Electrorheological fluid flow mode rheological property test device

A technology of electrorheological fluid and flow mode, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of inaccurate results, inability to measure high shear rate of electrorheological fluid, inaccurate test results, etc., and achieve liquid volume utilization High efficiency, solving sealing difficulties, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, an embodiment of the present invention will be described in detail, and the present embodiment is implemented in the preparation of the present invention, the detailed embodiment and the specific operation process are given, but the scope of protection of the present invention is not limited to the implementation below. example.

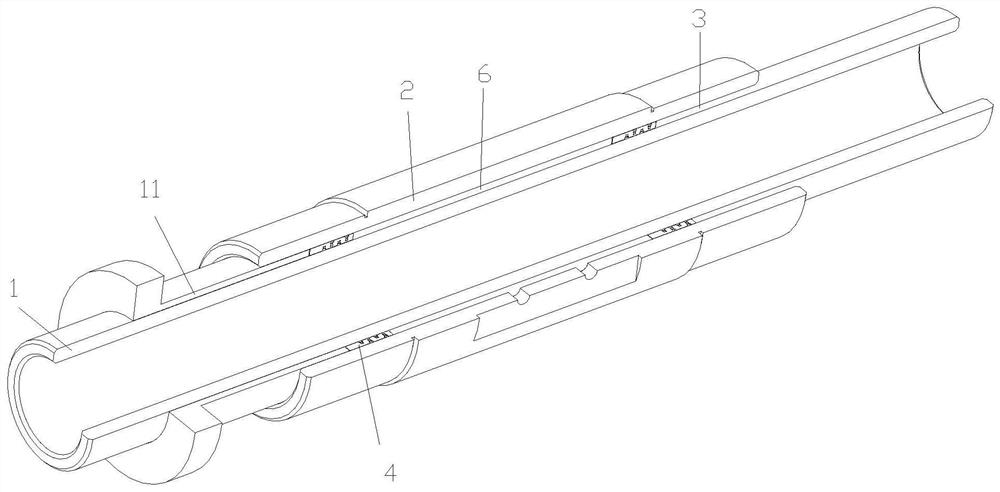

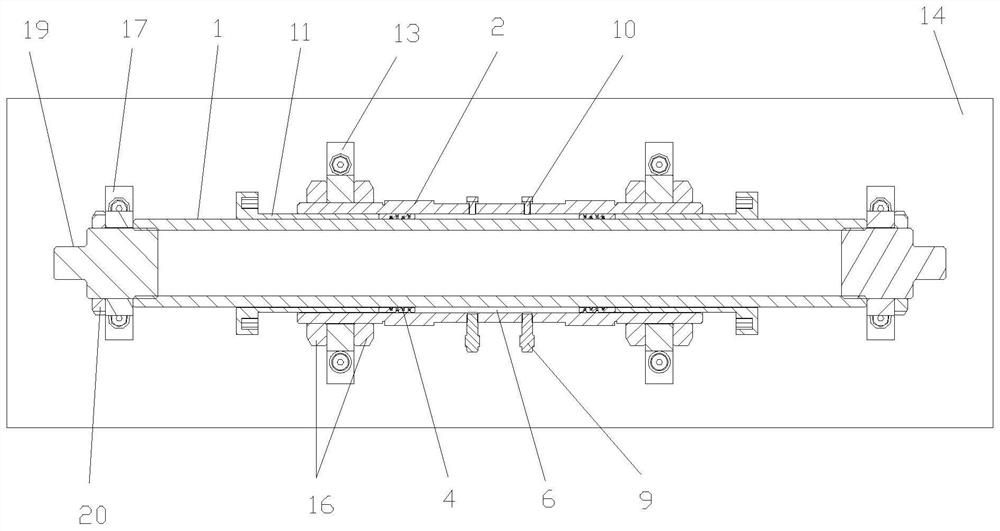

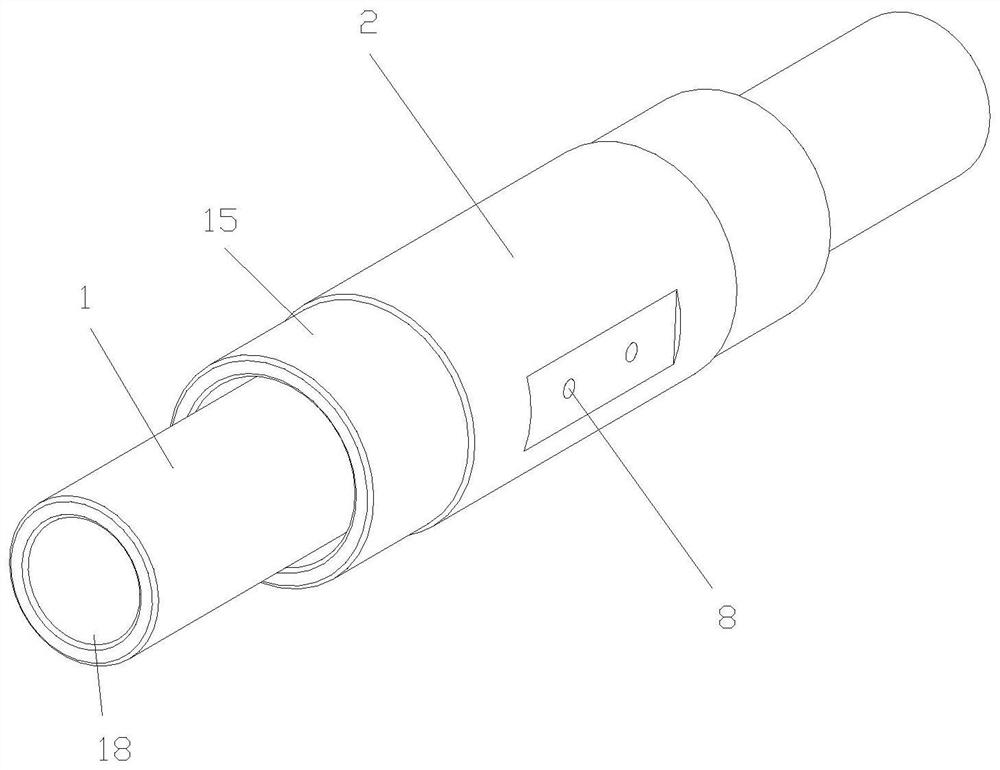

[0029] See Figure 1 to 9 , The present embodiment discloses electrorheological fluids flow pattern rheological properties testing device, comprising an anode electrode arranged coaxially inside and outside the cylinder along the cylinder 12 and the cathode electrode, anode electrode tube 1 ends are cylinder 2 protrudes out of the cathode electrode both ends of the outside. An anode electrode formed cylindrical annular gap and the gap between the cathode electrode 2 cylinder 3, an annular gap 3 equipped with two annular piston 4, opposite ends of each piston 4 abutting annular sealing an annular gap between the inner and outer walls 3, the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com