Drive motor liquid cooling device, its manufacturing method and drive motor

A technology for driving motors and cooling devices, used in cooling/ventilation devices, electromechanical devices, manufacturing motor generators, etc., can solve the problems of difficult sealing, complicated assembly of inner and outer water jackets, etc., to solve difficult sealing, reduce requirements, and increase cooling. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

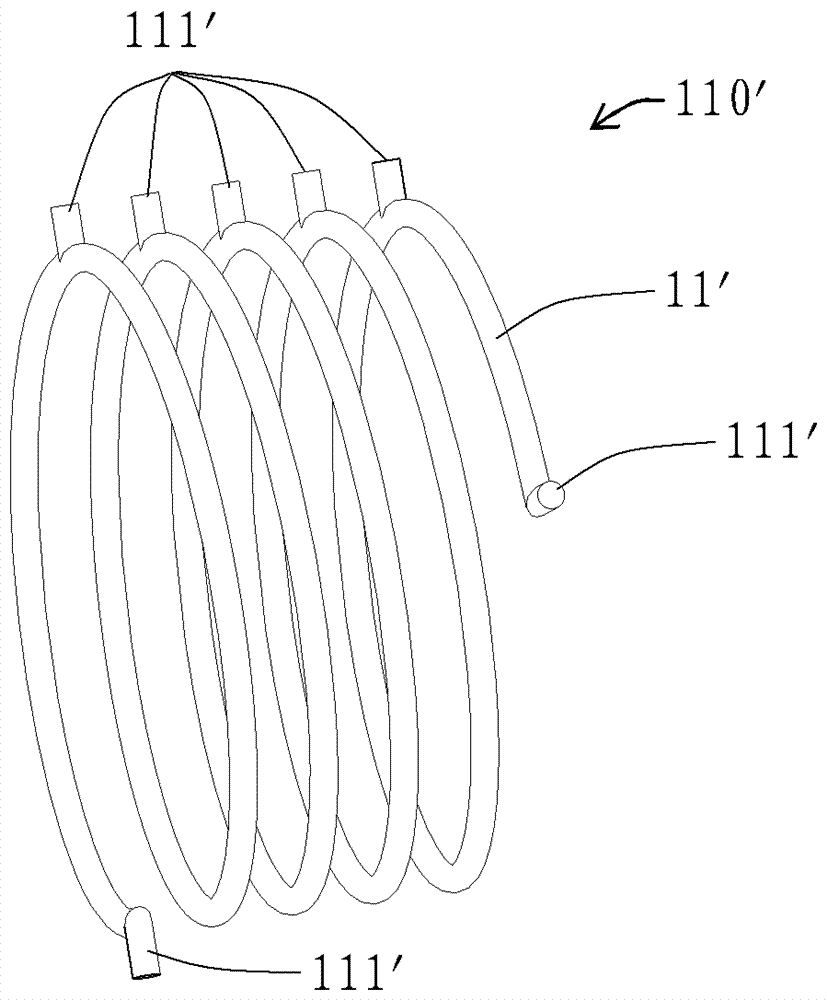

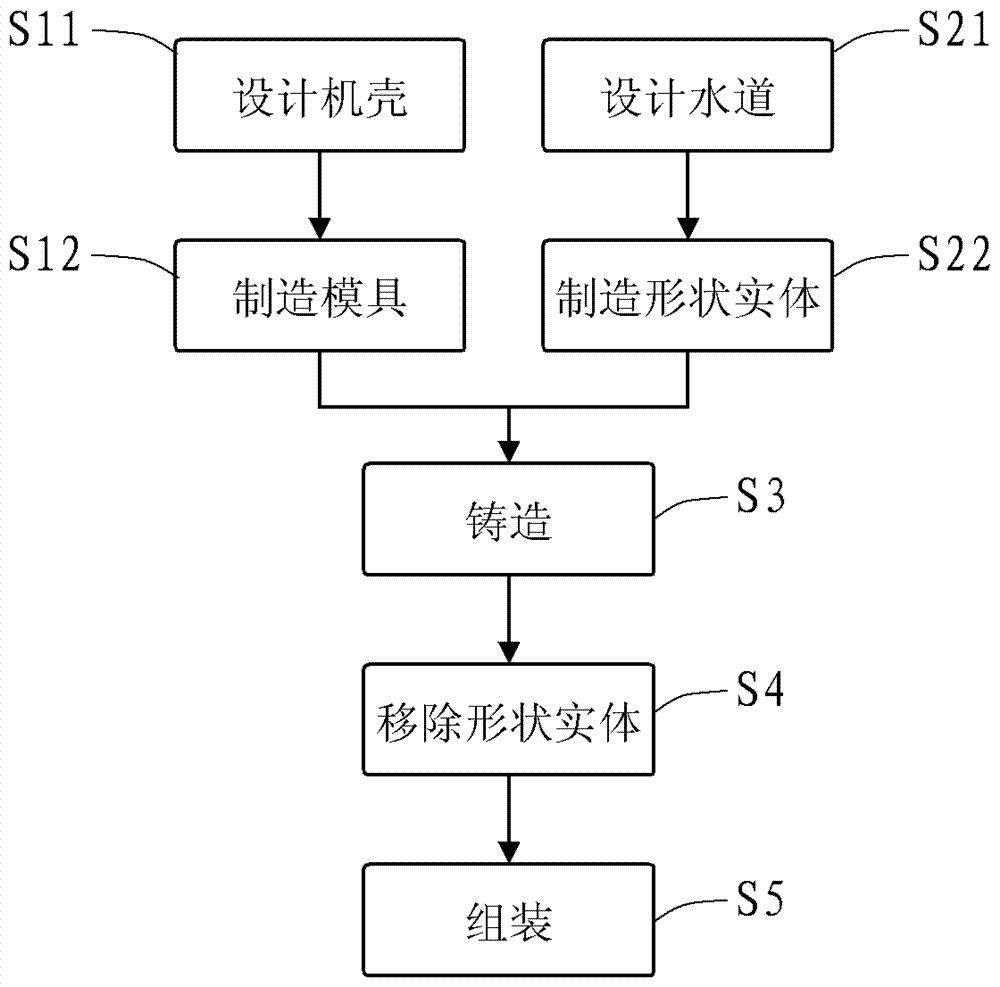

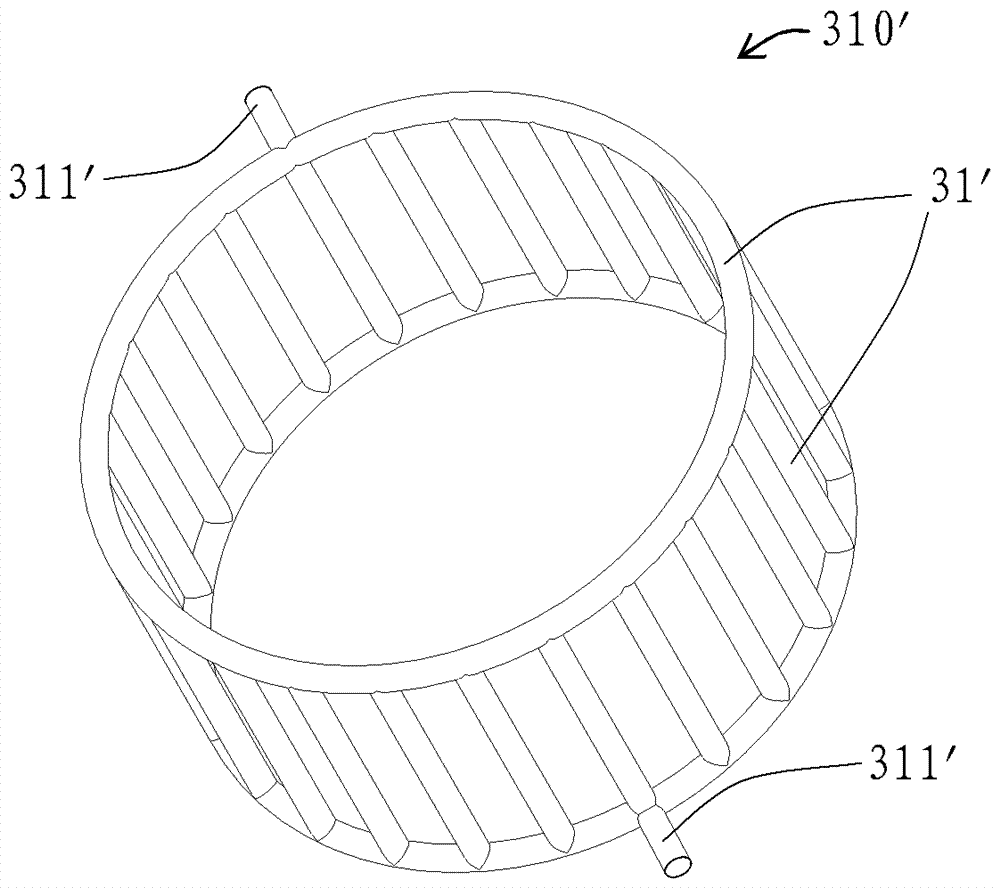

[0028] The drive motor liquid cooling cooling device of the present invention adopts an integrated structure to replace the traditional cooling structure of the inner and outer water jackets and O-shaped sealing rings, and adopts lost-foam casting by designing solid models of various shapes of cooling liquid channels The method can integrally form cooling liquid passages of various corresponding shapes. figure 1 It shows a flow chart of the manufacturing method of the drive motor liquid cooling device in a specific embodiment of the present invention, please refer to Figure 2 to Figure 4 As shown, a specific embodiment of the manufacturing method of the drive motor liquid cooling cooling device includes the step S11 of designing the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com