Tower type cyclone flow test device for converting axial compression into radial sealing

A technology of radial sealing and flow testing, which is applied in the direction of measuring devices, engine testing, and engine sealing, etc. It can solve problems such as the influence of reliability of test results, difficulty in stabilizing test data, and affecting test efficiency, so as to improve the accuracy of test results , reliable results, avoid interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

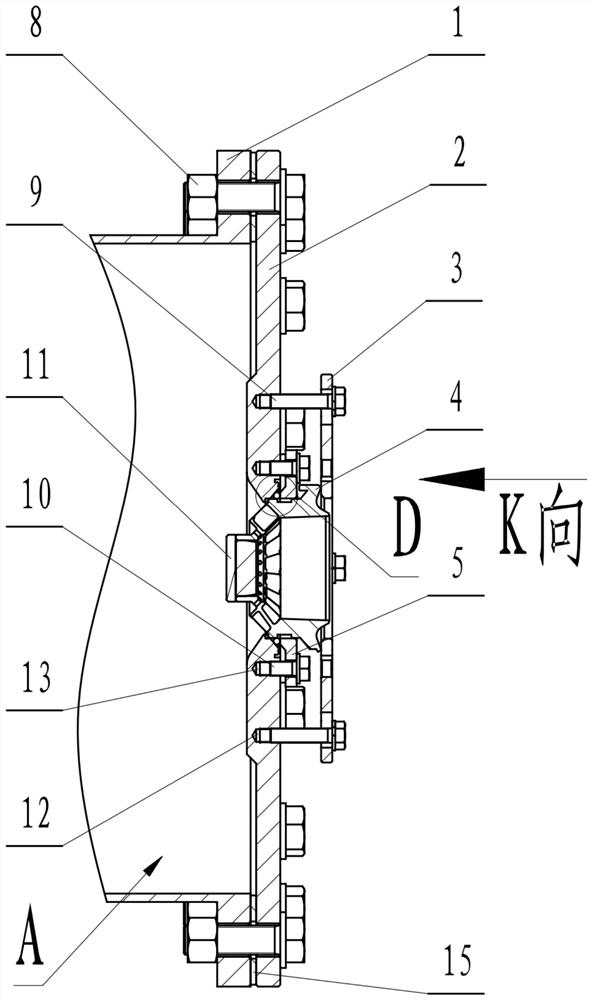

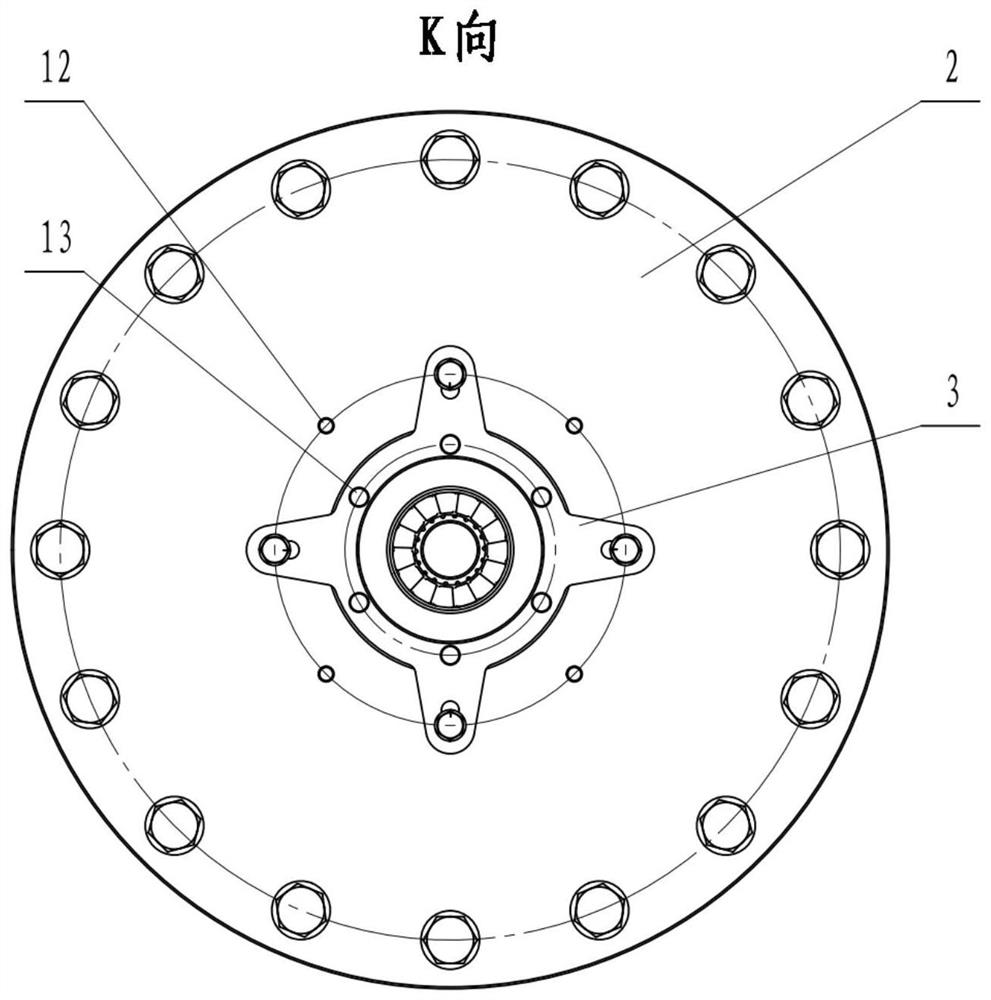

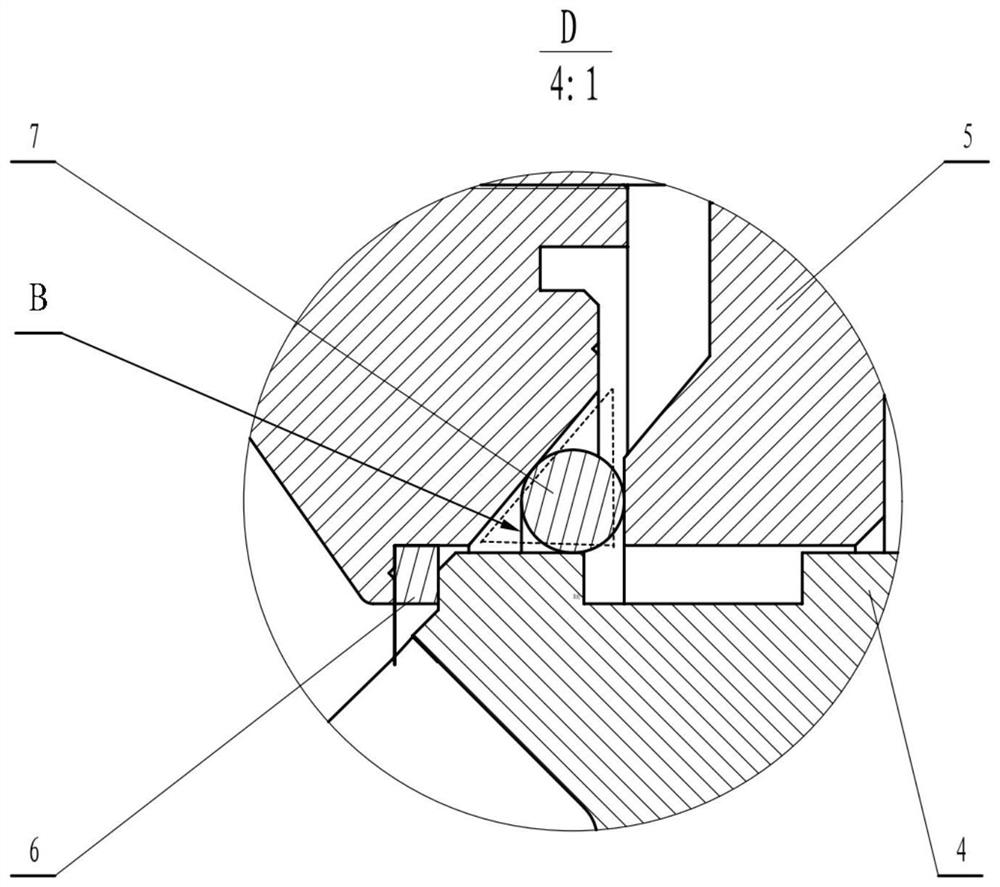

[0017] combine Figure 1-3 , mainly including supporting components, pressing components and sealing components.

[0018] Such as figure 1 As shown, the support assembly mainly includes a pressure-stabilizing cylinder 1, a convex-concave cover plate 2, a fastener 8, and a sealing ring 15, wherein the pressure-stabilizing cylinder 1 buffers the incoming air through a large-volume inner chamber A to reduce the gas flow rate, so that the The incoming air pressure obtained from the test air source is more stable, thereby reducing the difficulty of pressure regulation and improving the accuracy of the test results; the convex-concave cover plate 2 adopts the design of a central opening and a convex step on one side and a concave cavity on the other. The central opening can ensure that the cyclone is sufficient The flow installation space can be adjusted according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com