Tube-in-tube fuel warmer prepared with positive temperature coefficient high-molecular material

A warmer and sleeve-type technology, applied in fuel heat treatment devices, charging systems, mechanical equipment, etc., can solve problems such as heat-generating materials and electrode sealing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

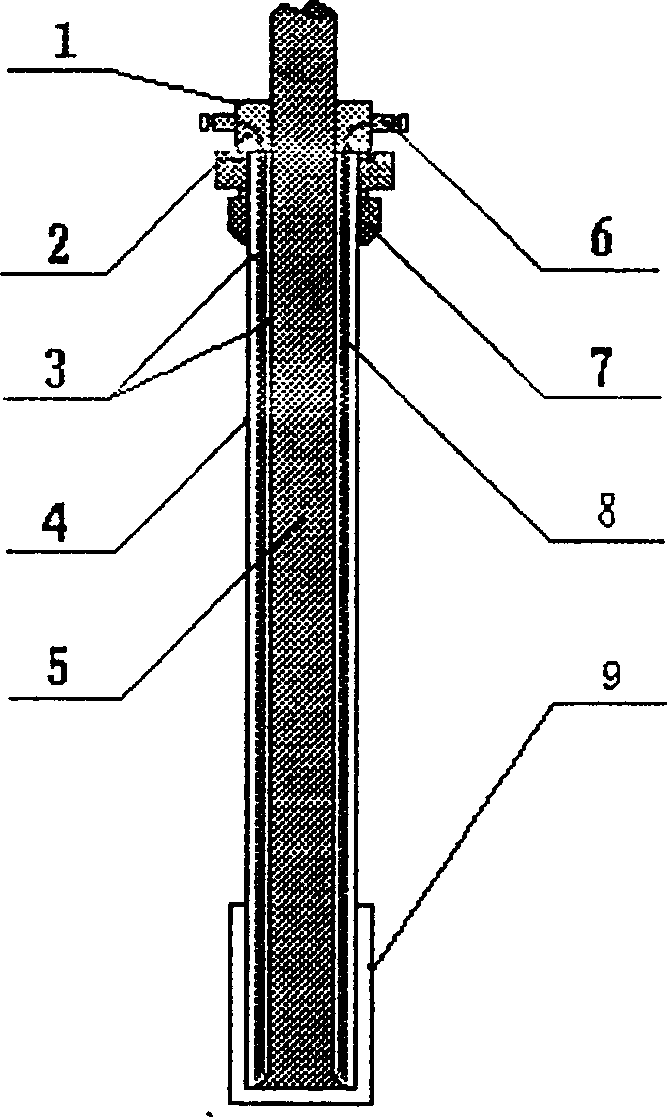

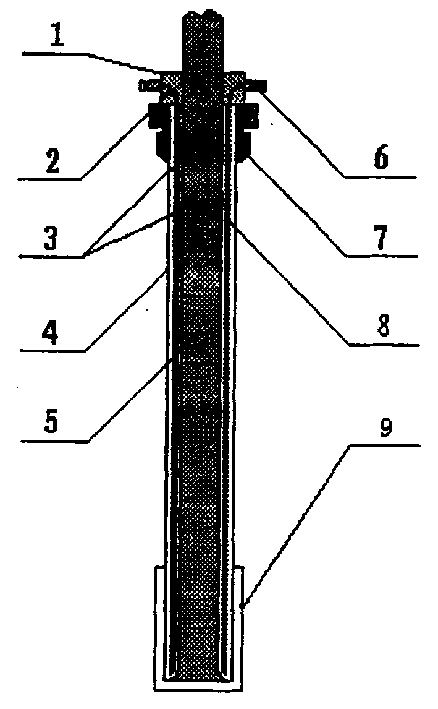

[0017] This embodiment consists of figure 1 The nine parts shown in the figure are composed of: sealing box 1 is made of high-density polyethylene, potting material 2 is epoxy resin plus curing agent, insulating layer 3 is made of polyester film with a thickness of 0.1mm, and oil barrier layer 4 is made of wall thickness of 0.4mm thin-walled stainless steel pipe, the oil suction pipe 5 is a commercially available metal oil suction pipe with an outer diameter of Φ10mm, the electrode terminal 6 is a commonly used copper terminal, the screw diameter is Φ3mm, the fixing part 7 is made of carbon steel, and the thread The diameter is Φ32mm, the heat pipe 8 adopts a PTC heat pipe with a self-limiting temperature of 90°C, the inner diameter of the pipe is 11.5mm, and the wall thickness is 1.5mm. The ampere can completely melt the solidified diesel oil at -33°C in the oil suction pipe within 5 minutes.

Embodiment 2

[0019] This embodiment consists of figure 1 In addition to the insulating layer 3, it consists of eight parts: the oil separation layer 4 is a polyester tube, and the oil suction pipe 5 is an oil-resistant plastic oil pipe for commercially available automobiles, with an outer diameter of Φ10mm. No insulating layer, close contact. The heating pipe 8 adopts a PTC heating pipe with a self-limiting temperature of 85°C. The inner diameter of the heating pipe is 11.2mm, and the wall thickness is 1.4mm. The fixing nut 7 is made of polypropylene material, and the rest are the same as in Example 1. The bottom oil suction pipe 5 and the fixing nut 7 are welded and connected with the oil barrier layer 4 respectively. In this embodiment, the voltage used is 24 volts and the current is 0.8 ampere, which can completely melt the solidified diesel oil at -33° C. in the oil suction pipe within 7 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com