Conductive composite diaphragm suitable for deposition type slurry battery

A slurry battery and composite diaphragm technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of easy to pierce the isolation layer, reduce the service life of the battery, improve the clogging of the diaphragm, and improve the volume utilization rate , prevent puncture, improve the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

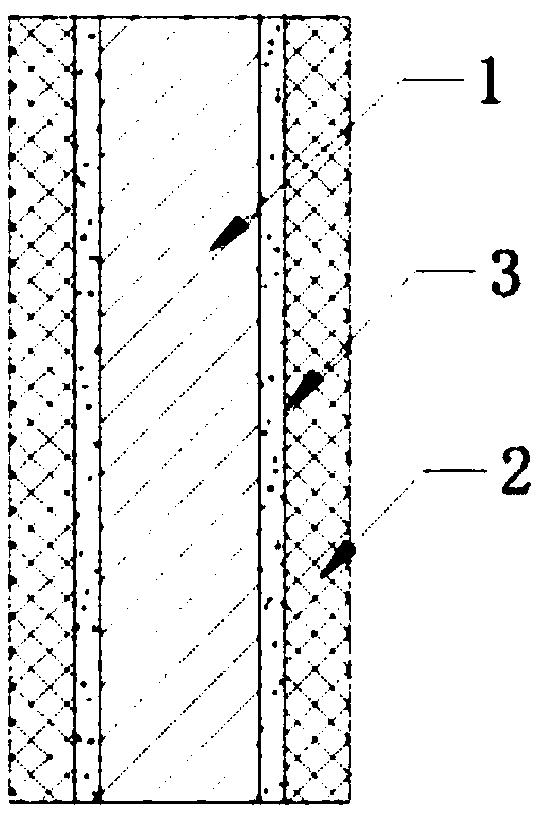

[0026] Such as figure 1 As shown, this embodiment provides a conductive composite separator suitable for deposition-type slurry batteries, which includes an isolation layer 1, a conductive layer 2 disposed on both sides of the isolation layer 1, and a conductive layer disposed on the conductive layer 2. and the insulating coating 3 between the isolation layer 1; wherein, the conductive layer 2, the insulating coating 3, the isolation layer 1, the insulating coating 3 and the conductive layer 2 are sequentially stacked and Laminated into one, the gap between two adjacent layers is not greater than 10μm.

[0027] In this embodiment, two layers of conductive layers 2 and one layer of isolation layer 1 form the conductive composite diaphragm, and the insulating coating 3 is provided between the conductive layer 2 and the isolation layer 1, so that the The side of the conductive layer 2 close to the isolation layer 1 is in a state covered by the insulating coating 3, thereby avoid...

Embodiment 2

[0040] On the basis of Example 1, this example further provides a specific preparation method for the conductive composite diaphragm suitable for fluidized batteries:

[0041] The conductive layer 2 is made of 240-mesh metal mesh, and the metal mesh is made of metal wire with a diameter of 15 μm; the conductive layer 2 contacting the positive electrode slurry is made of aluminum wire, and the conductive layer 2 contacting the negative electrode is made of aluminum wire. Layer 2 is made of copper wire; the isolation layer 1 adopts a dry stretched single-layer PP diaphragm, the porosity of the isolation layer 1 is 50%, and the thickness of the isolation layer 1 is 10 μm; the insulating coating 3. The coating is made of insulating thermoplastic polymer material;

[0042] During production, firstly, the conductive layer 2 is coated, and all parts of the conductive layer 2 except the leading end are immersed in the coating of the insulating coating 3, and then taken out to dry, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com