Automatic carpet encasement machine

A cartoning machine and carpet technology, which is applied in the field of automatic carpet cartoning machines, can solve the problems of poor product consistency and slow packaging speed in manual work, and achieve the effects of visual operation, fast cartoning speed and good overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

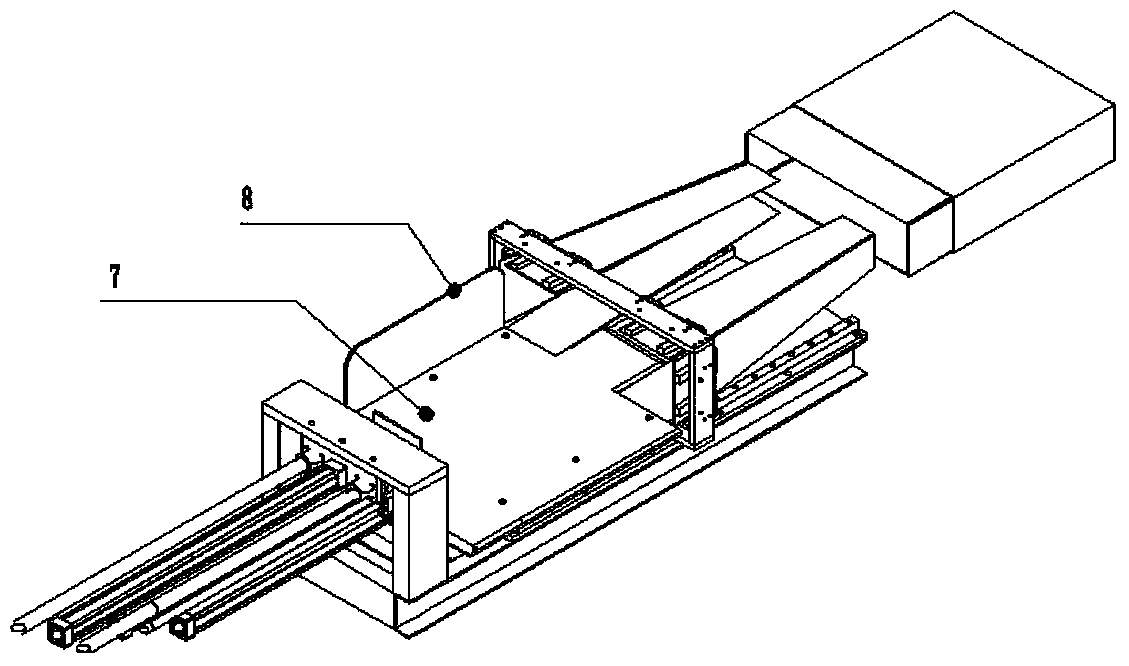

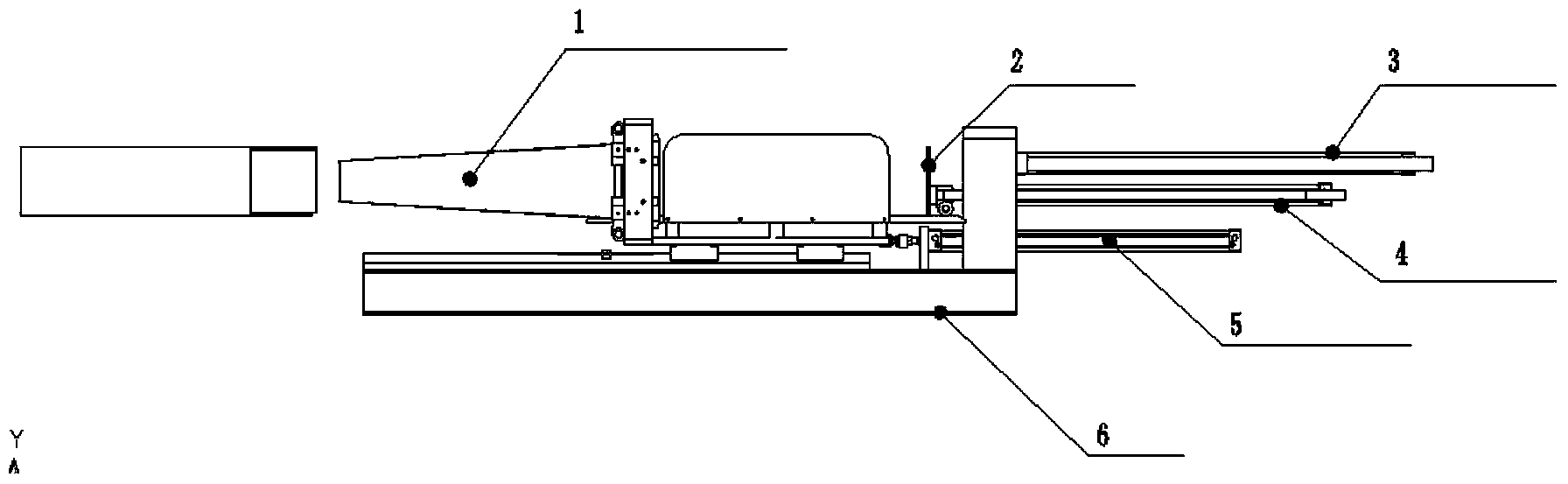

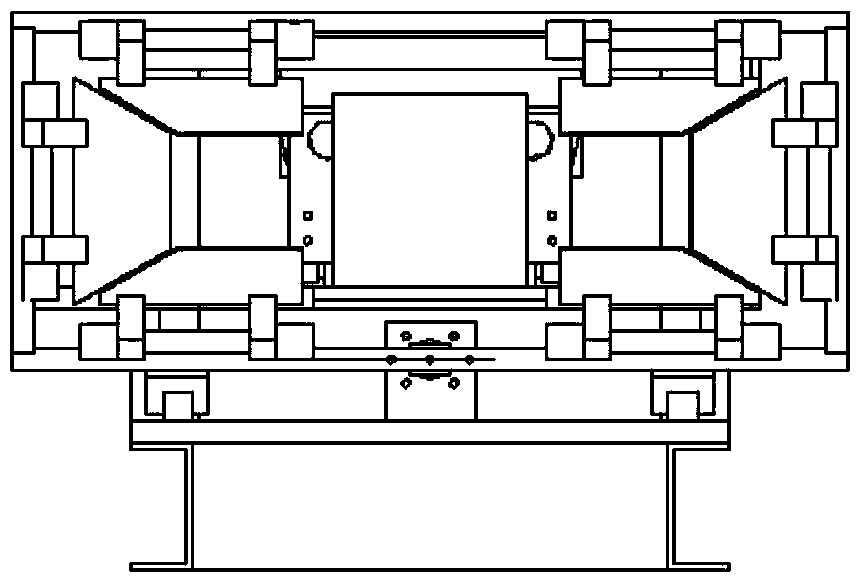

[0022] Attached below Figure 1-9 The present invention is further described.

[0023] Such as Figure 1-9 As shown, an automatic carpet packing machine includes a carpet packing guide plate 1, a packing push plate 2, a packing push plate cylinder 3, a packing push plate cylinder 4, a carpet carrying plate cylinder 5, a frame 6, a carpet Carrying plate 7, carpet limit baffle 8, described carpet limit baffle 8 is connected with carpet carrier plate 7, and described carpet carrier plate 7 is connected with carpet carrier plate cylinder 5, when a certain amount of carpets that have been reshaped and stacked Stop at the set position under the effect of the carpet limit baffle, then the carpet carrying plate cylinder 5 drives the carpet carrying plate 7 to advance, and the carpet packing guide plate 1 is pushed into the carton to stop at the set position. Described packing push pedal 2 is connected with packing push pedal cylinder 4, and now packing push pedal cylinder 3 drives p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com