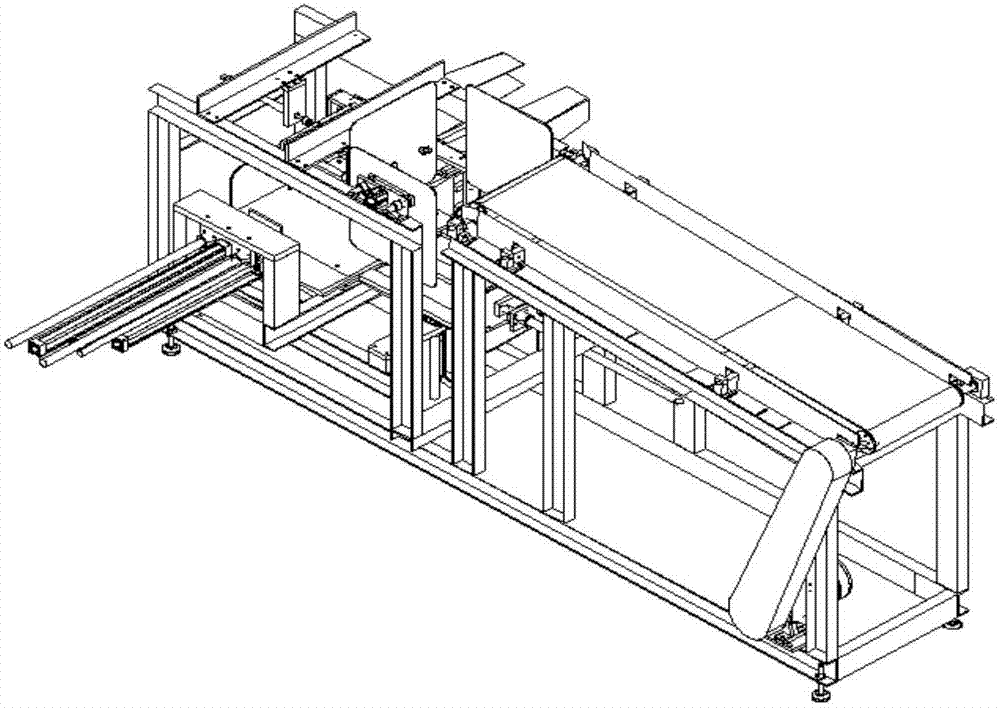

Carpet shaping, stacking and boxing all-in-one machine

An all-in-one machine and carpet technology, which is applied in the field of carpet shaping, stacking, and boxing all-in-one machines, can solve the problems of slow packaging speed and poor consistency of manual work products, and achieve fast boxing speed, visual operation, and good overall rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

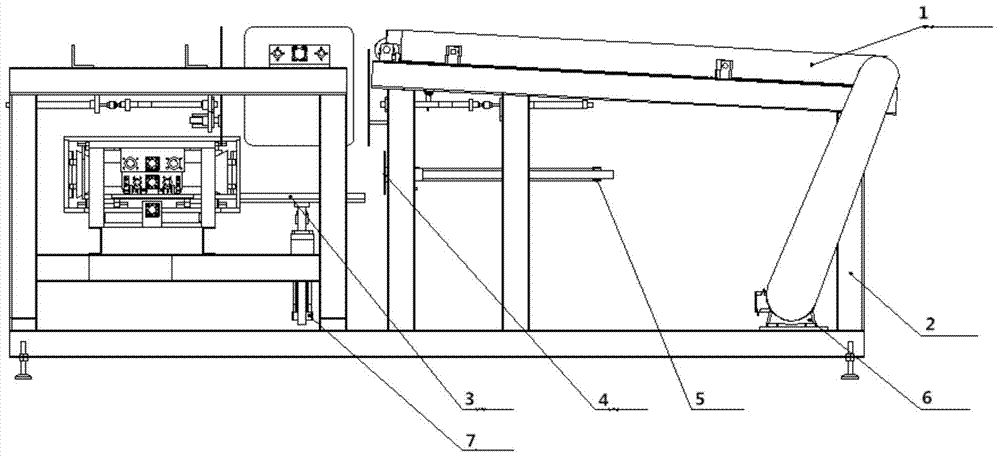

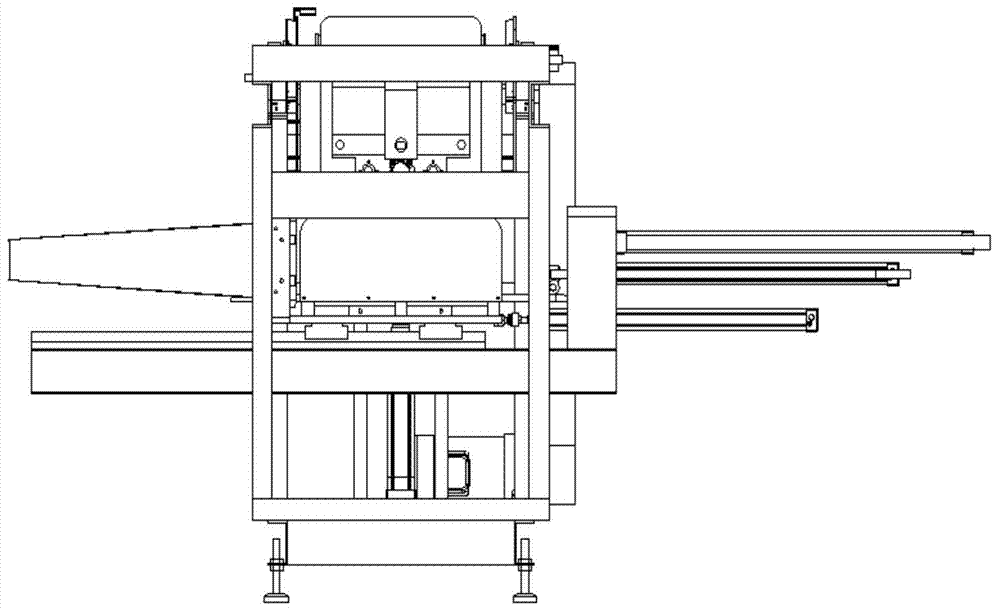

[0029] Attached below Figure 1-13 The present invention is further described.

[0030] Such as Figure 1-13 As shown, the carpet baffle (1), frame (2), lifting plate (3), shifting plate (4), shifting plate cylinder (5), three-phase asynchronous AC motor (6), lifting plate cylinder ( 7), photoelectric detection switch (8), conveyor belt (9), movable finishing board cylinder (10), movable finishing board (11), movable finishing board (12), buffer rod cylinder (13), buffer rod (14) , buffer rod (15), buffer rod cylinder (16), movable finishing board cylinder (17), fixed finishing board (18), fixed finishing board (19), carpet packing guide plate (20), packing push plate ( 21), packing push plate cylinder (22), packing push plate cylinder (23), carpet packing guide plate moving cylinder (24), carpet packing carrying plate (25).

[0031] The carpet baffle (1) is set on both sides of the conveyor belt (9). When the power is turned on, the three-phase asynchronous AC motor (6) dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com