclusions in ultrasonic vibration and vacuum filtration manners. The organic electrolyte is environmentally friendly and low in toxicity. By utilizing the organic electrolyte, body injury to operation staff is obviously reduced, electrolysis time is shortened by accelerating electrolysis through an external magnetic field, the problem that a large number of iron and inclusions of iron and inclusions are difficult to be separated from the anode mud is overcome, and the non-metallic inclusions are accurately and roundly extracted with use of the cellulose acetate plastic bag.

Owner:SHANGHAI UNIV +1

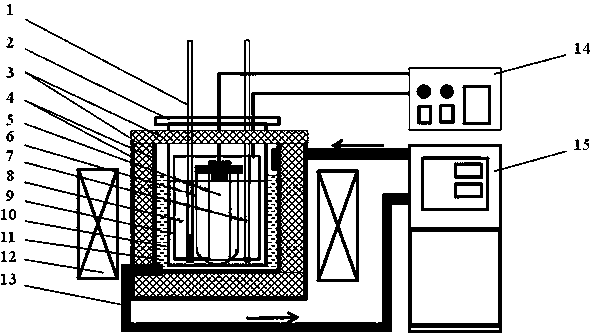

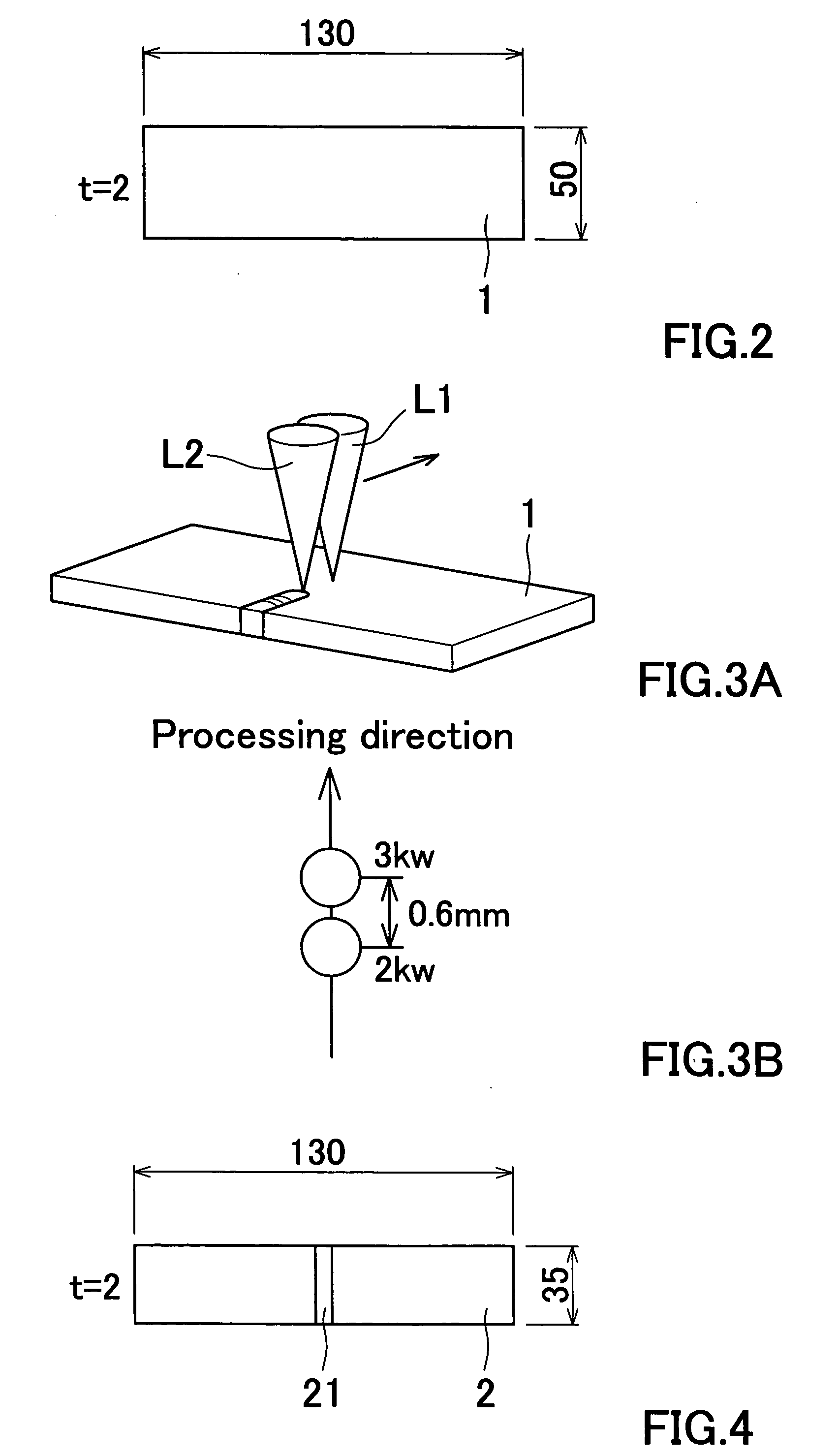

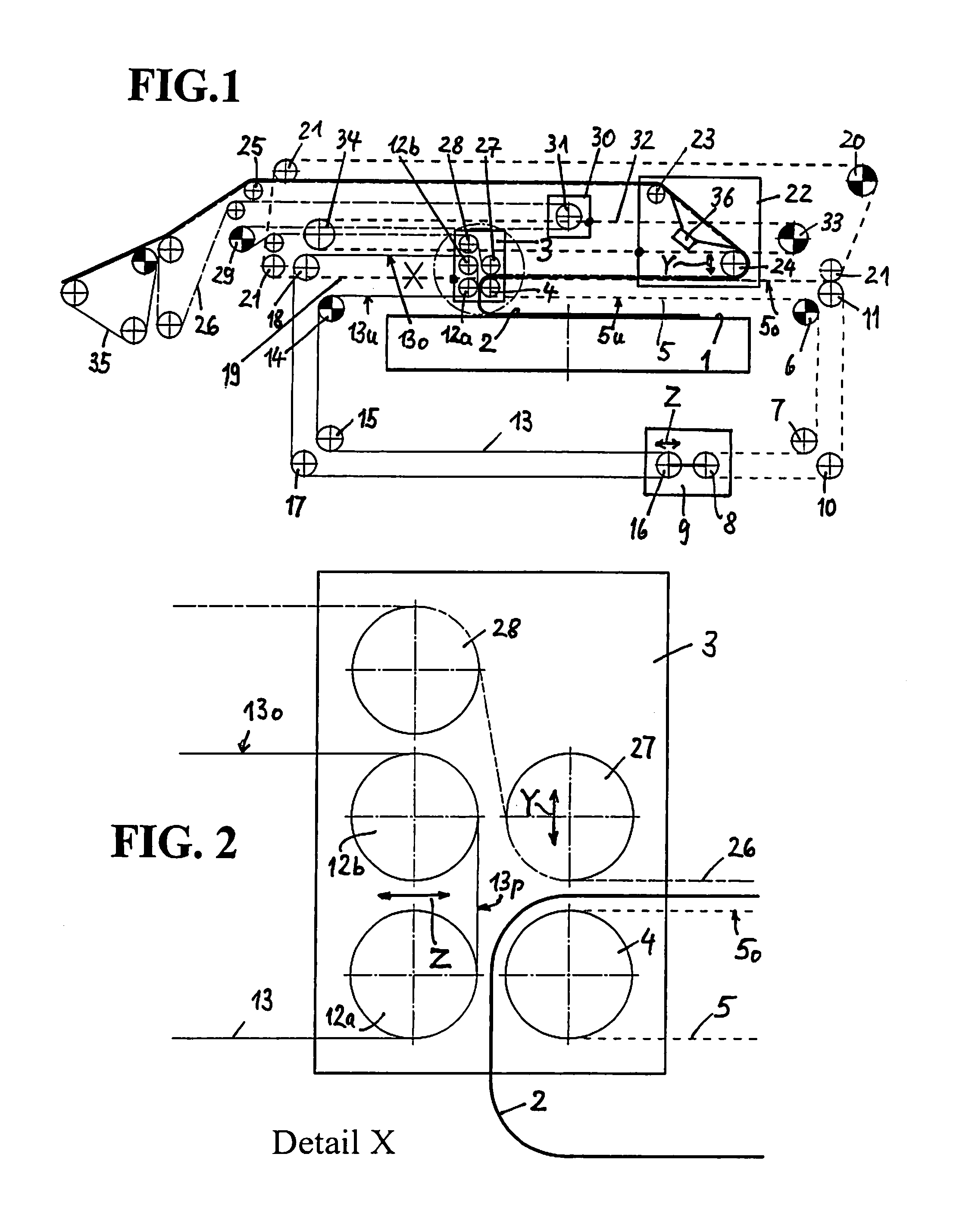

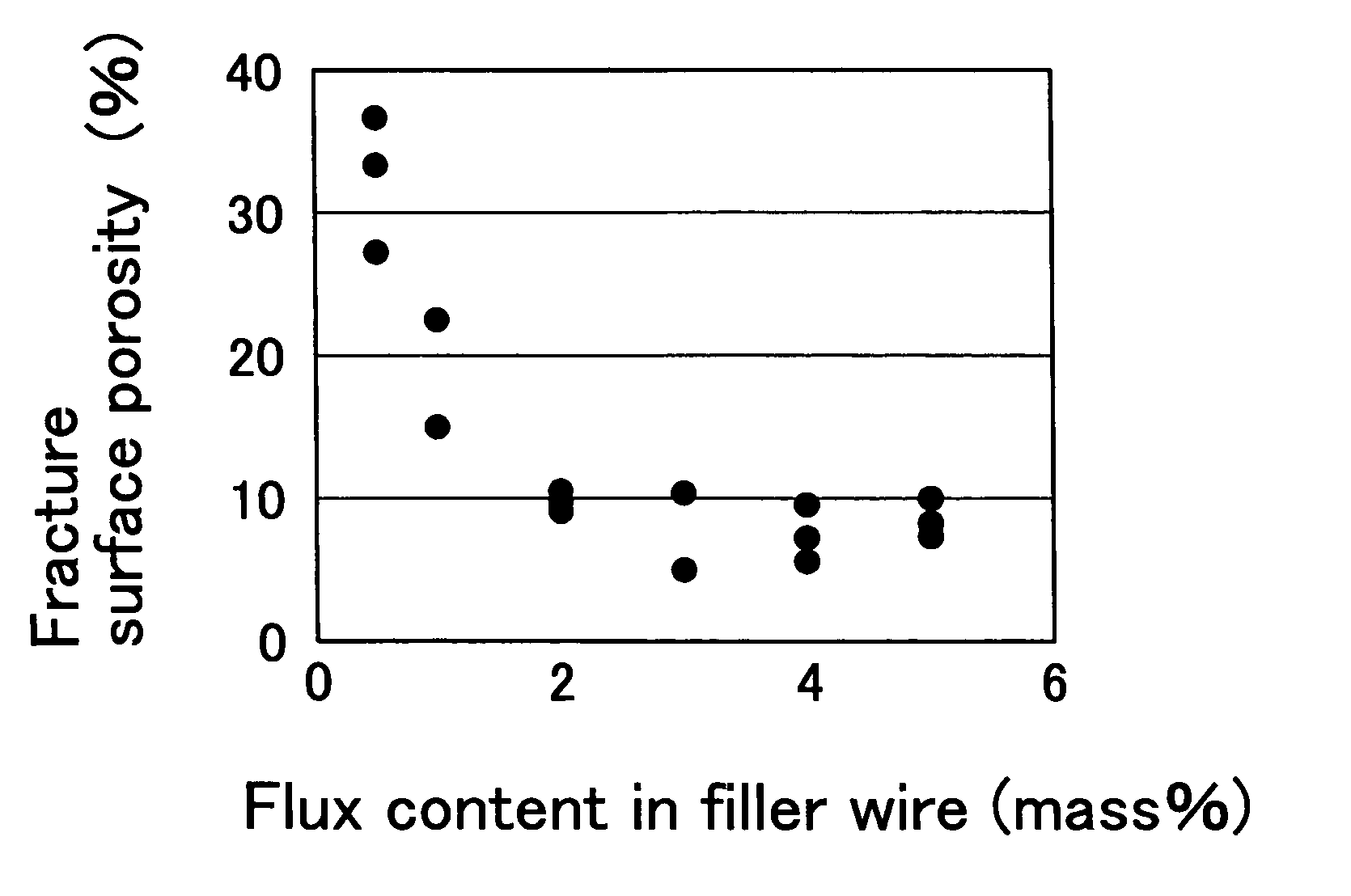

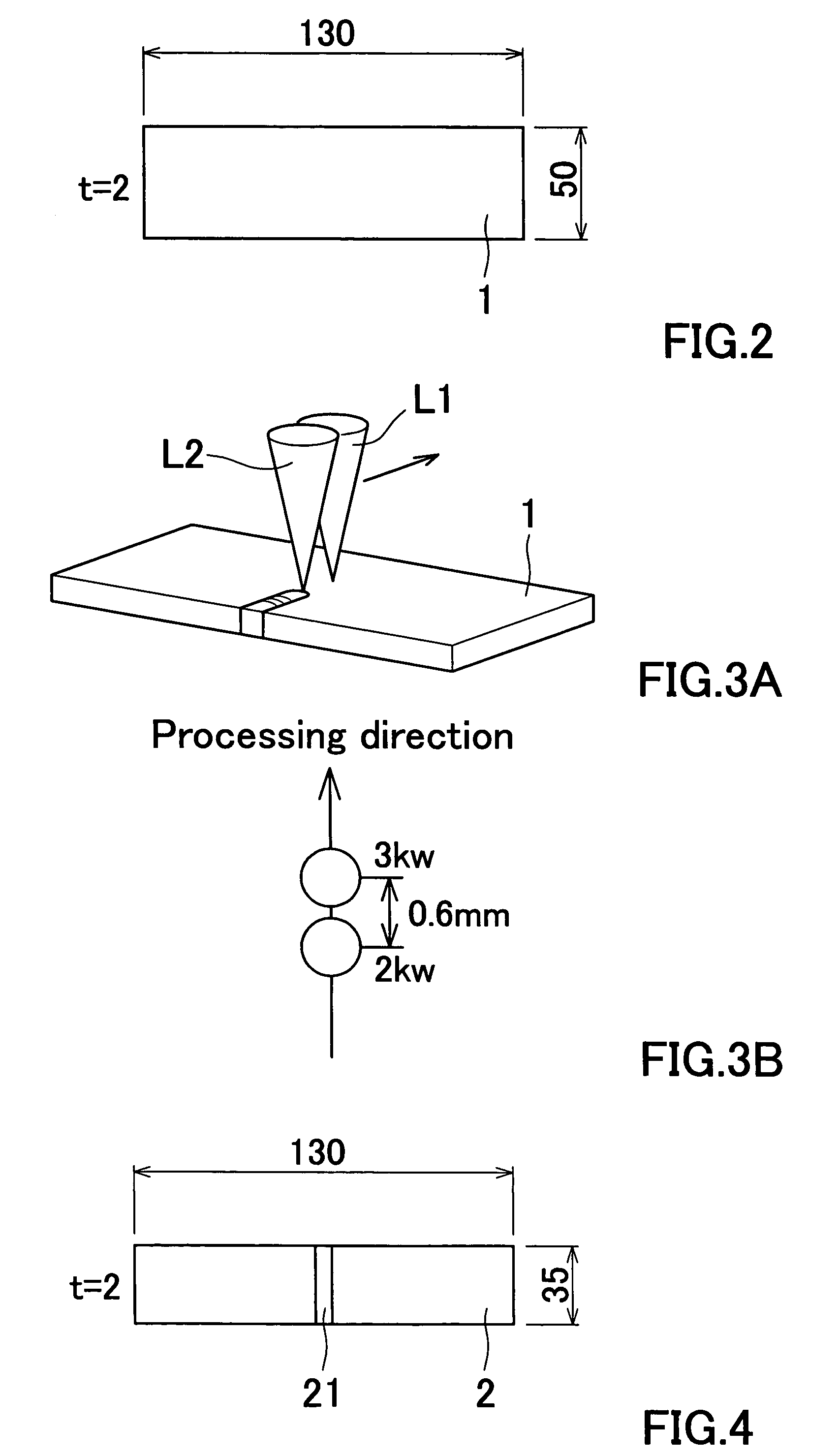

Filler material for use in welding of Mg-contained aluminum alloy die-cast members, welding method, and welded article

InactiveUS20050023258A1High strengthSuppress generationWelding/cutting media/materialsWelding/soldering/cutting articlesFilling materialsDie casting

An aluminum alloy filler material for use in welding of metal members including at least one aluminum die-cast member containing Mg includes an aluminum or an aluminum alloy as base material and Al—K—F series flux. The Al—K—F series flux is contained by 2 to 4 mass % with respect to the entire filler material.

Owner:NISSAN MOTOR CO LTD +1

Preparation method of electric welding protective clothing fabric and prepared electric welding protective clothing fabric

ActiveCN107604656AImprove fabric strength and flame retardancyLow priceVegetal fibresProtective GarmentDecabromodiphenyl ethane

The invention relates to a preparation method of an electric welding protective clothing fabric and the prepared electric welding protective clothing fabric. The method comprises the following steps:a) cellulose fibers and unmodified vinylon or modified vinylon are provided for blending, and a textile is obtained; b) the textile obtained in step a) is dyed with a dye, and a dyed textile is obtained; c) the dyed textile obtained in step b) is soaked in a tetrahydroxymethyl phosphorus compound aqueous solution, drying, ammonia fumigation and oxidation are performed, and a flame retardant textile is obtained; d) coating composition is applied to the front of the flame retardant textile obtained in step c), then thermally setting is performed, and a front-coated flame retardant textile is obtained, wherein the coating composition contains aqueous polyurethane resin, a crosslinking agent, aluminum hydroxide powder, decabromodiphenyl ethane, antimony trioxide, a penetrant and lignin powder;e) a fluorine-based water repellent is locally applied to the reverse side of the front coated flame retardant textile obtained in step d).

Owner:思迈(威海)新材料科技有限公司 +2

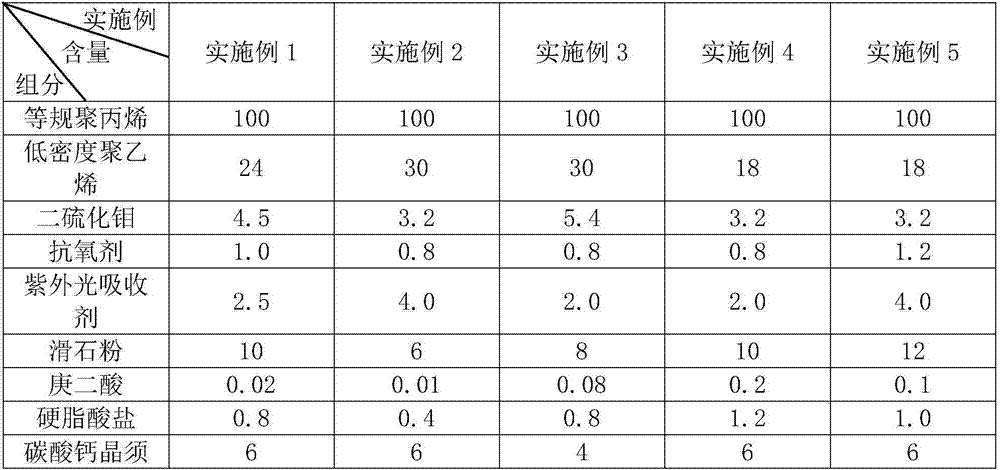

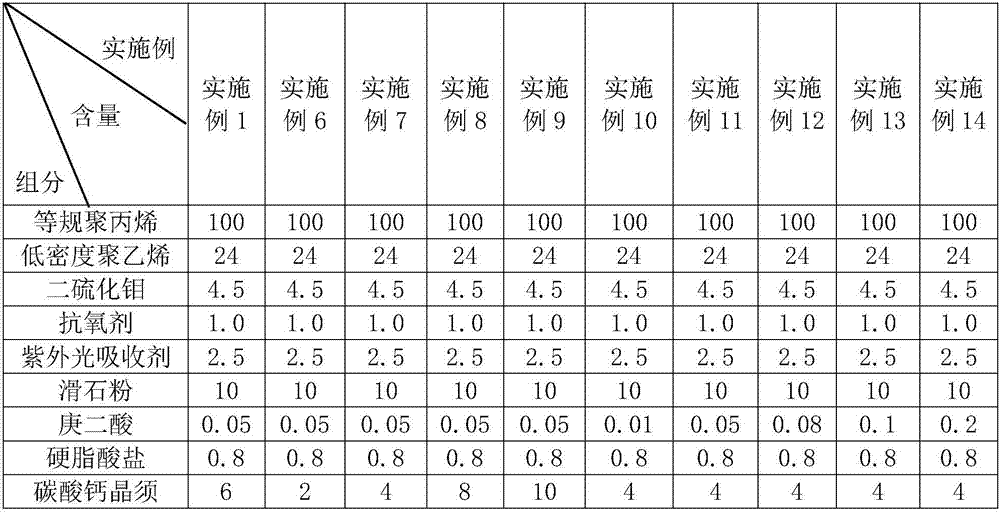

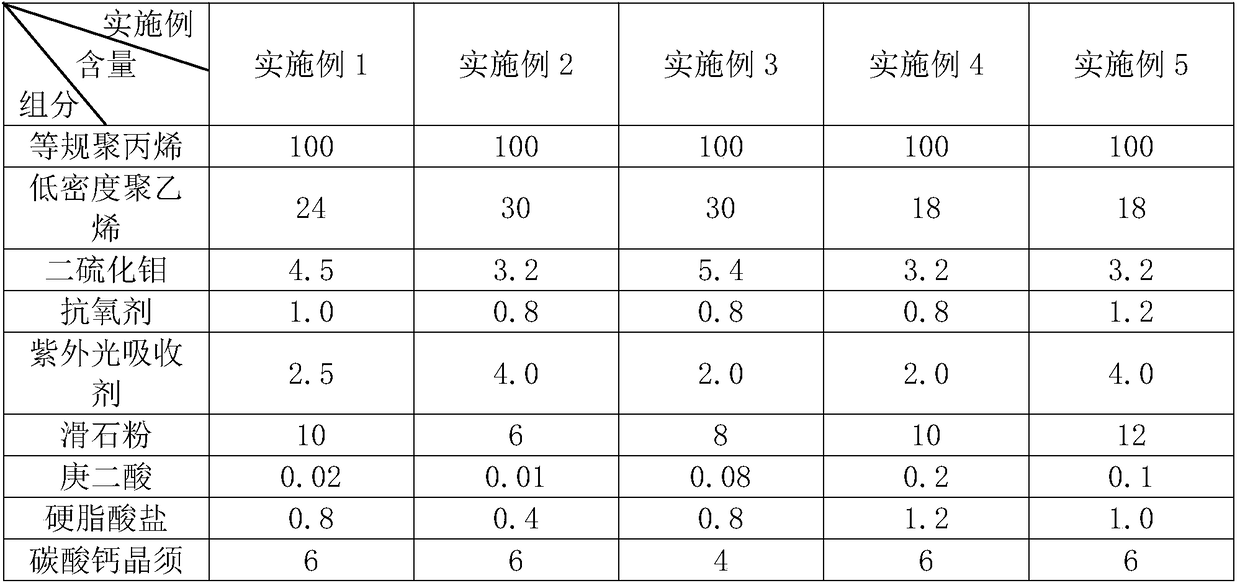

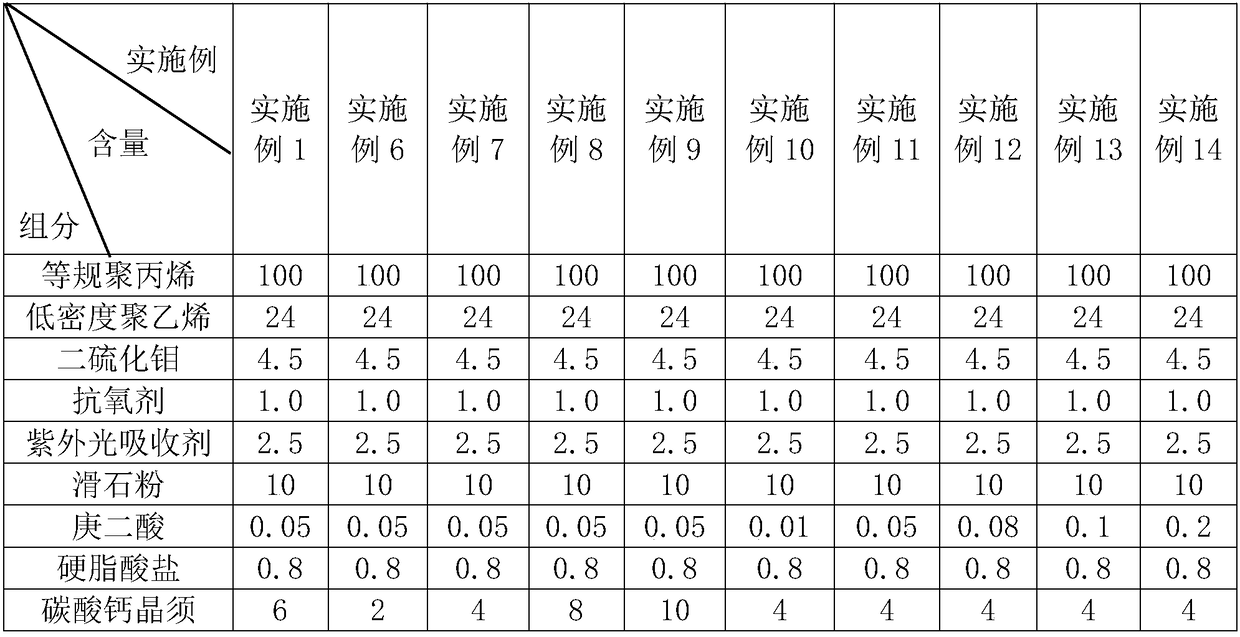

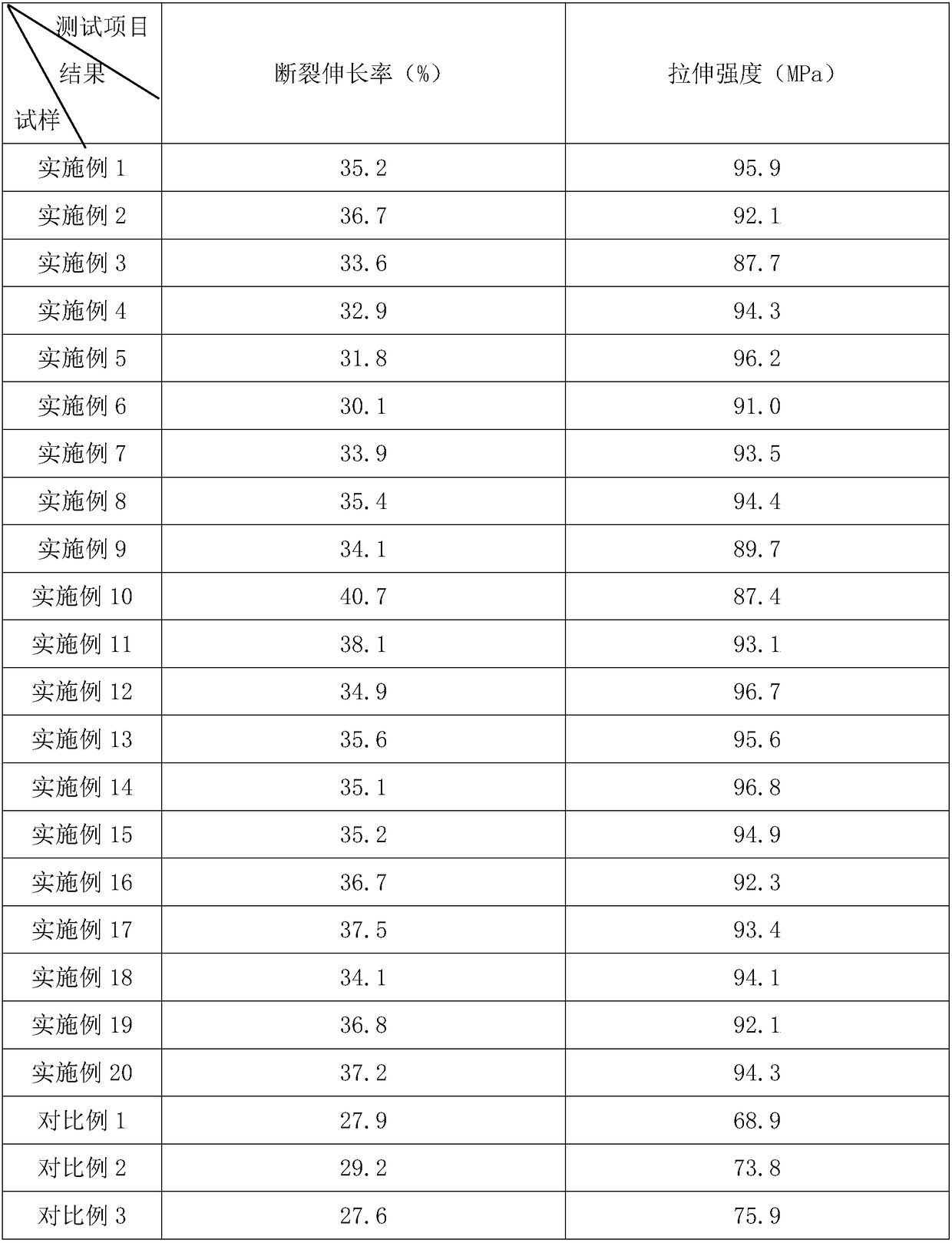

Material for reinforced plastic woven bag

The invention discloses a material for a reinforced plastic woven bag. The material is characterized by being prepared from the following raw materials in parts by weight: 100 parts of isotactic polypropylene, 18 to 30 parts of low density polyethylene, 3.2 to 5.4 parts of molybdenum disulfide, 0.8 to 1.2 parts of an antioxidant, 2 to 4 parts of an ultraviolet absorbent, 6 to 12 parts of talcum powder, 0.01 to 0.2 part of pimelic acid, 0.4 to 1.2 parts of stearate and 2 to 10 parts of calcium carbonate whiskers, wherein stearate comprises calcium stearate. The material has the advantages of high tensile strength and high toughness.

Owner:浙江海威包装有限公司

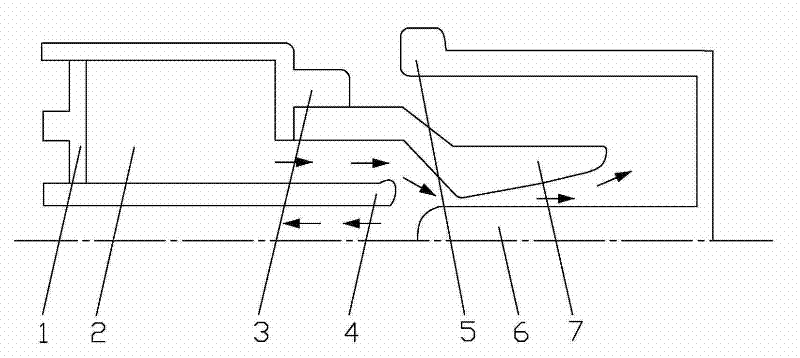

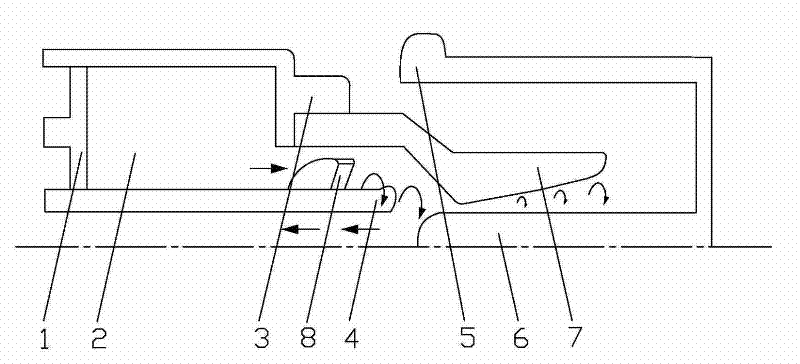

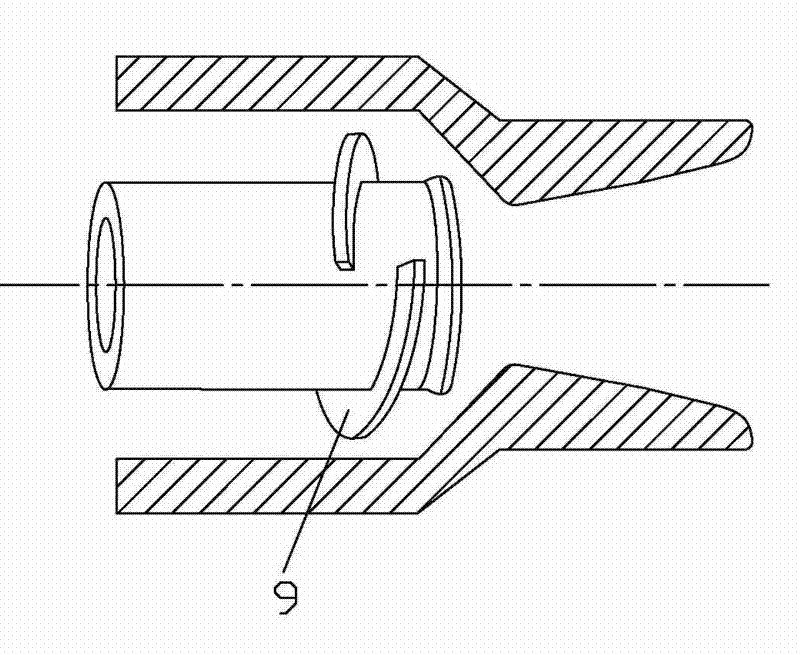

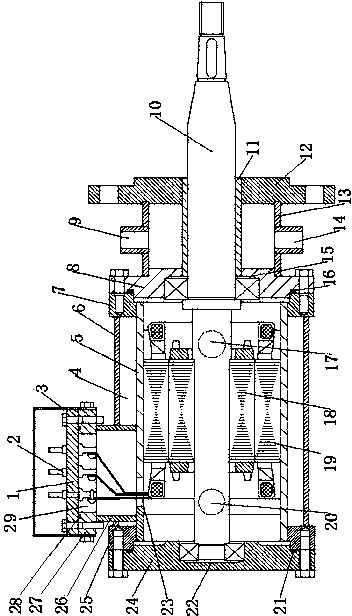

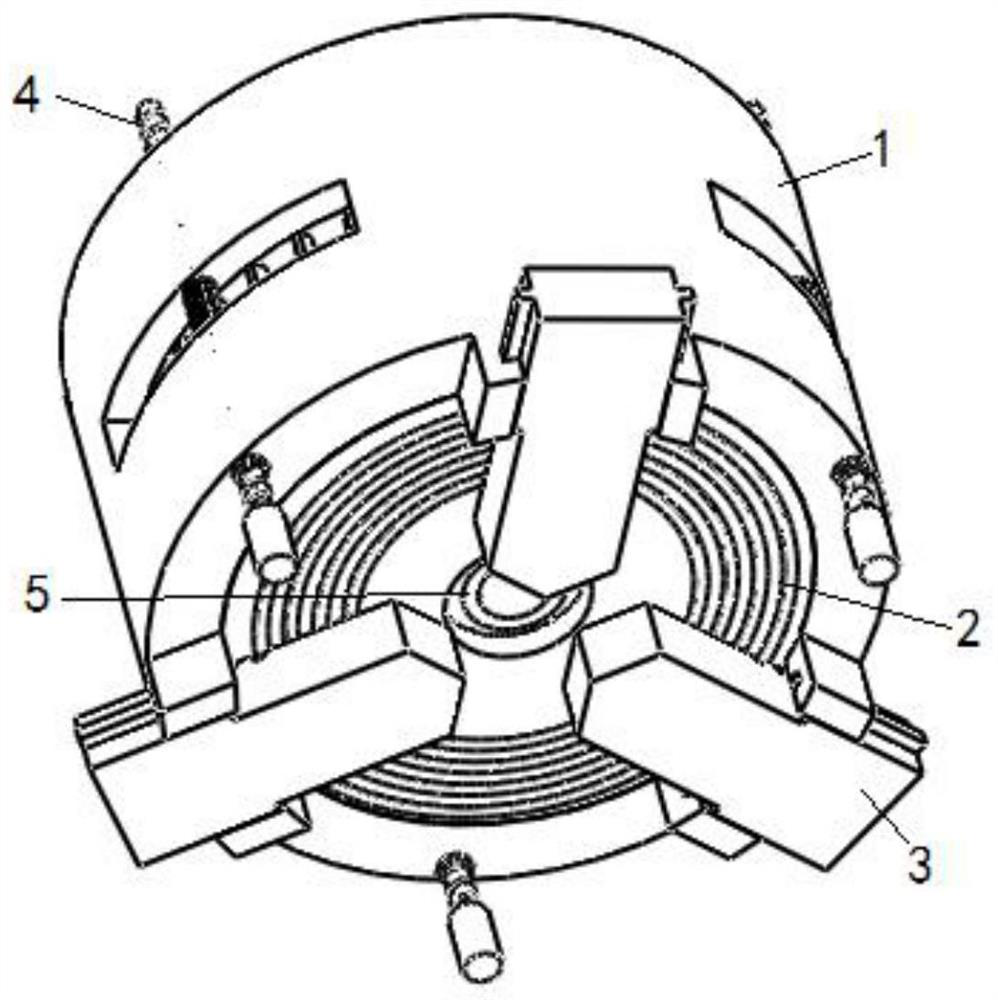

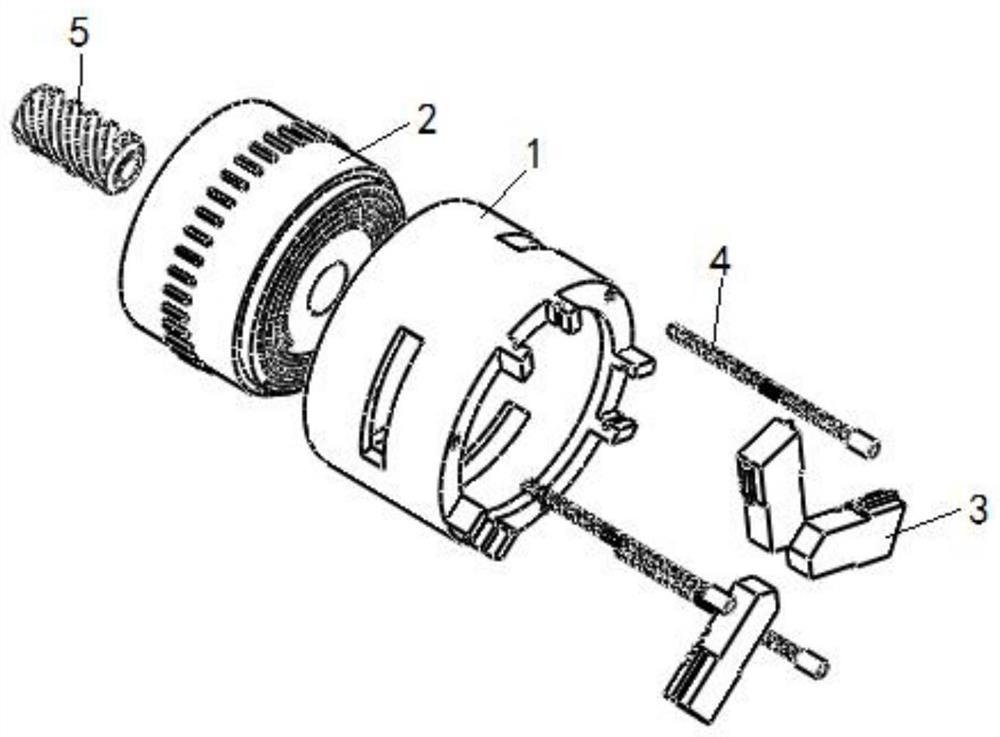

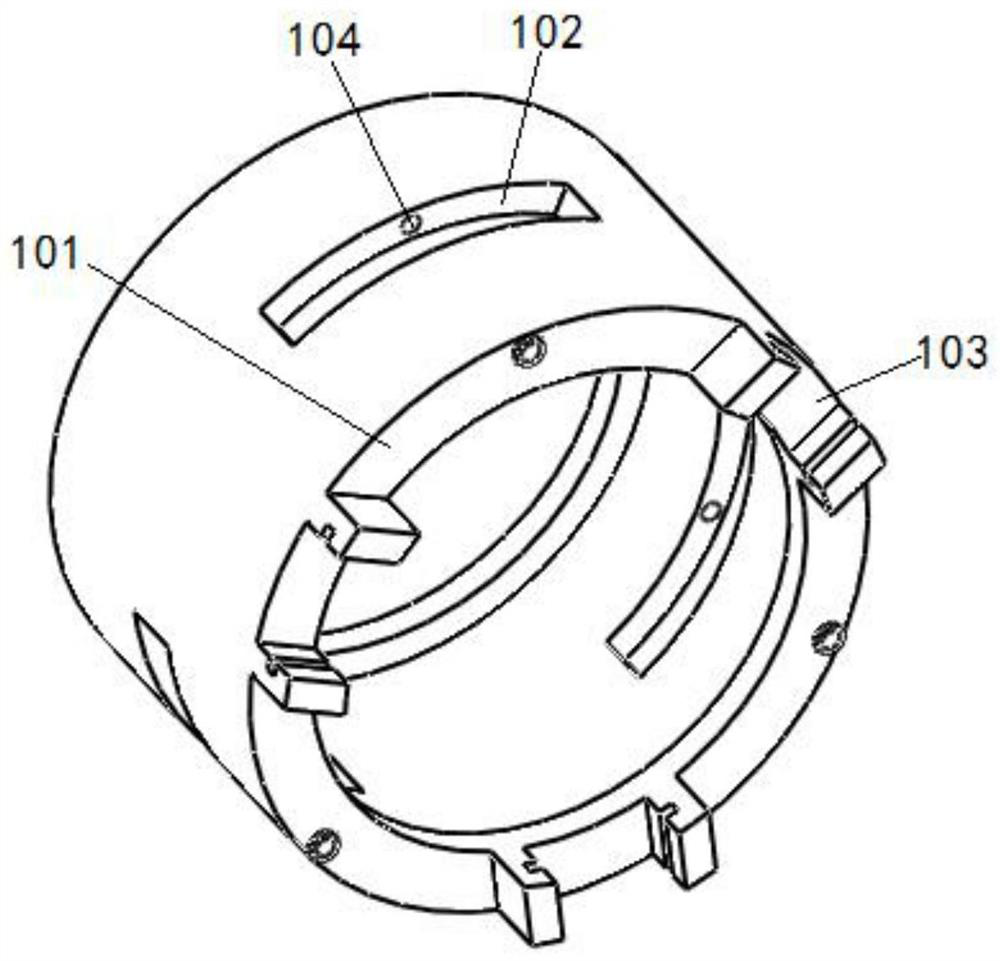

Gas rotation energy separation type high-voltage SF6 circuit breaker and energy separation method thereof

ActiveCN102364656AAccelerate offImprove breaking capacityHigh-tension/heavy-dress switchesAir-break switchesFan bladeArc energy

The invention belongs to the field of high-voltage SF6 circuit breakers, in particular to a gas rotation energy separation type high-voltage SF6 circuit breaker and an energy separation method thereof. The circuit breaker comprises a piston (1), an air cylinder (2), a movable main contact (3), a movable arcing contact (4), a static arcing contact (5), a static main contact (6) and a nozzle (7), wherein a vortex diversion mechanism (8) is fixedly arranged near the end part of the movable arcing contact (4) on the upstream of the nozzle (7), consists of a group of flow deflector units (9) with intersected structures and can consist of a fan blade type flow deflector (16) or a screw type flow deflector (21). By the circuit breaker and the method, SF6 gas which flows out of the air cylinder is subjected to vortex motion, temperature gradient variation along the radial direction is formed in the motion process, and arc energy is quickly dissipated; and the circuit breaker has a high arc temperature reduction speed, a high insulating property, high breaking capacity and high operation reliability and is convenient to mount and maintain.

Owner:SHENYANG POLYTECHNIC UNIV

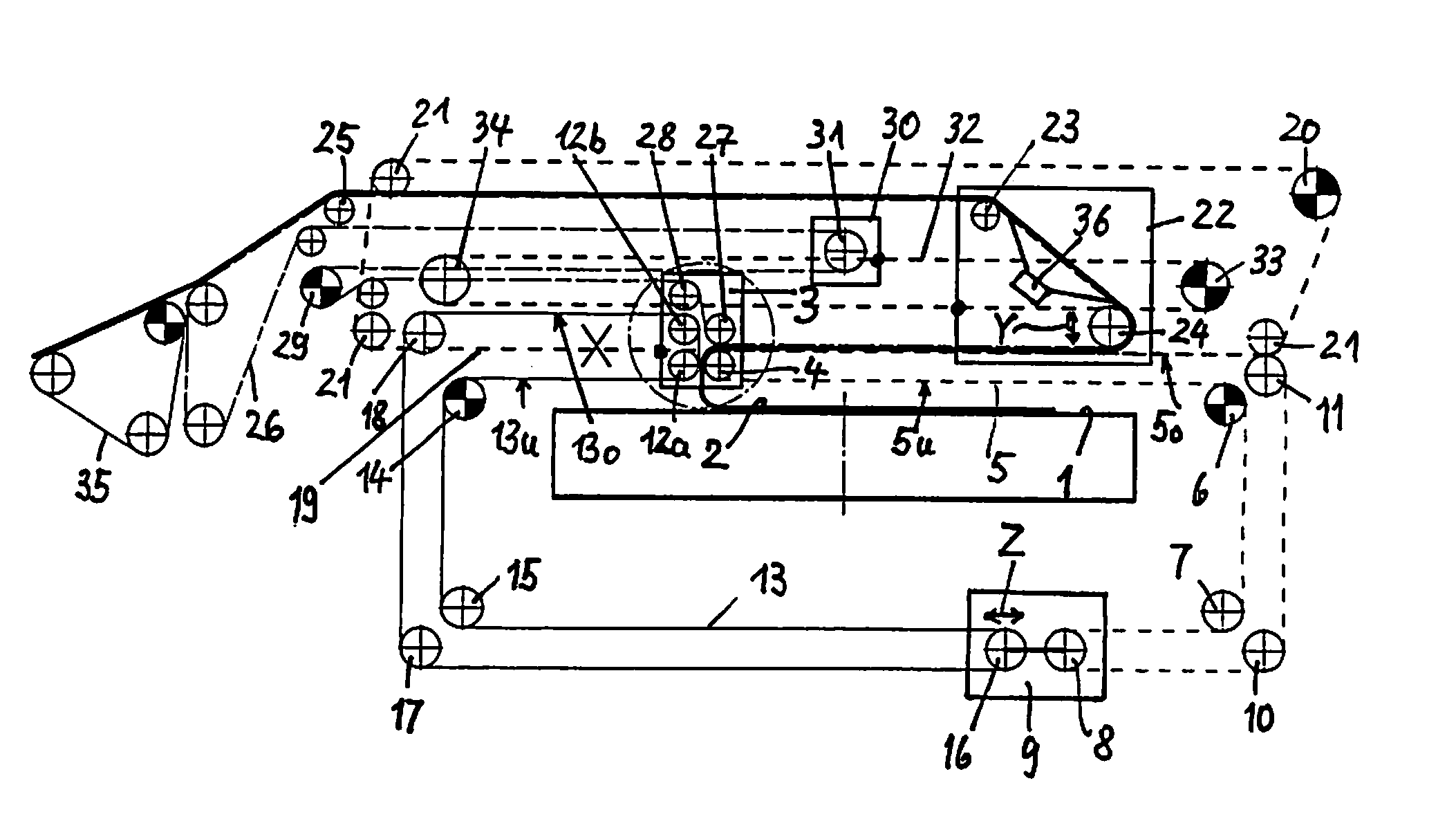

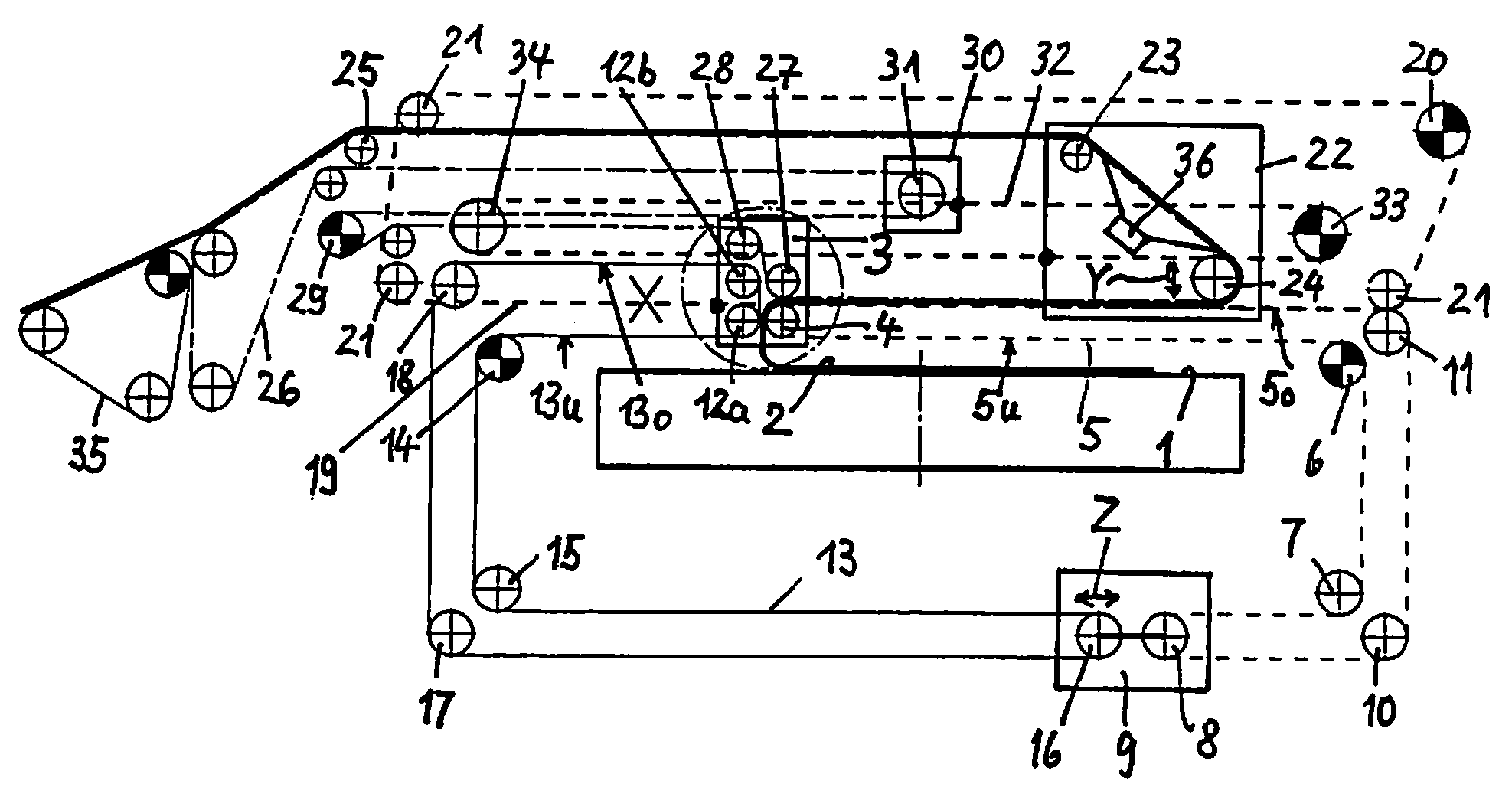

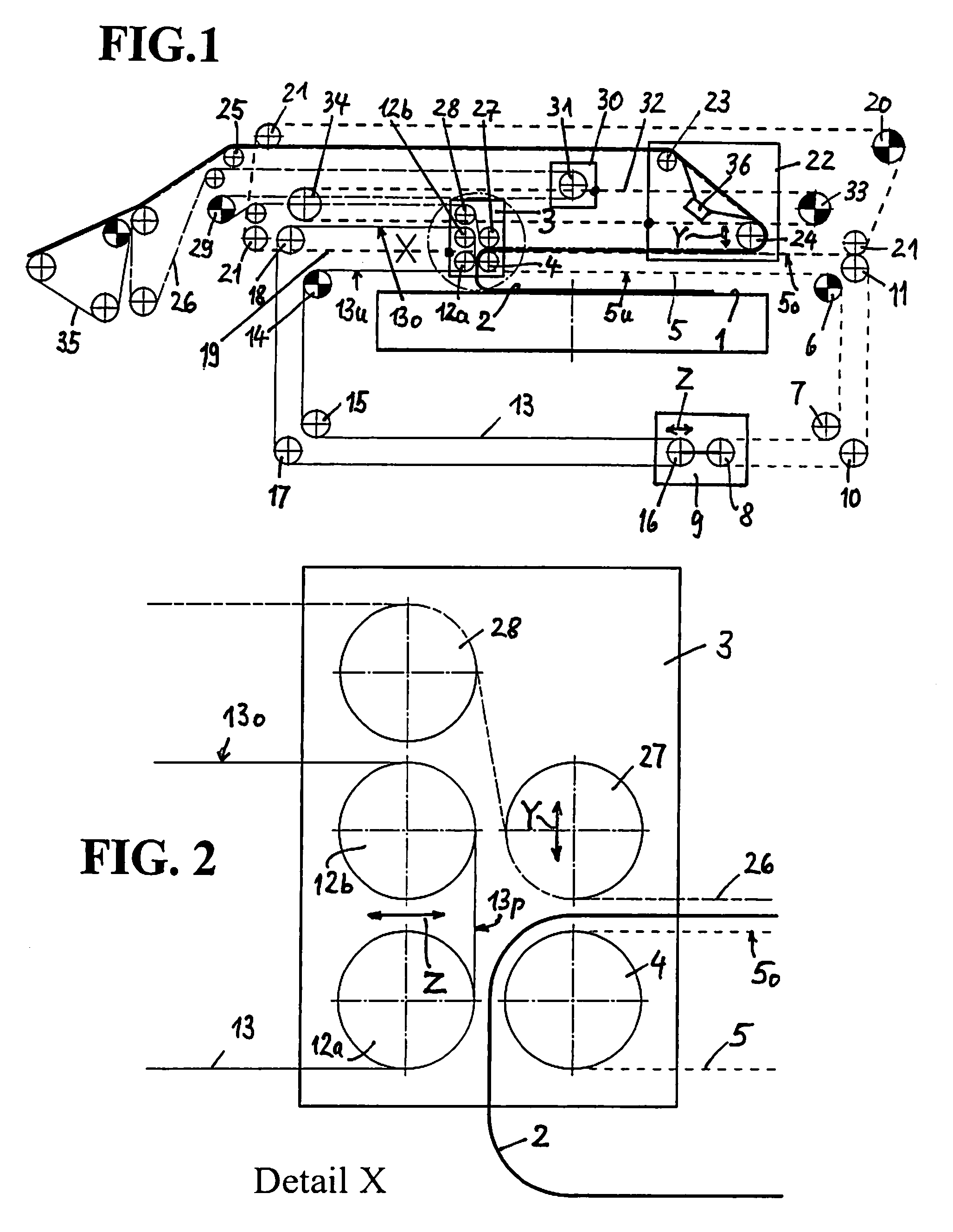

Cross lapper

A cross lapper for laying a fleece from a card web includes a laying carriage movable transversely with respect to an output conveyor belt and an upper carriage as well as a plurality of card web belts to guide the card web over the upper carriage and the laying carriage into a laying nip formed at the laying carriage, wherein a belt inlet is formed at the upper carriage over which a card web transport belt is guided, which from a lower end of an inlet path extends in the direction towards the laying carriage and is accompanied in parallel in this portion by an upper section of a first, endless cover belt guided through the laying carriage, said cover belt enclosing the card web together with same up to the laying carriage. The card web transport belt returned from the laying carriage to the upper carriage leaves the laying carriage above the upper section of a second endless cover belt passed through the laying carriage. This second cover belt forms a baffle surface within the laying carriage above the laying nip and in juxtaposition thereof, said baffle surface ensuring a safe guidance of the card web into the laying nip also case of higher card web transport speeds.

Owner:DILO MASCHF OSKAR

Filler material for use in welding of Mg-contained aluminum alloy die-cast members, welding method, and welded article

InactiveUS7150797B2High strengthSuppress generationWelding/cutting media/materialsWelding/soldering/cutting articlesFilling materialsDie casting

An aluminum alloy filler material for use in welding of metal members including at least one aluminum die-cast member containing Mg includes an aluminum or an aluminum alloy as base material and Al—K—F series flux. The Al—K—F series flux is contained by 2 to 4 mass % with respect to the entire filler material.

Owner:NISSAN MOTOR CO LTD +1

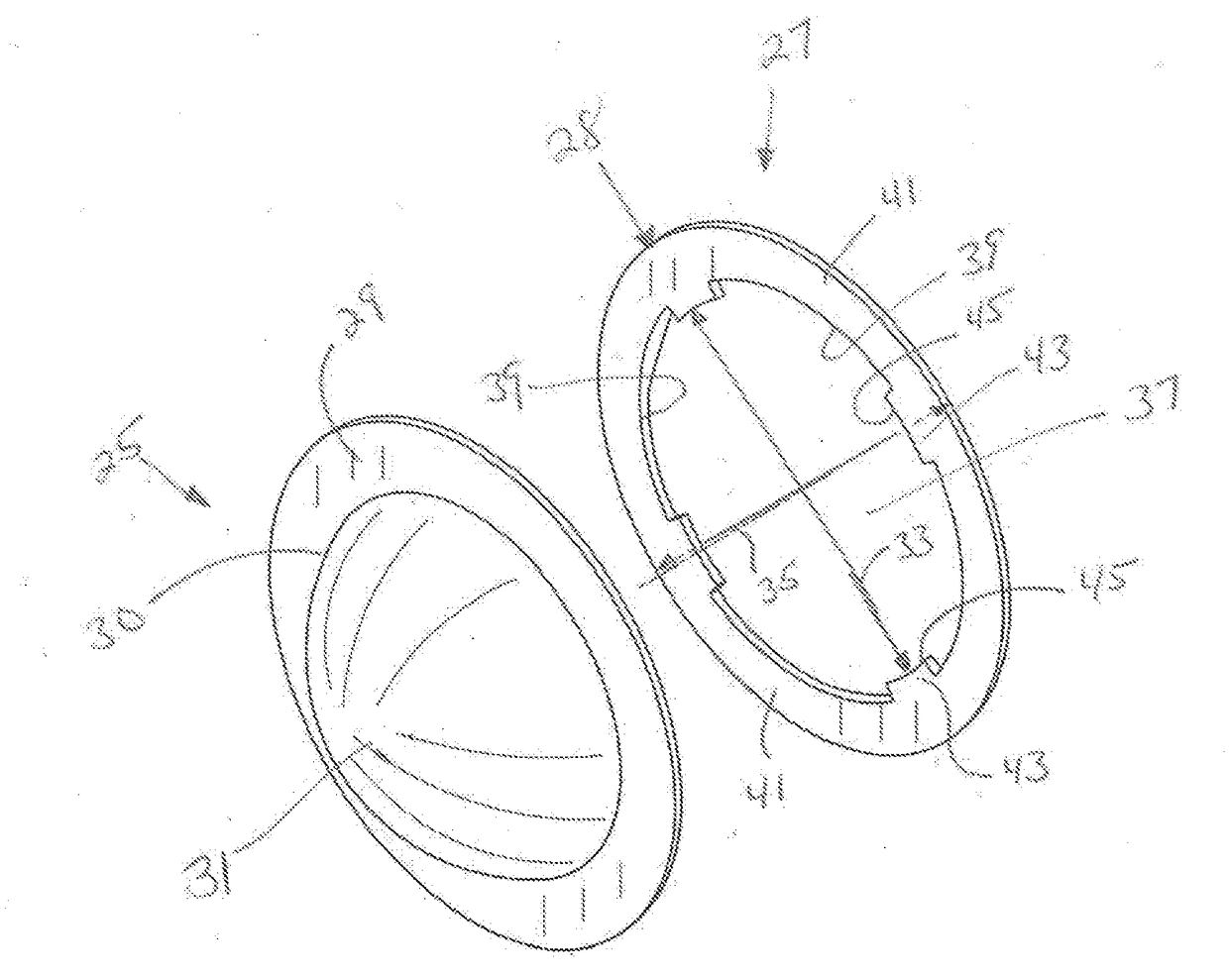

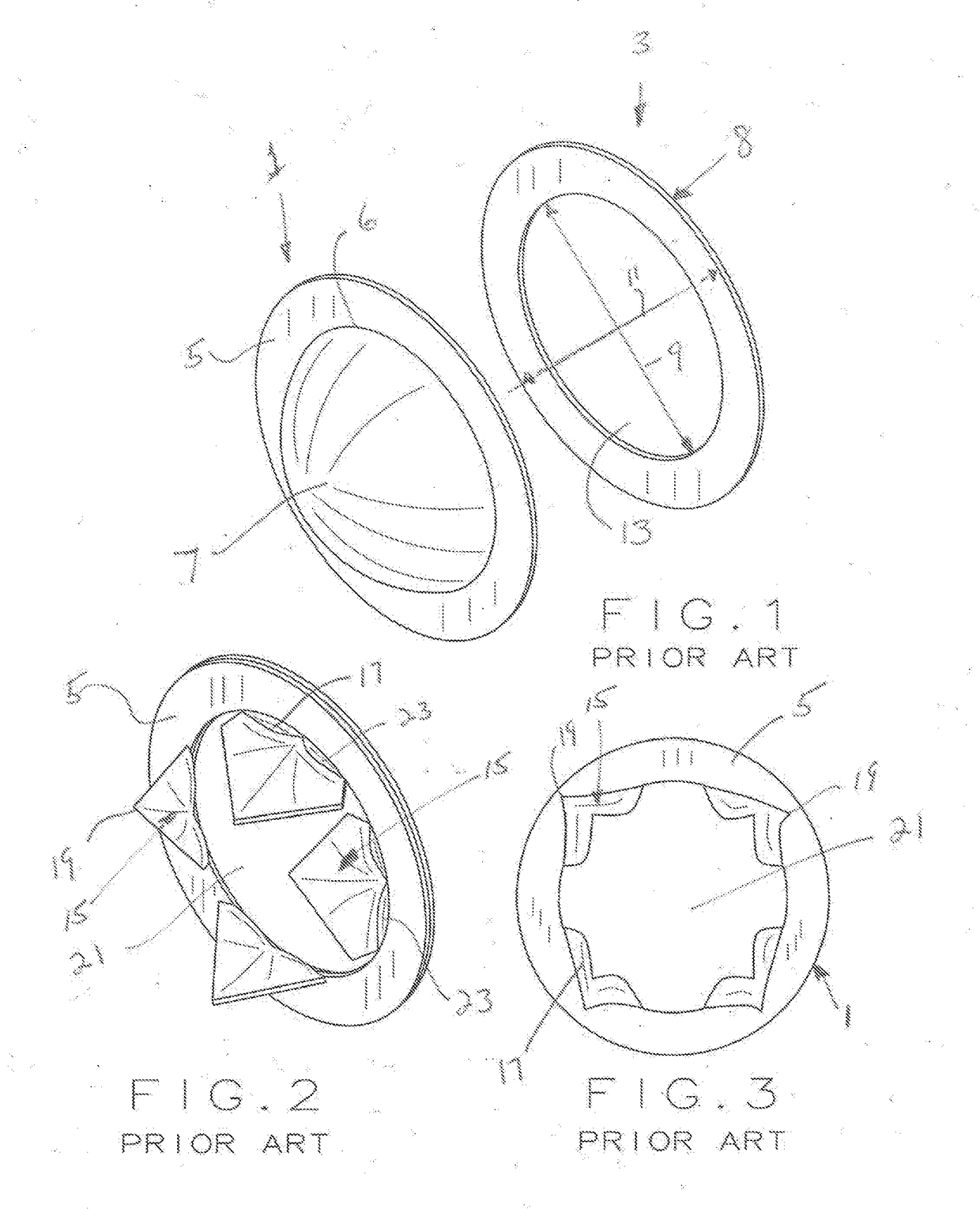

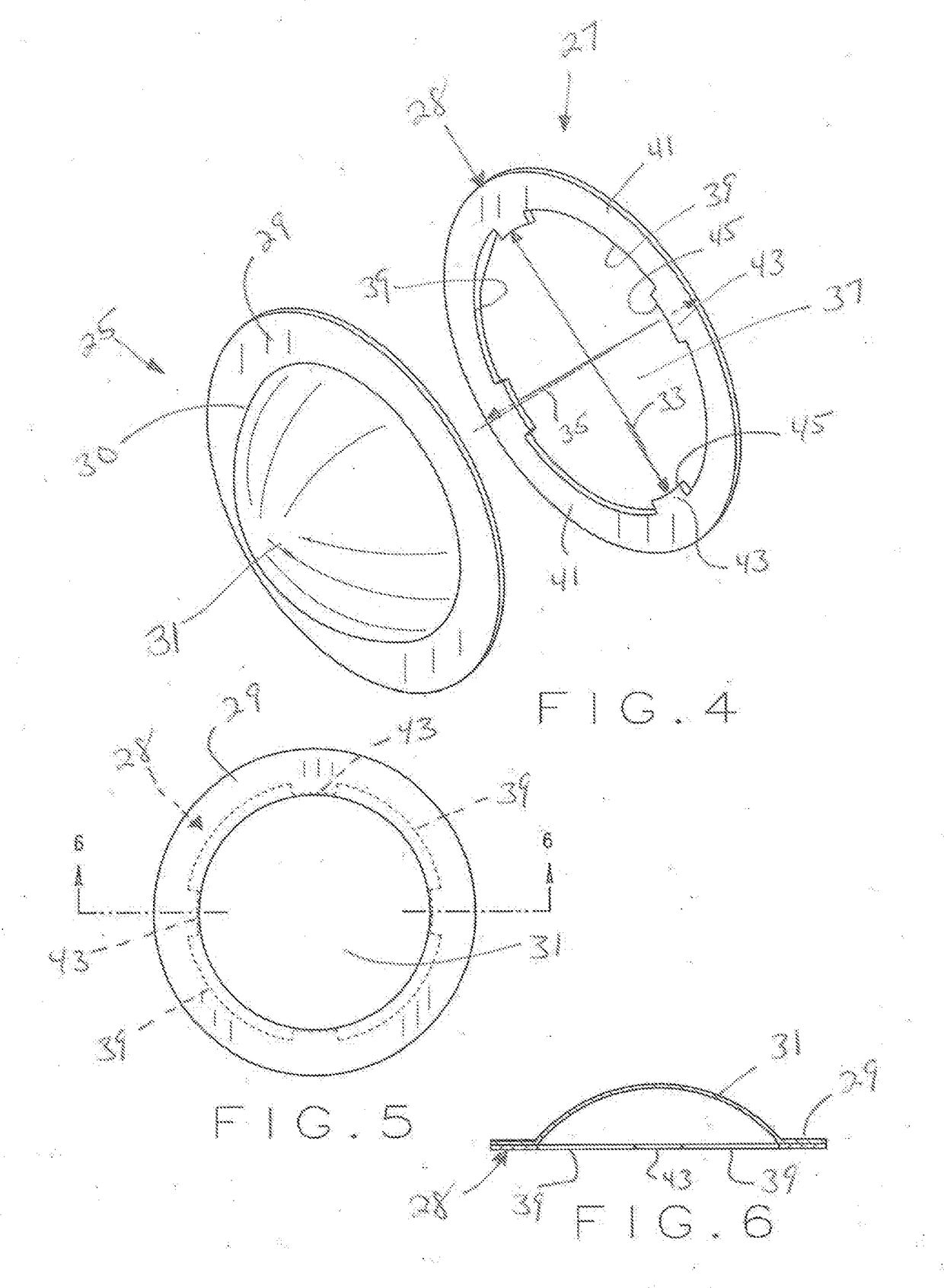

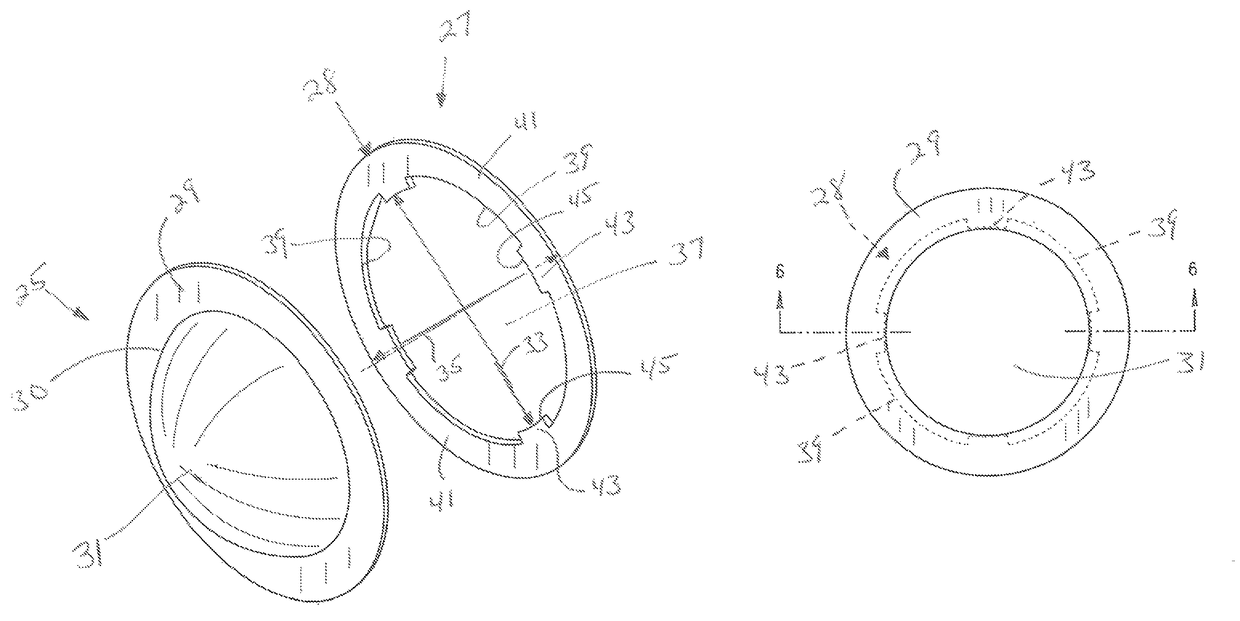

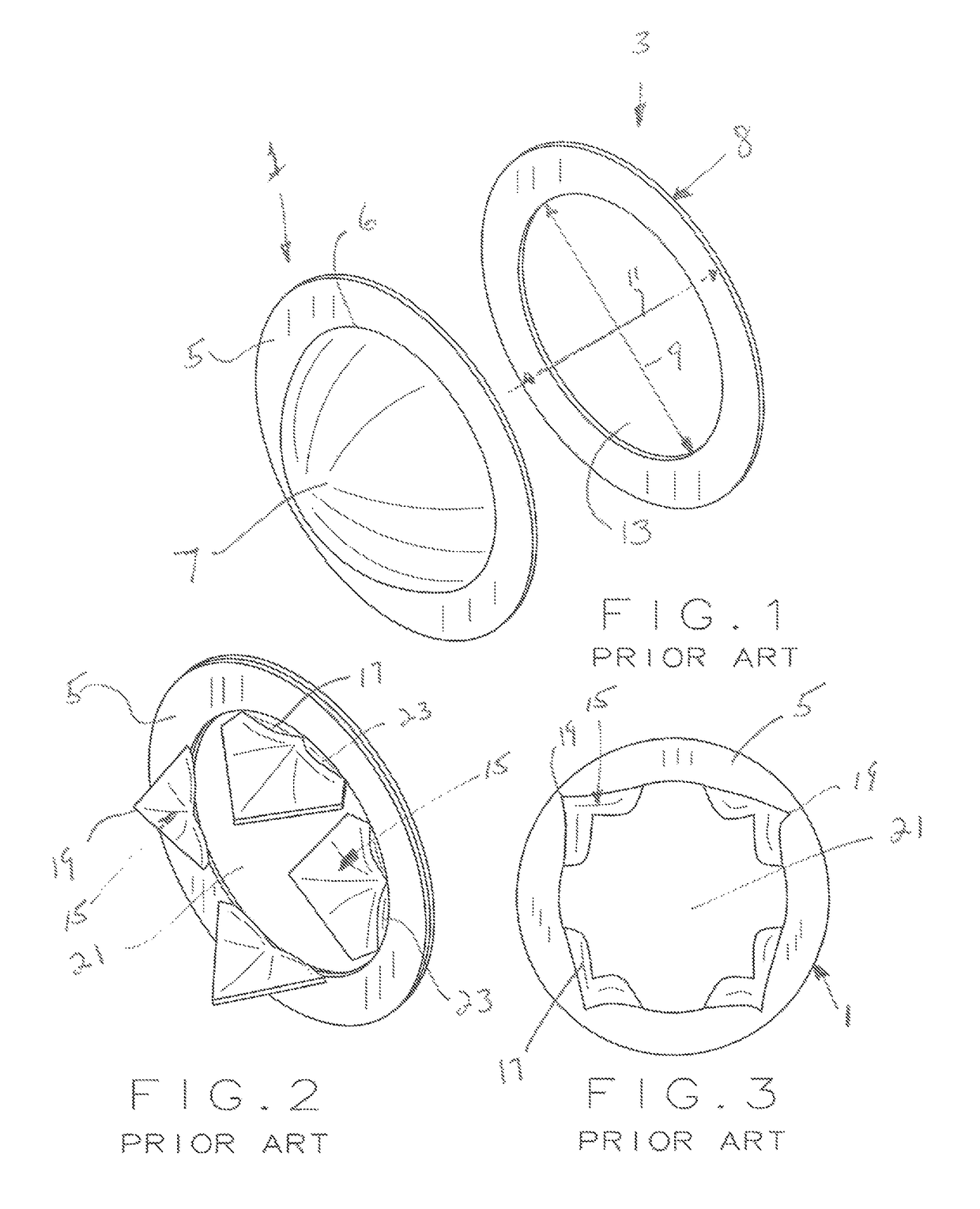

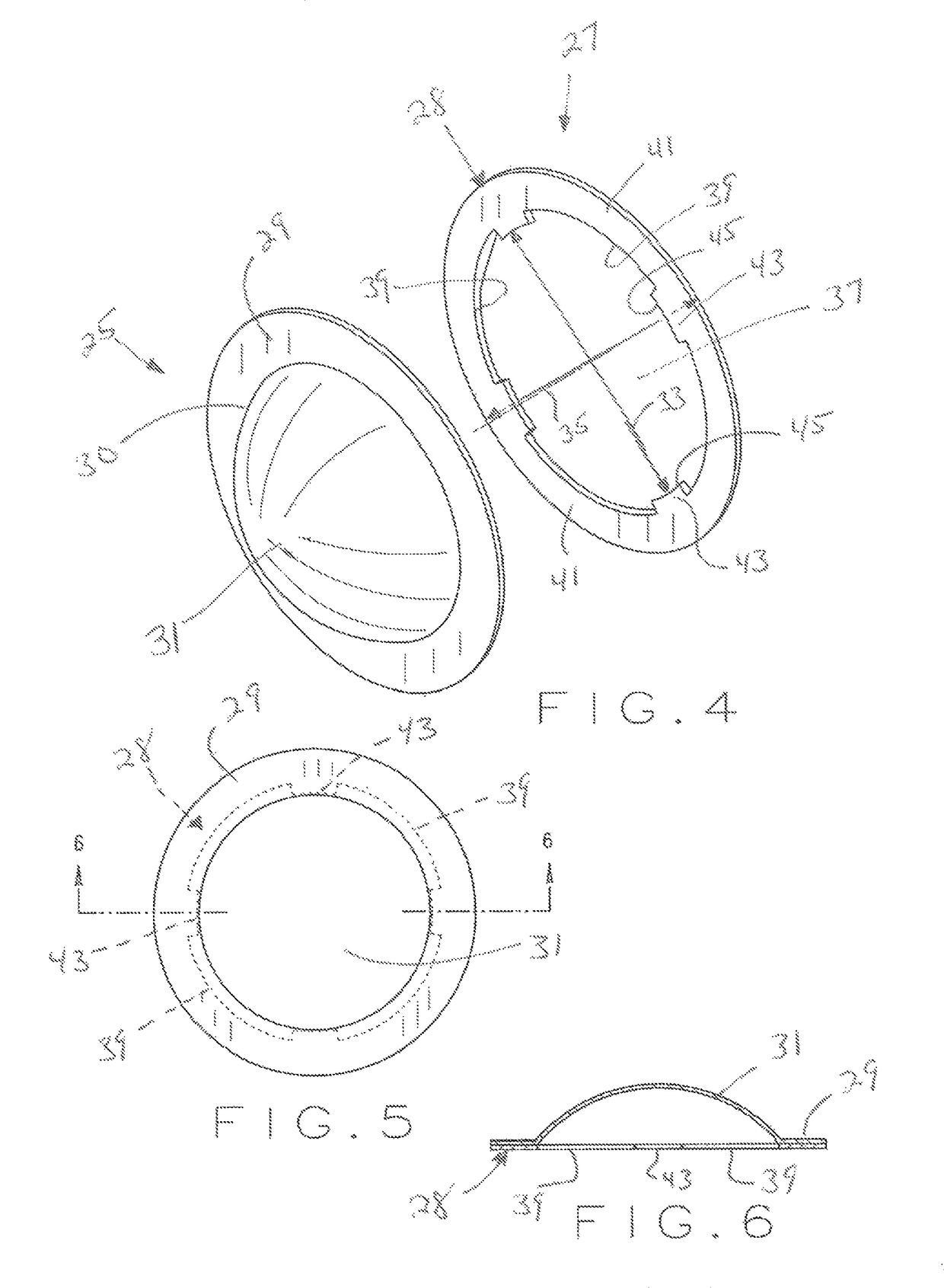

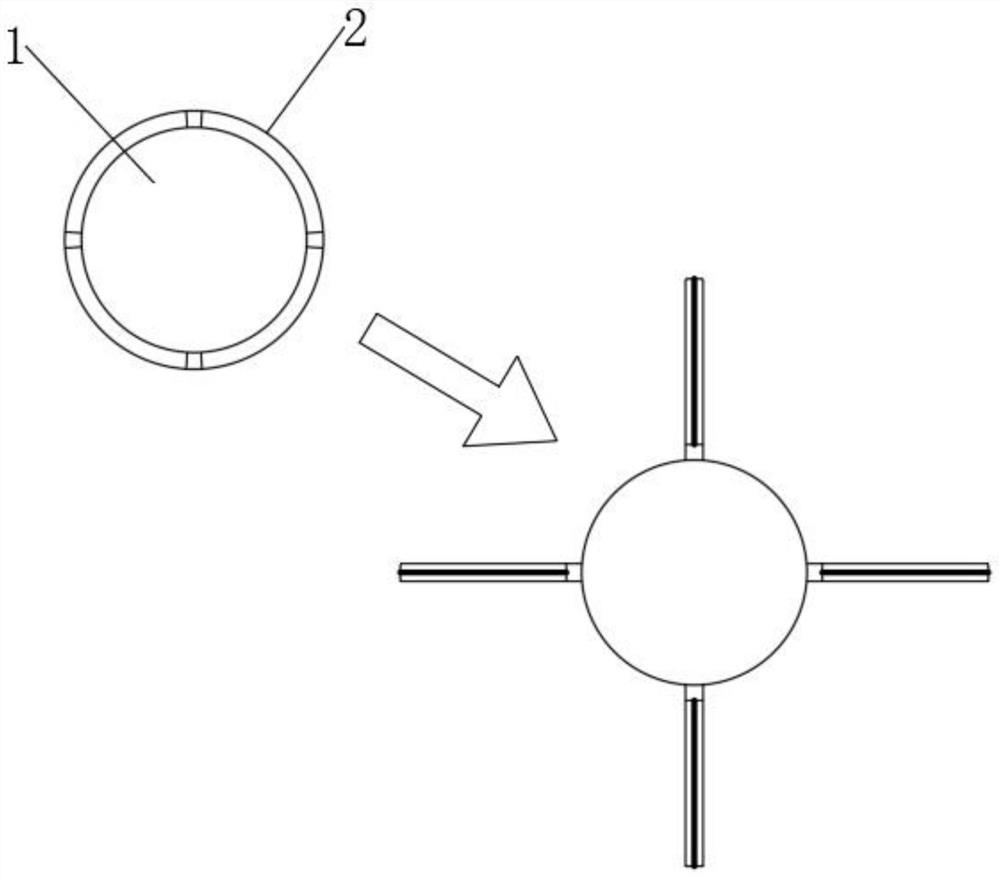

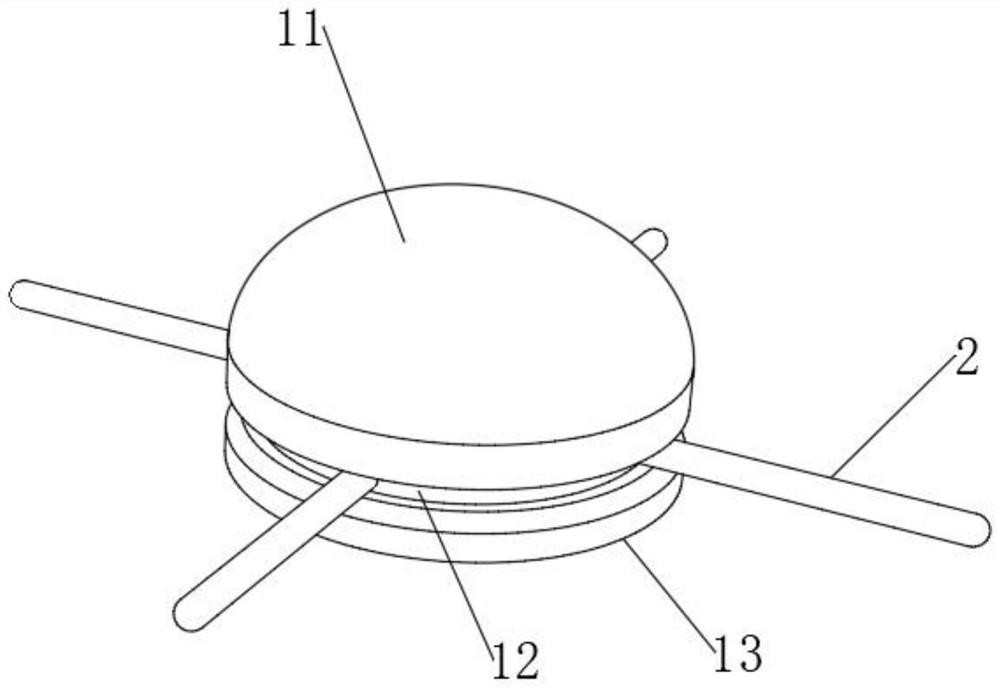

Inlet support structure for a tension acting rupture disc

ActiveUS20180051819A1Quickly and easily flowQuickly relieve pressureEqualizing valvesSafety valvesEngineeringRupture disc

An inlet support structure for use with a rupture disc, the inlet support structure including an annular member having an inner diameter, an outer diameter, a plurality of spaced apart cut-outs extending from the inner diameter towards the outer diameter, a central non-circular opening extending through the annular member and including the cut-outs, the cut-outs providing additional space for the petals of a rupture disc to be received therein when the rupture disc ruptures so as to provide a greater flow area through the rupture disc.

Owner:CONTINENTAL DISC CORP

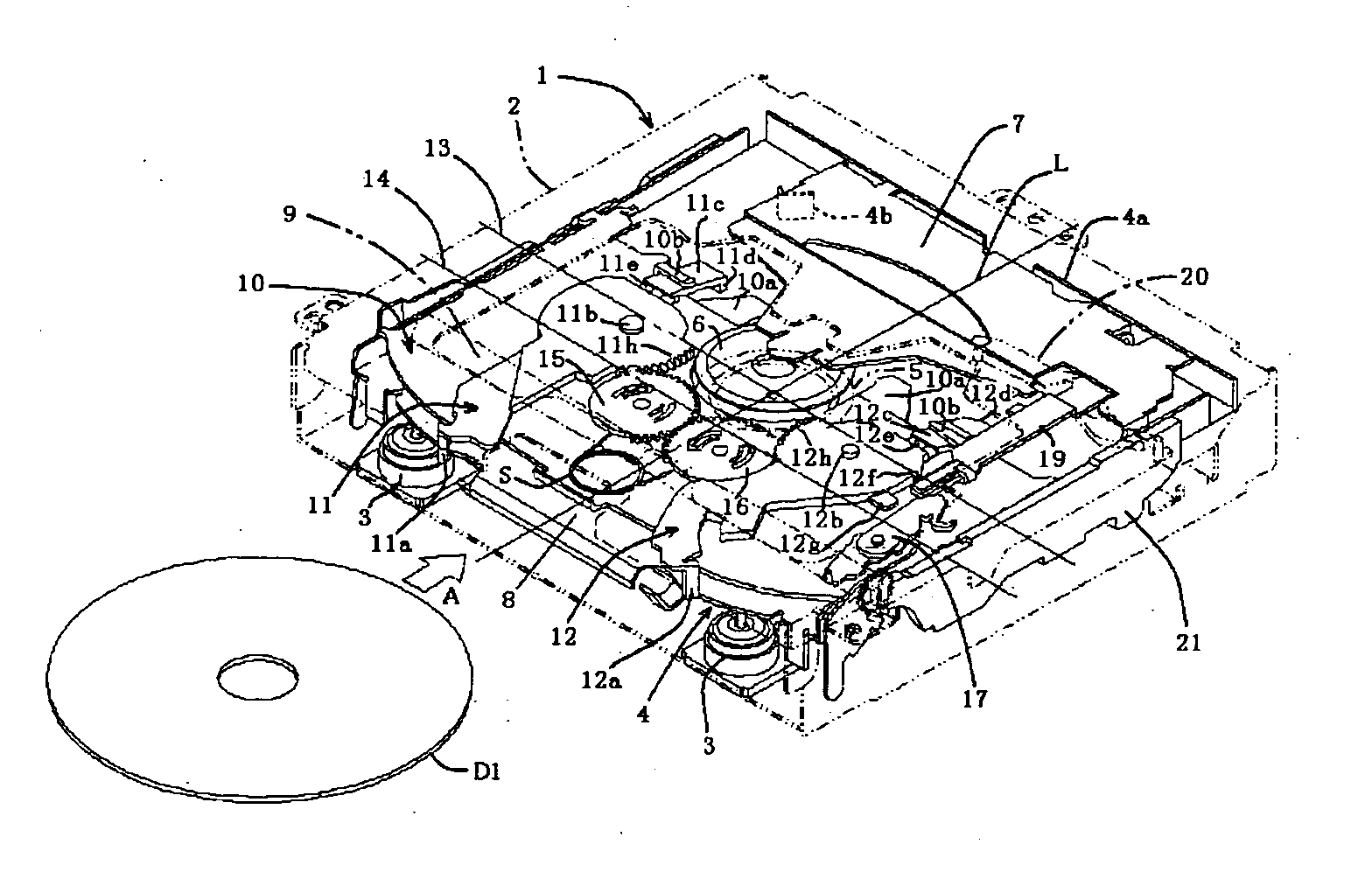

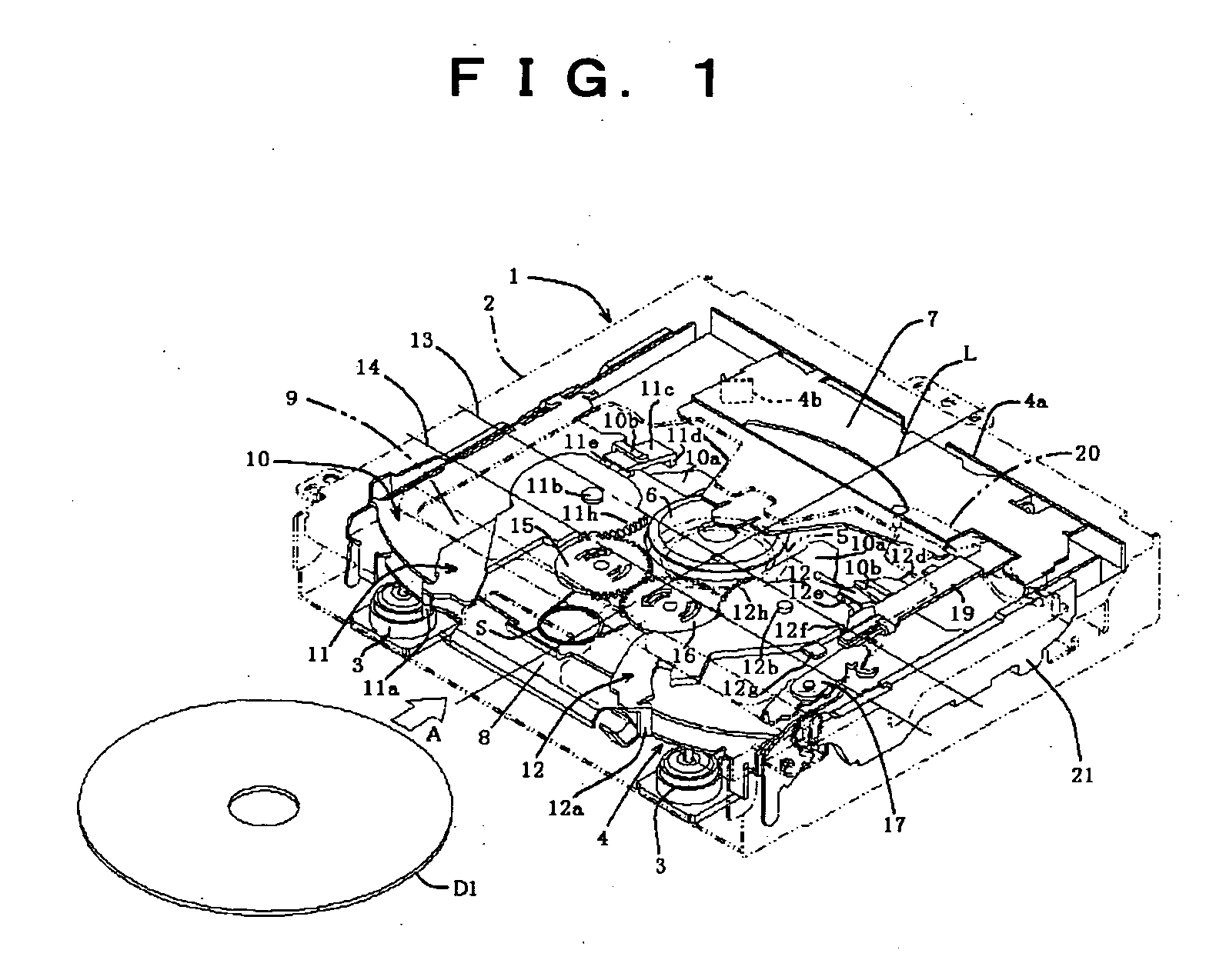

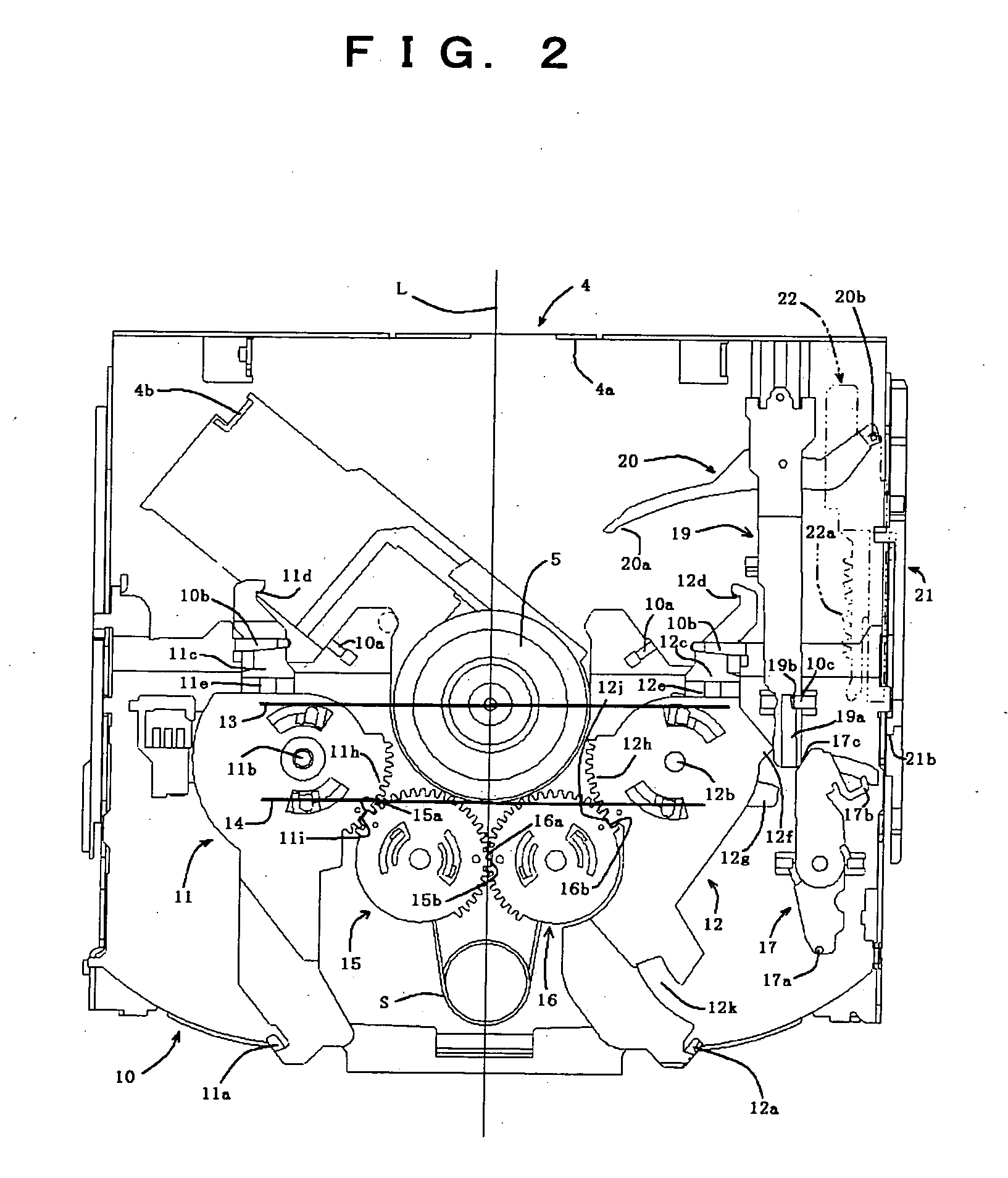

Disc centering device

InactiveUS20060242658A1Improve completenessAccelerate escapeRecord information storageCompact discMechanical engineering

Owner:TANASHIN DENKI CO

High-property flame-retardant PA6 (polyamide 6) alloy and preparation method thereof

ActiveCN104086991AImprove physical performanceImprove mechanical propertiesPolyamideMagnesium Sulfate whiskers

The invention relates to a high-property flame-retardant PA6 (polyamide 6) alloy and a preparation method thereof. The high-property flame-retardant PA6 alloy is prepared from the following components in parts by weight: 70-90 parts of PA6, 10-16 parts of treated basic magnesium sulfate whiskers, 1-5 parts of nanometer silicon dioxide and 0.2-0.5 part of antioxidants. The preparation method comprises the following steps: uniformly mixing the PA6, the treated basic magnesium sulfate whiskers and the nanometer silicon dioxide by using a double screw extruder, and granulating to obtain the product, namely the high-property flame-retardant PA6 alloy. PA6 has the advantages of excellent comprehensive property, good insulativity, abrasion resistance, oil resistance and better forming processing property and has bad physical property and flame-retardant property, so that the application of the PA6 in certain fields is limited. According to the high-property flame-retardant PA6 alloy disclosed by the invention, the treated basic magnesium sulfate whiskers and the nanometer silicon dioxide are innovatively added, so that the flame-retardant property and physical property of the PA6 alloy are enhanced, the application field of the material is greatly expanded, and very important practical significance is achieved.

Owner:HEFEI GENIUS NEW MATERIALS

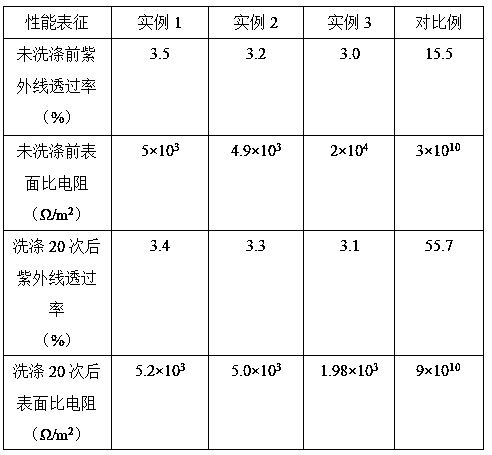

Preparation method of anti-ultraviolet anti-static fabric

InactiveCN109281179AImprove transmittanceImprove anti-staticFibre typesElectro-spinningFiberPolymer science

The invention relates to a preparation method of an anti-ultraviolet antistatic fabric, and belongs to the technical field of fabrics. A fiber membrane which is prepared by adding ATO powder and zincoxide into a polyvinyl alcohol solution as a spinning stock solution, the fiber membrane subjected to heat treatment is clamped between two layers of non-woven fabrics, and the fiber membrane and thenon-woven fabrics are bonded through heat treatment to form a non-woven fabric-nanofiber membrane- non-woven fabric sandwich material, a double-quaternary ammonium salt surfactant is arranged on the sandwich material by adopting a two-dipping and two-rolling finishing method so as to prepare the anti-ultraviolet anti-static fabric; the ATO powder is uniformly dispersed in the fabric to interact toform a conductive film, and electric charges in the conductive film can move to achieve high transmission rate and anti-static electricity; the anti-ultraviolet anti-static fabric disclosed by the invention has good anti-ultraviolet performance and anti-static performance, is excellent in washing resistance, and has a wide application prospect and a wide market prospect.

Owner:FOSHAN SENANG BIO TECH CO LTD

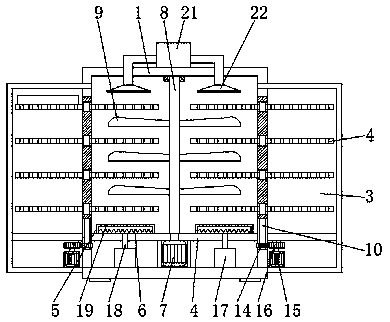

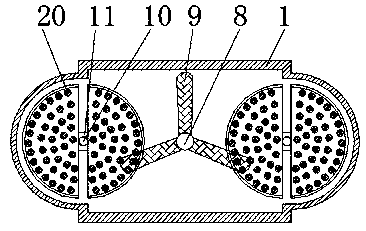

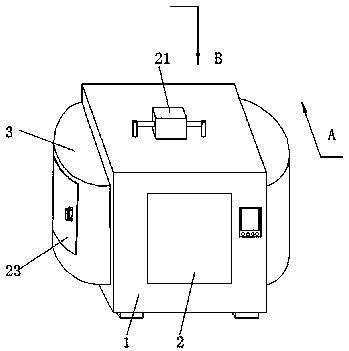

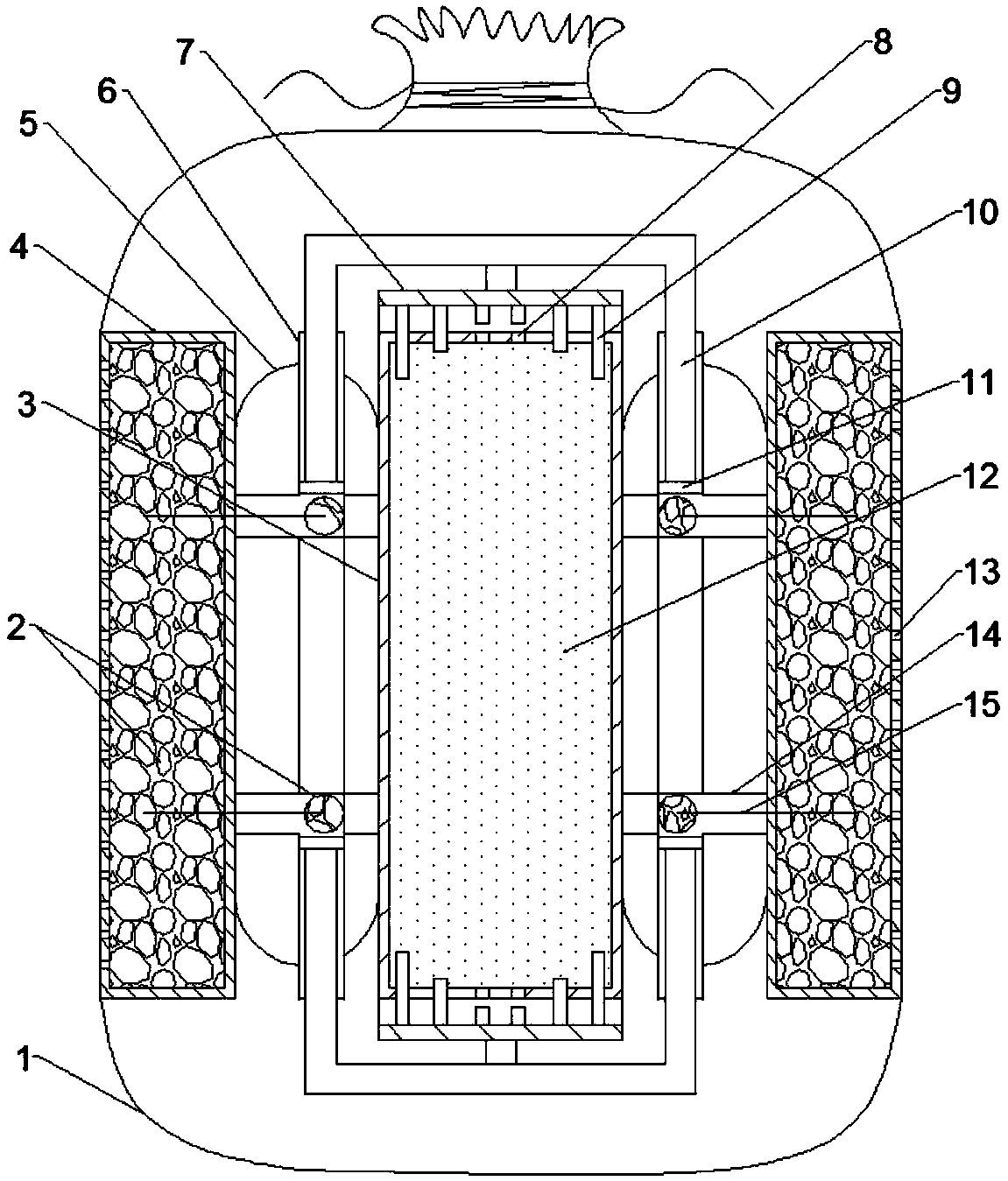

Drying device for producing and processing lithium battery

ActiveCN110986536APrevent fallingSmooth rotationDrying gas arrangementsDrying chambers/containersElectric machineFan blade

The invention discloses a drying device for producing and processing a lithium battery. The drying device comprises a drying box; a transparent observing window is arranged on the surface of the frontside of the drying box; arc-shaped expansion cavities are separately and integrally connected to two sides of the drying box; baffles are fixed to the lower end of the inner side of the drying box; heating covers are separately arranged on two sides of a part above the baffles; a heating wire is arranged on the inner side of each heating cover; a first motor is arranged below the baffles; an output shaft of the first motor penetrates through the baffles and is fixedly connected with a rotating shaft through a coupling; a plurality of air circulating auxiliary fan blades are sequentially fixedto the outer wall of the rotating shaft from top to bottom; driven shafts are rotationally connected between the arc-shaped expansion cavities and the drying box; lithium battery drying plates are fixedly mounted on the outer walls of the driven shafts through fixed blocks; a semi-circular accommodating groove is formed in each lithium battery drying plate; and the lithium battery drying plates are symmetrically distributed with the driven shafts as the center of symmetry. The drying device can be applied to drying of different kinds of lithium batteries, the drying uniformity of each lithiumbattery is high, the drying time is short, and the working efficiency can be effectively improved.

Owner:DONGGUAN UNIV OF TECH

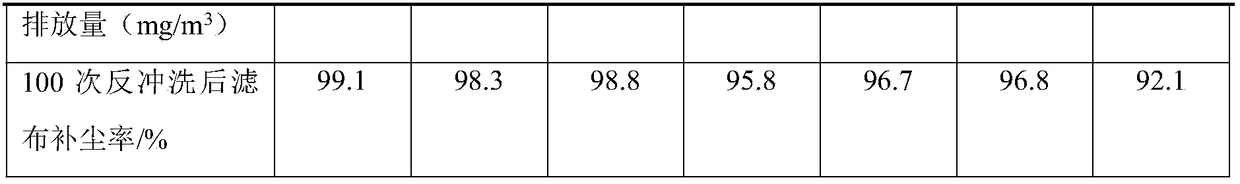

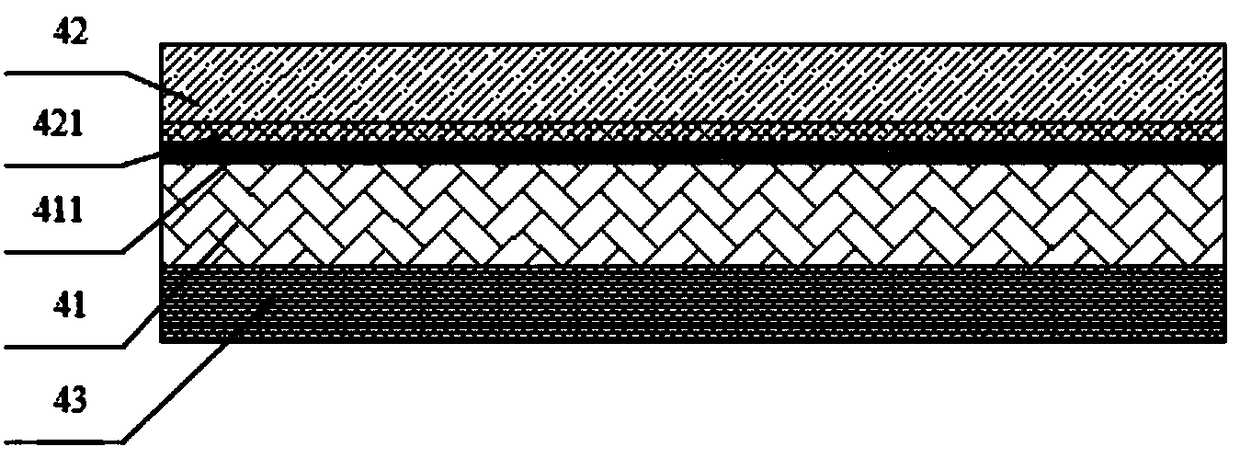

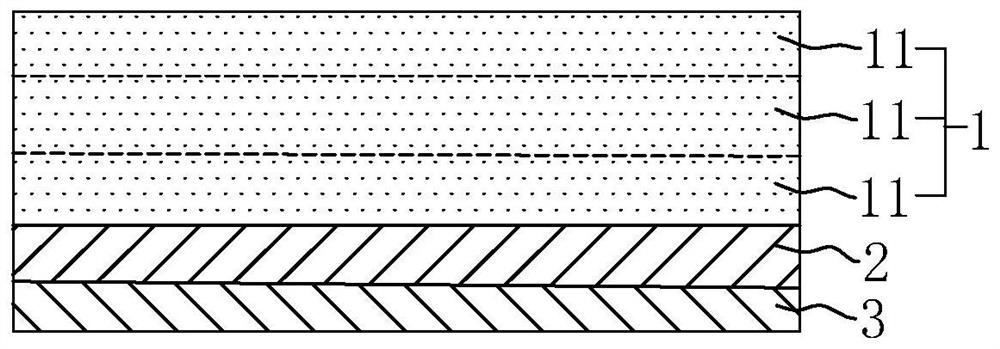

Dust-removing antistatic filter material and preparation method thereof

ActiveCN108379934AImprove conductivityReduce resistanceSynthetic resin layered productsMembrane filtersFiberPolyester

The invention provides a dust-removing antistatic filter material and a preparation method thereof. The dust-removing antistatic filter material comprises a base cloth layer and a wear-resistant layerand a dust receiving layer which are respectively arranged on two sides of the base cloth layer and is characterized in that the base cloth of the base cloth layer is woven by warps and wefts, the warps are woven by teflon fibers and glass fibers through twisting and strand combination, the wefts are woven by polyester fibers and metal conductive fibers through twisting and strand combination, the surface layer of the base cloth subjected to liquid soaking is sprayed with conductive metal powder, microwave solidification is performed, the wear-resistant layer is prepared by alkali-free glassfibers, the dust receiving layer is prepared by polyisophthaloyl metaphenylene diamine fibers, the dust receiving face of the dust receiving layer is provided with FMS needled felt through needling, and the back side of the dust receiving layer is subjected to mechanical raising. The dust-removing antistatic filter material is good in toughness and high temperature resistance, the filter materialformed by the base cloth, the wear-resistant layer and the dust receiving layer is evident in antistatic performance, the soaked bath cloth is subjected to microwave heat solidification, resin can beheated and solidified from inside to outside, uniform film forming on the surface of the fibers is achieved, and surface comprehensive performance is increased.

Owner:JIANGSU LINGFULONG ENVIRONMENTAL ENG CO LTD

Electromotor combined with pressure vessel

InactiveCN104300731AEasy to useImprove heat resistanceMechanical energy handlingSupports/enclosures/casingsEngineeringHigh pressure

The invention relates to an electromotor combined with a pressure vessel. The electromotor comprises an electromotor shell, a rotating shaft, a stator, a rotor, a shaft extension end cover, a non-shaft extension end cover, a terminal box, a terminal box cover, a terminal board and electric connection components, wherein the terminal board and the electric connection components are arranged in the terminal box, and connection components are arranged at the two ends of the electromotor shell. The electromotor is characterized in that a bearing hole in the non-extension shaft end cover does not penetrate through the outer end face, a shaft sleeve is fixed to the outer end face of the shaft extension end cover in a sealed mode, a flange is fixed to the other end of the shaft sleeve in a sealed mode, the shaft extension end of the rotating shaft penetrates through the shaft extension end cover and the shaft sleeve and extends out of the flange, sealing elements are arranged between the connection components of the shaft extension end cover, the non-shaft extension end cover and the electromotor shell, and a sealing element is arranged between the terminal board and the terminal box. The rotating shaft of the electromotor is used as the rotating shaft of a stirrer of the pressure vessel, the pressure in the pressure vessel shifts into the electromotor through the shaft sleeve, and the problem that the pressure vessel is difficult to seal is well solved through the good sealing performance of the electromotor shell and all the components. The electromotor is suitable for high-pressure operation environments.

Owner:荣成市先锋电机厂

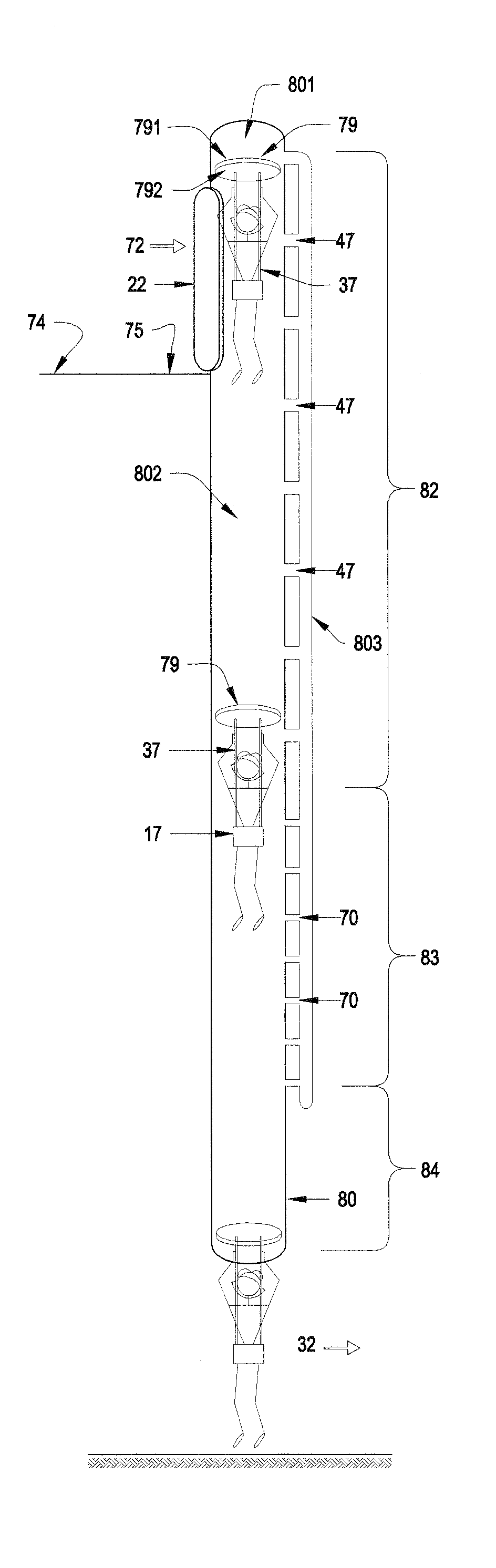

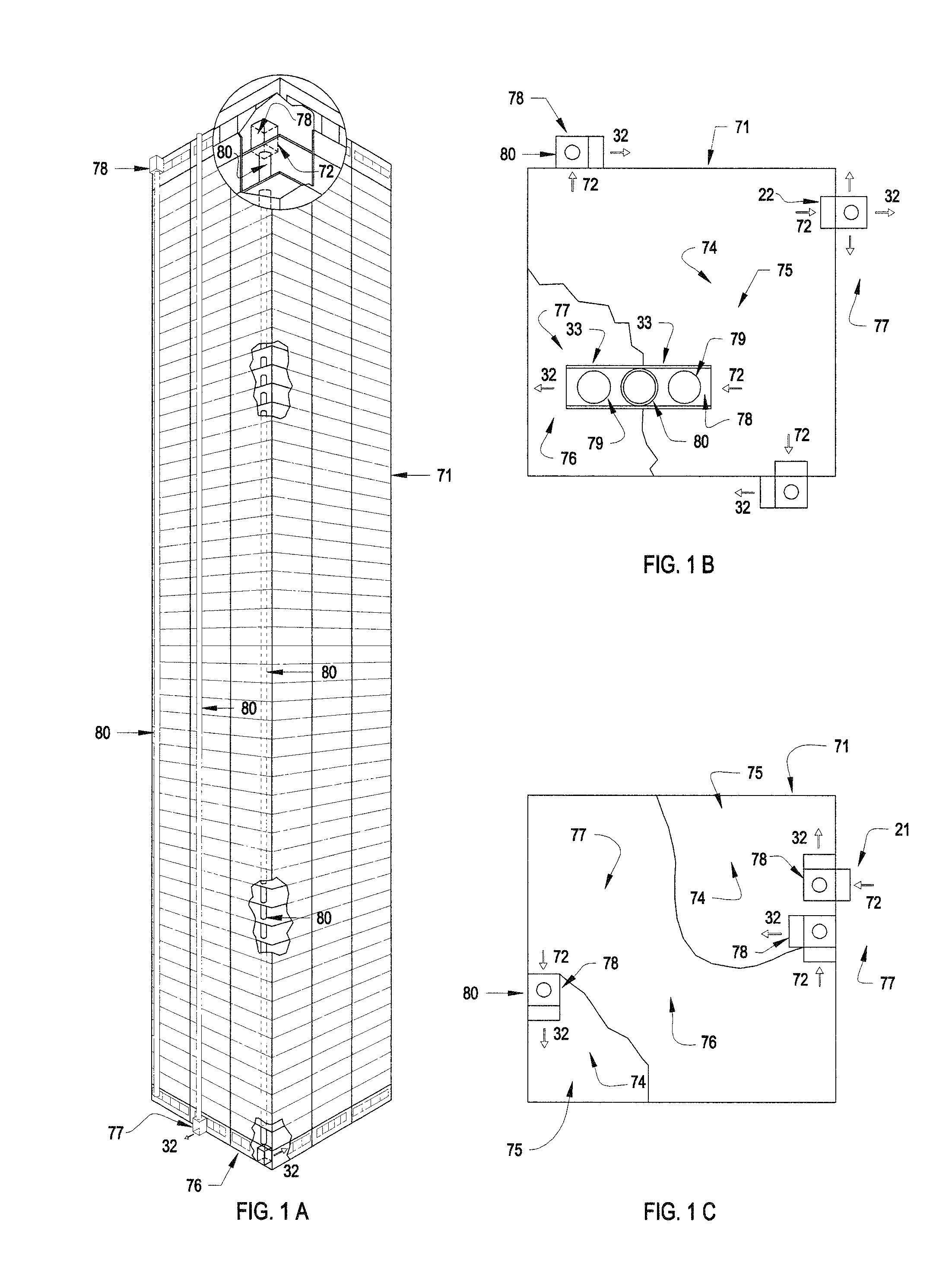

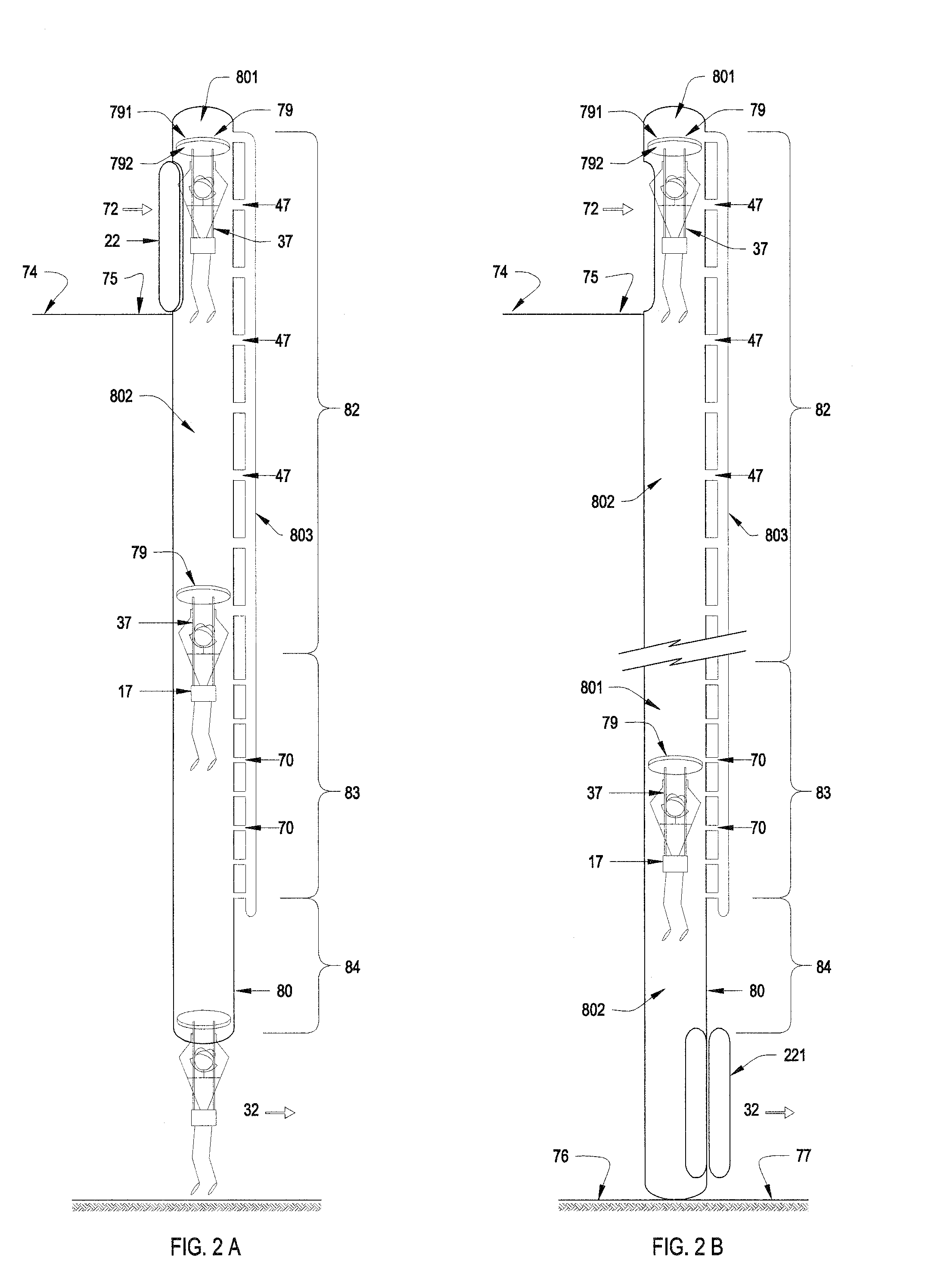

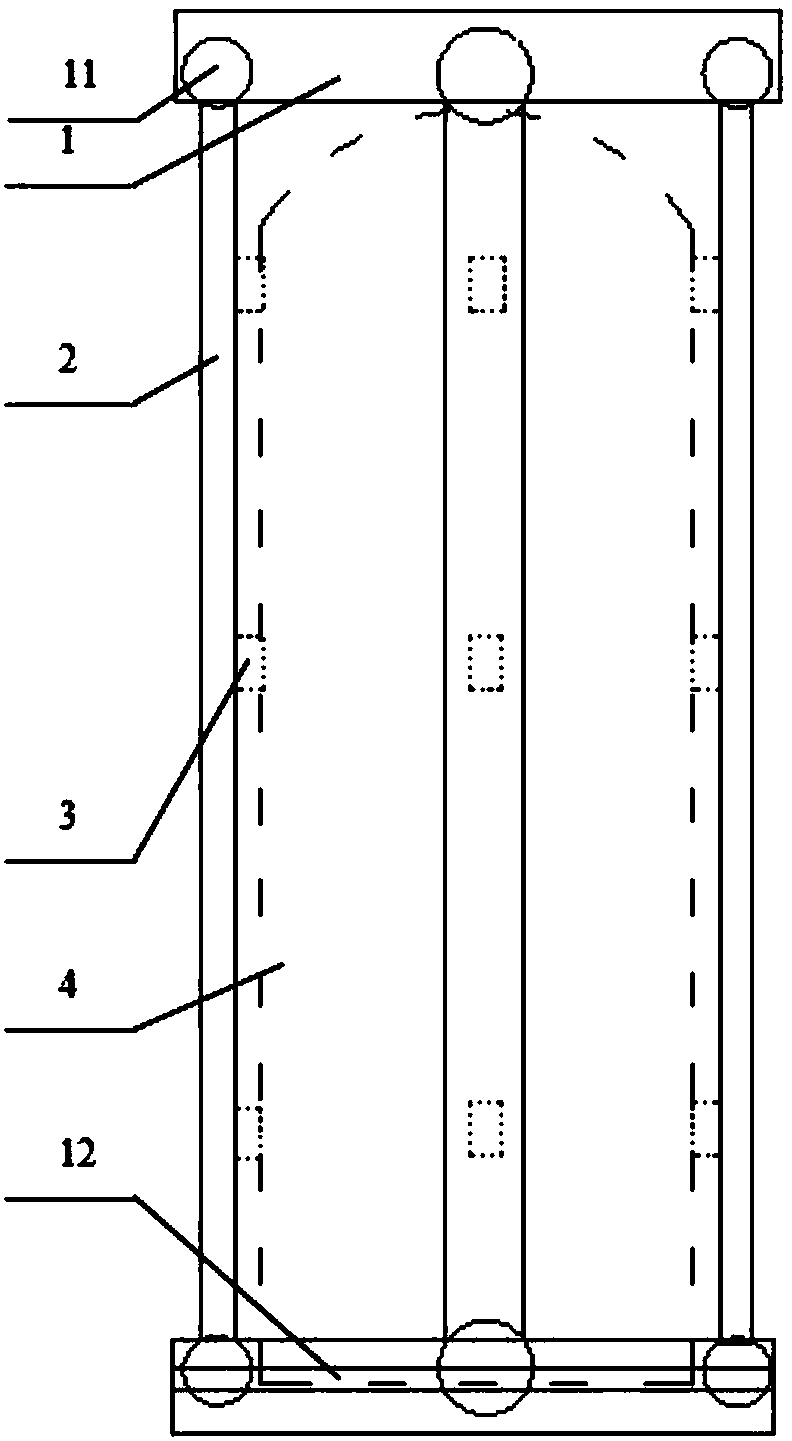

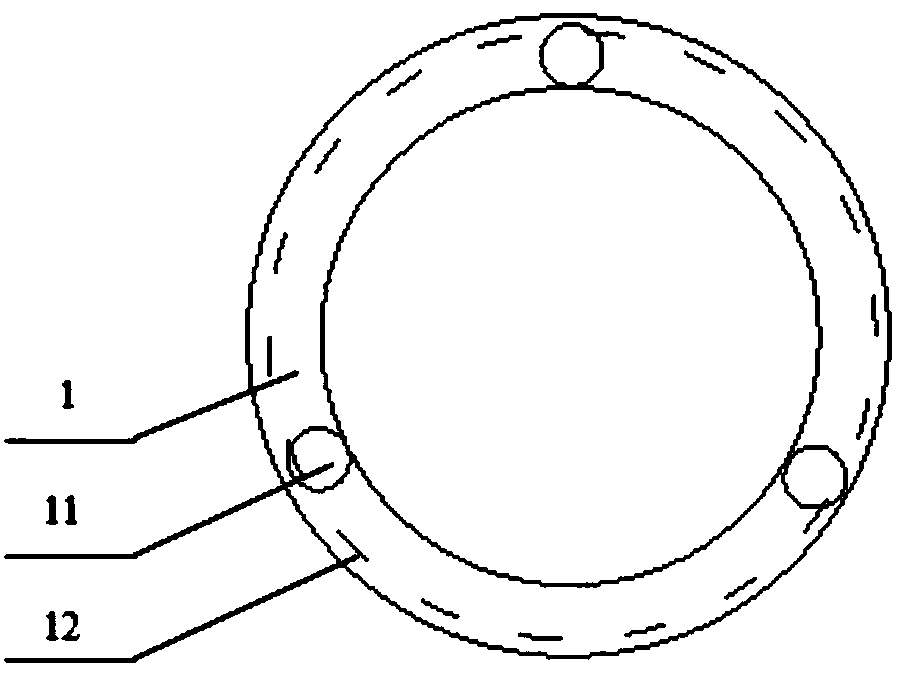

Multistory building fast escape and rescue device

InactiveUS8122999B2Easy to useFast resultsAircraft ejection meansSafety beltsVertical tubeFire evacuation

An escape and rescue device used in a multistory building during a terrorist threat or a fire to: a) evacuate a person or persons attached to an expandable disc support with an attachment that is lowered from an upper level of a building through a vertical tube, by using a lesser pressure at the top of the tube and a higher pressure at the bottom of the tube, using a door at the top or a door at the bottom to maintain pressure or by artificial air pressure, thereby permitting the fast evacuation of many people in a short time, b) it can be used by firemen in training in its use and benefits, c) also at amusement parks, where there would be a ride that would teach the users about its reliability and safety, and d) to transport firemen in a fast way from the ground to the upper floors without interfering with the evacuation in process at the congested stairways of the building.

Owner:GUILLERMETY MANUEL IVAN

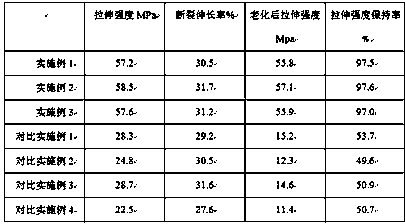

Method for preparing anti-aging plastic woven bag ribbon-like filament

InactiveCN110437524AImprove mechanical propertiesGood anti-ultraviolet aging performanceFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention discloses a method for preparing anti-aging plastic woven bag ribbon-like filaments and relates to the technical field of woven bags. The anti-aging plastic woven bag ribbon-like filament prepared by adding a self-made modified aluminum borate crystal whisker and a modified composite fiber has good mechanical properties, and meanwhile is excellent in ultraviolet aging resistance, andultraviolet aging tests show that the tension strength retention rate is up to 97%.

Owner:合肥卓汇新材料科技有限公司

Industrial dust removing device

ActiveCN108554010ASimple structureQuick installationDispersed particle filtrationFiltration separationSurface layerEngineering

The invention discloses an industrial dust removing device. The industrial dust removing device comprises a framework and a detachable filter bag mounted in the framework, wherein vibrating devices are arranged at two ends of the framework and connected through connecting rods; bumps in contact with the outer surface of the filter bag are arranged on the connecting rods; dust falls off timely since the filter bag is flapped by the bumps on the filter rod; the filter bag at least comprises a base fabric layer and a dust meeting layer; the base fabric layer and the dust meeting layer are connected by needling; after the base fabric layer is subjected to liquid immersion treatment, the surface of the base fabric layer is pre-coated to form a coating layer; one surface, connected with the basefabric layer, of the dust meeting layer, is subjected to gigging treatment; by precoating the surface layer of the base fabric layer with one coating layer, the defect of low dust removing efficiencyat an earlier stage of a novel filter material is overcome; one surface, connected with the base fabric layer, of the dust meeting layer, is mechanically gigged to form a layer of short threads for covering texture pores; when the filter material is back washed, a precoated coating layer powder flushed from the surface of the base fabric can be captured, so that effect loss of a precoated coatinglayer along with the increase of back wash times is avoided.

Owner:JIANGSU LINGFULONG ENVIRONMENTAL ENG CO LTD

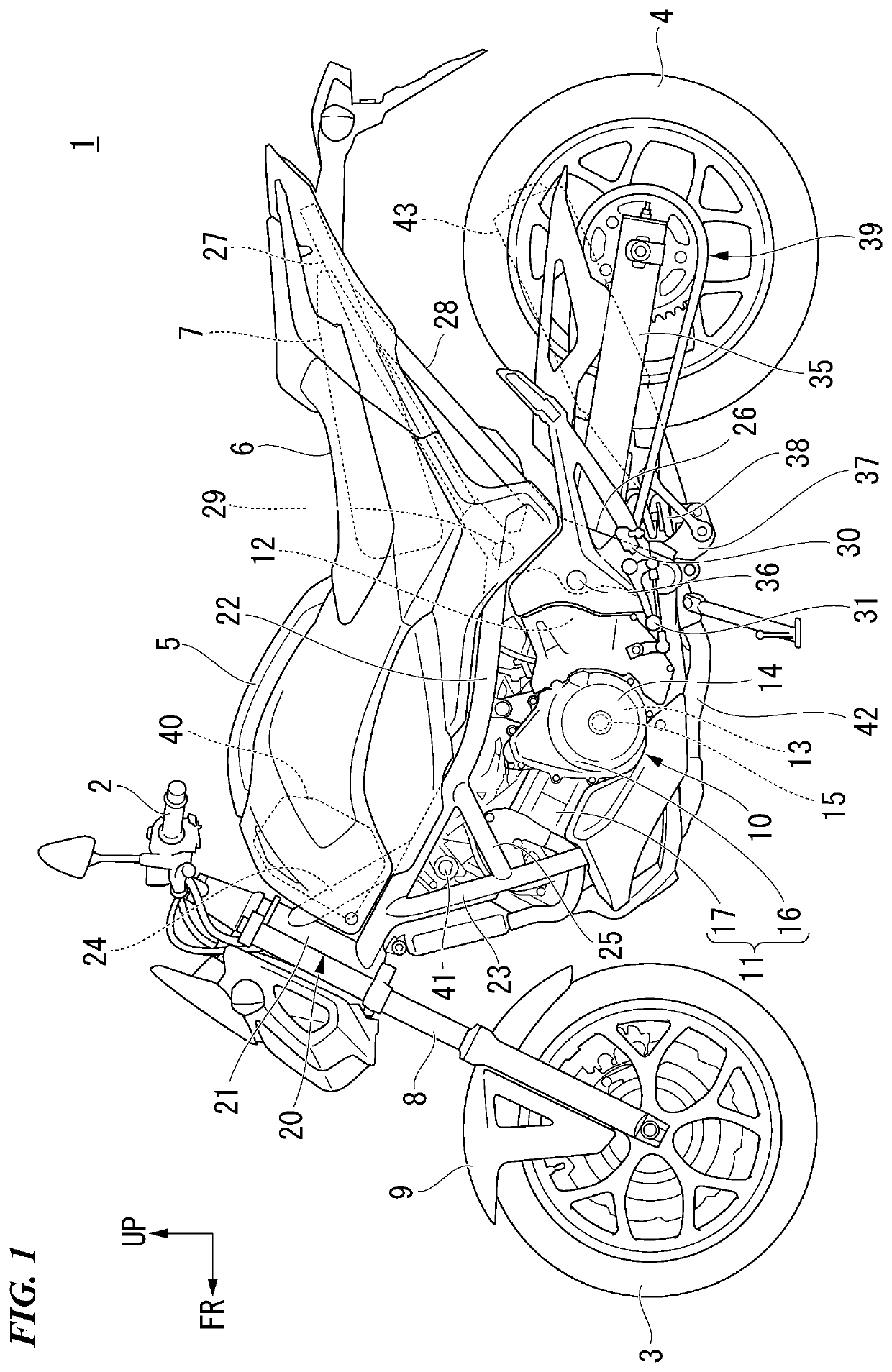

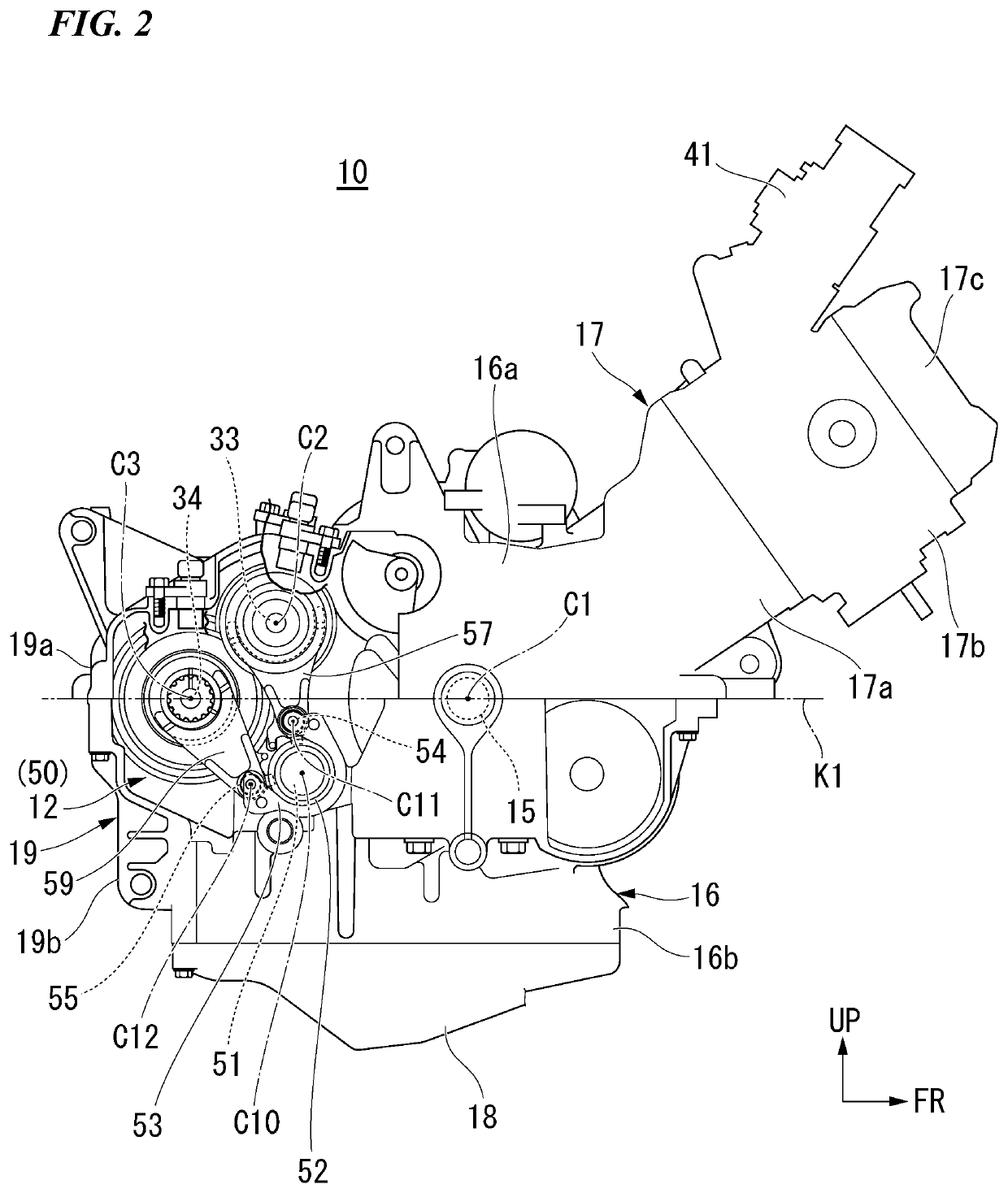

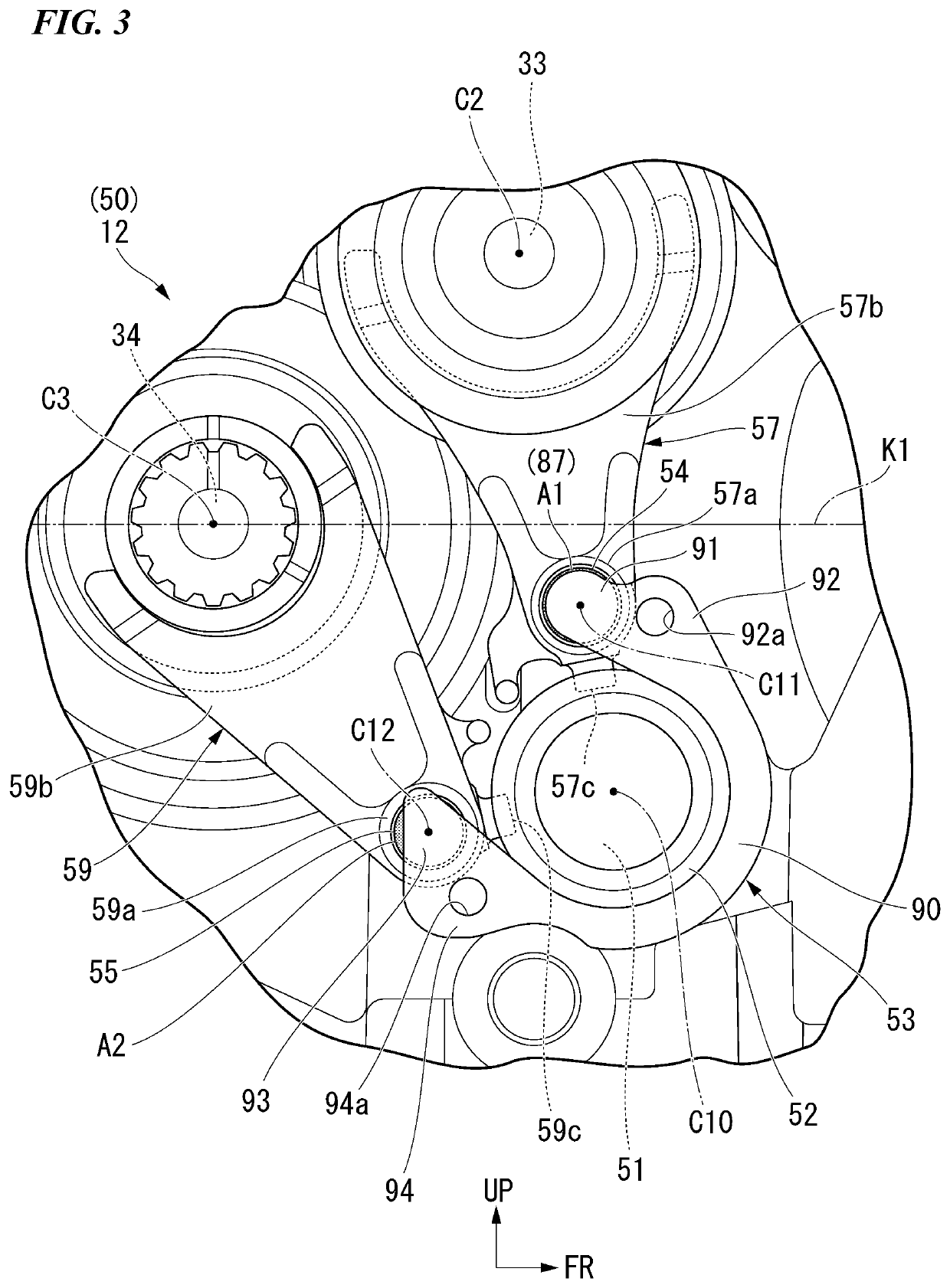

Vehicle transmission structure

ActiveUS20200200254A1Guaranteed uptimeReduce in quantityOperating means/releasing devices for valvesGear vibration/noise dampingStructural engineeringControl theory

A vehicle transmission structure of an embodiment includes a shift drum which rotates in accordance with a shift operation; a bearing member which rotatably supports the shift drum with respect to a transmission case; a set member which positions the bearing member; a shift fork shaft supported by the transmission case; and a shift fork supported by the shift fork shaft to be movable in an axial direction. An end portion of the shift fork shaft is movably fitted to an insertion hole provided in the transmission case, a cap is provided at an end portion of the shift fork shaft, a first gap is provided between an end surface of the insertion hole and the cap, the set member is disposed at a position overlapping the insertion hole when viewed in the axial direction, and a second gap is provided between an end surface of the insertion hole and the set member.

Owner:HONDA MOTOR CO LTD

Cross lapper

A cross lapper for laying a fleece from a card web includes a laying carriage movable transversely with respect to an output conveyor belt and an upper carriage as well as a plurality of card web belts to guide the card web over the upper carriage and the laying carriage into a laying nip formed at the laying carriage, wherein a belt inlet is formed at the upper carriage over which a card web transport belt is guided, which from a lower end of an inlet path extends in the direction towards the laying carriage and is accompanied in parallel in this portion by an upper section of a first, endless cover belt guided through the laying carriage, said cover belt enclosing the card web together with same up to the laying carriage. The card web transport belt returned from the laying carriage to the upper carriage leaves the laying carriage above the upper section of a second endless cover belt passed through the laying carriage. This second cover belt forms a baffle surface within the laying carriage above the laying nip and in juxtaposition thereof, said baffle surface ensuring a safe guidance of the card web into the laying nip also case of higher card web transport speeds.

Owner:DILO MASCHINENFABRIK KG

Secretly-made perfume satchel

InactiveCN108272928AWith elastic deformation propertiesEasy to shapeBiocidePowder deliveryFlavorAcorus calamus

The invention discloses a secretly-made perfume satchel in the technical field of perfume satchels. The perfume satchel comprises a satchel body and raw materials; and the raw materials of the perfumeconsist of folium artemisiae argyi, flos caryophyllata, mint, calamus, perilla leaves and wrinkled gianthyssop herb. The secretly-made perfume satchel provided by the invention has the effects of dispersing mosquitoes and cooling and refreshing consciousness besides the effects of traditional perfume.

Owner:重庆正刚中医骨科医院有限公司

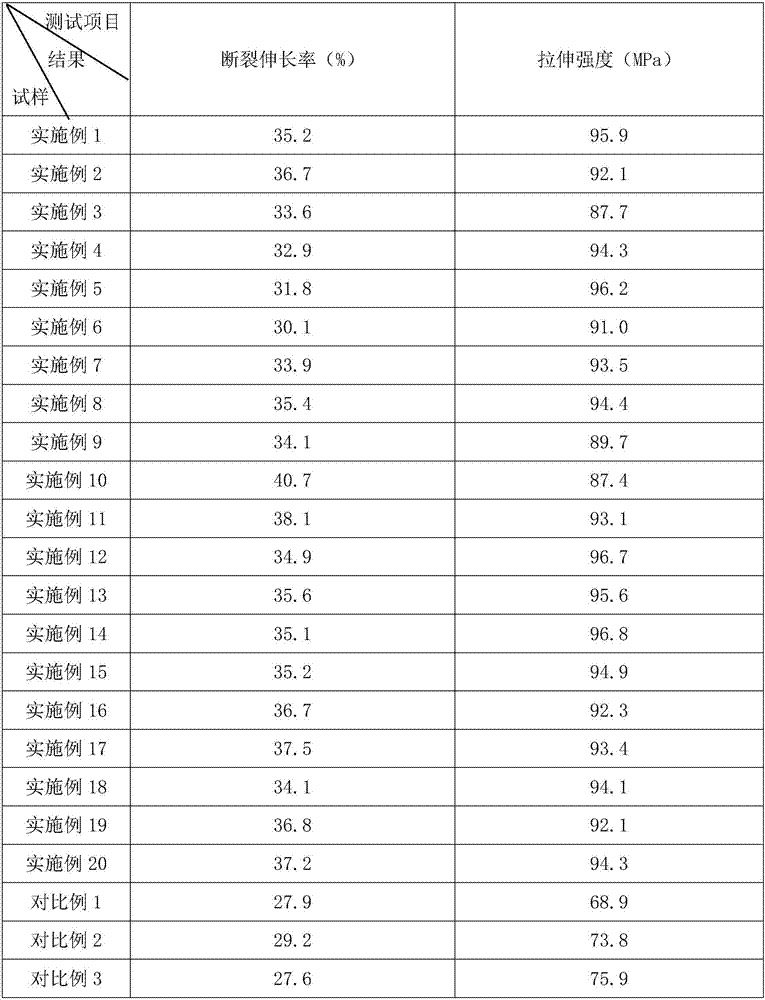

A kind of high-performance flame-retardant PA6 alloy and preparation method thereof

The invention relates to a high-performance flame-retardant nylon 6 alloy and a preparation method thereof, which is made of the following components by weight: 70-90 parts of PA6, 10-16 parts of treated basic magnesium sulfate whiskers, 1-5 parts of nano silicon dioxide, 0.2-0.5 parts of antioxidant. Use a twin-screw extruder to uniformly mix PA6, treated basic magnesium sulfate, and nano-silicon dioxide, and granulate to obtain the product. PA6 has excellent comprehensive performance, good insulation, wear resistance, oil resistance, and better molding performance, but some of its physical properties and flame retardancy are not good, which greatly limits its application in some fields. The innovative addition of treated basic magnesium sulfate whiskers and nano silicon dioxide in the invention improves the flame retardancy and physical properties of the PA6 alloy, which greatly expands the application field of the material and has very important practical significance.

Owner:HEFEI GENIUS NEW MATERIALS

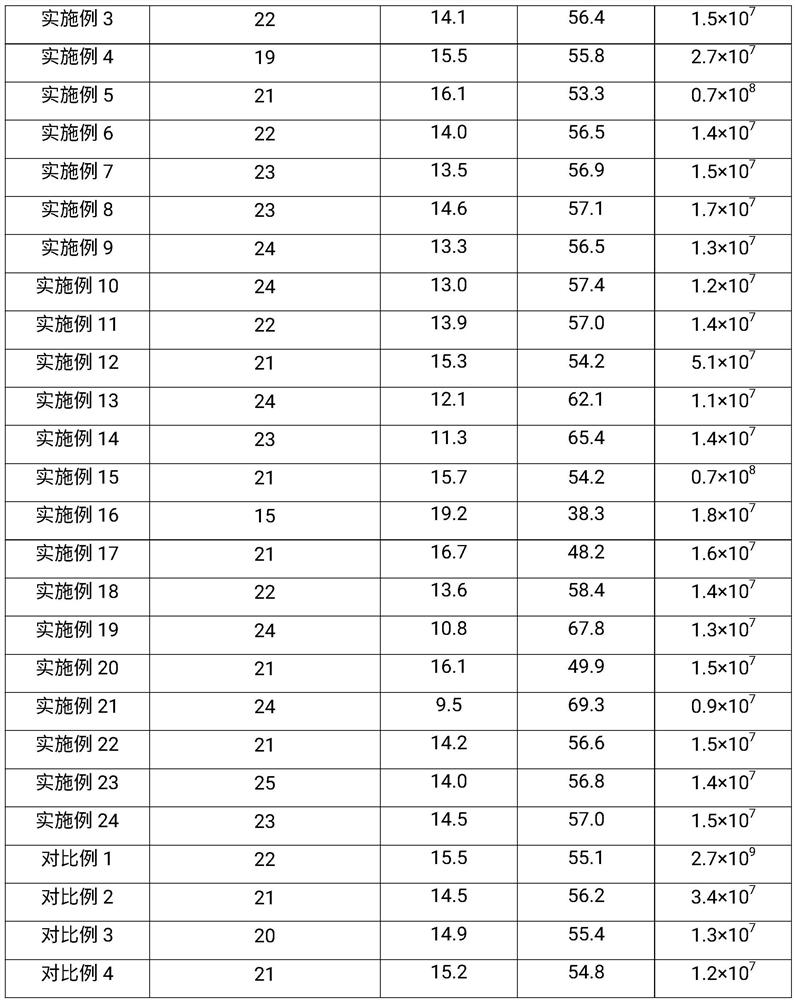

Antistatic protective clothing fabric and preparation method thereof

InactiveCN111746057AAccelerate escapeImprove absorption efficiencySynthetic resin layered productsLaminationThin membraneElectrically conductive

The invention relates to the technical field of protective clothing. The invention discloses an antistatic protective clothing fabric which comprises a non-woven fabric base layer, a partition layer and a thin film layer from inside to outside, wherein the non-woven material base layer comprises a plurality of layers of non-woven fabrics which are bonded with one another, an antistatic agent is attached to the non-woven material base layer, the partition layer is formed by interweaving blended yarns and organic conductive fibers, the content of the organic conductive fibers in the partition layer is 0.5%-1.3%, and the thin film layer is a TPEE breathable film. The preparation method comprises the following steps: S1, preparing the non-woven material base layer and the partition layer; S2,carrying out intermediate treatment of a non-woven material base layer; and S3, carrying out protective clothing cloth synthesis treatment. According to the antistatic protective clothing fabric, theantistatic effect can be improved, and the situation that static electricity is generated by friction between protective clothing and other objects and affects electronic equipment is avoided.

Owner:东莞市天鸿纺织品有限公司

Inlet support structure for a tension acting rupture disc

ActiveUS10100942B2Quickly and easily flowQuickly relieve pressureEqualizing valvesSafety valvesEngineeringRupture disc

An inlet support structure for use with a rupture disc, the inlet support structure including an annular member having an inner diameter, an outer diameter, a plurality of spaced apart cut-outs extending from the inner diameter towards the outer diameter, a central non-circular opening extending through the annular member and including the cut-outs, the cut-outs providing additional space for the petals of a rupture disc to be received therein when the rupture disc ruptures so as to provide a greater flow area through the rupture disc.

Owner:CONTINENTAL DISC CORP

Manufacturing method of water-repellent flame-retardant hook-and-loop fastener

InactiveCN111877002AAccelerate diasporaReduce electrostatic effectHeat resistant fibresDry-cleaning apparatus for textilesMetal meshProcess engineering

The invention provides a manufacturing method of a water-repellent flame-retardant hook-and-loop fastener. The manufacturing method comprises the following specific steps of weaving a nylon hook-and-loop fastener according to the arrangement rule that one silver-plated nylon bottom yarn is arranged every 6-9 common nylon bottom yarns; cleaning the hook-and-loop fastener; sequentially performing flame-retardant finishing and water-repellent finishing on the nylon hook-and-loop fastener; performing resin finishing on the nylon hook-and-loop fastener; performing anti-static finishing on the nylonhook-and-loop fastener subjected to resin finishing; and dehydrating the nylon hook-and-loop fastener in a dehydrator. When the hook-and-loop fastener prepared by the method is used in an extreme environment, the electrostatic effect is reduced by a metal net formed by the silver-plated bottom yarns and the fine titanium dioxide added in resin finishing. In addition, an antistatic agent is used for finishing, so that static electricity generation is reduced, static electricity dissipation is accelerated, the static effect is reduced, and the fabric is suitable for flammable and combustible environments. Through flame-retardant finishing and water-repellent finishing, the flame-retardant performance and the water-repellent performance of the fabric are improved respectively, so that the fabric is suitable for high-temperature, high-humidity or soaking environments.

Owner:天津兴华织造有限公司

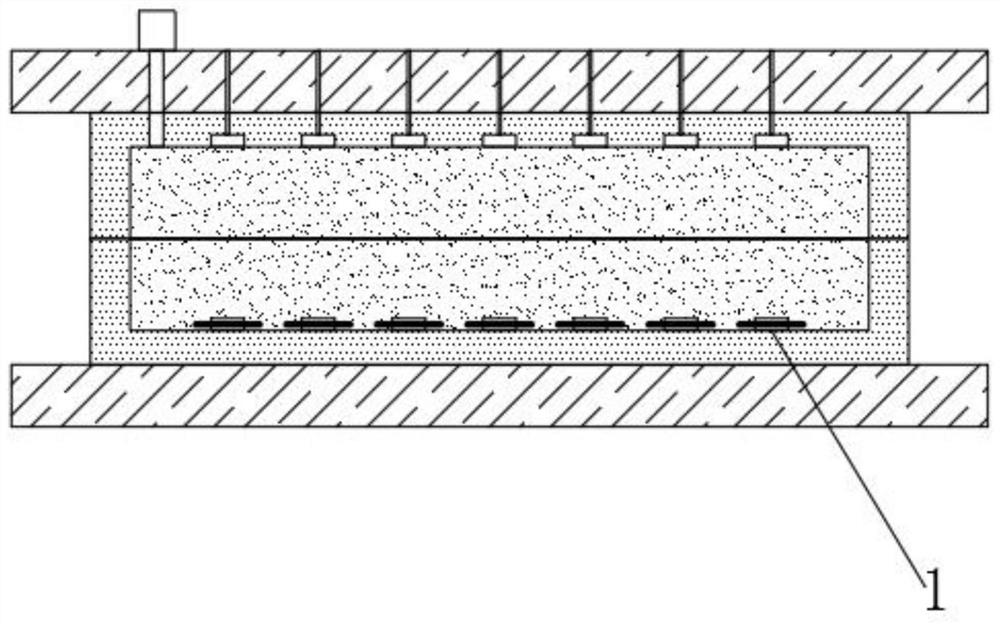

Pore-free aluminum alloy casting process

The invention discloses a pore-free aluminum alloy casting process, and belongs to the technical field of casting. According to the pore-free aluminum alloy casting process provided by the invention,the deformation expansion actions of composite degassing discs can be triggered by utilizing heat after an aluminum alloy melt is poured in a mode of presetting a plurality of composite degassing discs and containing grooves through a casting mold; a magnetic field is applied above the casting mold, so that the composite degassing discs in the casting mold are forced to move upwards; bubbles existing in the aluminum alloy melt are broken in the moving process, so that gas is forced to escape upwards along with the upward movement of the composite degassing discs and is finally exhausted through gas flow channels communicating with the containing grooves; and the composite degassing discs automatically restore to the initial shapes after exhausting is finished, and the composite degassing discs and the containing grooves reserved on the casting mold are combined to jointly form a cavity, so that forming of an aluminum alloy is not interfered, the casting defects such as air holes, shrinkage cavities and shrinkage porosity can be obviously overcome, a high-density casting is obtained, and the forming performance is greatly improved.

Owner:TIANHEXING METAL & PLASTIC SHENZHEN CO LTD

A kind of reinforced plastic woven bag material

The invention discloses a material for a reinforced plastic woven bag. The material is characterized by being prepared from the following raw materials in parts by weight: 100 parts of isotactic polypropylene, 18 to 30 parts of low density polyethylene, 3.2 to 5.4 parts of molybdenum disulfide, 0.8 to 1.2 parts of an antioxidant, 2 to 4 parts of an ultraviolet absorbent, 6 to 12 parts of talcum powder, 0.01 to 0.2 part of pimelic acid, 0.4 to 1.2 parts of stearate and 2 to 10 parts of calcium carbonate whiskers, wherein stearate comprises calcium stearate. The material has the advantages of high tensile strength and high toughness.

Owner:浙江海威包装有限公司

A kind of perfume bottle with temperature control function and control method

ActiveCN108158189BPlay a limiting roleAccelerate escapePackaging toiletriesPackaging cosmeticsTemperature controlControl engineering

Owner:嘉兴考普诺机械科技有限公司

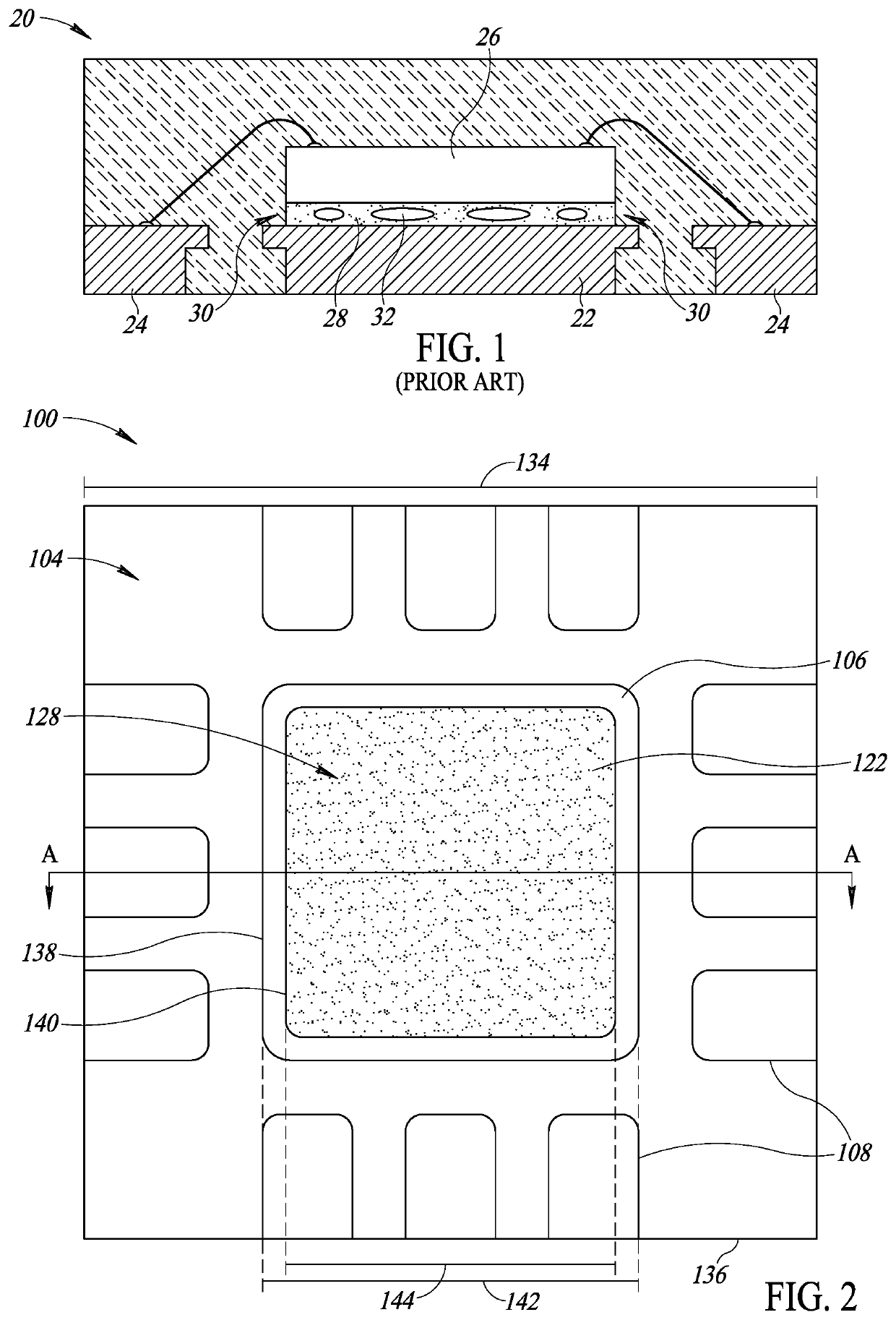

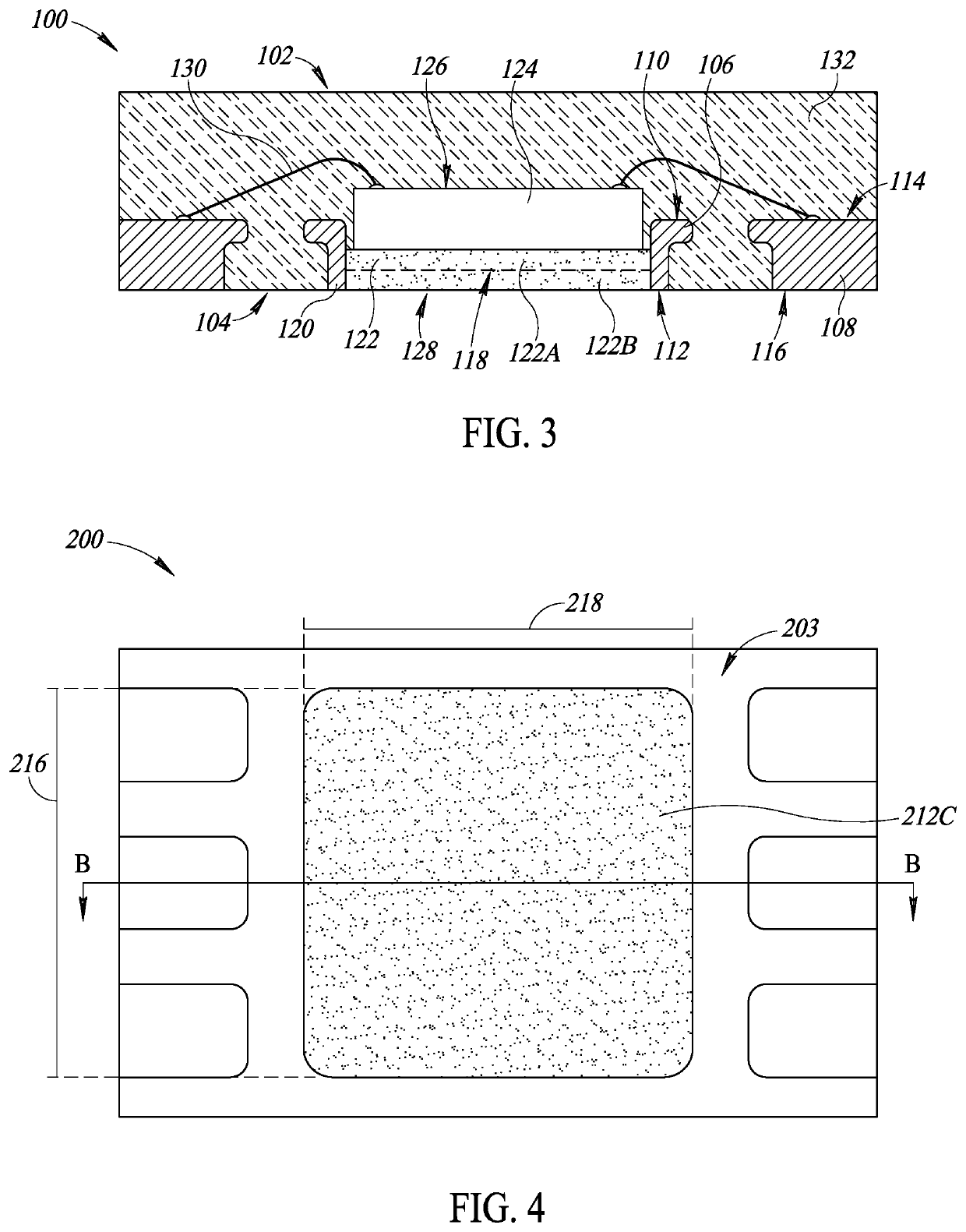

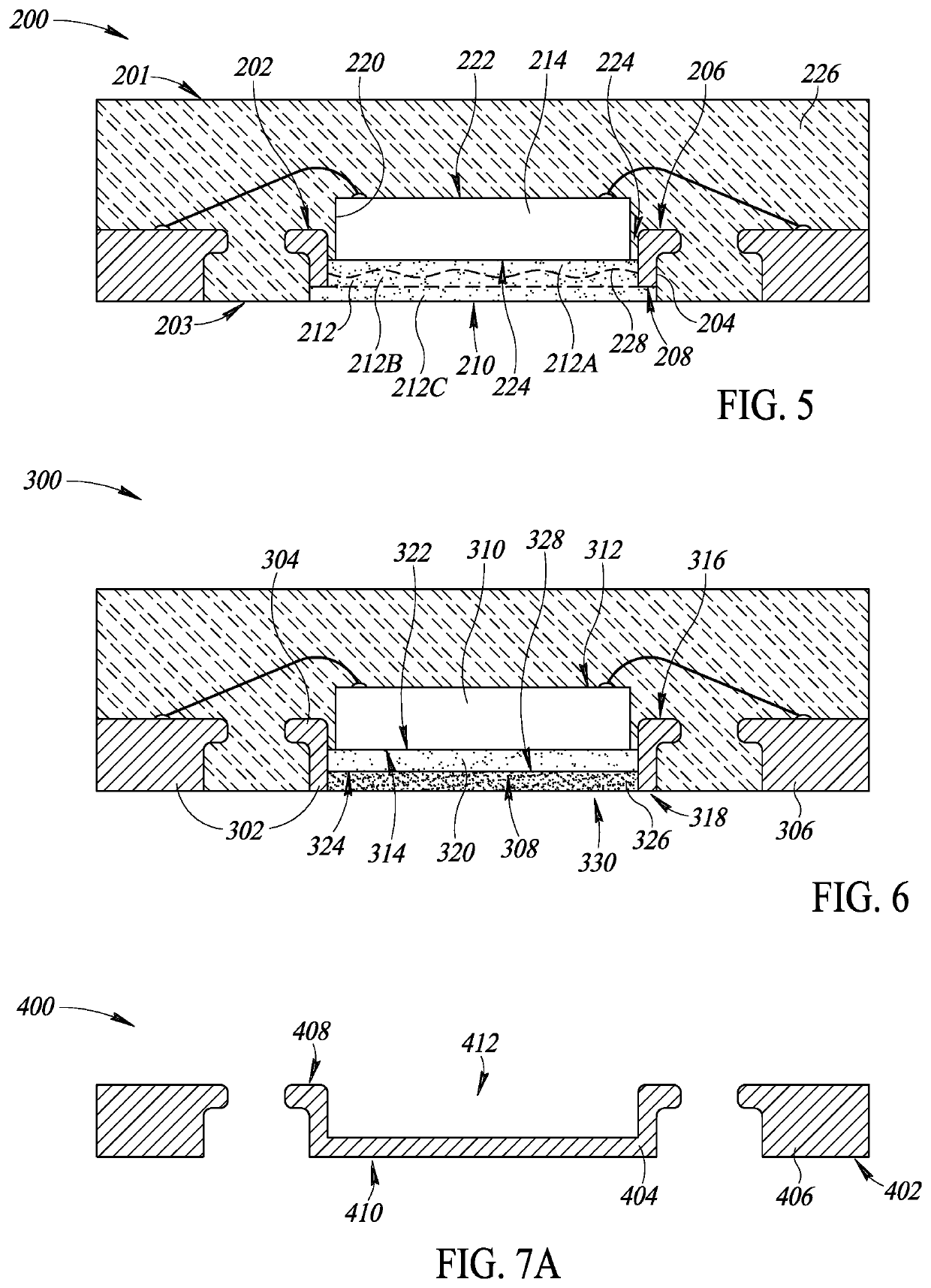

Semiconductor package with a cavity in a die pad for reducing voids in the solder

ActiveUS11133241B2Strong physical and electrical connectionFirmly connectedElectrically conductive connectionsSemiconductor/solid-state device detailsSemiconductor packageMechanical engineering

A semiconductor package having an aperture in a die pad and solder in the aperture coplanar with a surface of the package is disclosed. The package includes a die pad, a plurality of leads, and a semiconductor die coupled to the die pad with a die attach material. A cavity or aperture is formed through the die pad to expose a portion of the die attach material. Multiple solder reflows are performed to reduce the presence of voids in the die attach material. In a first solder reflow, the voids of trapped gas that form when attaching the die to the die pad are released. Then, in a second solder reflow, solder is added to the aperture coplanar with a surface of the die pad. The additional solder can be the same material as the die attach material or a different material.

Owner:STMICROELECTRONICS SRL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com