Electromotor combined with pressure vessel

A pressure vessel and motor technology, applied in the field of motors, can solve problems such as pressure vessel sealing difficulties, achieve the effects of accelerating heat dissipation, reasonable structural design, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

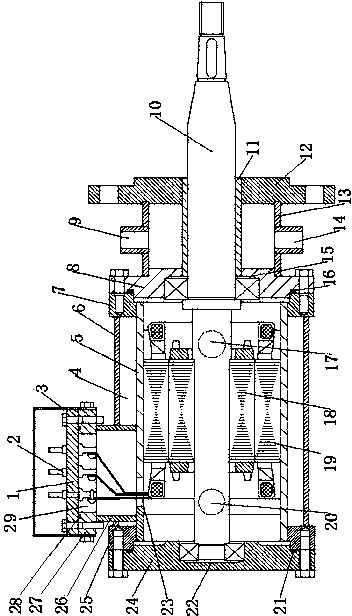

[0012] exist figure 1 Among them, a motor used in conjunction with a pressure vessel, which includes a casing 5, a rotating shaft 10, a stator 19, a rotor 18, a shaft end cover 8, a non-shaft end cover 24, a junction box 27, a junction box cover 3 and wiring Board 1 and electrical connection part 2. Among them, the stator 19 is assembled in the casing 5 and is composed of a conventional stator core and stator windings; the rotor 18 is assembled on the rotating shaft 10 and is composed of a conventional rotor core and rotor windings; the junction box 27 is arranged outside the casing 5 ; The junction box cover 3 is matched with the junction box 27 in a conventional manner; In order to increase the sealing performance between parts, such as figure 1 As shown, a second seal 28 is provided between the terminal block 1 and the terminal box 27 .

[0013] exist figure 1 Among them, connecting parts are respectively provided at both ends of the casing 5 . The connecting part may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com