Patents

Literature

34results about How to "Solve sealing difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

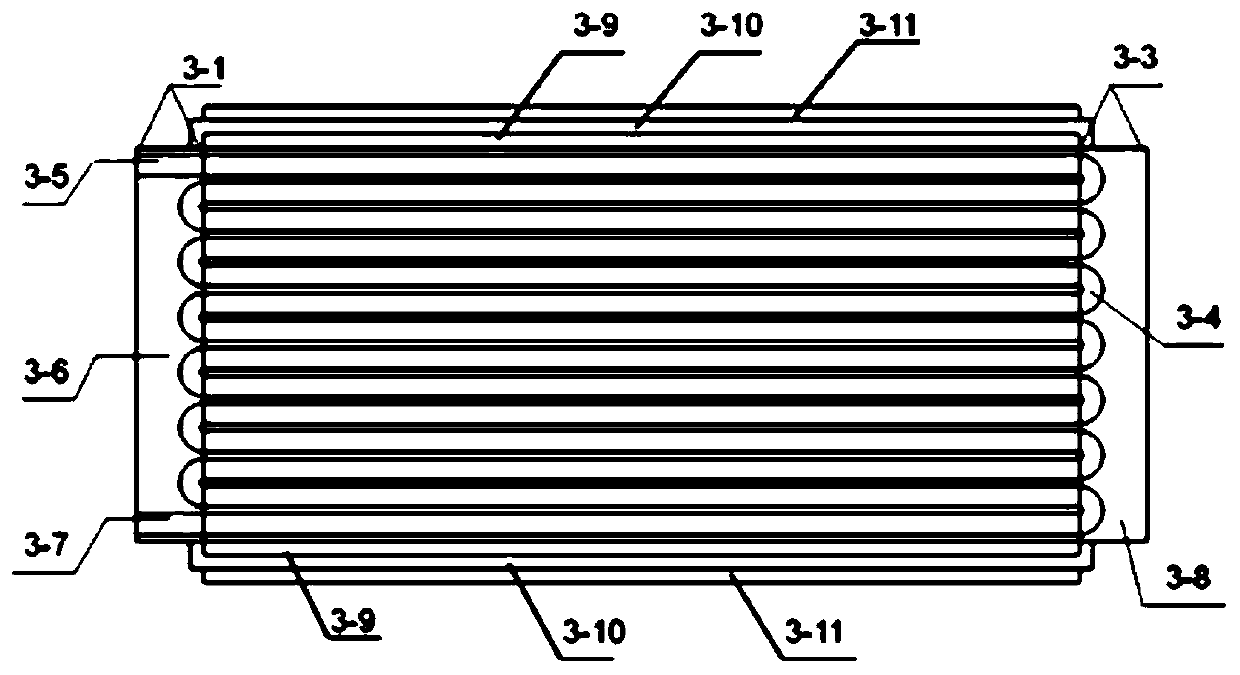

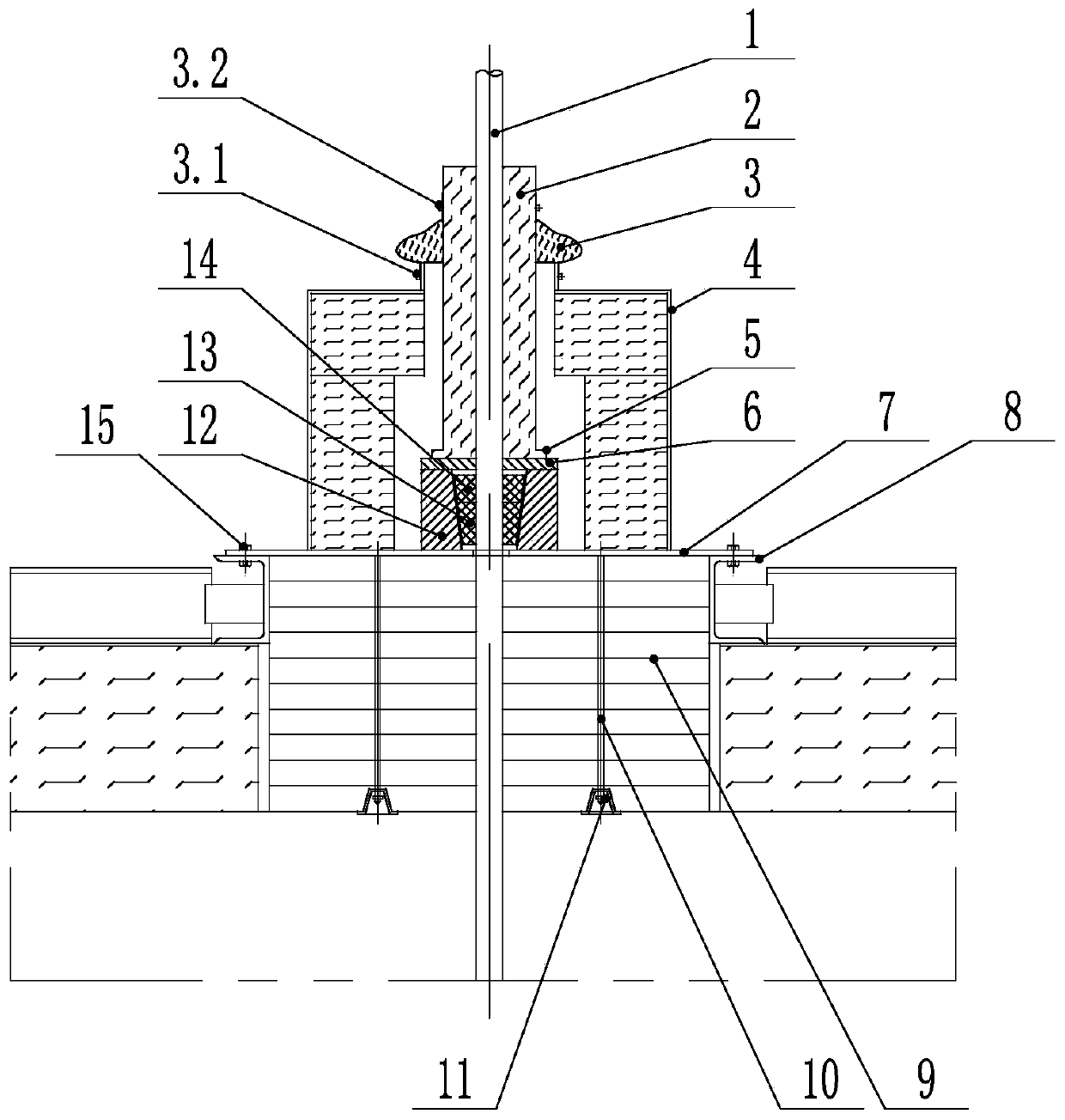

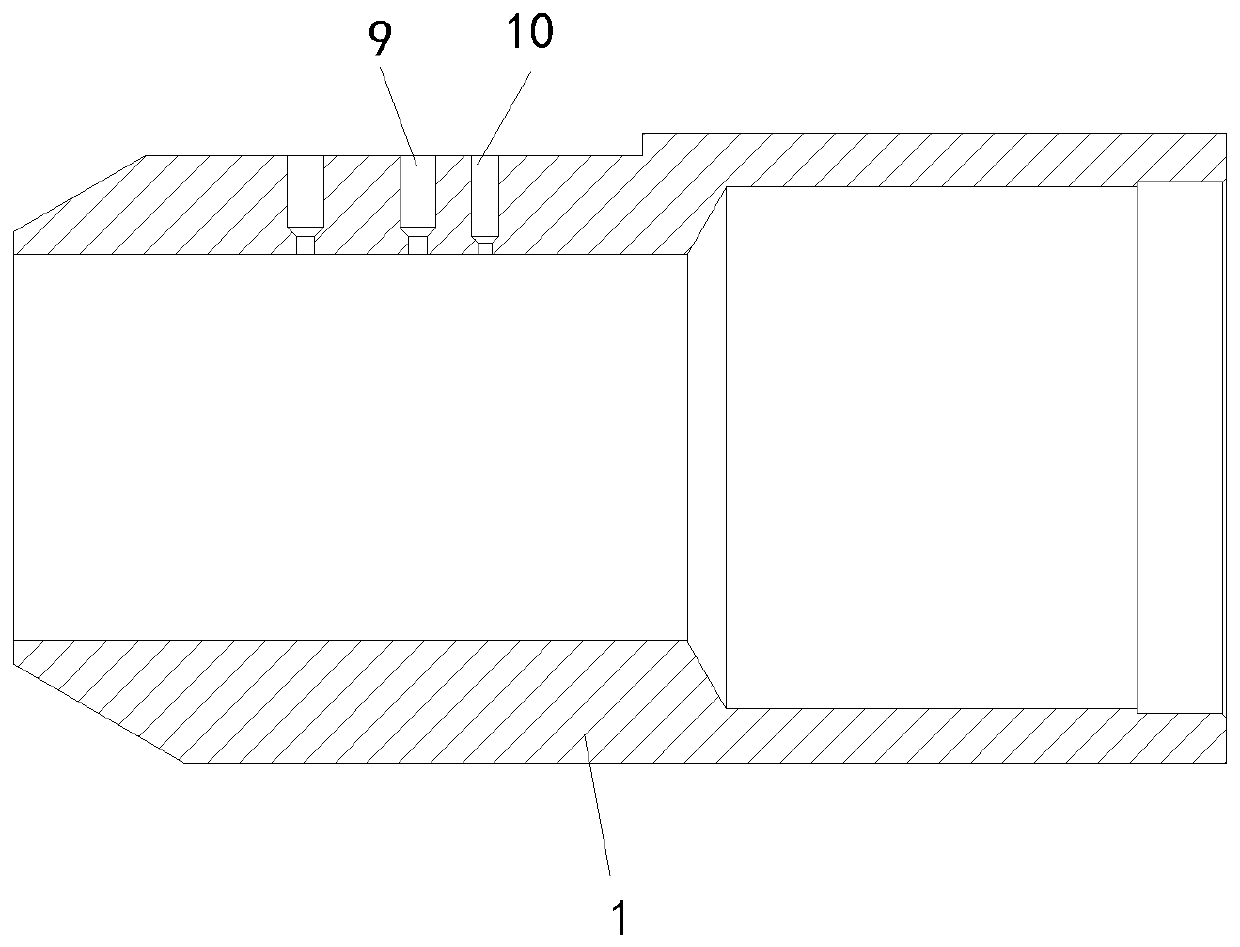

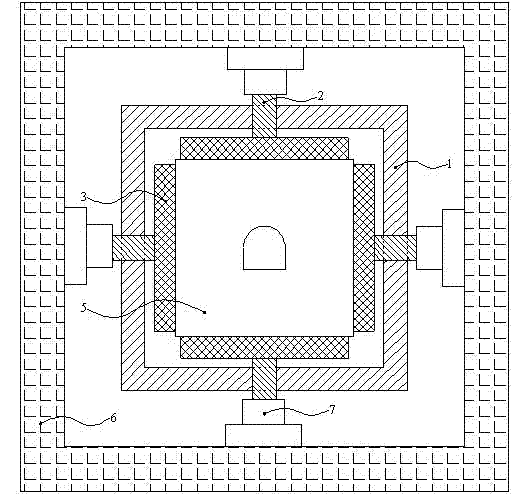

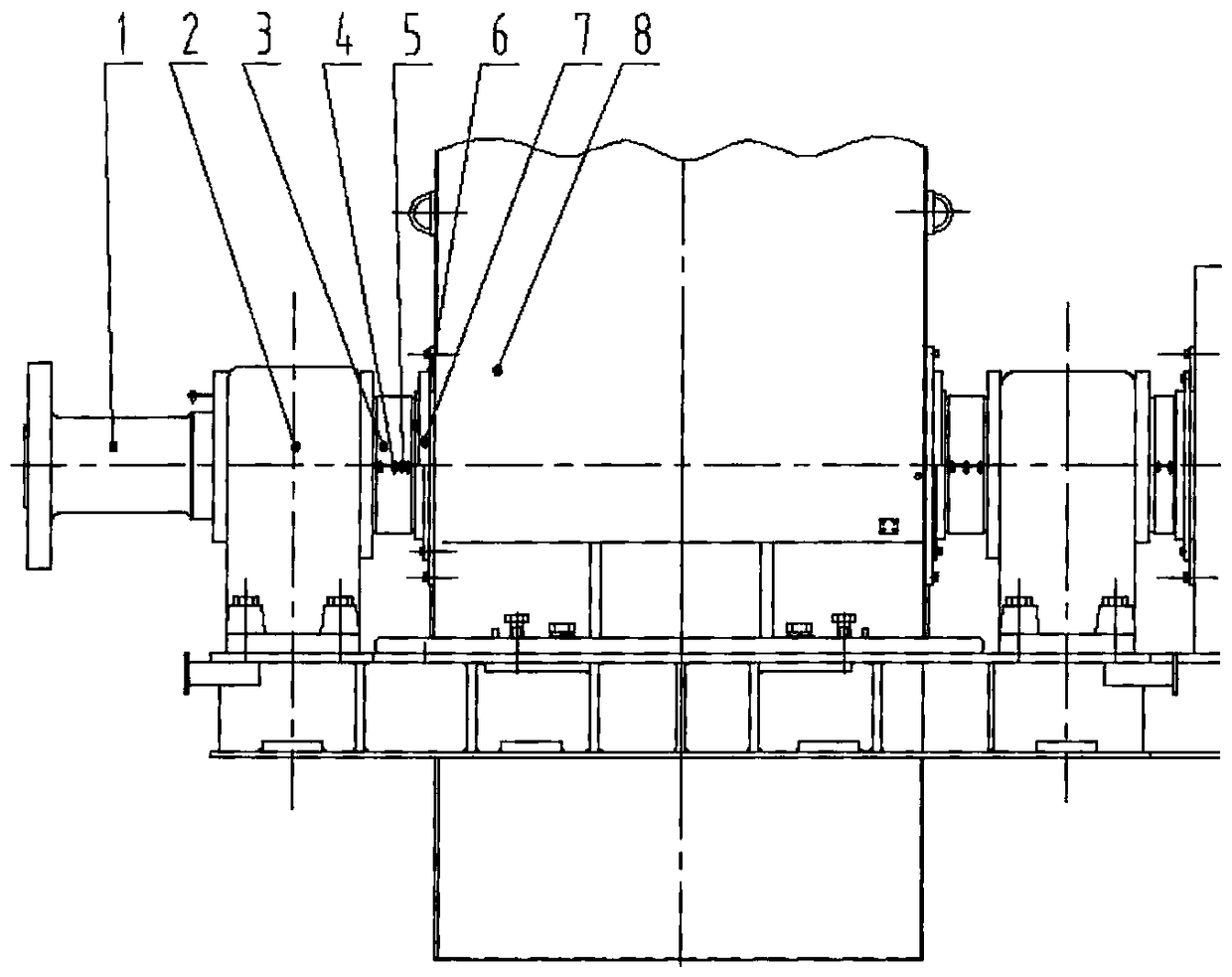

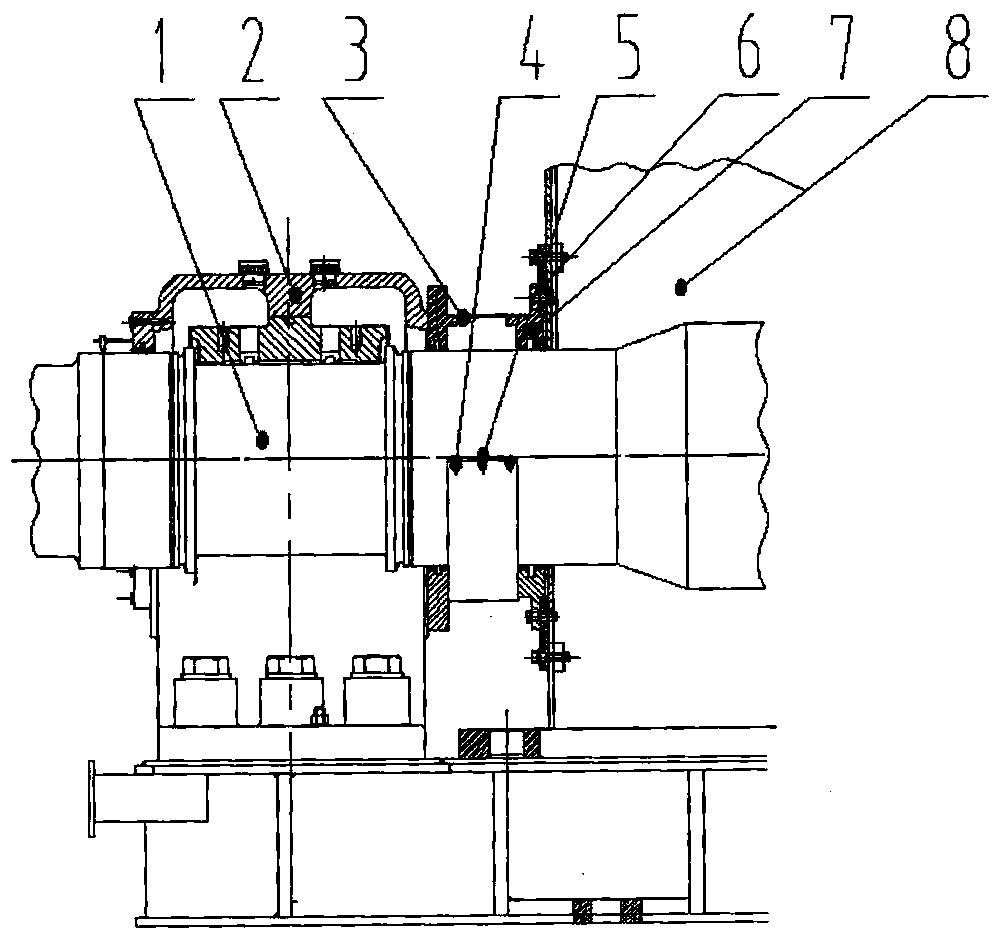

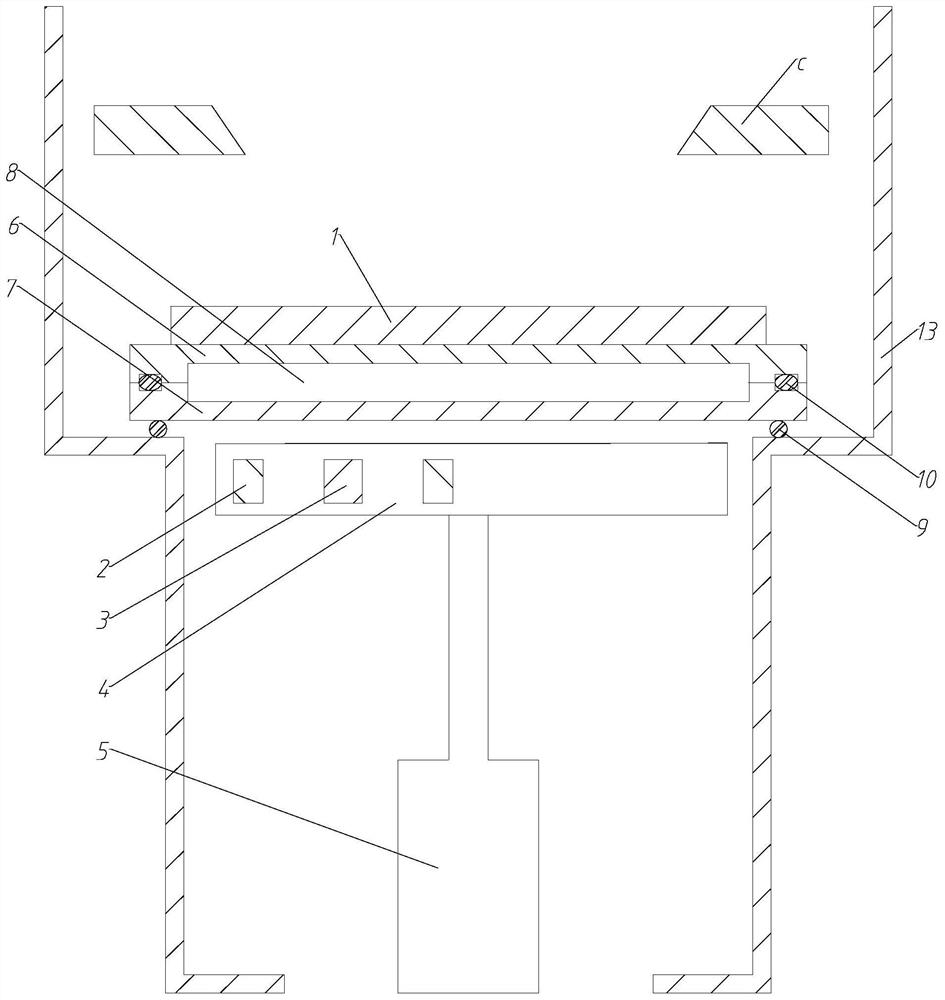

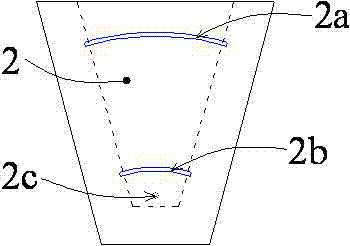

Experimental device for gas permeation under complex conditions

InactiveCN103471975ASolve sealing difficultiesSimple structurePermeability/surface area analysisField conditionsEngineering

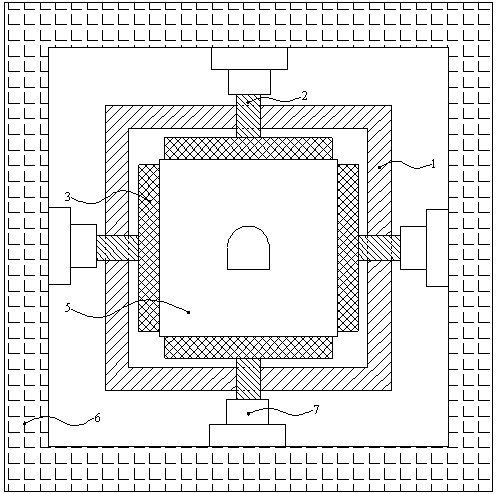

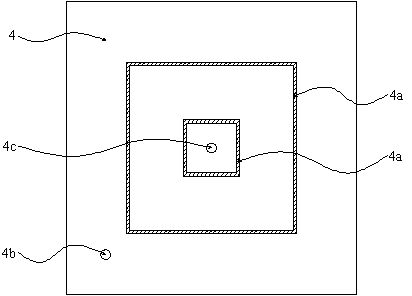

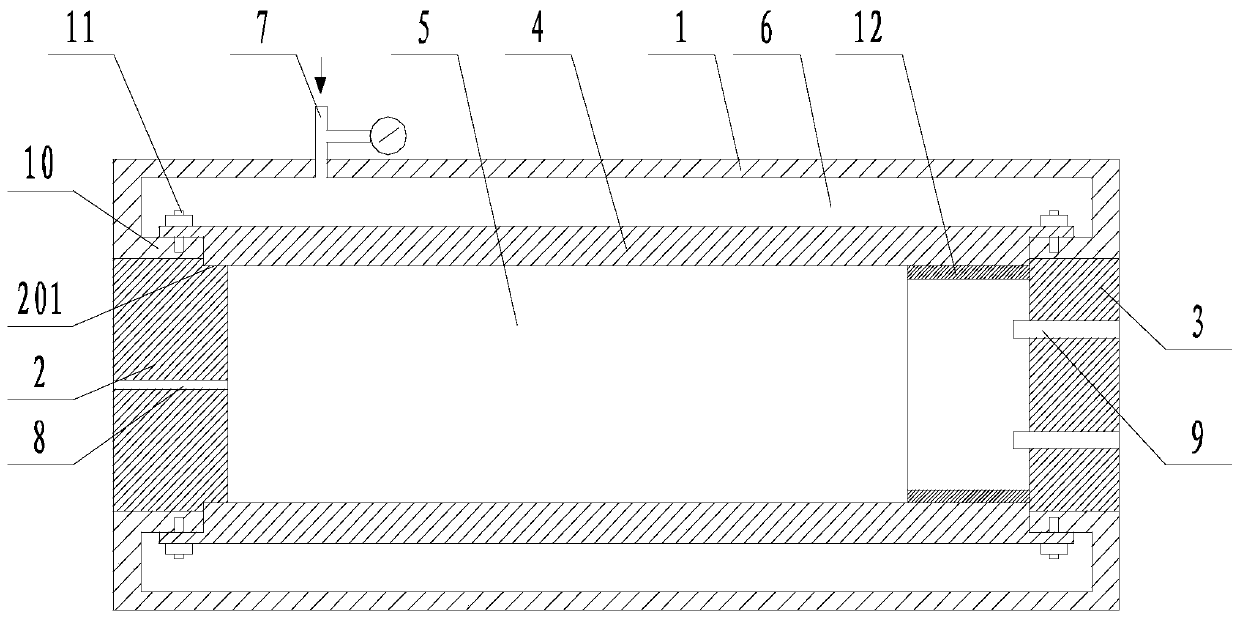

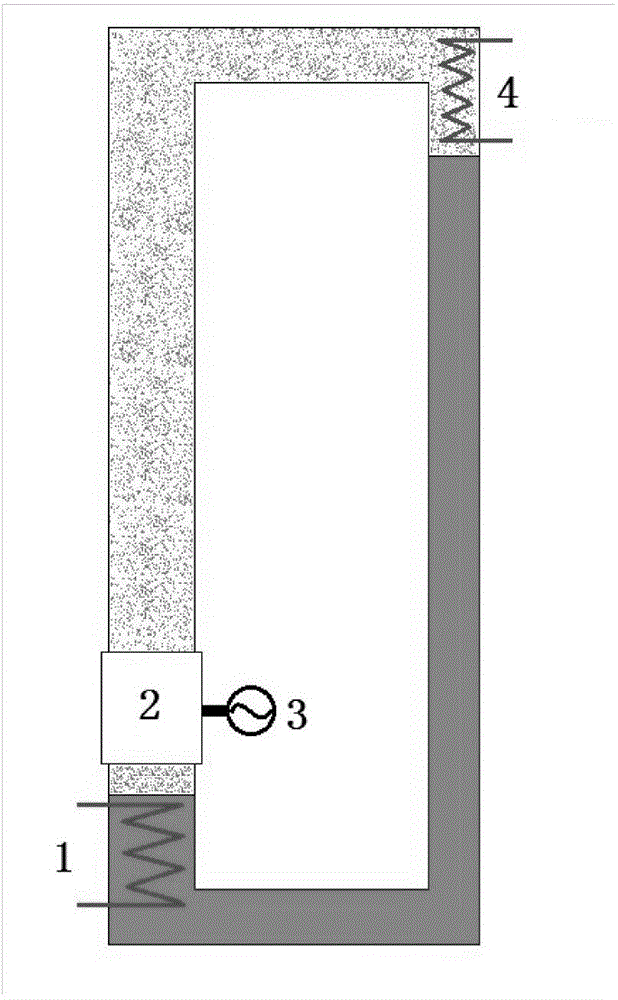

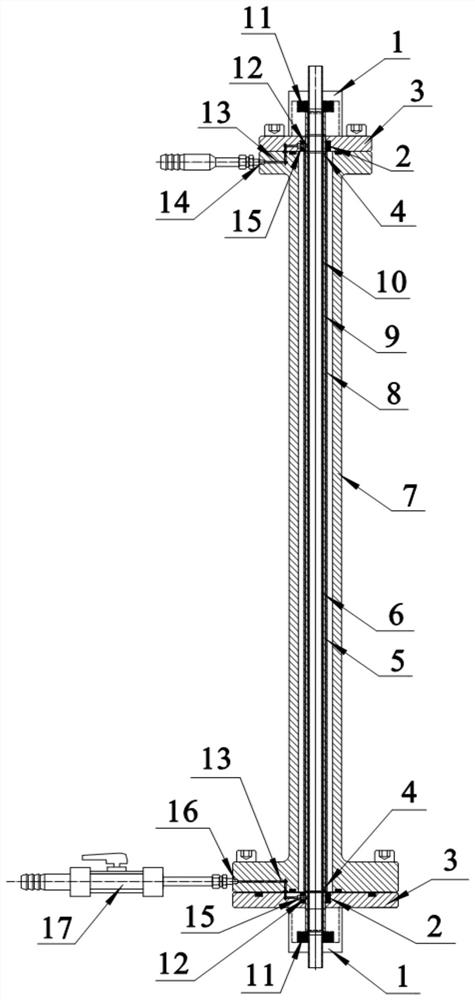

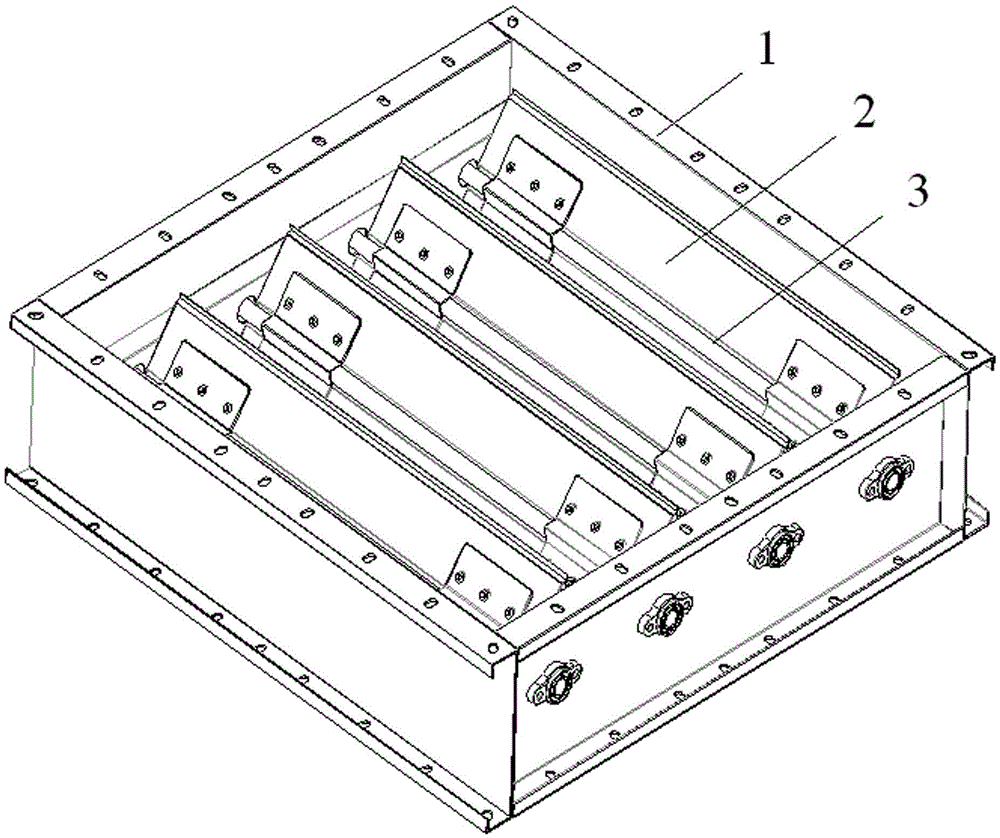

The invention discloses an experimental device for gas permeation under complex conditions. The experimental device is characterized by comprising a sealing loading box, a permeation test piece, a loading device, an oil pressure sealing system, a gas supplying system and a gas balancing system, wherein the loading device is used for loading the permeation test piece to enable the permeation test piece to be in a predetermined stress state; under the assistance of the oil pressure sealing system, a first pressure chamber comprises a rectangular frame, force transmission columns, side baffle plates and the outer side surface of the permeation test piece, and a second pressure chamber comprises the side baffle plates and the inner side surface of the permeation test piece; under the effect of gas pressure difference, gas in the first pressure chamber gradually permeates into the second pressure chamber, so that the permeation law of the gas around holes can be researched. The experimental device can be used for enabling coal and rock masses to be in a stress state similar to field conditions, and the influence of the breaking situations of the coal and rock masses around the holes in the permeation law can be considered, so that the experimental device has great significance on the research on the permeation, absorption and resolution law of the gas in the coal and rock masses around roadways under the complex conditions.

Owner:SHANDONG UNIV OF SCI & TECH

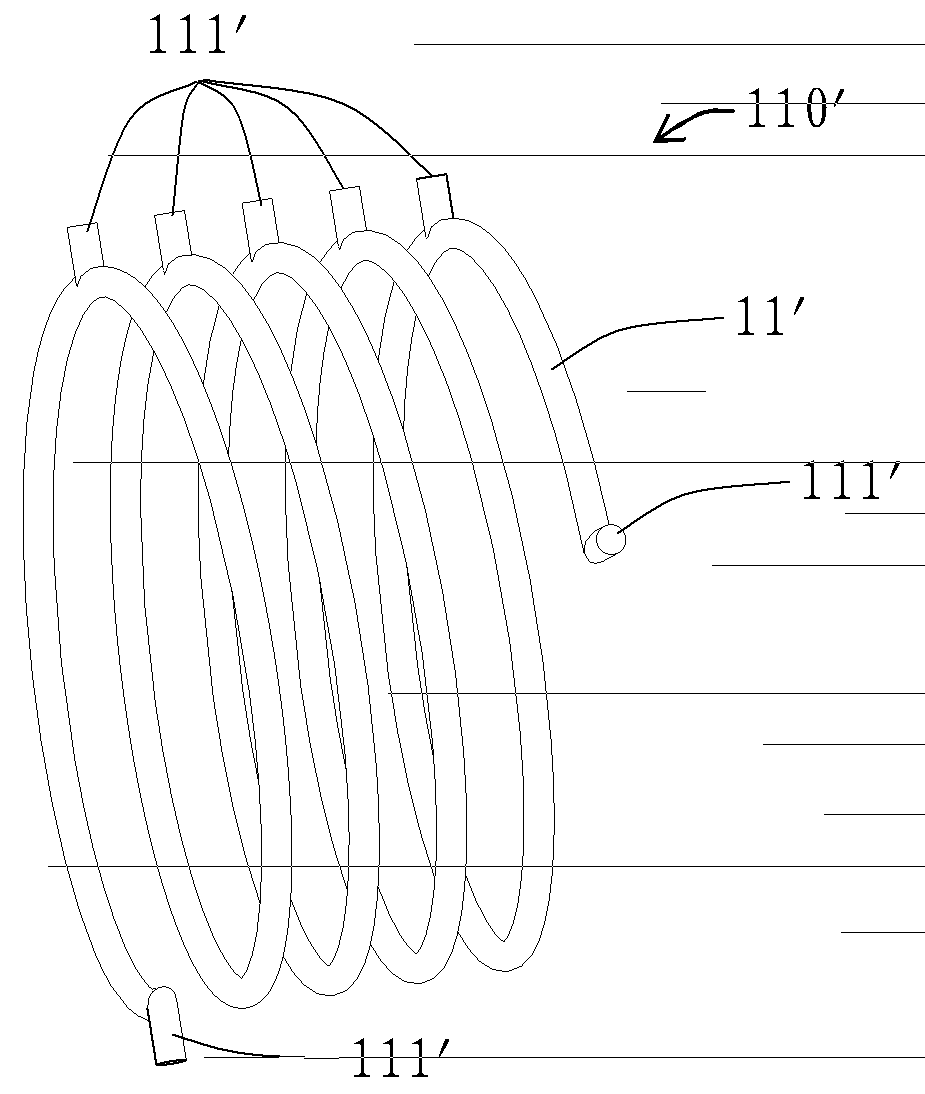

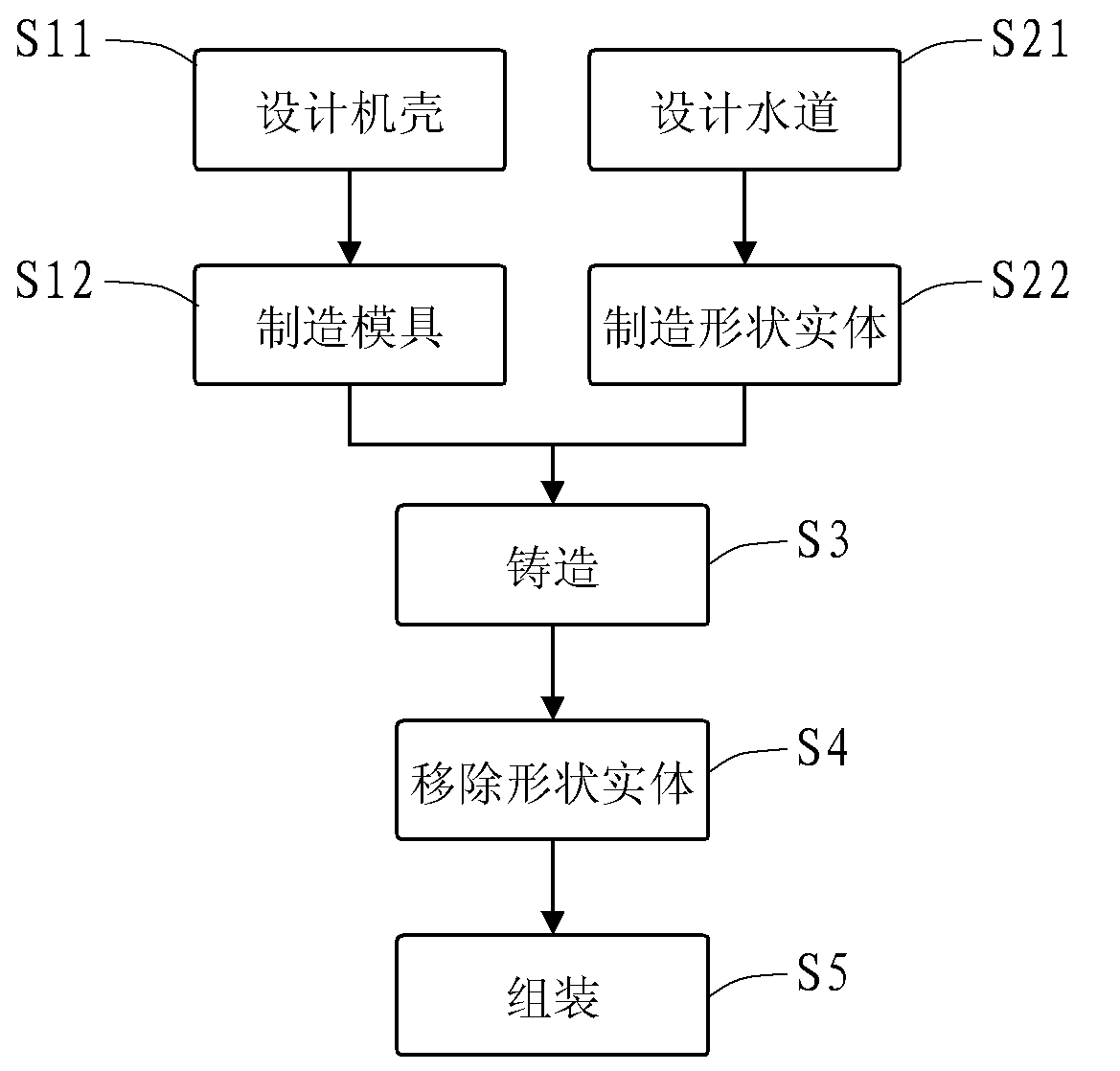

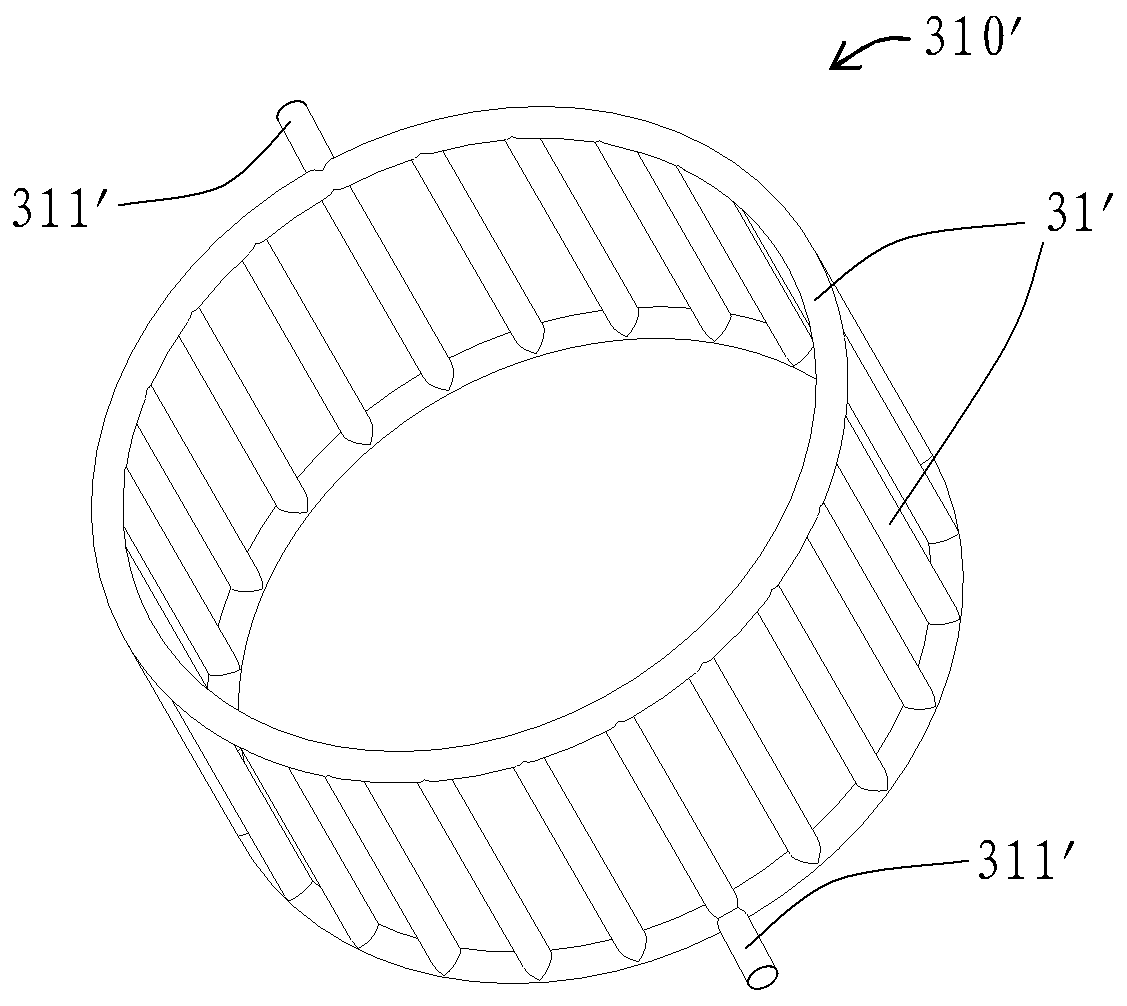

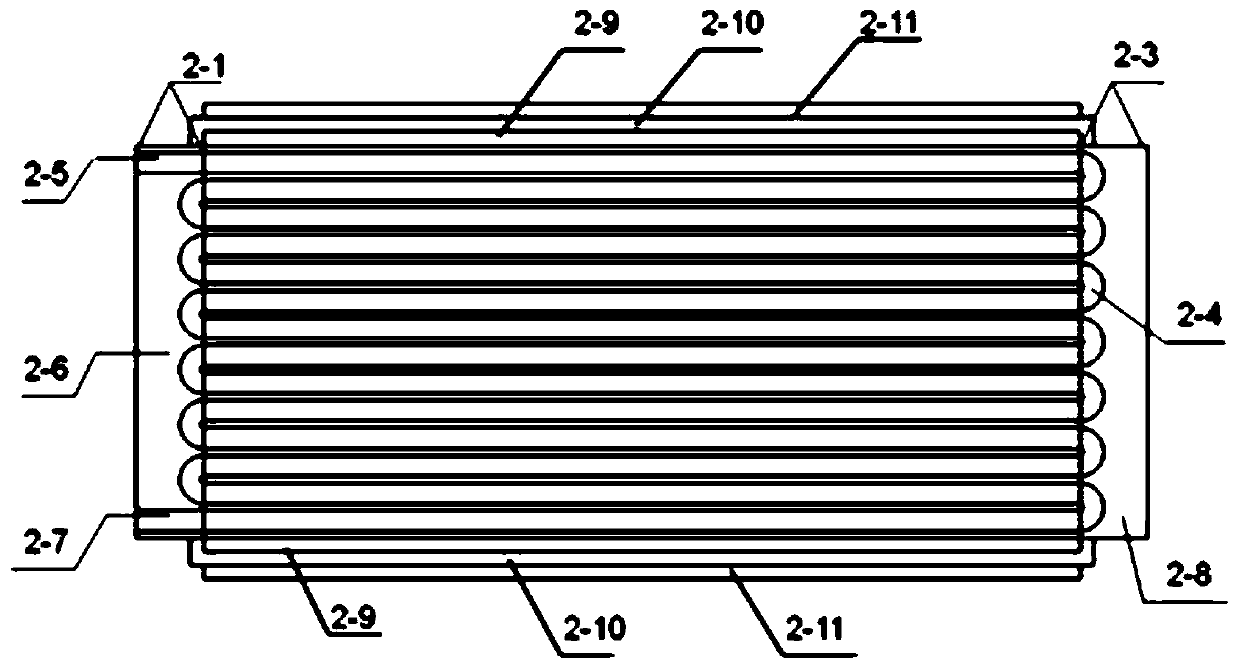

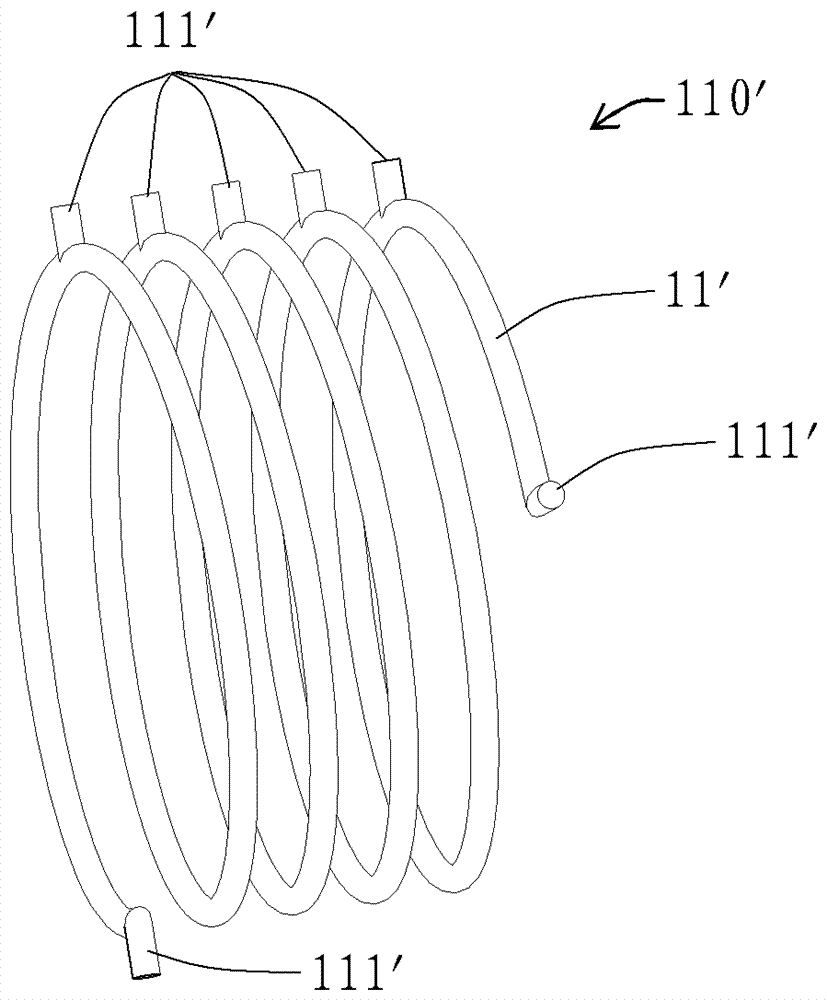

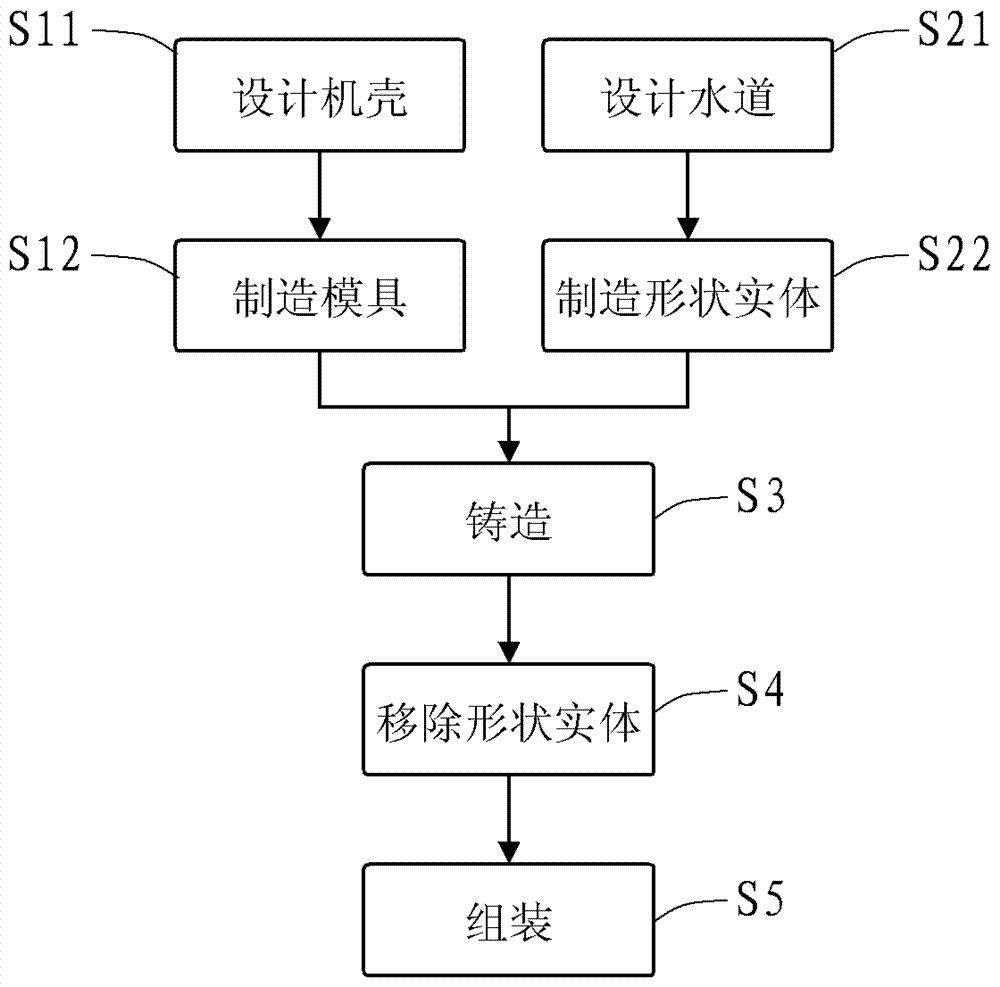

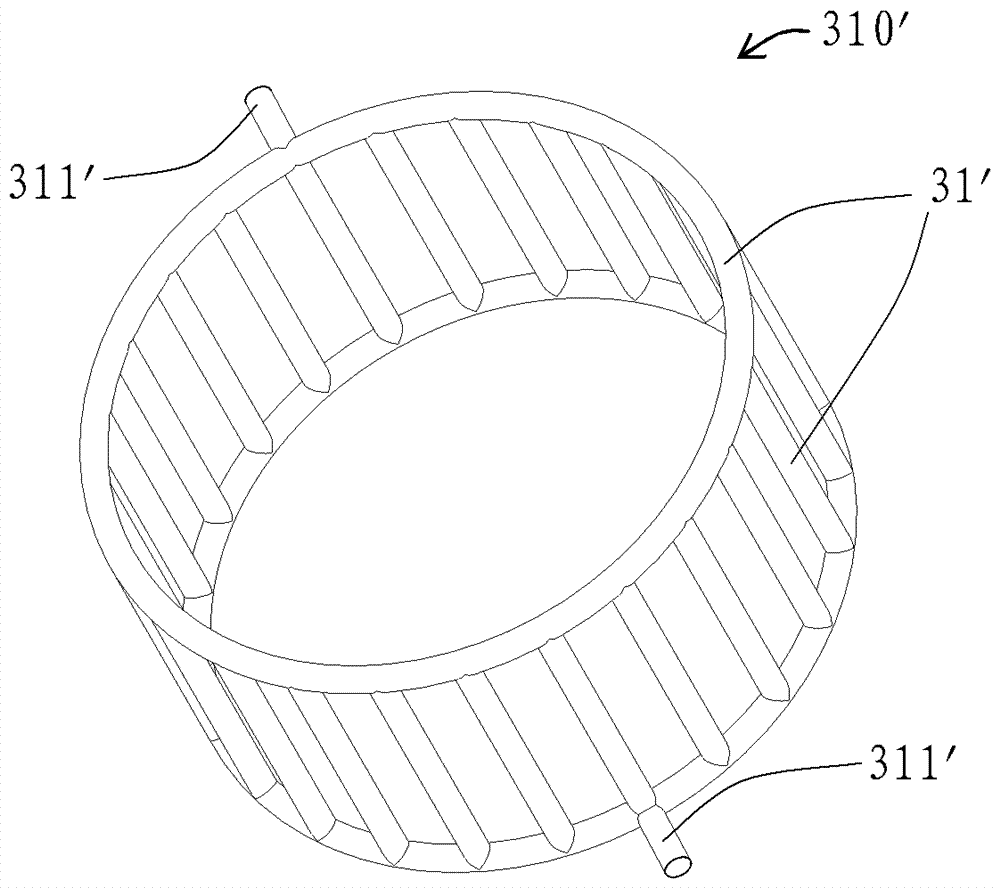

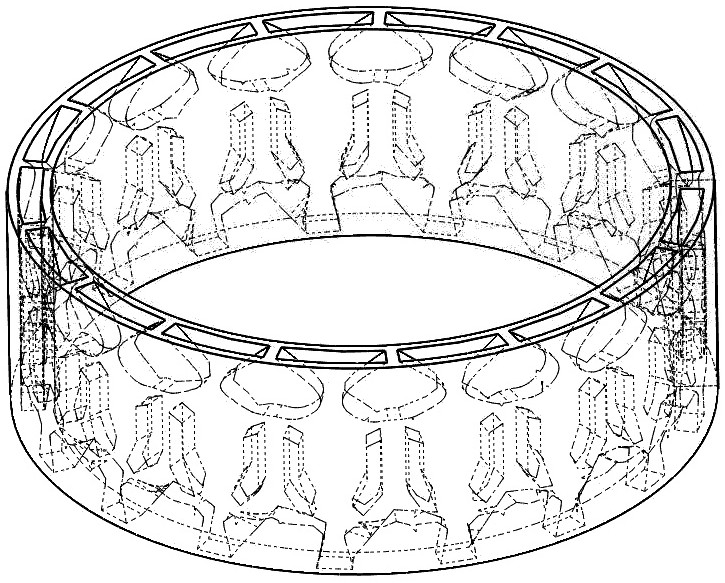

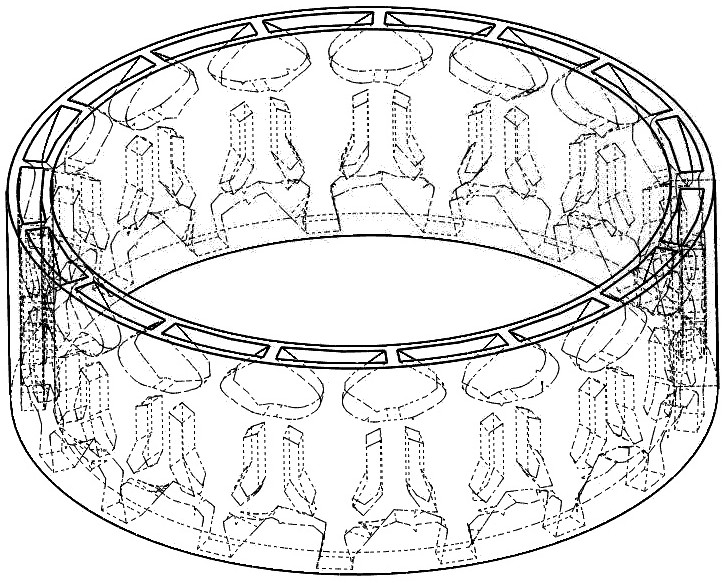

Driving motor liquid cooling device and manufacturing method thereof, and the driving motor

ActiveCN103475159AImprove cooling effectSolve sealing difficultiesManufacturing dynamo-electric machinesCooling/ventillation arrangementDrive motorEngineering

The invention discloses a driving motor liquid cooling device and a manufacturing method thereof, and the driving motor. The driving motor liquid cooling device comprises a motor shell part. The motor shell part comprises a hollow cavity which is formed by a circumference wall. The circumference wall of the motor shell part possesses a cooling liquid channel formed through lost pattern casting. The cooling liquid channel possesses a bending portion. The manufacturing method comprises the following steps that integral casting molding of the motor shell is performed; a cooling liquid channel shape entity model is removed from the motor shell after casting molding; the cooling liquid channel and at least two holes which are connected with the cooling liquid channel are integrally formed in the motor shell. Because of a one-piece cooling structure, problems that existing internal and external water jacket assembling is complex and sealing is difficult to be achieved can be solved; cost is reduced and production efficiency is increased.

Owner:SHANGHAI E PROPULSION AUTO TECH

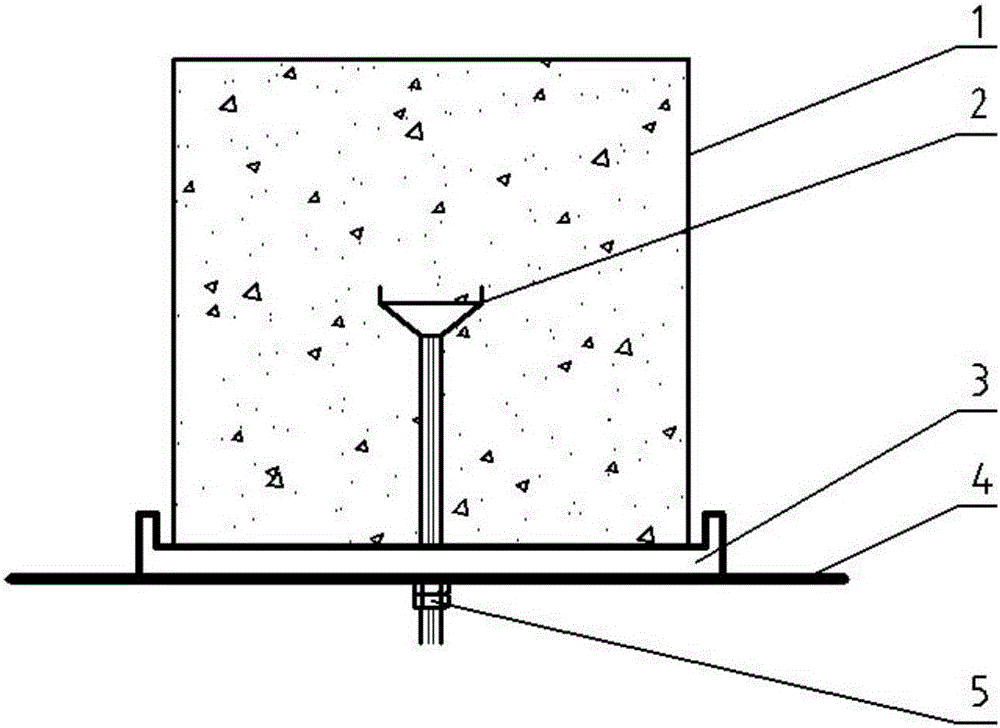

Concrete impermeability test method and test apparatus thereof

InactiveCN105910970AImprove sealingOmit sealing procedurePermeability/surface area analysisEngineeringTested time

The invention provides a concrete impermeability test method and a test apparatus thereof. The test method comprises the following steps: fixedly connecting one end of a pre-embedded pressure leading tube with a concrete sample through pouring, connecting the other end of the pre-embedded pressure leading tube with a water tube, allowing pressure water to go through the pre-embedded pressure leading tube and to enter test concrete, and determining the water pressure of the water tube, which is the test pressure, when water infiltrates from the periphery of the concrete sample. The invention also relates to the concrete impermeability test apparatus. The method and the apparatus are adopted to carry out concrete sample impermeability test without sealing the sample, so the problem of difficult sealing between the sample and a frame test mold in the concrete sample impermeability test process is solved, the success rate of impermeability tests is improved, the operating flow is simplified, the test time is shortened, the water seepage path is visually reflected, and the practicality of an impermeability tester in engineering is improved.

Owner:黄显彬

Rock core holder for mud dynamic pollution experiment

PendingCN110658125AImprove accuracySimulation is accuratePermeability/surface area analysisRock coreMechanical engineering

The invention discloses a rock core holder for a mud dynamic pollution experiment. The holder comprises a sleeve, first and second plugs and a membrane, the first and second plugs are detachably connected to the two ends of the sleeve respectively, the membrane is arranged in the sleeve and forms a cylindrical structure coaxial with the sleeve, a hollow area formed by the membrane in a surroundingmode is a rock core clamping area, a confining pressure area is arranged between the outer wall of the membrane and the inner wall of the sleeve, and a pressurizing opening communicated with the confining pressure area is formed in the surface of the sleeve. The provided rock core holder for the mud dynamic pollution experiment can solve the problems that simulation of the mud dynamic pollution experiment has a large error and limited in accuracy, the special-purposed rock core holder is realized for the mud dynamic pollution experiment, and objective parameters in the experiment process aresimulated more accurately.

Owner:CHENGDU NORTH OIL EXPLORATION DEV TECH

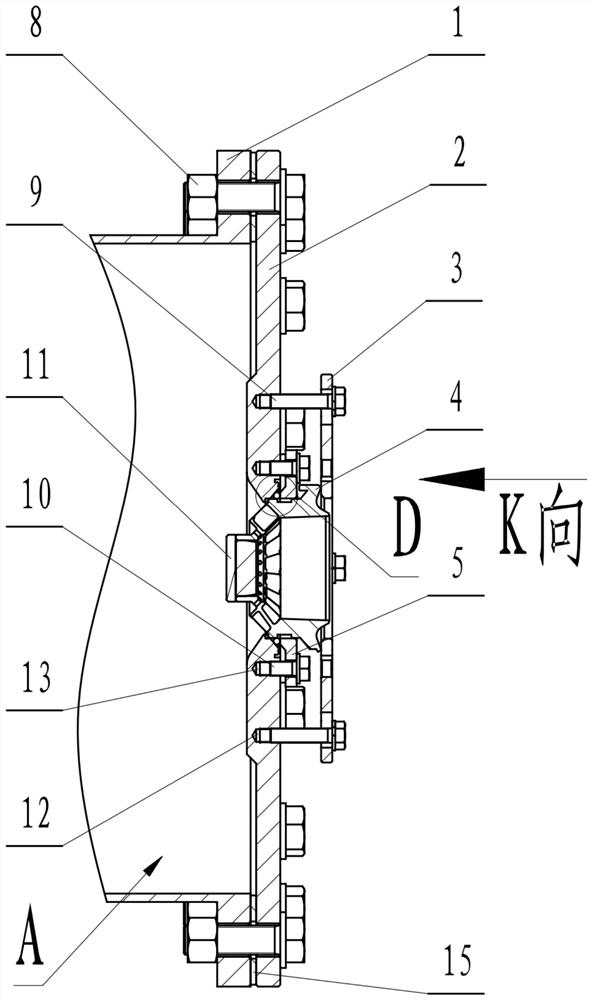

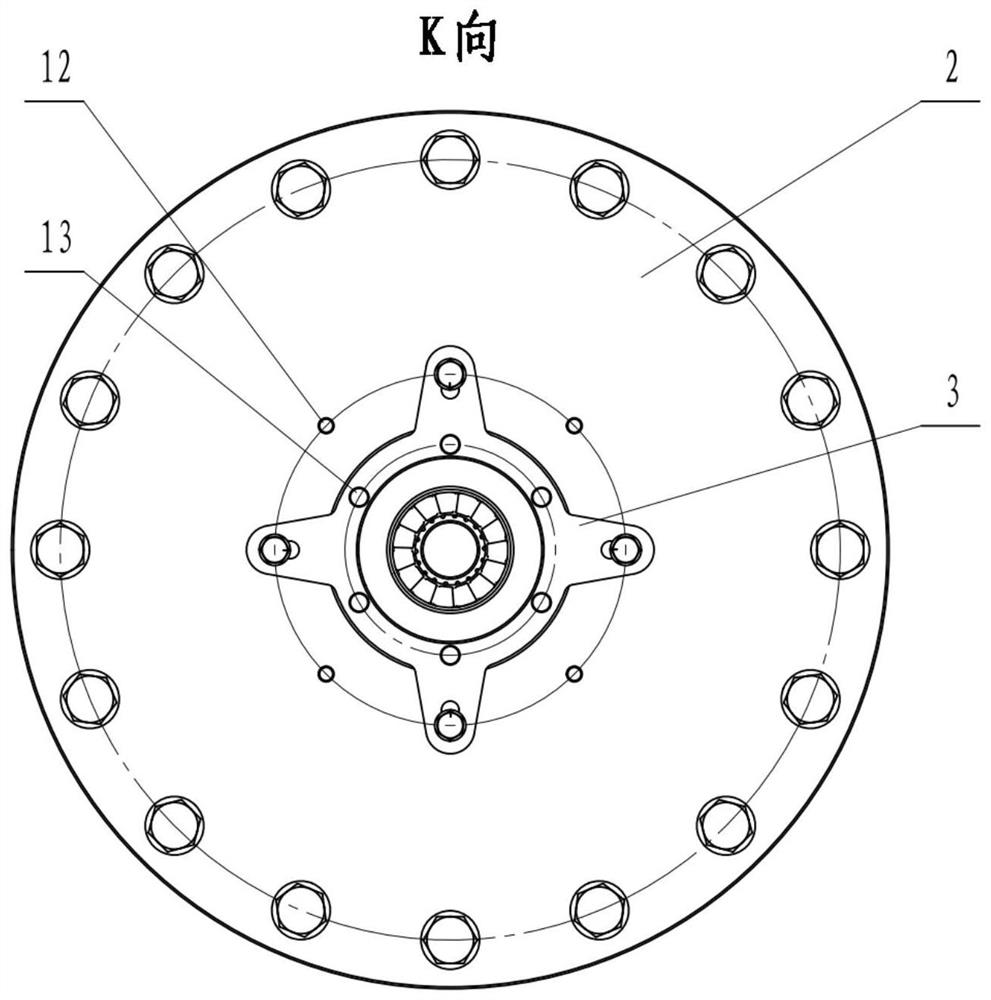

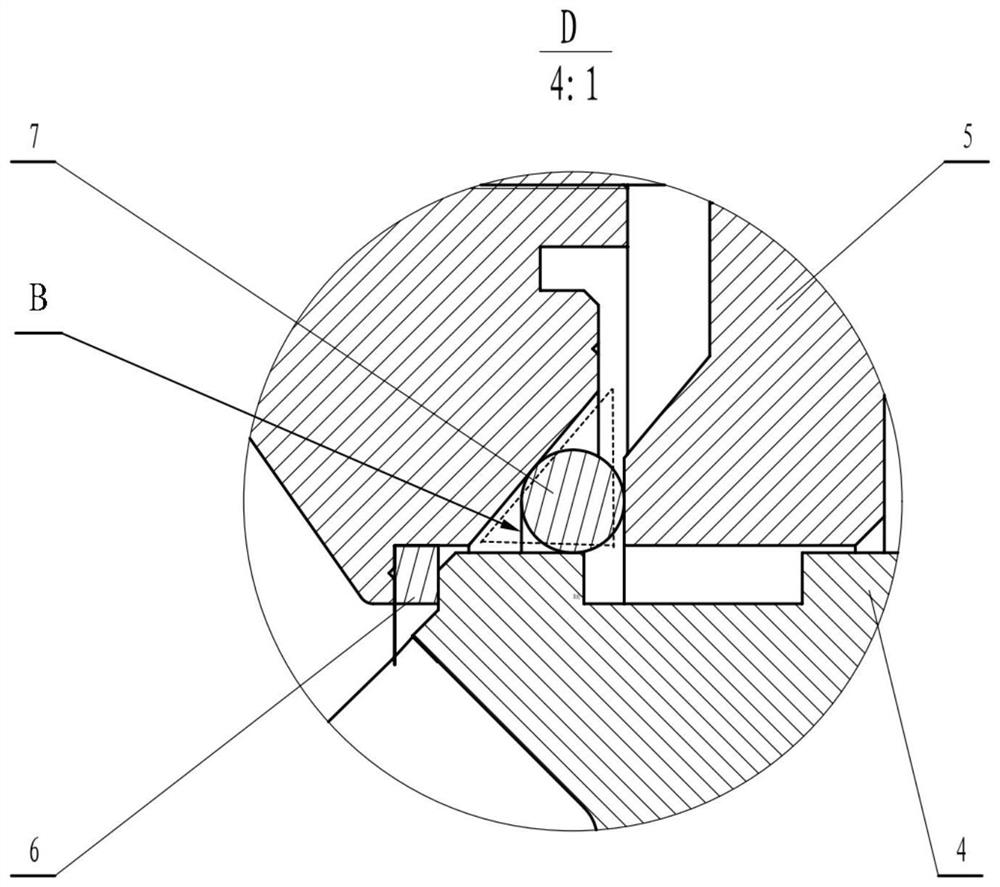

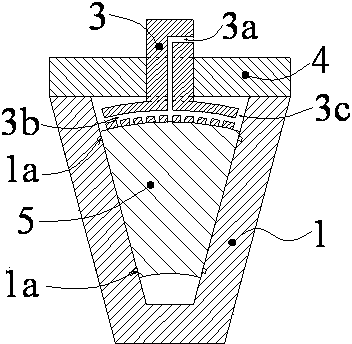

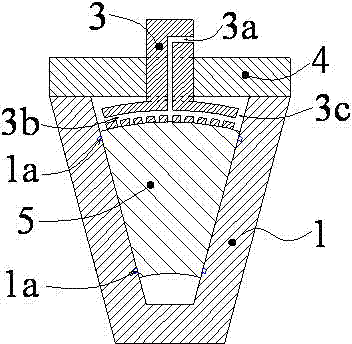

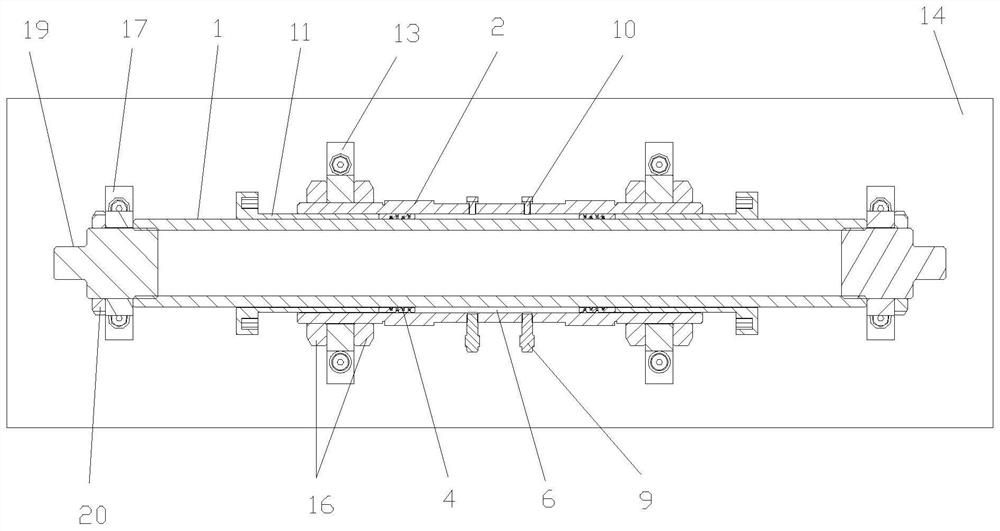

Tower type cyclone flow test device for converting axial compression into radial sealing

ActiveCN112362352ATight and reliable sealSolve sealing difficultiesEngine sealsGas-turbine engine testingAxial compressionTower

The invention aims to provide a tower-type cyclone flow test device for converting axial compression into radial sealing. The device comprises a pressure stabilizing cylinder, a convex-concave cover plate and a cross-shaped pressing plate, the pressure stabilizing cylinder and the convex-concave cover plate are fixed together through a fastener, the convex-concave cover plate adopts a convex stepon the inner cavity surface, and adopts a stepped design on the outer cavity surface. A center hole is formed in the center of the convex-concave cover plate, a conical-column-shaped rubber plug and atower-type cyclone are arranged in the center hole, the axial position of the tower-type cyclone is fixed through a small flat end face of a step, the convex step and the edge of the center hole adopt an air inlet angle in smooth transition, a cross pressing plate is fixed to the convex-concave cover plate, and a hole is formed in the middle of the cross pressing plate. And the middle part of thetower-type cyclone is arranged in a hole in the middle part of the cross pressing plate. An O-shaped ring is compact and reliable in sealing in the formed triangular annular belt space, axial pressing is converted into radial sealing, and the problem that a flow test is difficult to seal due to the fact that the unnecessary axial installation end face of a current tower type cyclone becomes smaller and smaller is effectively solved.

Owner:中国船舶重工集团公司第七0三研究所

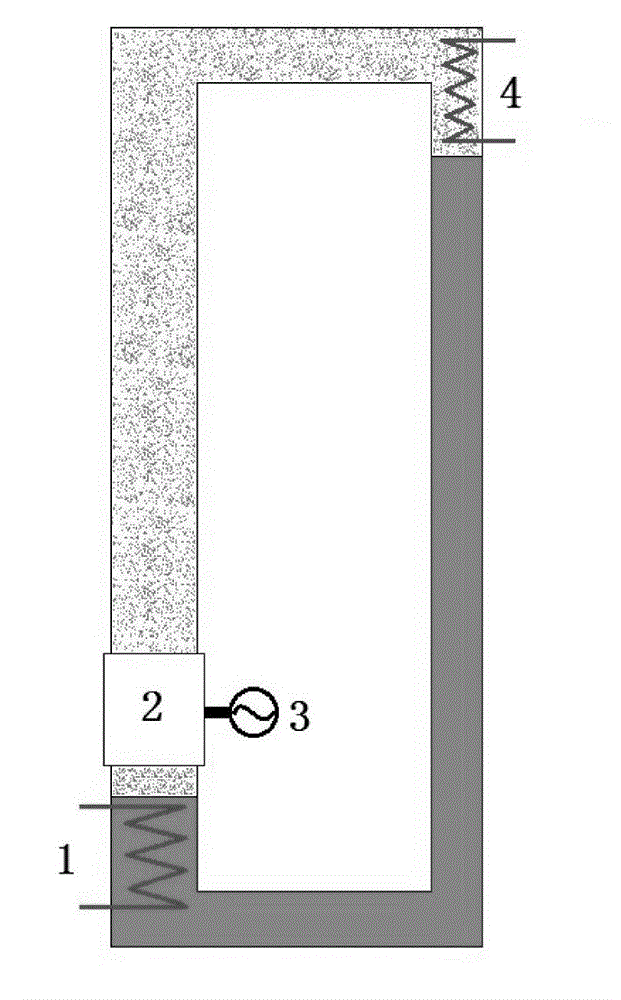

Electromotor combined with pressure vessel

InactiveCN104300731AEasy to useImprove heat resistanceMechanical energy handlingSupports/enclosures/casingsEngineeringHigh pressure

The invention relates to an electromotor combined with a pressure vessel. The electromotor comprises an electromotor shell, a rotating shaft, a stator, a rotor, a shaft extension end cover, a non-shaft extension end cover, a terminal box, a terminal box cover, a terminal board and electric connection components, wherein the terminal board and the electric connection components are arranged in the terminal box, and connection components are arranged at the two ends of the electromotor shell. The electromotor is characterized in that a bearing hole in the non-extension shaft end cover does not penetrate through the outer end face, a shaft sleeve is fixed to the outer end face of the shaft extension end cover in a sealed mode, a flange is fixed to the other end of the shaft sleeve in a sealed mode, the shaft extension end of the rotating shaft penetrates through the shaft extension end cover and the shaft sleeve and extends out of the flange, sealing elements are arranged between the connection components of the shaft extension end cover, the non-shaft extension end cover and the electromotor shell, and a sealing element is arranged between the terminal board and the terminal box. The rotating shaft of the electromotor is used as the rotating shaft of a stirrer of the pressure vessel, the pressure in the pressure vessel shifts into the electromotor through the shaft sleeve, and the problem that the pressure vessel is difficult to seal is well solved through the good sealing performance of the electromotor shell and all the components. The electromotor is suitable for high-pressure operation environments.

Owner:荣成市先锋电机厂

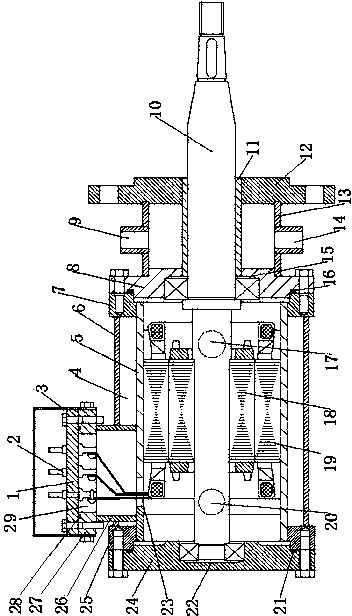

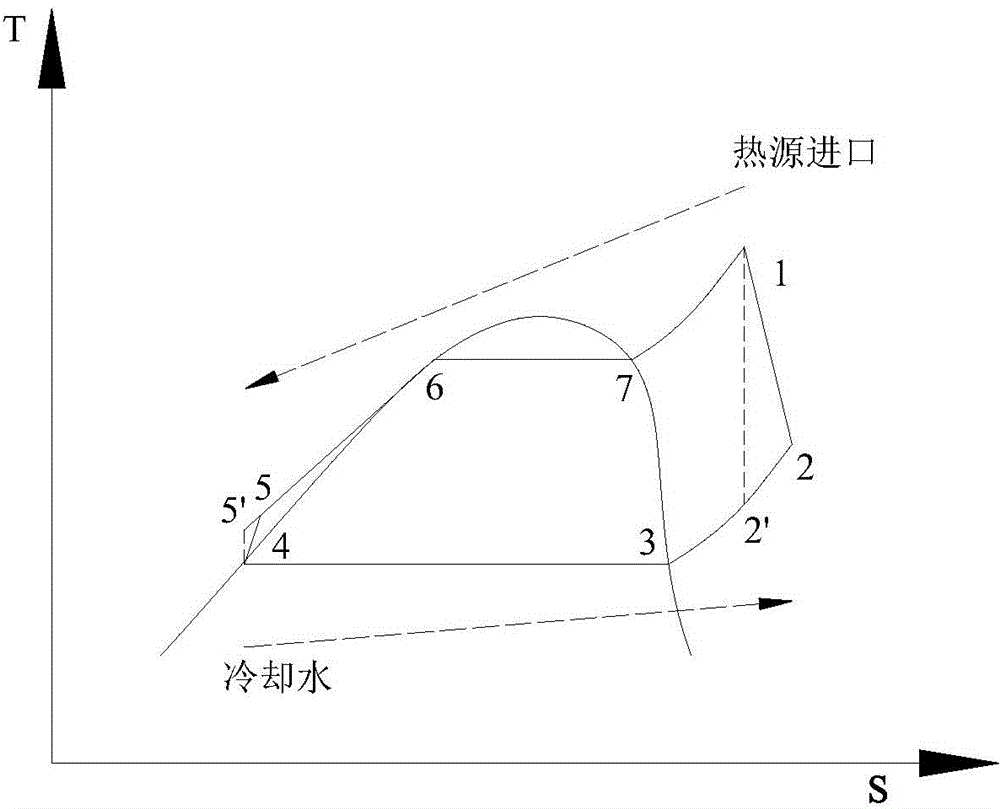

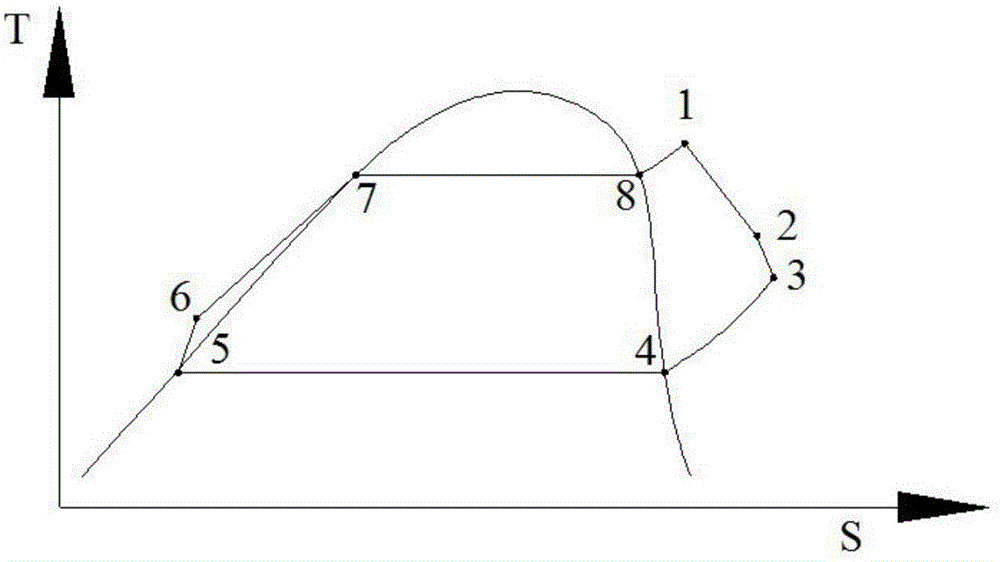

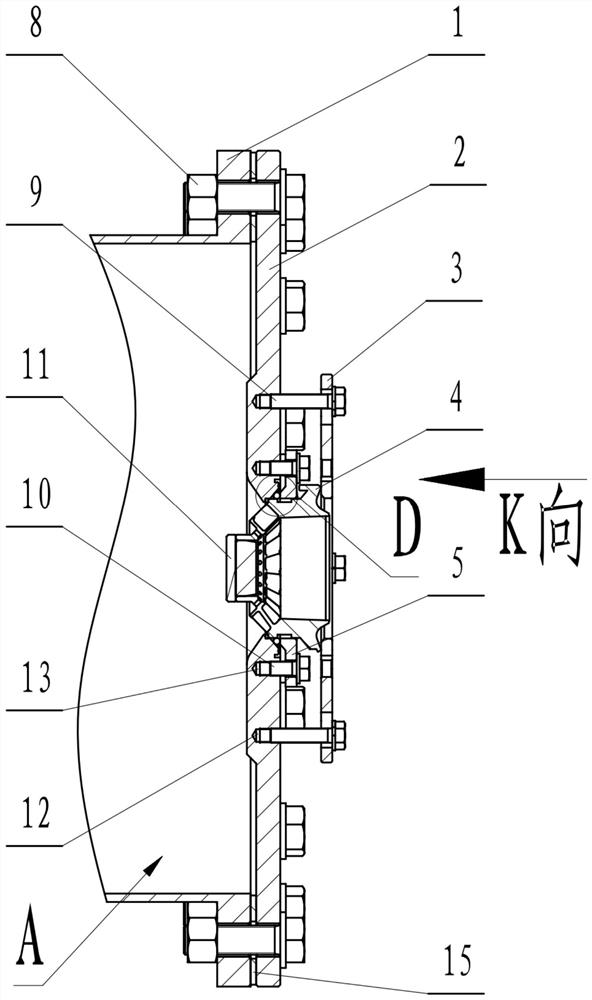

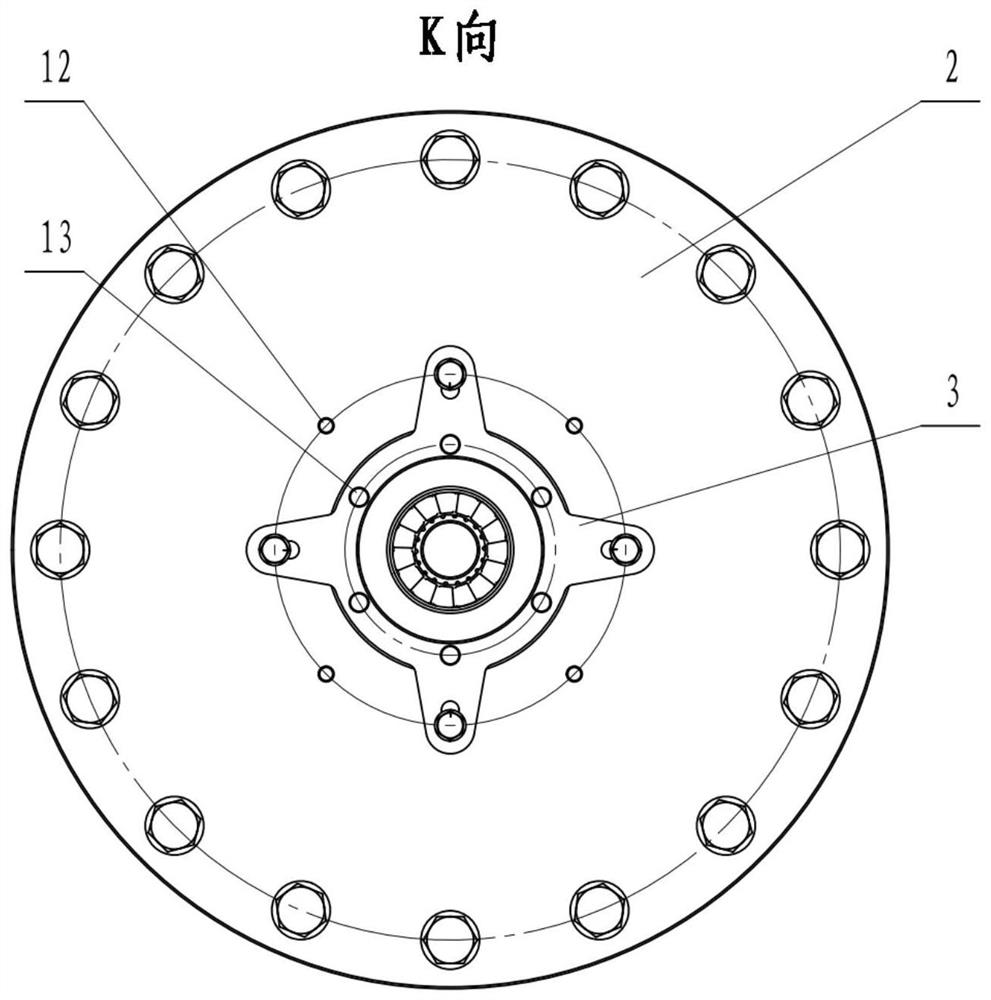

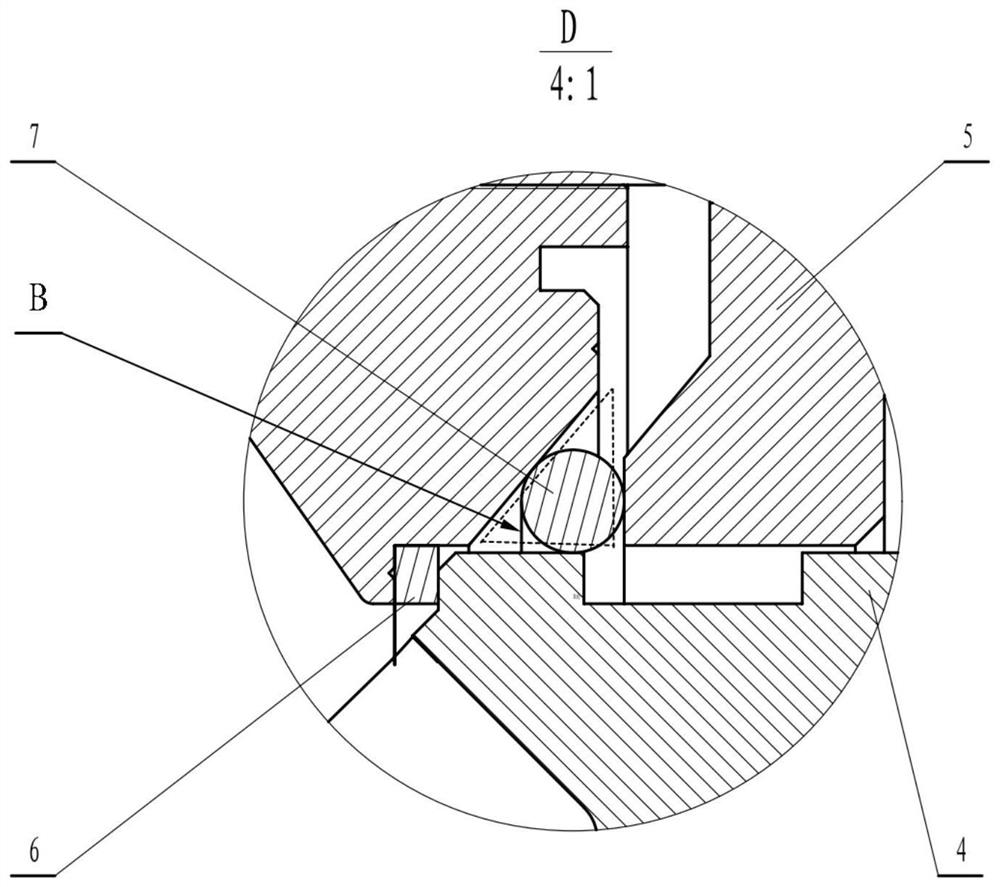

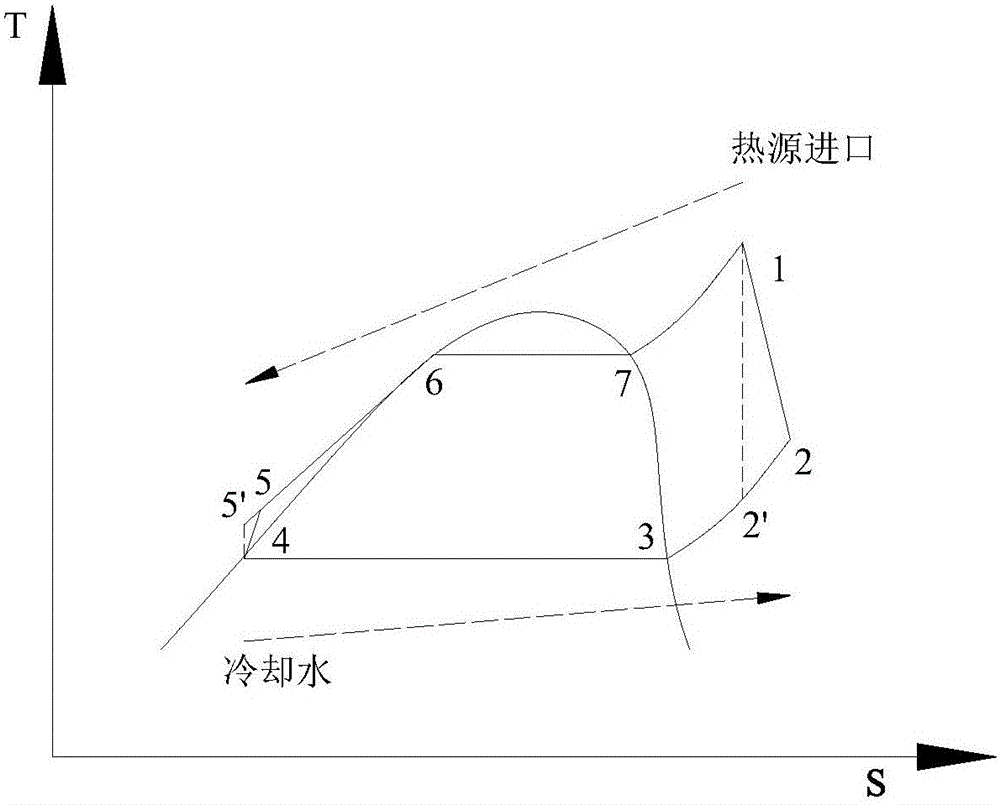

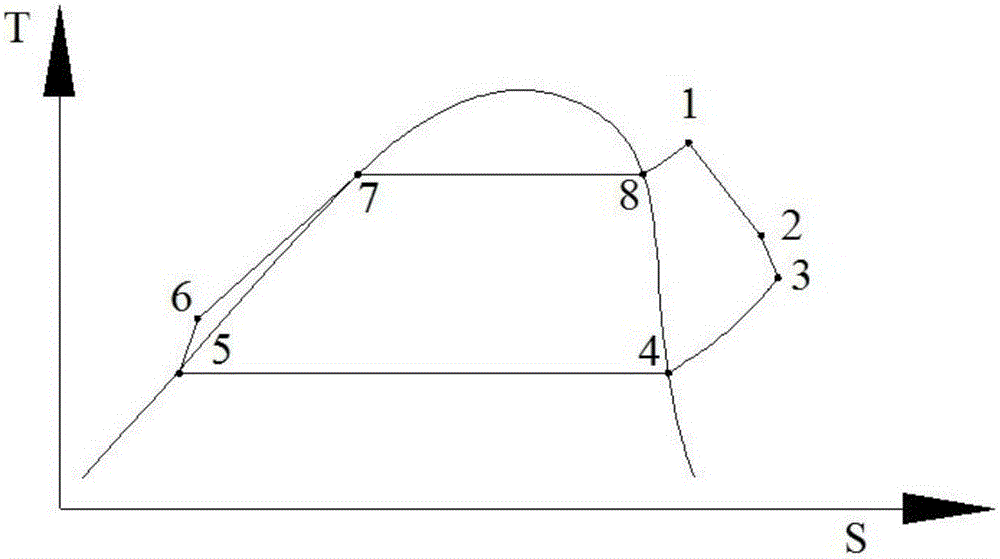

Single-stage gravity pump organic Rankine power generation and heat supply combined system and cycle thereof

ActiveCN103982253AImprove cycle efficiencySolve sealing difficultiesSteam useBoiling pointElectric generator

The invention provides a single-stage gravity pump organic Rankine power generation and heat supply combined system and a cycle of the combined system, wherein the combined system comprises a circulation power generation closed loop formed by sequentially connecting an evaporator, an expansion machine and a condenser, the expansion machine is externally connected with a power generator, the condenser comprises an organic working medium pipeline and a circulation water pipeline, low-boiling-point organic working media release heat to circulation water in the condenser, the circulation water pipeline is connected with a floor heating pipeline through a regulating valve, the floor heating pipeline is then connected with the circulation water pipeline through a circulation water pump, and a floor heating closed loop is formed; the circulation power generation closed loop and the floor heating closed loop form the combined system. The pressure difference of the organic working media is utilized for replacing working medium conveying equipment of a working medium pump, the heat energy is directly converted into the pressure difference required by the circulation, and the working medium pressurization and the application of the conveying equipment are avoided.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

Cylindrical heating rod test section filled with inert gas and air gap sealing method

ActiveCN111638243AGuaranteed air tightnessSolve sealing difficultiesVessel mounting detailsEngine sealsThermodynamicsHeater Rod

The invention discloses a cylindrical heating rod test section filled with inert gas and an air gap sealing method. The test section comprises a test section outer sleeve, an outer surface, a heatingblock and an inner surface which are coaxially arranged in sequence from outside to inside, radial size fixing and air gap sealing are conducted through an outer sealing ring and an inner sealing ringat the two ends of the pipe, and axial fixing is conducted through a specially-made flange and a gland. Inert gas filling is conducted on the inner and outer air gaps through the air inlet in one endof the test section outer sleeve, and after a period of time, the air gaps are filled with inert gas, and an air outlet valve is closed for pressure maintaining. The cylindrical heating rod test section filled with the inert gas can simulate the air gap state of the cylindrical heating rod, the adopted two pairs of cone seals can ensure the air tightness of the inner and outer air gaps of the test section, and the adopted unique air path solves problems of inert gas filling and air gap pressure maintaining of the cylindrical heating rod test section.

Owner:XI AN JIAOTONG UNIV

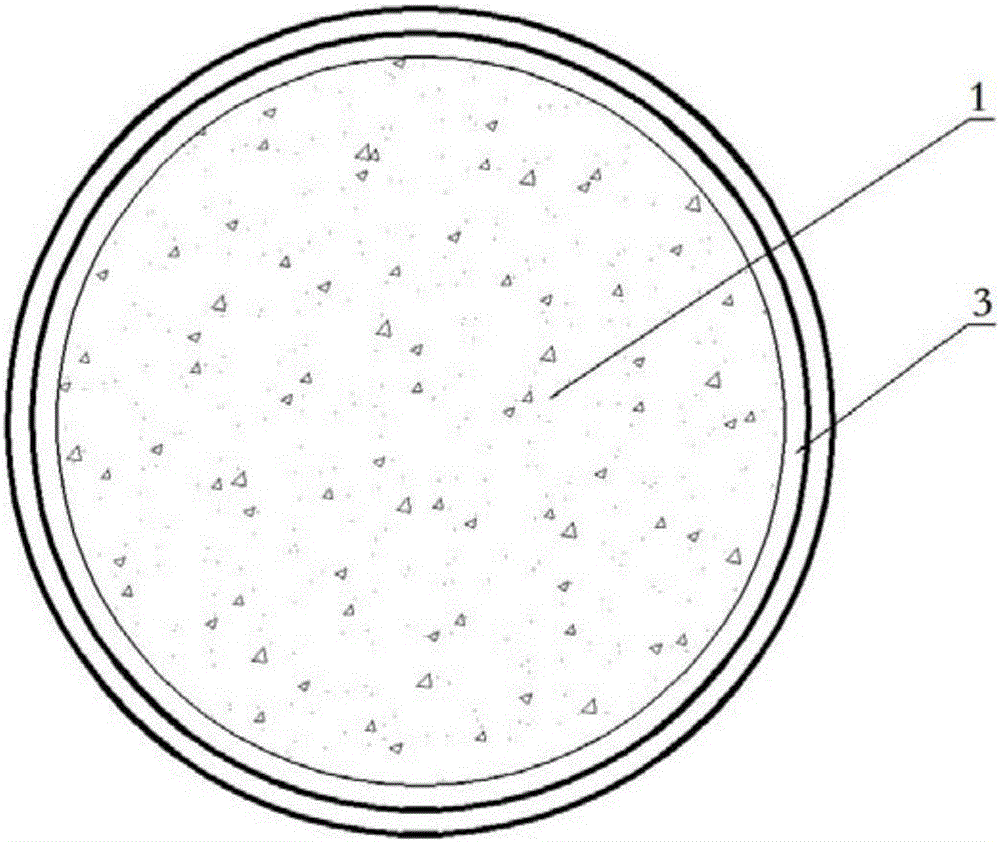

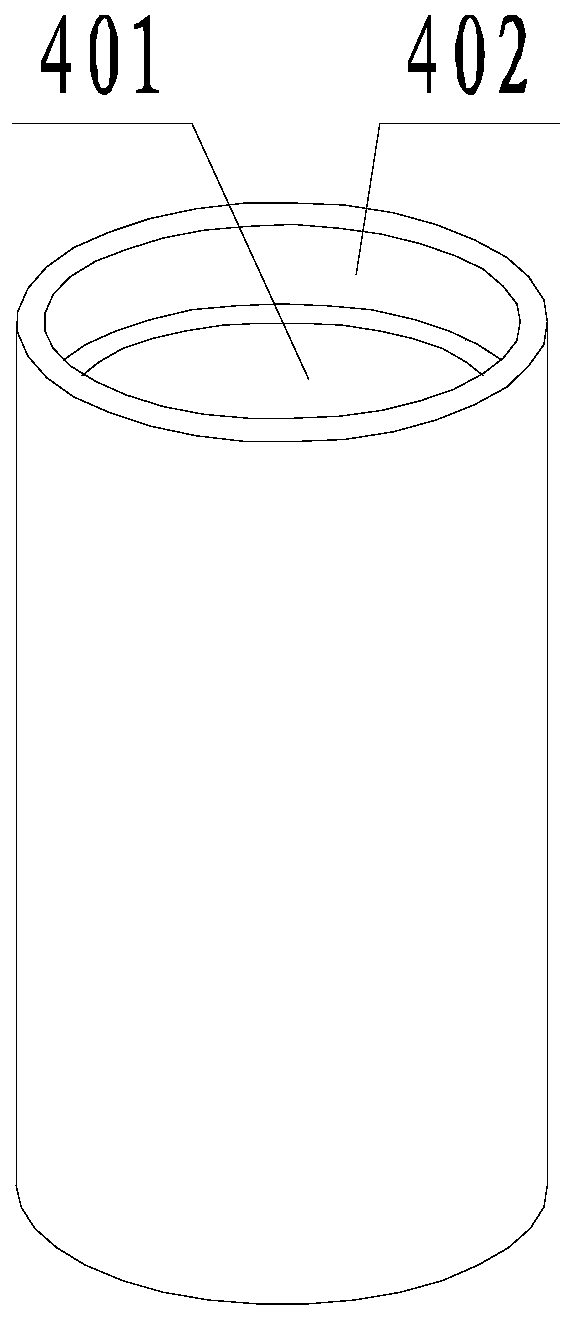

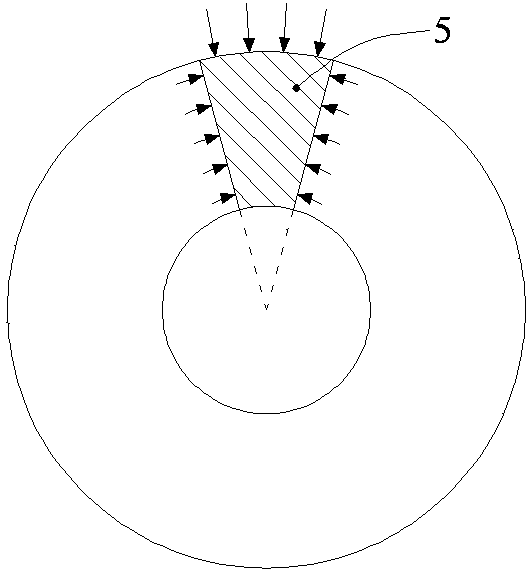

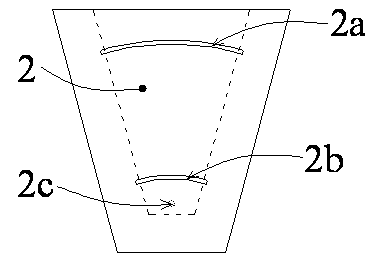

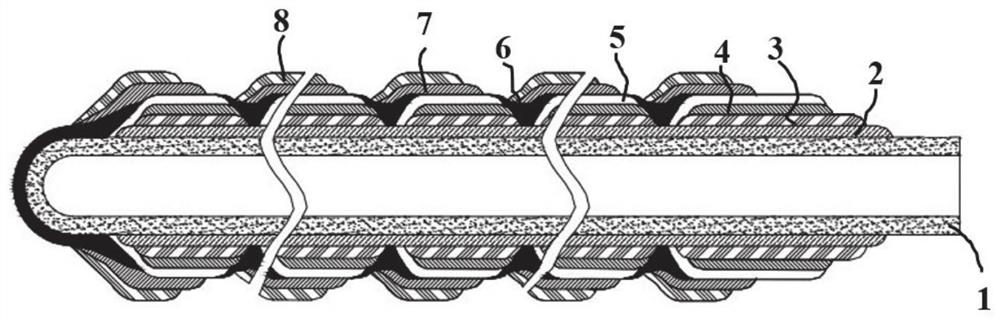

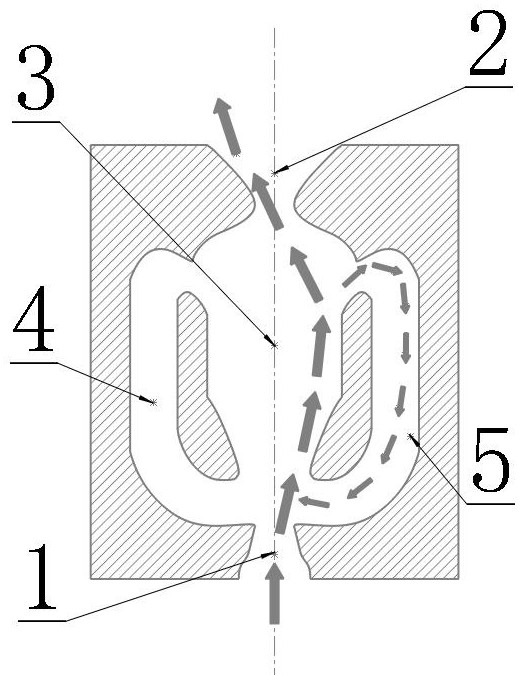

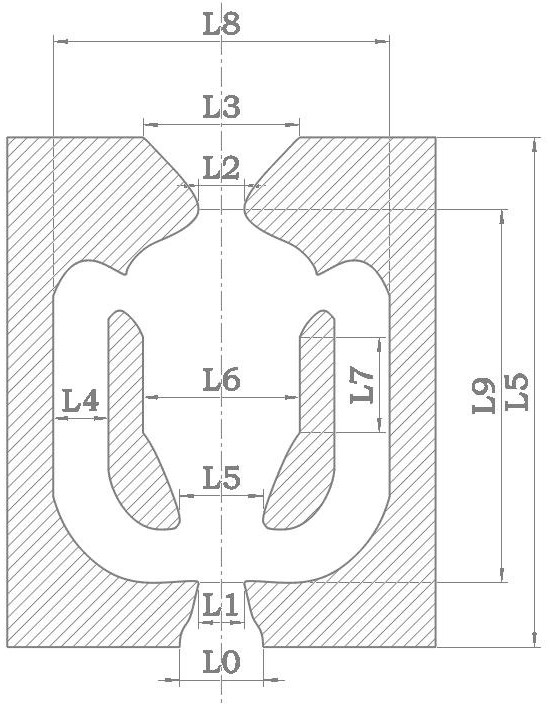

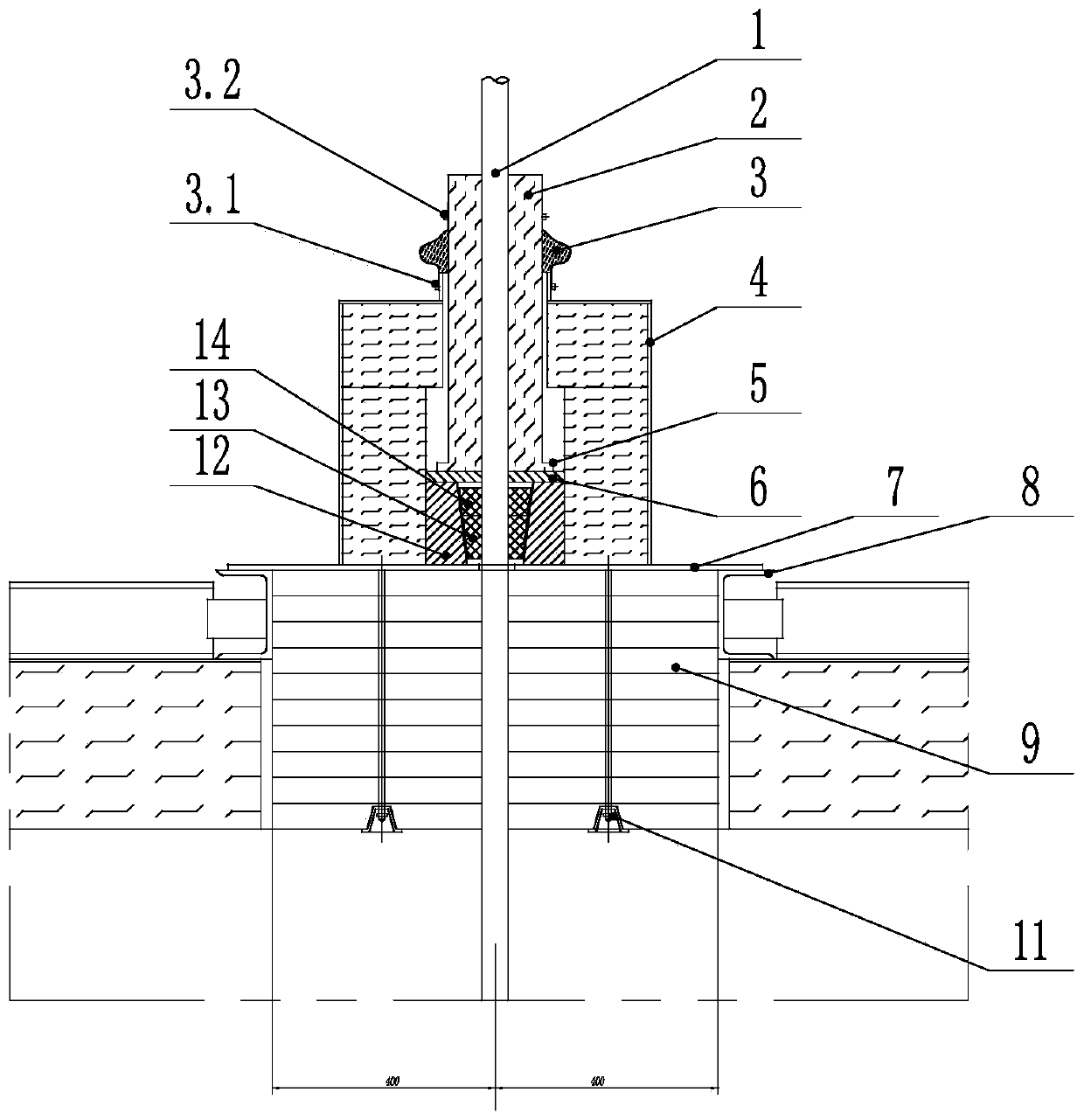

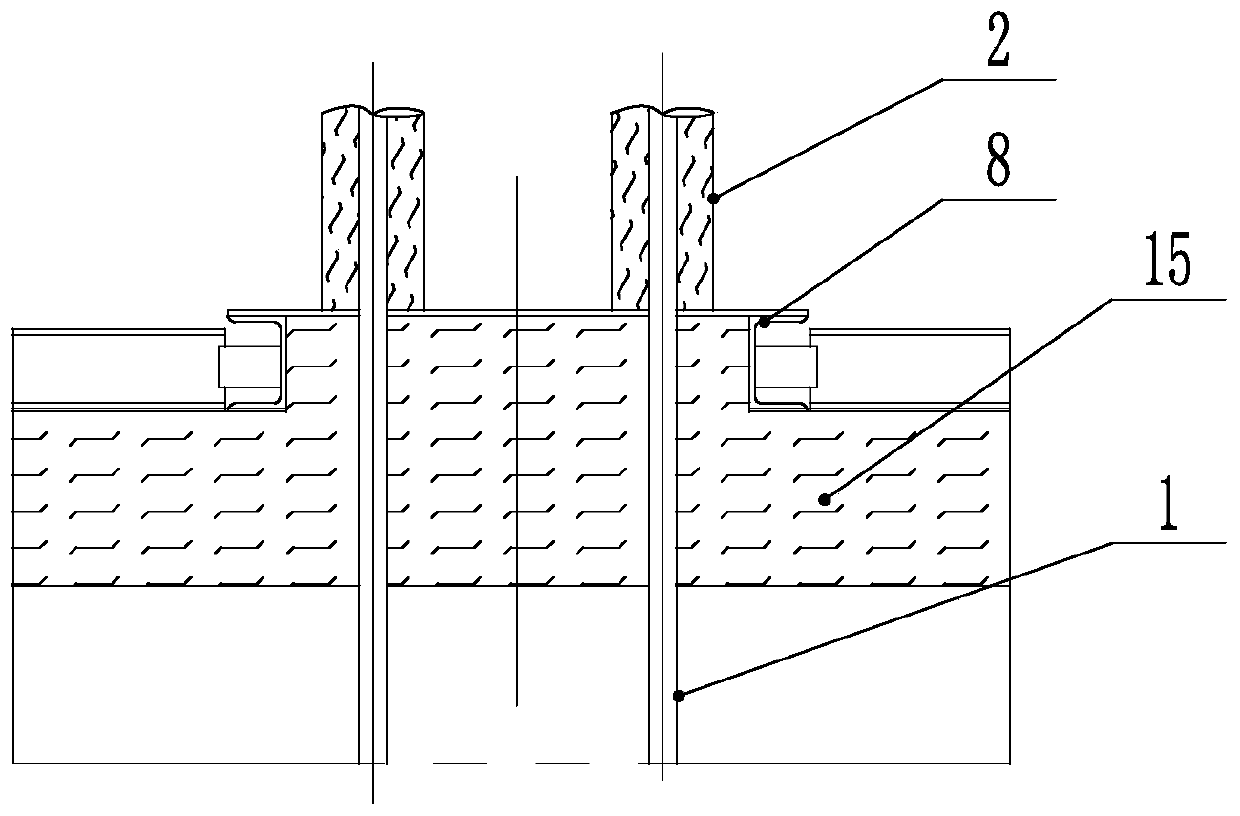

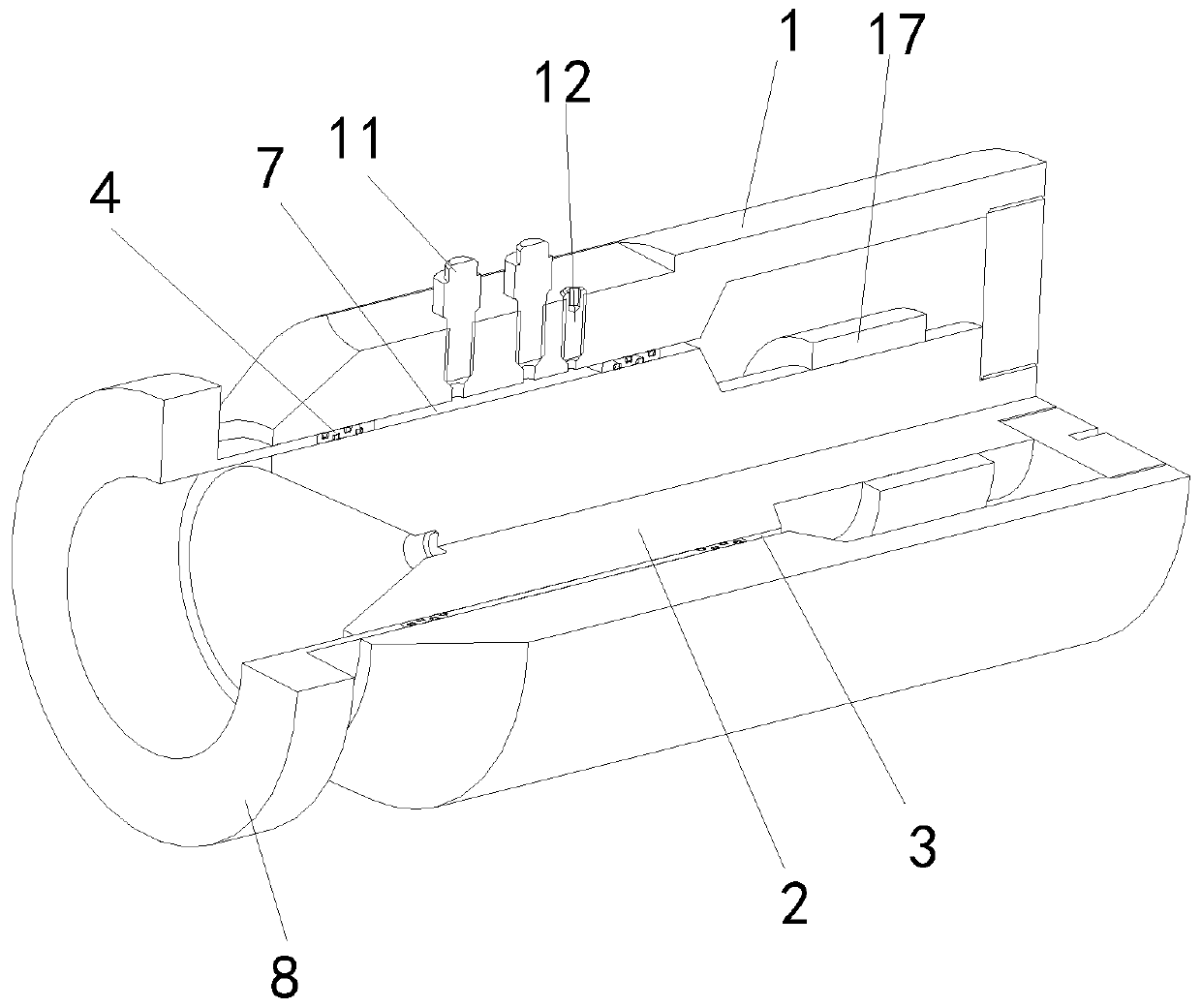

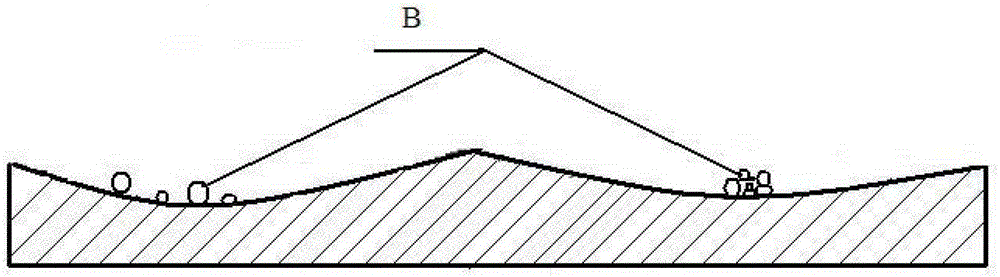

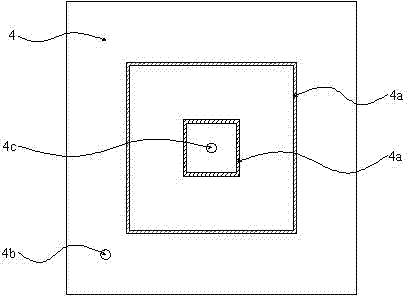

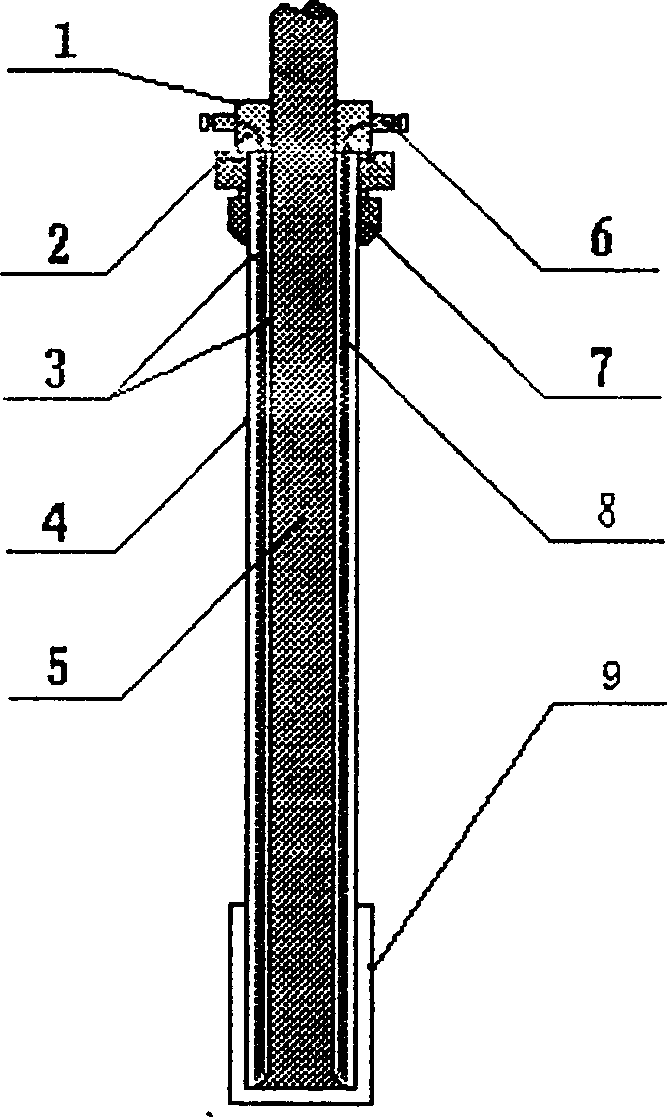

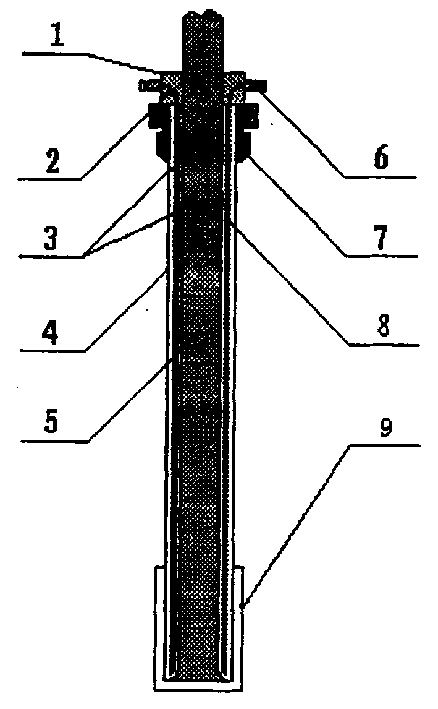

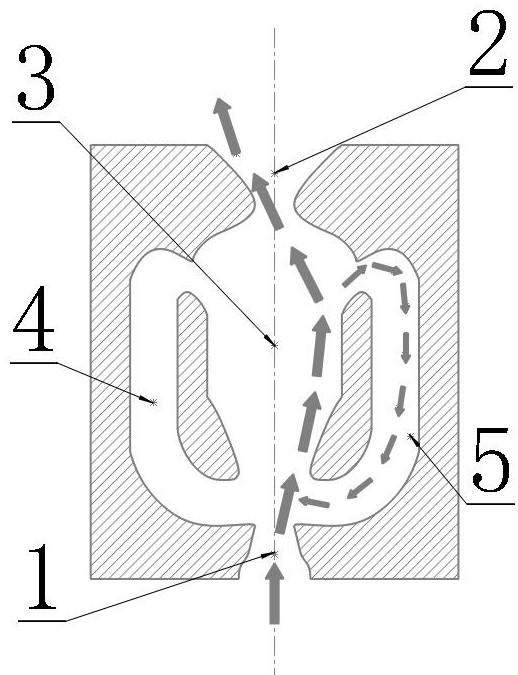

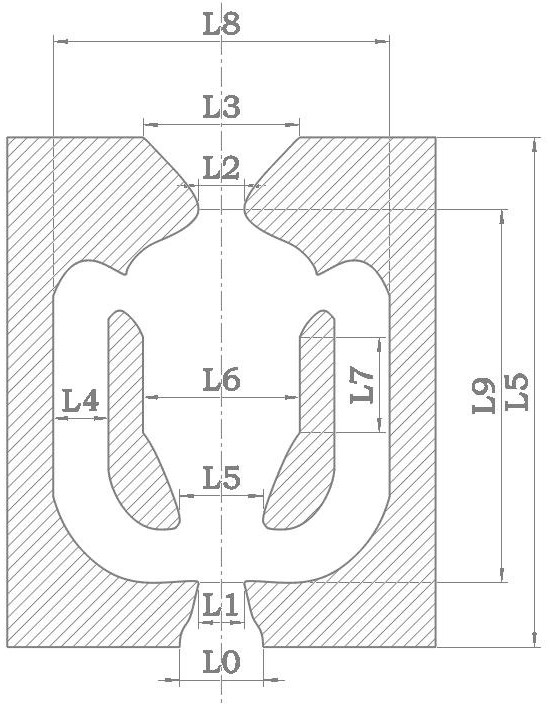

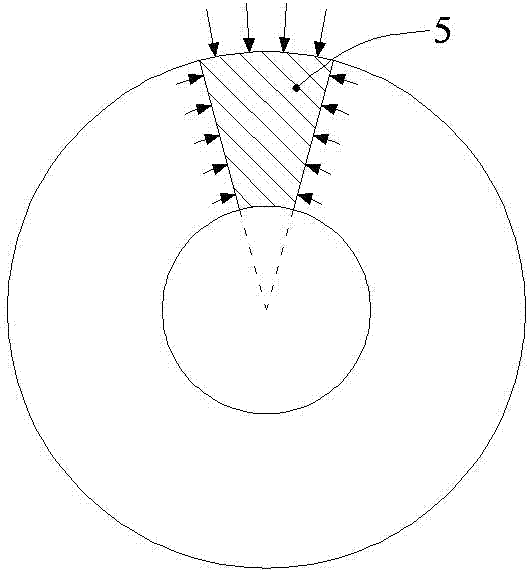

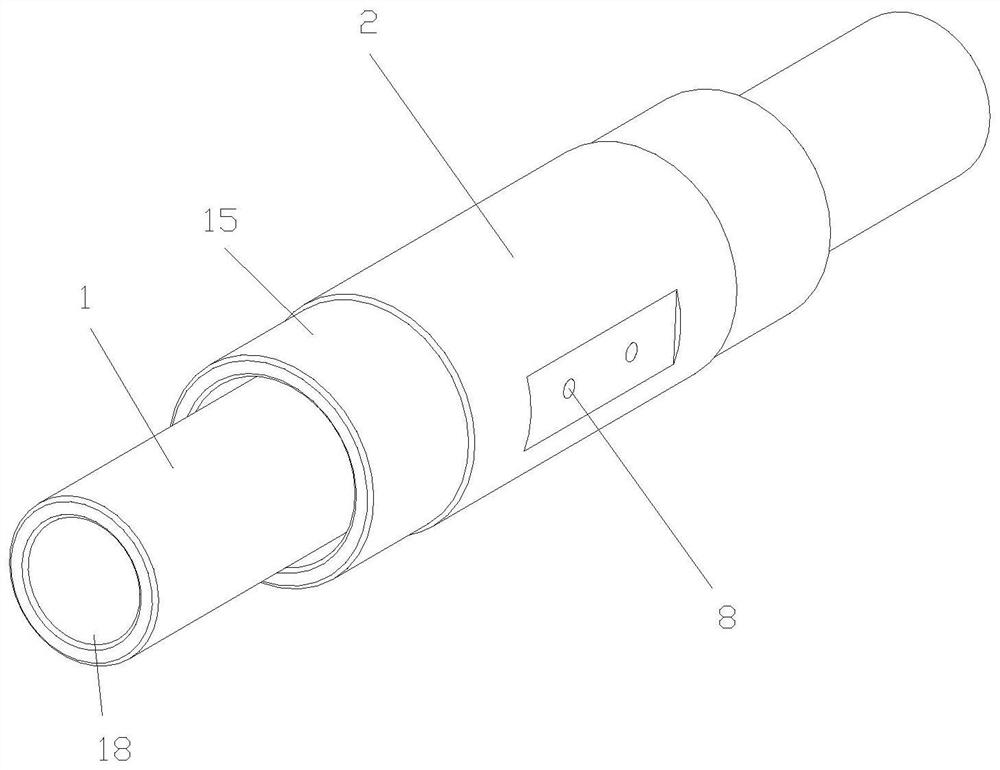

Experiment device for gas permeation around round hole

InactiveCN103471960ASolve sealing difficultiesSimple structurePermeability/surface area analysisExperimental researchField conditions

The device discloses an experiment device for gas permeation around a round hole. The experiment device is characterized by comprising a sealing load box, a permeation specimen, an oil pressure sealing system, a gas supply system and a gas balance system. On the basis that a permeation rule of coal and rock mass around the round hole can be considered to be axisymmetric, the device takes one part for an experiment so as to reflect the overall permeation property of surrounding rocks. Relative to a whole-section experiment device, the device can carry out a large-scale experimental study. The device enables the specimen to be in a stress state similar to that under site conditions through simple loading and can consider the influence of breaking conditions of the coal and rock mass around the round hole to the permeation rule. The device has the characteristics of simple structure and low experiment cost. The device has important meaning for studying gas permeation, adsorption and analysis rules in the coal and rock mass under the particular stress condition around the round hole.

Owner:SHANDONG UNIV OF SCI & TECH

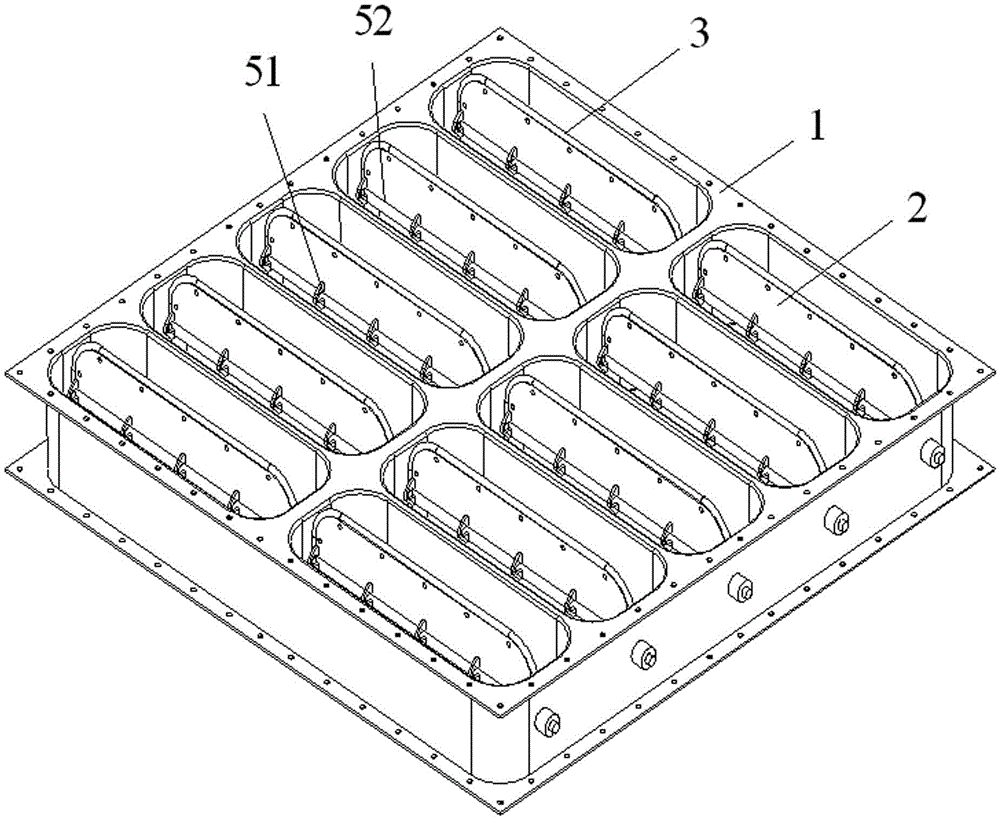

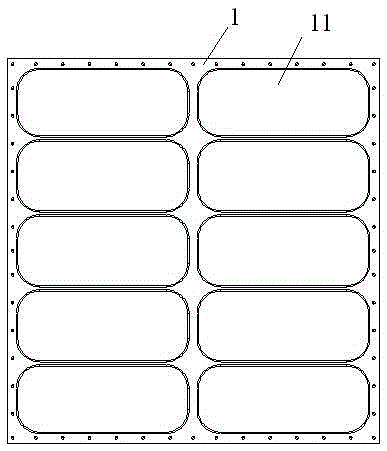

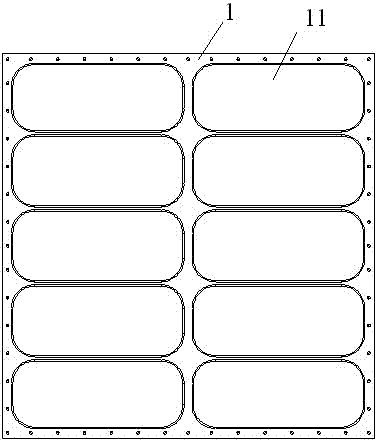

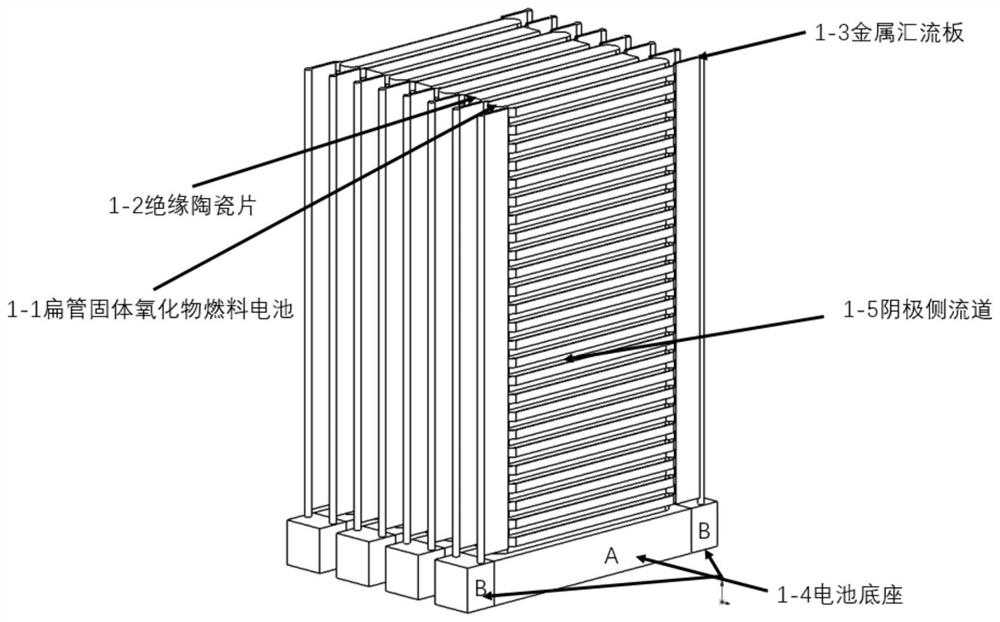

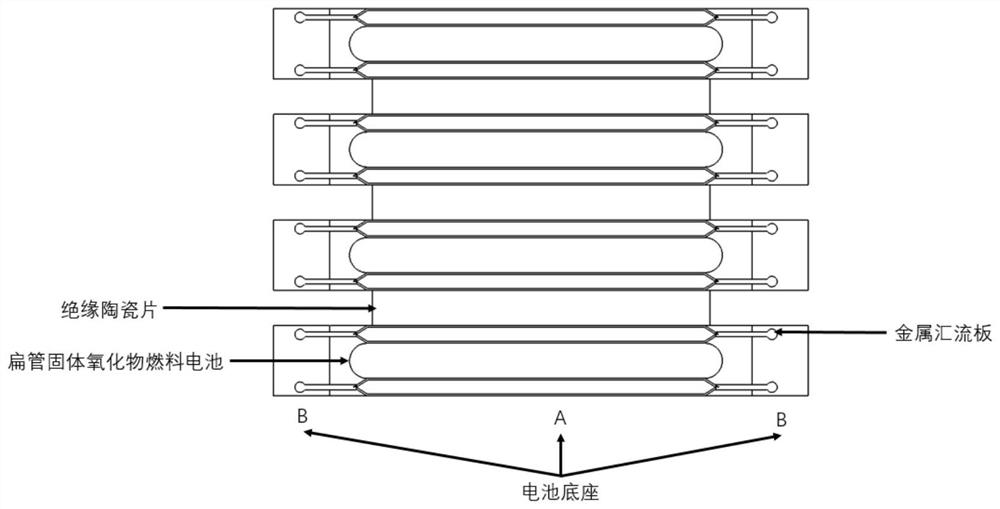

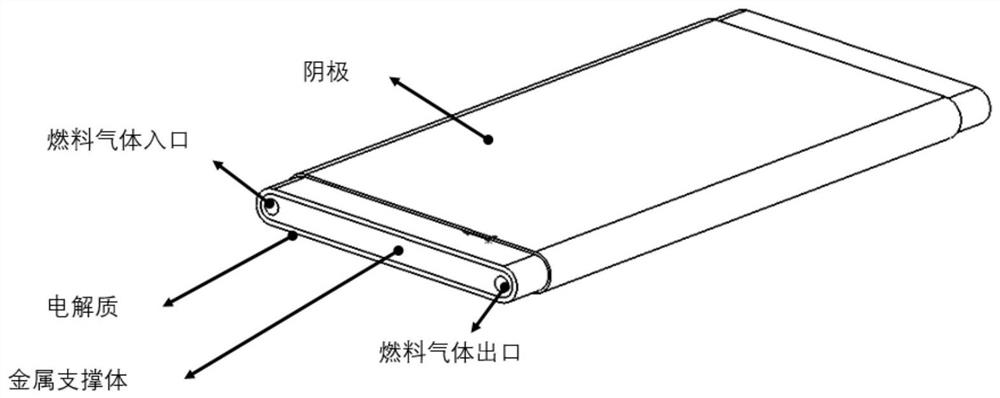

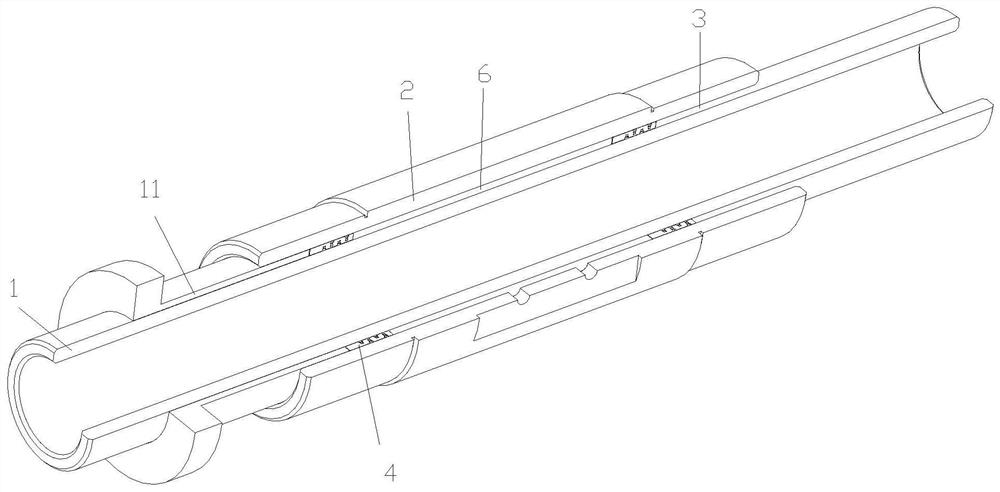

Metal flat tube supporting body, battery/electrolytic cell and battery stack structure

ActiveCN111416134APrevent gas leaksPrevent air leakageCellsReactant parameters controlPhysicsChemistry

The invention provides a metal flat tube supporting body, a battery / electrolytic cell and a battery stack structure. The metal flat pipe supporting body structure comprises a closed end, a porous structure, a fuel gas flow channel and an open end. The closed end and the open end are respectively positioned at two ends of the porous structure; the fuel gas flow channel is arranged in the porous structure and is used for circulating fuel gas; the closed end is of a compact structure and is used for sealing the first end of the fuel gas flow channel. According to the structure provided by the invention, the closed end and the open end are in contact with the electrolyte layer, so the purpose of self-sealing is achieved, and the sealing problem existing in the metal-supported solid oxide fuelcell is effectively solved.

Owner:XI AN JIAOTONG UNIV

Drive motor liquid cooling device, its manufacturing method and drive motor

ActiveCN103475159BImprove cooling effectSolve sealing difficultiesManufacturing dynamo-electric machinesCooling/ventillation arrangementDrive motorCooling fluid

The invention discloses a driving motor liquid cooling device, a manufacturing method thereof and a driving motor. The driving motor liquid cooling device includes a motor casing part, the motor casing part includes a hollow cavity formed by surrounding walls, and there is a cooling liquid channel formed by lost foam casting in the peripheral wall of the motor casing part. The coolant passage has a bent portion. The manufacturing method includes performing integral casting of the motor casing; and removing the solid model of the shape of the cooling liquid channel from the cast and formed motor casing, and integrally forming the cooling liquid channel and at least two communicating with it in the motor casing. hole. This one-piece cooling structure can solve the problems of complex assembly and difficult sealing of the existing inner and outer water jackets, reduce costs and improve production efficiency.

Owner:SHANGHAI E PROPULSION AUTO TECH

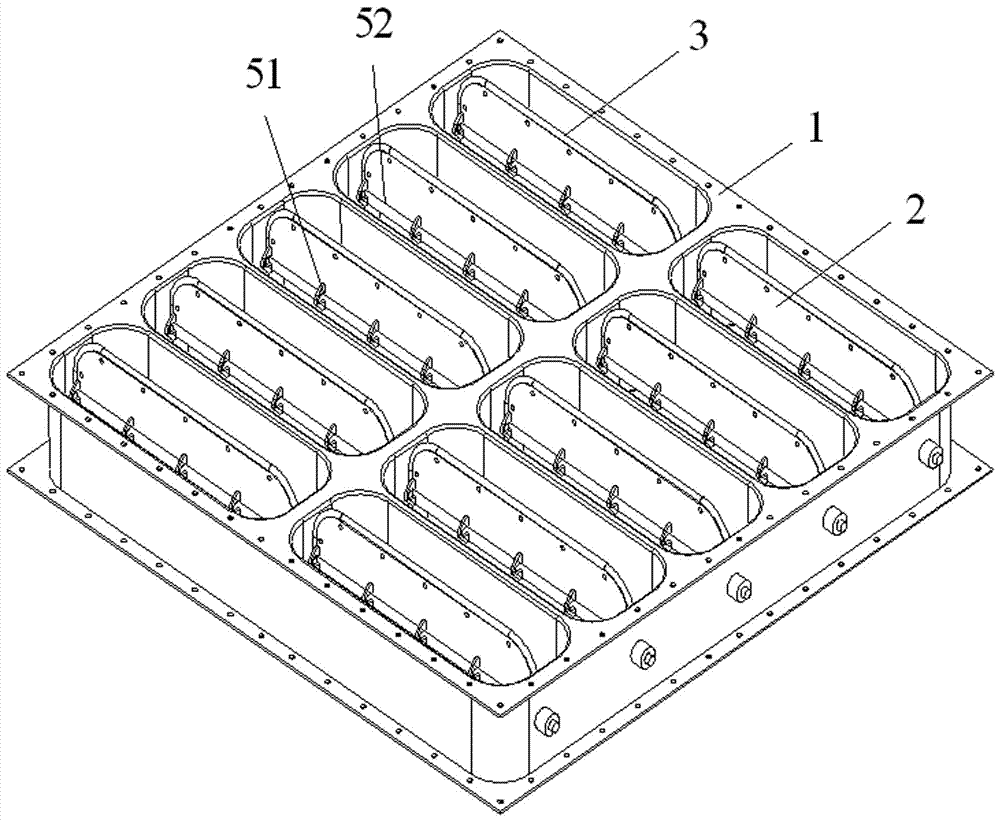

Multiple-blade closed air valve

ActiveCN105351540AImprove sealingSolve sealing difficultiesLift valveEngineeringMechanical engineering

Owner:DIANDUO ELECTROMECHANICAL ENG JIANGSU

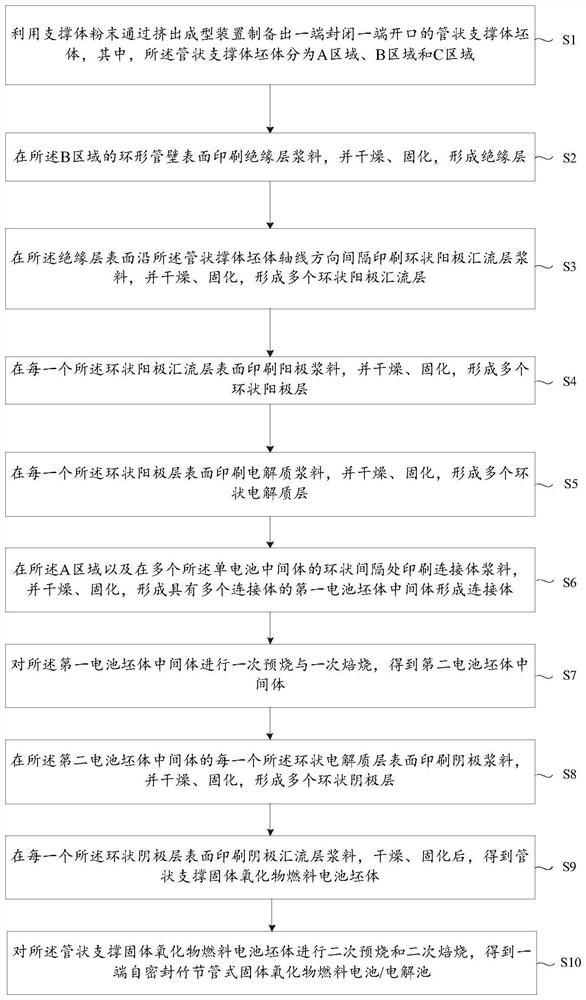

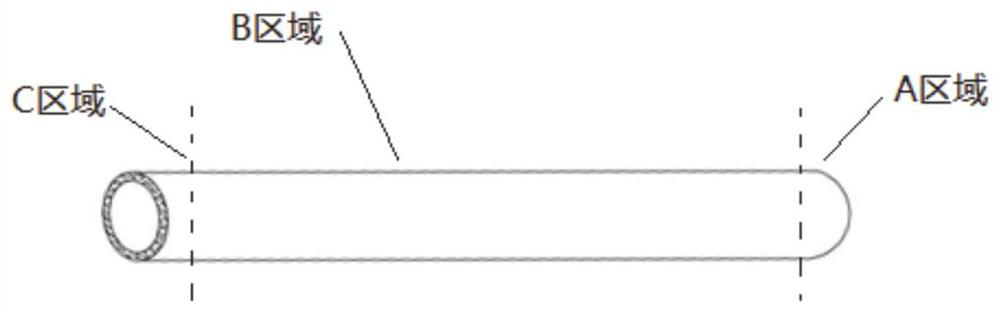

One-end self-sealing bamboo joint pipe type solid oxide fuel cell/electrolytic cell and preparation method of cell/electrolytic cell stack thereof

PendingCN114824388AFast film formationImprove preparation efficiencySolid electrolyte fuel cellsComposite materialElectrical battery

The invention provides a bamboo joint tube type solid oxide fuel cell / electrolytic cell with one self-sealed end and a preparation method of a cell / electrolytic cell stack thereof, and the preparation method comprises the following steps: taking ceramic powder with different properties in a hydrogen environment as a raw material for preparing a support body to obtain a tubular metal ceramic support body blank with a closed end; and then preparing an insulating layer on the surface of the annular tube wall of the support body blank, and preparing a plurality of single batteries connected in series on the surface of the insulating layer, so that a plurality of single battery structures are prepared on the surface of the metal ceramic circular tube-shaped support body. By adopting the screen printing technology, the film forming speed of a plurality of single cell series structures on the support body is effectively improved, the preparation efficiency is effectively improved, the preparation method is simplified, the preparation cost is saved, and commercialized popularization of the solid oxide fuel cell is facilitated.

Owner:XI AN JIAOTONG UNIV

Self-excited oscillation annular jet stirring system

ActiveCN111632570ADoes not harm the molecular structureNo strong shear flowProcess control/regulationChemical/physical/physico-chemical stationary reactorsElectric machineryEngineering

The invention belongs to the technical field of stirring, and particularly relates to a self-excited oscillation annular jet stirring system. The problem that the traditional stirring equipment is difficult to seal due to a motor shaft is solved. The stirring system comprises a stirring kettle shell, an oscillation jet annular stirring device, a medium inlet, a supernatant outlet, a jet liquid pipeline, a diaphragm pressure pump and a medium outlet, wherein the oscillation jet annular stirring device is arranged in the stirring kettle shell, the medium inlet is formed in the top of the stirring kettle shell, the supernatant outlet is formed in one side of the upper part of the stirring kettle shell, the medium outlet is formed in the lower part of the stirring kettle shell, and the supernatant outlet is connected to an inlet of the oscillation jet annular stirring device through the diaphragm pressure pump andthe jet liquid pipeline. According to the self-excited oscillation annular jet flow stirring device, no paddle or blade is used, strong shear flow cannot be generated, and flora and molecular structures of related organic solutions cannot be damaged.

Owner:TAIYUAN UNIV OF TECH

Sealing system of radiation chamber furnace tube of tube-type heating furnace

InactiveCN109708472AImprove sealingThe sealing effect is maintained continuouslyFurnace typesElectric heating for furnacesEngineeringSlide plate

The invention relates to a sealing system of a radiation chamber furnace tube of a tube-type heating furnace, and belongs to the technical field of tube-type heating furnace sealing. The sealing system comprises a furnace top sliding plate arranged around the furnace tube, wherein the furnace top sliding plate is used for slip connection with a furnace top; a sealing element surrounding the furnace tube is arranged on the furnace top sliding plate; a heat preservation sleeve is arranged above the sealing element around the furnace tube; a sealing box is arranged outside the sealing element andthe heat preservation sleeve; the heat preservation sleeve extends out from the sealing box; the sealing element comprises a sealing base; the bottom of the sealing base is connected to the furnace top sliding plate; a taper hole is formed in the sealing base in a longitudinal direction and penetrates the sealing base; a taper sealing element is arranged in the taper hole and is matched with thetaper hole; the upper end of the taper hole has a big opening; the taper sealing element is set as split type taper sealing elements arranged around the furnace tube; the split type sealing elements are not fixedly connected to each other; a pressure plate is arranged above the sealing base; and the heat preservation sleeve is arranged above the pressure plate. The radiation chamber furnace tube sealing system has a simple structure and a good sealing effect.

Owner:王振清 +1

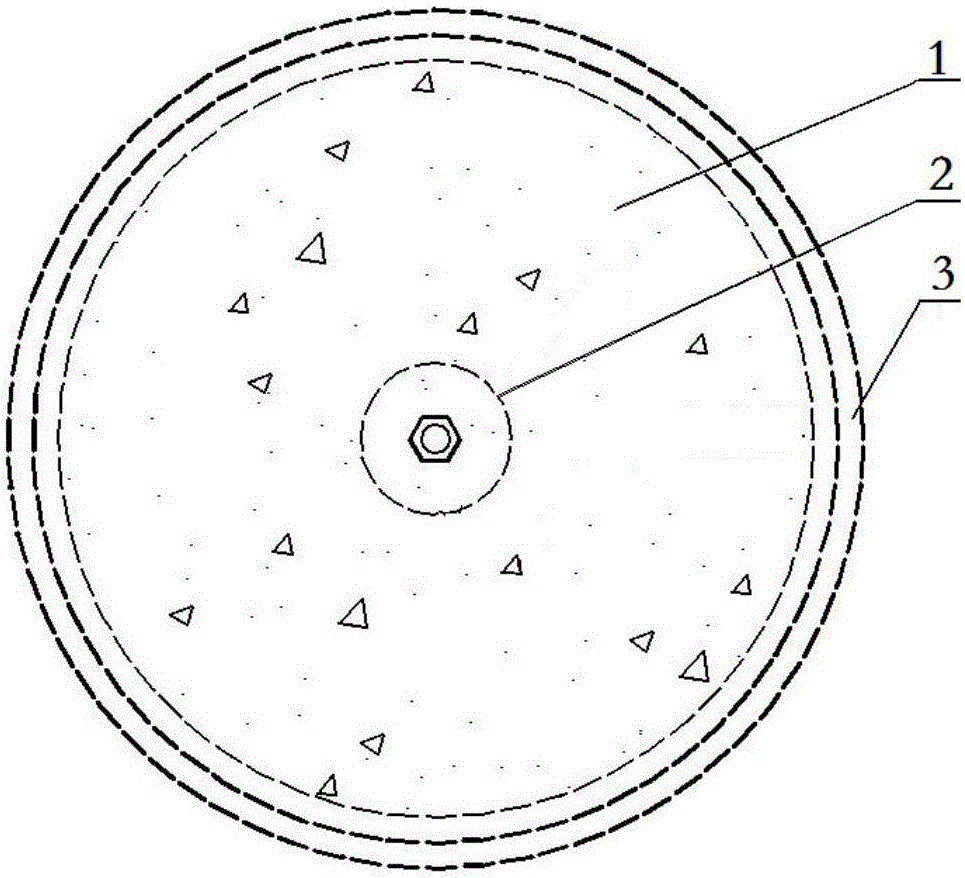

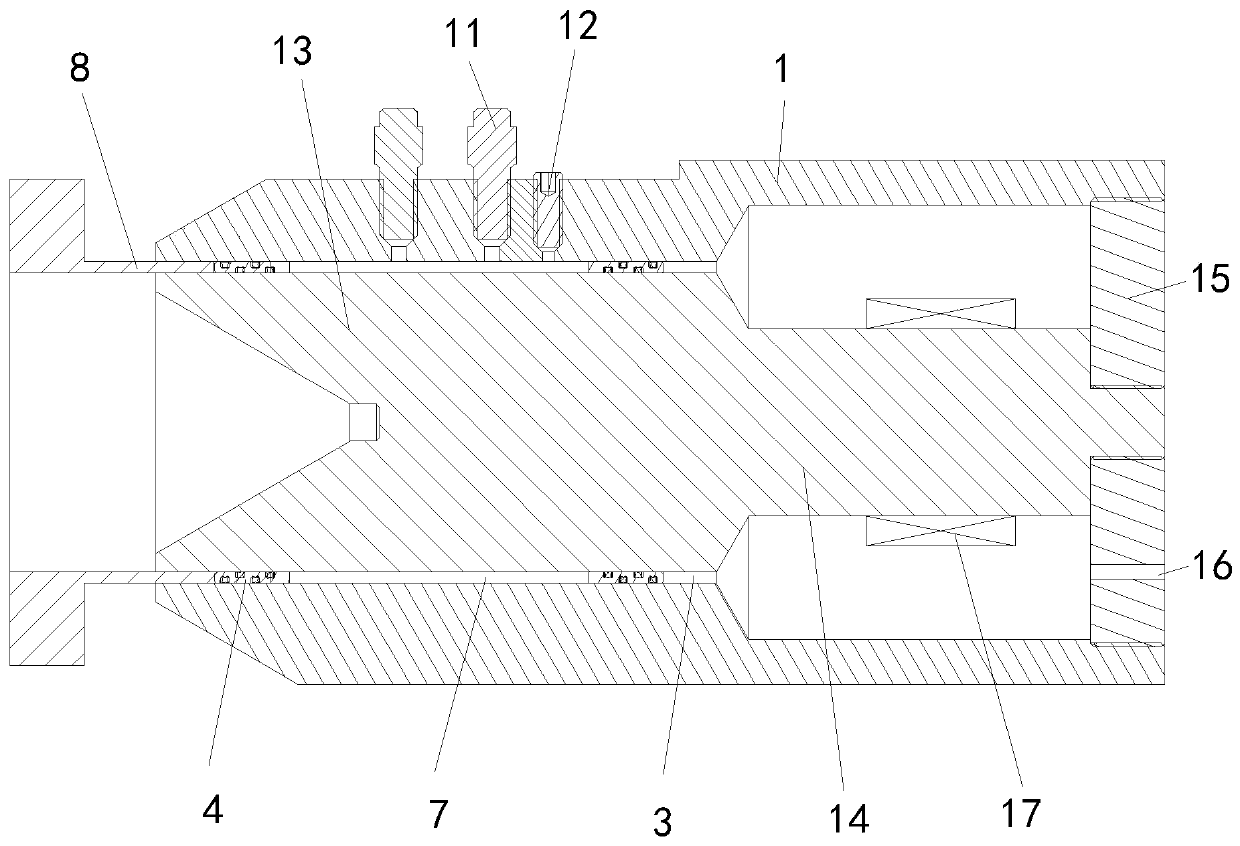

Magnetorheological fluid flow mode rheological property testing device

ActiveCN110736682AEliminate the effects ofImprove volume utilizationFlow propertiesMagnetorheological fluidElectric current flow

The invention discloses a magnetorheological fluid flow mode rheological property testing device. The device comprises a housing and an inner core, an annular gap is formed between the housing and theinner core, an annular piston is arranged in the annular gap, the two ends of the annular piston are in sealed butt joint with the inner wall and the outer wall of the annular gap respectively, a slot is formed in the middle section of the annular piston, the slot and the inner wall and the outer wall of the annular gap jointly define a containing cavity used for containing magnetorheological fluid, and the annular piston can move back and forth in the annular gap under the action of a driving mechanism so as to drive the magnetorheological fluid to move synchronously. The housing or the inner core is provided with a coil winding, the coil winding is connected with an external current source through a wire, the coil winding generates an electromagnetic field after being electrified, and the generated electromagnetic field can radially and uniformly penetrate the whole section of annular gap; and pressure sensors are respectively mounted at the two sensor mounting holes in the outer side of the housing. Compared with the prior art, the magnetorheological fluid flow mode rheological property testing device has the advantages that a rheological property testing scheme under a magnetorheological fluid flowing mode is provided, and the testing accuracy is guaranteed.

Owner:HEFEI UNIV OF TECH

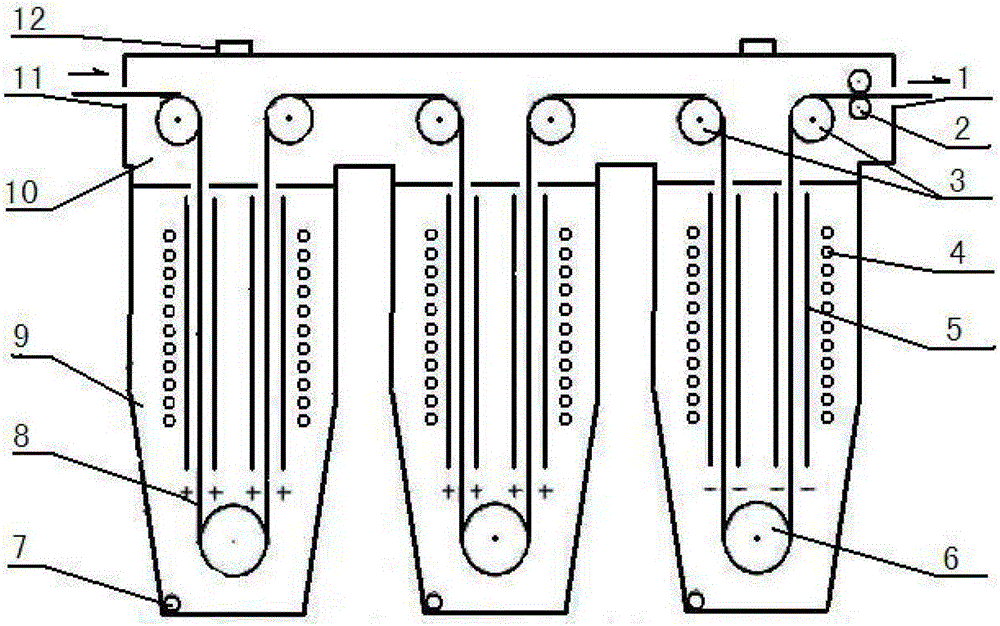

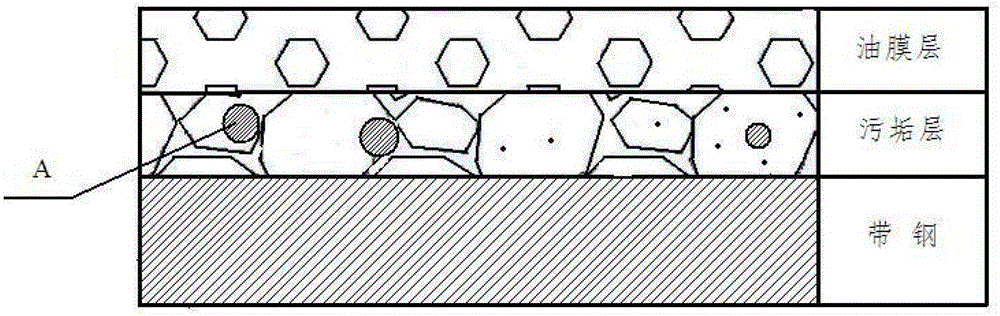

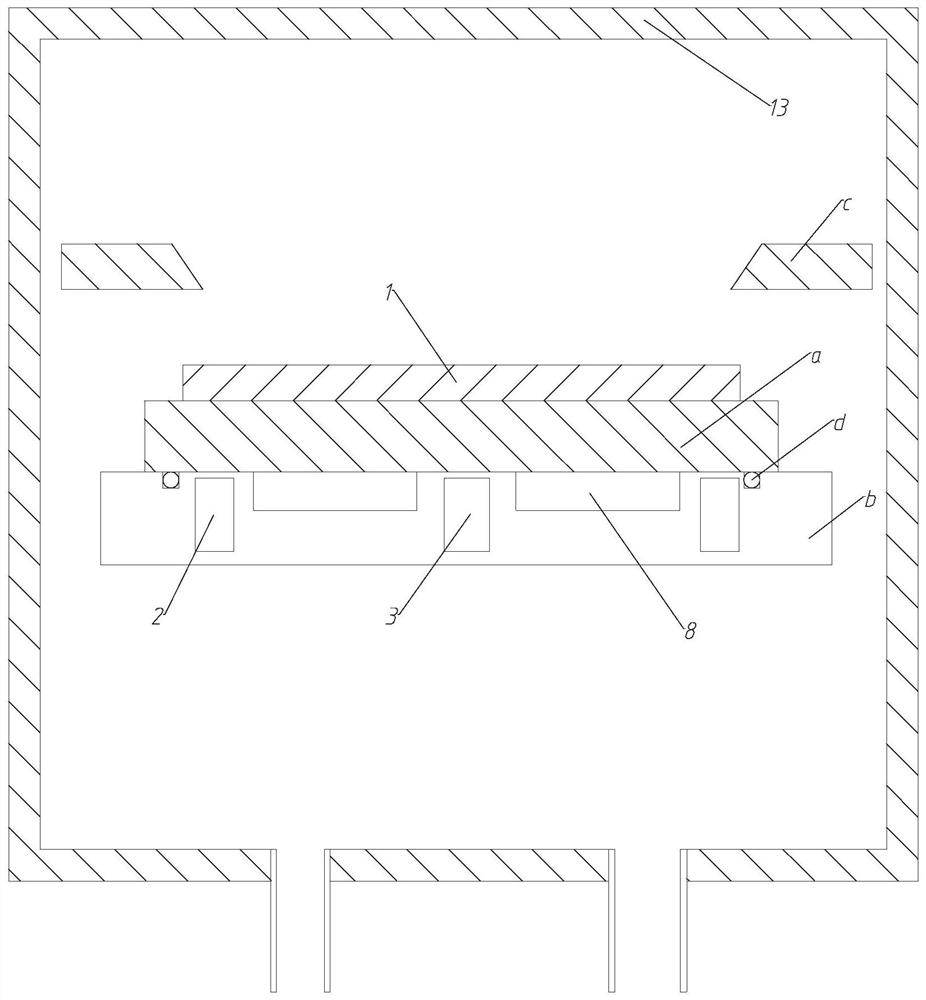

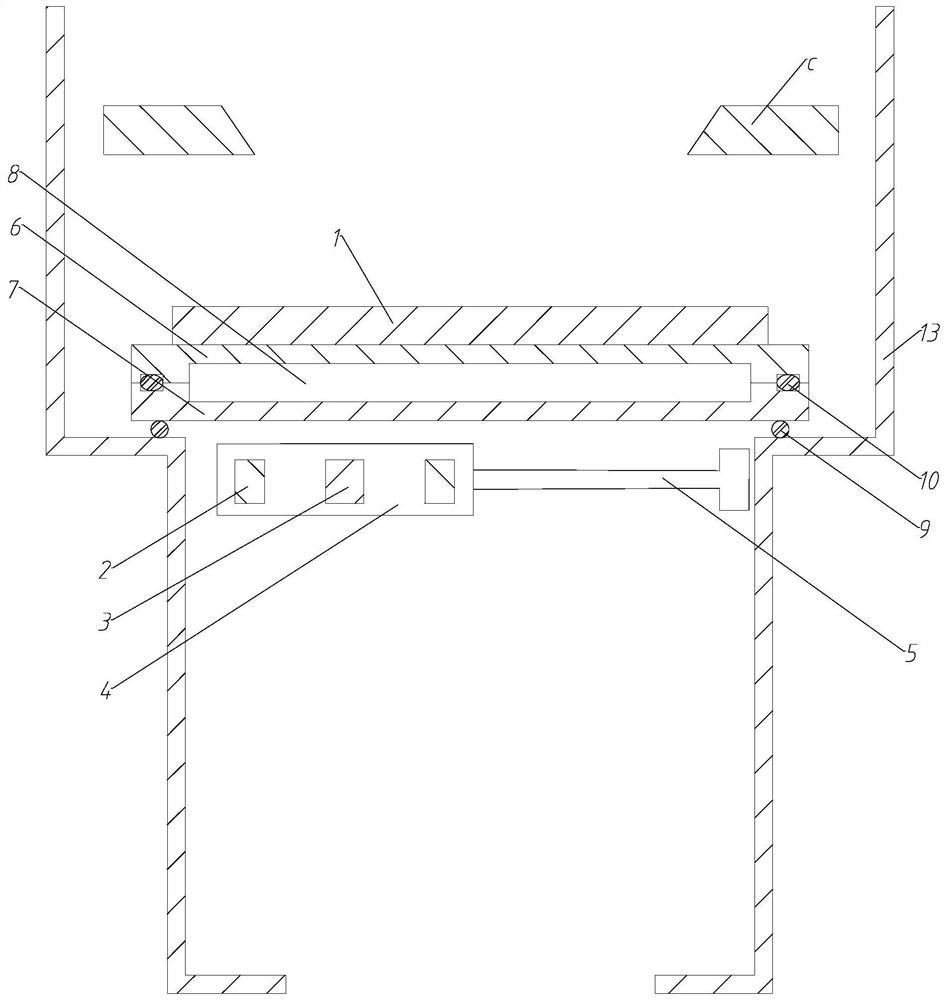

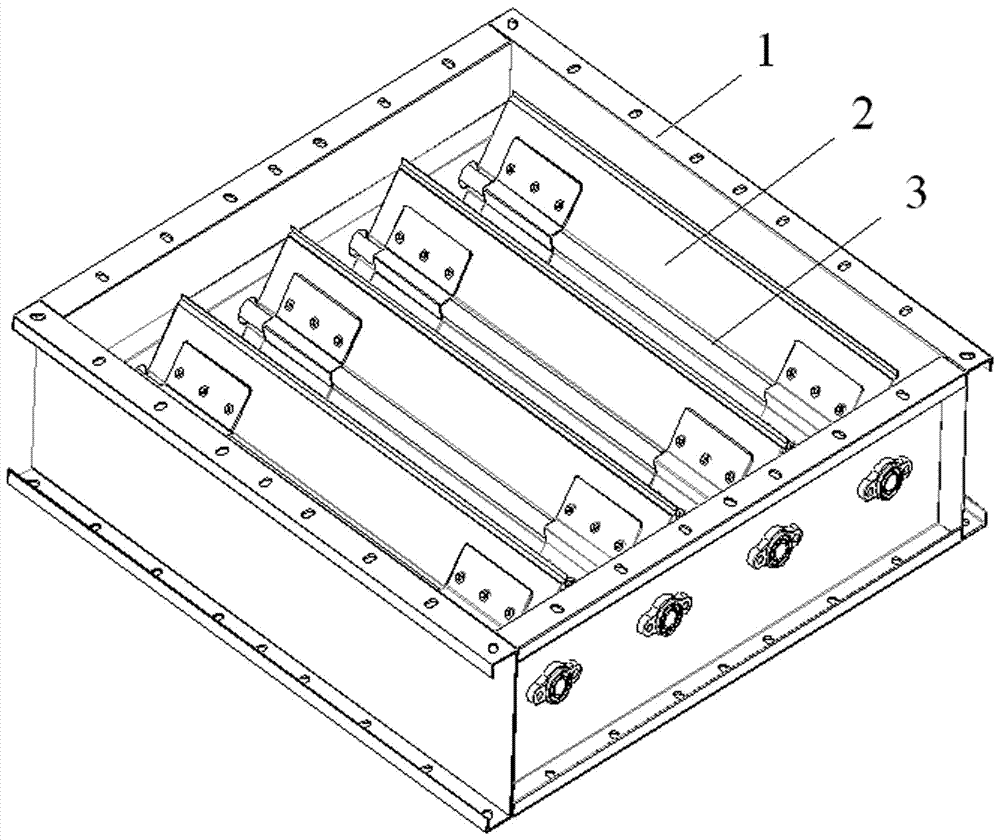

Electrolytic cleaning device for cold-rolled strip steel high-speed cleaning line

ActiveCN103266344BSolve sealing difficultiesQuality is not affectedElectrolysis componentsElectrical polarityStrip steel

The invention discloses an electrolytic cleaning device of a cold-strip steel high-speed cleaning line. The electrolytic cleaning device comprises electrolytic cells. The electrolytic cleaning device is characterized in that more than two sets of electrolytic cells, and more than two sets of plate electrodes, high-pressure shower pipes and sinking rollers arranged in the electrolytic cells are arranged in parallel; an overall transition groove is formed in the upper part of each of the more than two sets of electrolytic cells arranged in parallel; a turning roller is arranged inside each transition groove; a strip steel inlet and a strip steel outlet are arranged at the front end and the rear end of each transition groove; a steam exhaust port is formed in the top part of each transition groove; the plate electrodes inside the more than two sets of electrolytic cells arranged in parallel are respectively arranged according to the plate electrodes with positive and negative polarities; and the electrolytic cell with a negative plate electrode is arranged at the last position of all electrolytic cells which are arranged in parallel. The electrolytic cleaning device disclosed by the invention is good in cleaning effect; hydrogen of permeating into the strip steel in the cleaning process can be effectively removed; the hydrogen embrittlement phenomenon is avoided; and the quality of the strip steel after electrolytic cleaning is prevented from being affected.

Owner:TANGSHAN CAOFEIDIAN DISTRICT SHOUYAN MACHINERY CO LTD

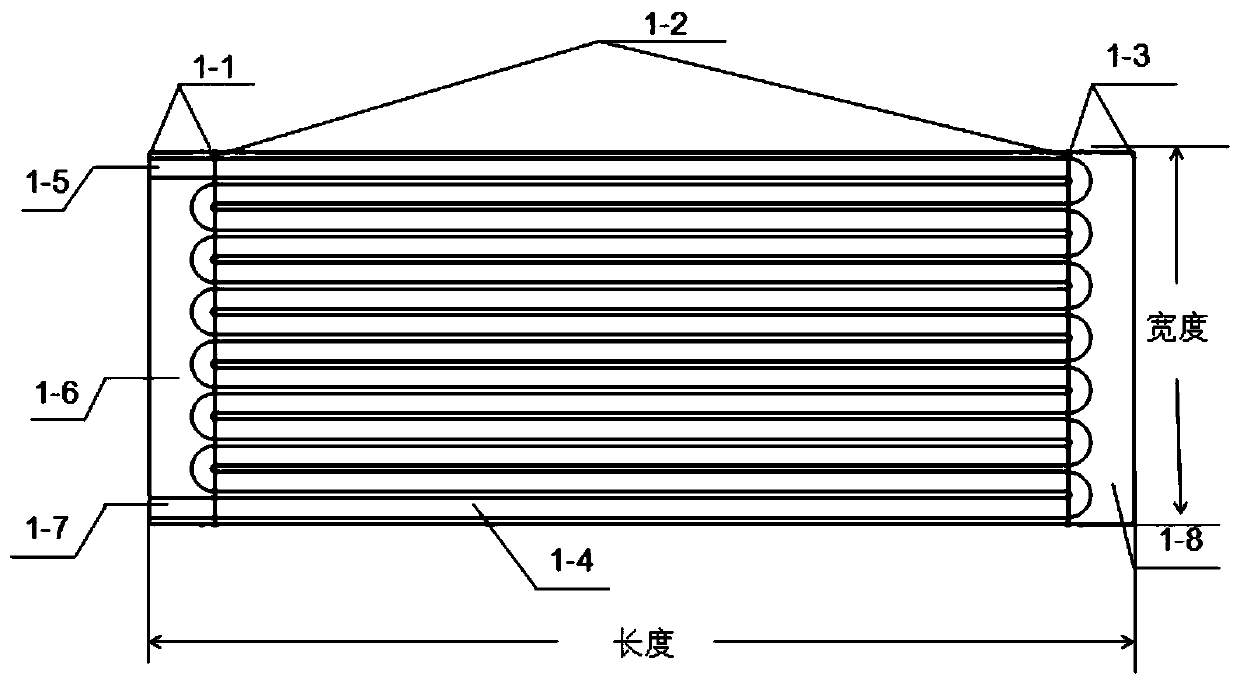

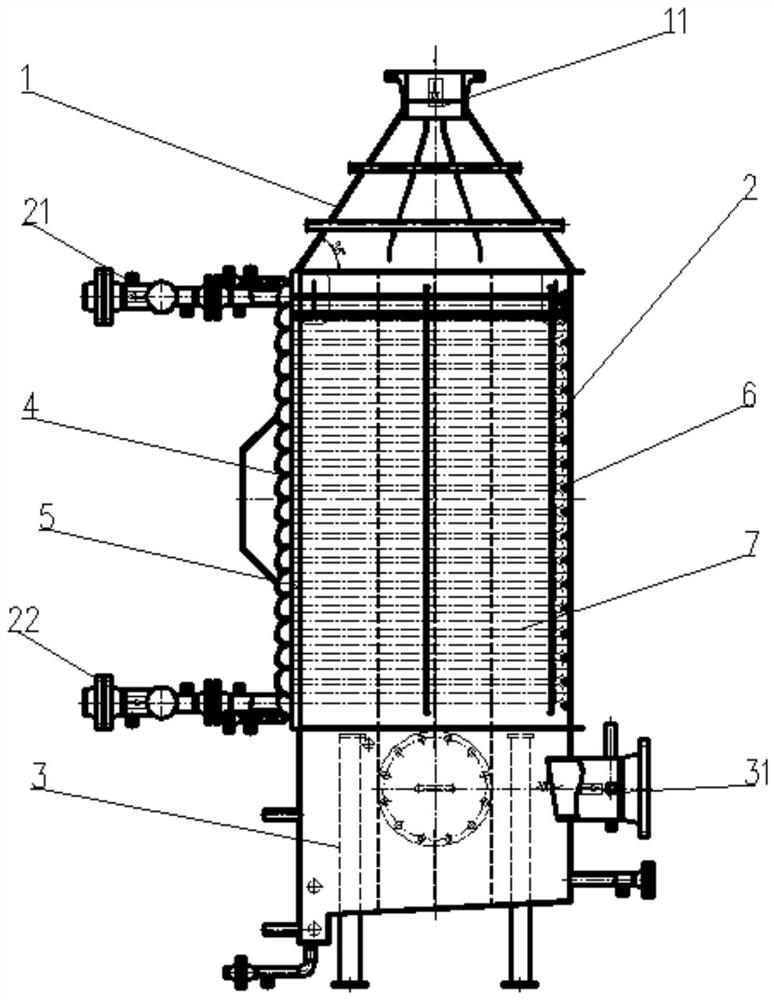

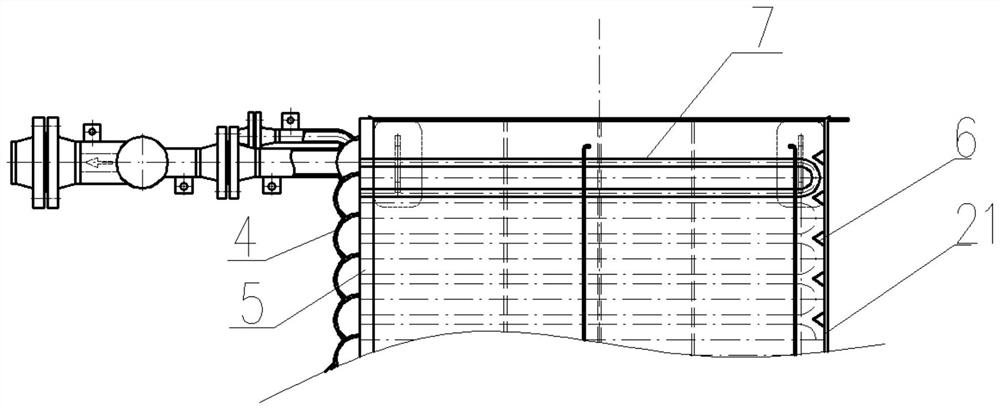

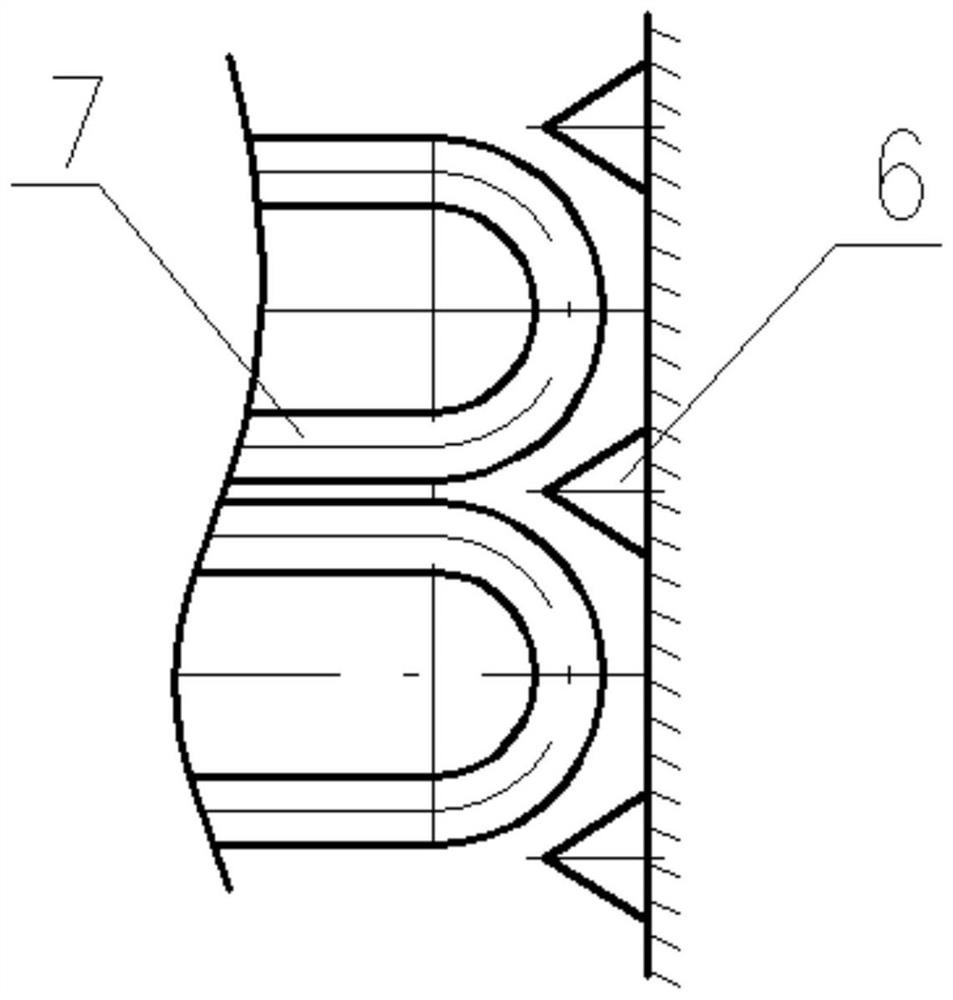

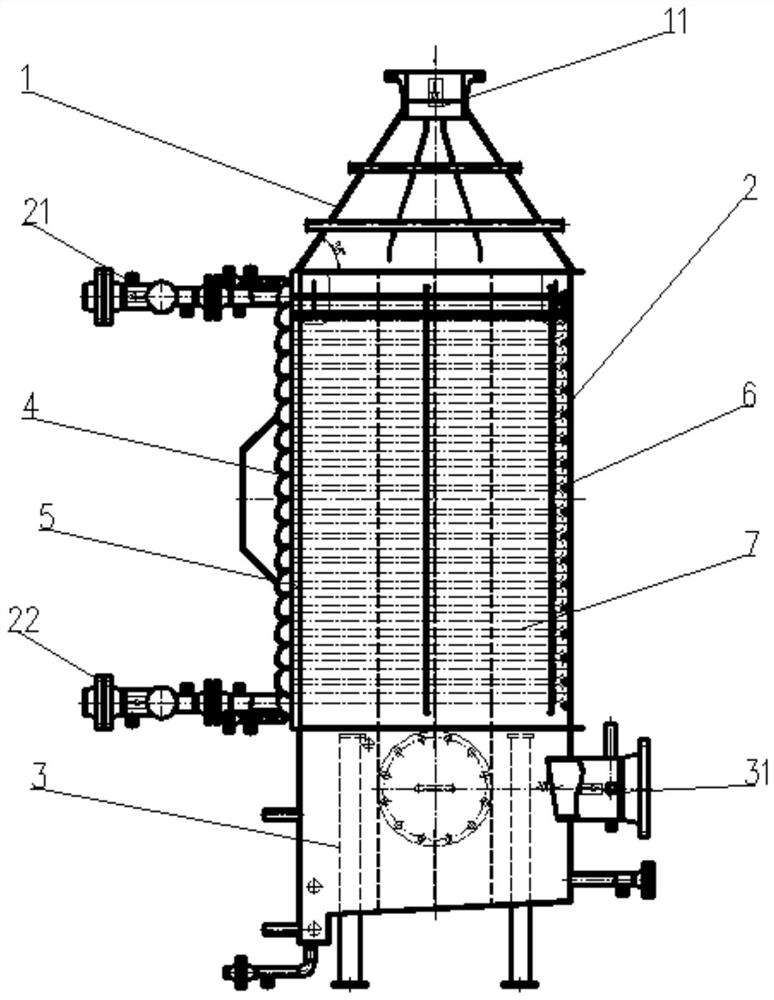

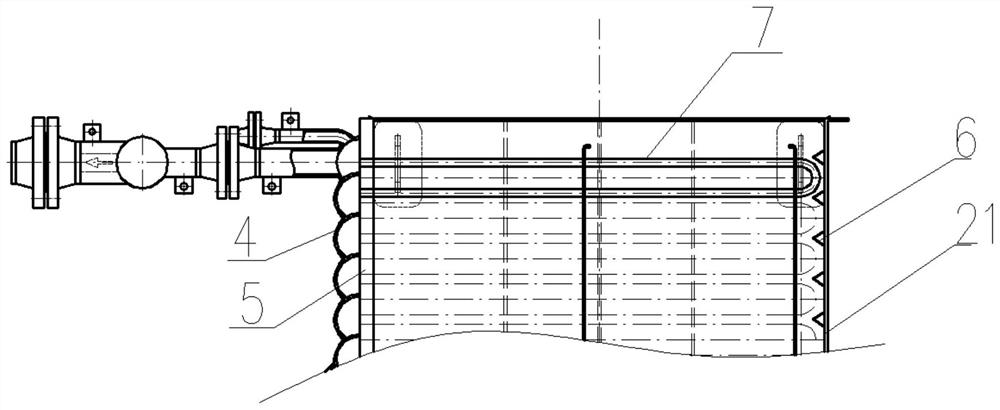

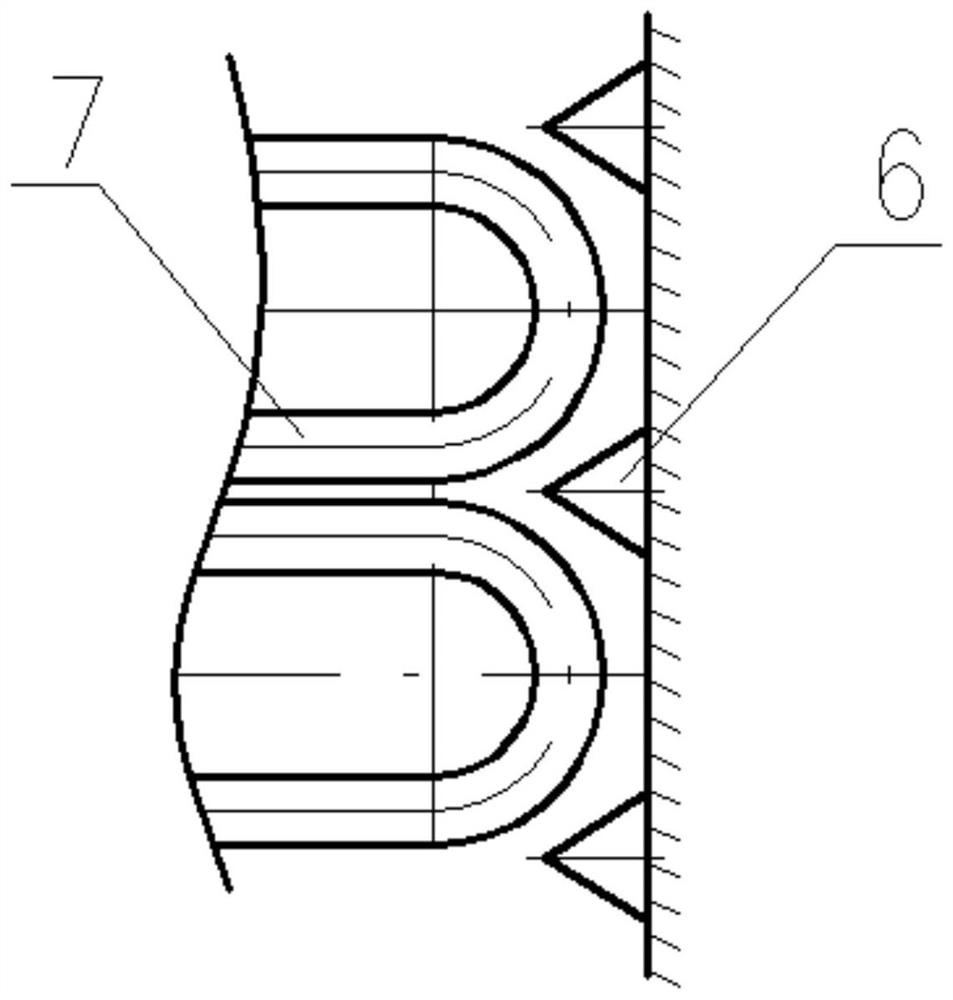

Square shell-and-tube heat exchanger

ActiveCN112146471ASolve sealing difficultiesProtection lifeHeat exchanger casingsStationary tubular conduit assembliesEngineeringMechanical engineering

The invention discloses a square shell-and-tube heat exchanger. The square shell-and-tube heat exchanger comprises a heat exchanger shell, an upper connector and a lower connector, wherein the upper connector is connected to the top of the heat exchanger shell, the lower connector is connected to the bottom of the heat exchanger shell, the heat exchanger shell is square, the two ends of the heat exchanger shell are open, a left side plate of the shell serves as a tube plate, and the outer side face of the tube plate is connected with a semicircular tube bundle; the semicircular tube bundle comprises a plurality of semicircular tubes which are not communicated with one another; a plurality of rows of U-shaped heat exchange tubes are connected in the shell, two communicating ends of each heat exchange tube are correspondingly communicated with two adjacent rows of tube holes in the tube plate, and the two communicating ends of each heat exchange tube are correspondingly communicated withtwo adjacent semicircular tubes; the semicircular pipes at the top end of the semicircular pipe bundle are communicated with a liquid inlet, and the semicircular pipes at the bottom end are communicated with a liquid outlet; and heat exchange liquid enters the heat exchange pipes through the liquid inlet and flows out of the liquid outlet. According to the square shell-and-tube heat exchanger, the more heat exchange tubes can be connected under the same length, so that the problem that the multi-flow heat exchange tubes are difficult to seal is solved.

Owner:YANGZHONG SHENYANG HEAT EXCHANGE EQUIP

A square shell-and-tube heat exchanger

ActiveCN112146471BSolve sealing difficultiesProtection lifeHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerEngineering

The invention discloses a square shell-and-tube heat exchanger, which comprises a heat exchanger shell, an upper connector connected to the top of the heat exchanger shell, and a lower connector connected to the bottom of the heat exchanger shell. The shell is square with openings at both ends. The left side plate of the shell is a tube plate. The outer surface of the tube plate is connected with a semicircular tube bundle. The semicircular tube bundle includes a plurality of semicircular tubes that are not connected to each other; A row of U-shaped heat exchange tubes, the two connected ends of the heat exchange tubes are respectively connected to the two adjacent rows of tube holes in the tube sheet, and the two connected ends of the heat exchange tubes are respectively connected to two adjacent semicircular tubes The semicircular tube at the top of the semicircular tube bundle communicates with the liquid inlet, and the semicircular tube at the bottom communicates with the liquid discharge port; the heat exchange liquid enters the heat exchange tube through the liquid inlet and flows out from the liquid discharge port; the present invention can be used in the same More heat exchange tubes are connected at a lower length, which solves the problem of difficult sealing of multi-process heat exchange tubes.

Owner:YANGZHONG SHENYANG HEAT EXCHANGE EQUIP

Experimental device for gas permeation under complex conditions

InactiveCN103471975BSolve sealing difficultiesSimple structurePermeability/surface area analysisField conditionsEngineering

The invention discloses an experimental device for gas permeation under complex conditions. The experimental device is characterized by comprising a sealing loading box, a permeation test piece, a loading device, an oil pressure sealing system, a gas supplying system and a gas balancing system, wherein the loading device is used for loading the permeation test piece to enable the permeation test piece to be in a predetermined stress state; under the assistance of the oil pressure sealing system, a first pressure chamber comprises a rectangular frame, force transmission columns, side baffle plates and the outer side surface of the permeation test piece, and a second pressure chamber comprises the side baffle plates and the inner side surface of the permeation test piece; under the effect of gas pressure difference, gas in the first pressure chamber gradually permeates into the second pressure chamber, so that the permeation law of the gas around holes can be researched. The experimental device can be used for enabling coal and rock masses to be in a stress state similar to field conditions, and the influence of the breaking situations of the coal and rock masses around the holes in the permeation law can be considered, so that the experimental device has great significance on the research on the permeation, absorption and resolution law of the gas in the coal and rock masses around roadways under the complex conditions.

Owner:SHANDONG UNIV OF SCI & TECH

Shaft run-through position sealed structure of pedestal type sliding bearing structured motor

PendingCN108258841ASolve sealing difficultiesReduce leakageMechanical energy handlingSupports/enclosures/casingsEngineeringPlain bearing

The invention relates to a shaft run-through position sealed structure of a pedestal type sliding bearing structured motor. The shaft run-through position sealed structure consists of a shaft, a pedestal type sliding bearing, pressing plates, a bolt connecting piece, a sealing cushion, a sealing plate, a sealing cover and a machine base; the shaft is mounted in the machine base; the pedestal typesliding bearing is mounted on the shaft; the upper and lower pressing plates are mounted between the machine base and the pedestal type sliding bearing through the bolt connecting piece; the sealing cushion is mounted between the upper and lower pressing plates; the sealing plate is mounted on the machine base through a bolt; and the sealing cover is mounted on the sealing plate. The shaft run-through position sealed structure is simple in structure and reasonable in design; and by forming an independent cavity between the sealing cover and the pedestal type sliding bearing, the original dynamic sealing structure is converted into a static sealing structure, and a good sealing effect is proved by tests, so that the problem of difficulty in shaft run-through position sealing for a long termis solved, the gas leakage amount of the motor cavity is greatly reduced, energy is saved, and product reliability and safety are improved.

Owner:JIAMUSI ELECTRIC MACHINE

Magnet rotating target gun

PendingCN112575304AUniform etchingUniform average etch rateVacuum evaporation coatingSputtering coatingEngineeringMaterials science

The invention relates to the technical field of vacuum coating equipment, and provides a magnet rotating target gun. The gun comprises a target material, a substrate and a magnetic control assembly which are sequentially arranged in a target gun cavity from top to bottom, and the magnetic control assembly comprises an outer ring magnet, a center magnet arranged in the center of the outer ring magnet and a coating layer coating the outer ring magnet and the center magnet. A driving device connected with the magnetic control assembly is additionally arranged, the driving device drives the magnetic control assembly to rotate or reciprocate, the substrate comprises an upper plate and a lower plate, a sealed cooling cavity is formed between the upper plate and the lower plate, and the lower portion of the substrate is connected with the target gun cavity in a sealed mode through a first sealing ring. By means of the technical scheme, the problem that in the prior art, the target material etching utilization rate is low is solved.

Owner:长沙元戎科技有限责任公司

A multi-blade airtight air valve

ActiveCN105351540BImprove sealingSolve sealing difficultiesLift valveEngineeringMechanical engineering

Owner:DIANDUO ELECTROMECHANICAL ENG JIANGSU

Tube-in-tube fuel warmer prepared with positive temperature coefficient high-molecular material

InactiveCN1123688CSolve sealing difficultiesMachines/enginesThermal treatment of fuelMolecular materialsScrew thread

The present invention relates to an automatic heating thermostatic device for fuel vehicle, in particular, it relates to a heating thermostatic device for diesel vehicle. Said invention adopts PTC sleeve to heat the whole fuel sucking pipe, and the inside and outside of the heating pipe soaked in the fuel are covered with metal pipe or plastic pipe, and its bottom end is welded and sealed. Said automatic heating thermostatic device is identical to the ordinary fuel sucking pipe in installation, i. e. uses the screw thread to make connection so as to solve the problems of only heating fuel sucking pipe part and difficult in sealing of heating material and electrode. The adoption of said automatic heating thermostatic device can completely melt the condensated diesel oil being in fuel sucking pipe within few minutes.

Owner:CHINA PETROCHEMICAL CORP

A cell stack structure of a flat tubular solid oxide fuel cell

ActiveCN111403765BIncrease volumetric power densityIncrease the effective areaFuel cell heat exchangeFuel cell shape/formFuel cellsEngineering

The invention provides a cell stack structure of a flat tubular solid oxide fuel cell, the cell stack structure includes: a plurality of battery units and a plurality of insulating ceramic units, and a set of insulating ceramic units is arranged between each two insulating ceramic units. The above-mentioned battery unit; wherein, the battery unit includes: a metal manifold, a flat tube type solid oxide fuel, a base A and a base B; the base A and the base B are respectively used to fix the flat tube type solid oxide fuel and the metal manifold, and Base A and Base B are also used to conduct anodic and cathodic currents, respectively. Through the structure provided by the present invention, while solving the sealing problem, it also effectively solves the problems of how to make and arrange the flat tube solid oxide fuel cells with battery functional layers on both parallel sides into a battery stack, how to lead out and collect the two parallel sides The cathodic current problem.

Owner:XI AN JIAOTONG UNIV

A self-excited oscillating annular jet mixing system

ActiveCN111632570BDoes not harm the molecular structureNo strong shear flowProcess control/regulationChemical/physical/physico-chemical stationary reactorsElectric machineryEngineering

The invention belongs to the technical field of stirring, in particular to a self-excited oscillating annular jet stirring system. It solves the problem that the traditional stirring equipment is difficult to seal due to the motor shaft, including the stirring tank shell, the oscillating jet annular stirring device, the medium inlet, the supernatant liquid outlet, the jet liquid pipeline, the diaphragm pressure pump and the medium outlet, and the oscillating jet annular stirring The device is installed in the shell of the stirred tank, the top of the shell of the stirred tank is provided with a medium inlet, the upper side of the shell of the stirred tank is provided with a supernatant outlet, the lower part of the shell of the stirred tank is provided with a medium outlet, and the outlet of the supernatant passes through the diaphragm pressure pump and the jet liquid The pipeline is connected with the inlet of the oscillating jet annular stirring device. The self-excited oscillating annular jet stirring device of the present invention does not use paddles and blades, does not generate strong shear flow, and does not damage the molecular structure of bacterial flora and related organic solutions.

Owner:TAIYUAN UNIV OF TECH

Experiment device for gas permeation around round hole

InactiveCN103471960BSolve sealing difficultiesSimple structurePermeability/surface area analysisExperimental researchField conditions

The device discloses an experiment device for gas permeation around a round hole. The experiment device is characterized by comprising a sealing load box, a permeation specimen, an oil pressure sealing system, a gas supply system and a gas balance system. On the basis that a permeation rule of coal and rock mass around the round hole can be considered to be axisymmetric, the device takes one part for an experiment so as to reflect the overall permeation property of surrounding rocks. Relative to a whole-section experiment device, the device can carry out a large-scale experimental study. The device enables the specimen to be in a stress state similar to that under site conditions through simple loading and can consider the influence of breaking conditions of the coal and rock mass around the round hole to the permeation rule. The device has the characteristics of simple structure and low experiment cost. The device has important meaning for studying gas permeation, adsorption and analysis rules in the coal and rock mass under the particular stress condition around the round hole.

Owner:SHANDONG UNIV OF SCI & TECH

A tower cyclone flow test device that converts axial compression into radial sealing

ActiveCN112362352BTight and reliable sealSolve sealing difficultiesEngine sealsGas-turbine engine testingAxial compressionTower

The object of the present invention is to provide a tower cyclone flow test device which converts axial compression into radial sealing, which includes a pressure stabilizing cylinder, a convex-concave cover plate, and a cross pressure plate. The pressure stabilizing cylinder and the convex-concave cover plate pass through The firmware is fixed together. The convex-concave cover plate adopts a convex step on the inner cavity surface and a stepped design on the outer concave cavity. There is a central hole in the center of the convex-concave cover plate. The central hole is equipped with a cone-shaped rubber plug and a tower swirl. The axial position of the tower cyclone is fixed by the small flat end face of the step. The inlet angle of the convex step and the center hole adopts a smooth transition. The cross pressing plate is fixed on the convex and concave cover plate, and the middle part of the cross pressing plate is opened. The middle part of the tower cyclone is located in the hole in the middle part of the cross platen. The O-ring of the present invention seals tightly and reliably in the formed triangular ring space, realizes the conversion of axial compression into radial sealing, and effectively solves the problem caused by the increasingly smaller non-essential axial installation end face of the current tower cyclone The problem of difficult sealing of flow test.

Owner:中国船舶重工集团公司第七0三研究所

Single-stage gravity pump organic Rankine power generation and heating combined system and its cycle

The invention provides a single-stage gravity pump organic Rankine power generation and heat supply combined system and a cycle of the combined system, wherein the combined system comprises a circulation power generation closed loop formed by sequentially connecting an evaporator, an expansion machine and a condenser, the expansion machine is externally connected with a power generator, the condenser comprises an organic working medium pipeline and a circulation water pipeline, low-boiling-point organic working media release heat to circulation water in the condenser, the circulation water pipeline is connected with a floor heating pipeline through a regulating valve, the floor heating pipeline is then connected with the circulation water pipeline through a circulation water pump, and a floor heating closed loop is formed; the circulation power generation closed loop and the floor heating closed loop form the combined system. The pressure difference of the organic working media is utilized for replacing working medium conveying equipment of a working medium pump, the heat energy is directly converted into the pressure difference required by the circulation, and the working medium pressurization and the application of the conveying equipment are avoided.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Electrorheological fluid flow mode rheological property test device

ActiveCN110579425BImprove volume utilizationGuaranteed accuracyFlow propertiesCoaxial lineEngineering

The invention discloses an electrorheological fluid flow mode rheological property testing device, which includes an anode electrode cylinder and a cathode electrode cylinder arranged coaxially along the inside and outside. The gap between the anode electrode cylinder and the cathode electrode cylinder forms an annular gap, and two annular pistons are connected with the anode electrode cylinder. The inner and outer walls of the annular gap together form a chamber for accommodating electrorheological fluid. Under the action of the driving mechanism, the two annular pistons can move back and forth synchronously in the annular gap, thus driving the electrorheological fluid in the chamber to synchronize Move; the radial uniform electric field generated after the anode electrode cylinder and cathode electrode cylinder are connected to the external power supply can vertically pass through the entire annular gap; there are two sensor installation holes and at least one exhaust bolt hole on the outside of the cathode electrode cylinder. A pressure sensor is installed at each sensor installation hole, and an exhaust bolt is installed at the exhaust bolt hole. Advantages of the present invention: It provides a rheological property testing scheme under the flow mode of electrorheological fluid, ensuring the accuracy of testing.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com