Concrete impermeability test method and test apparatus thereof

An impermeability test and test method technology, applied in the field of concrete impermeability detection methods and detection devices, can solve the problems of difficult observation, complicated operation, long sealing time, etc., and achieve the advantages of saving test time, simple operation and ensuring stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

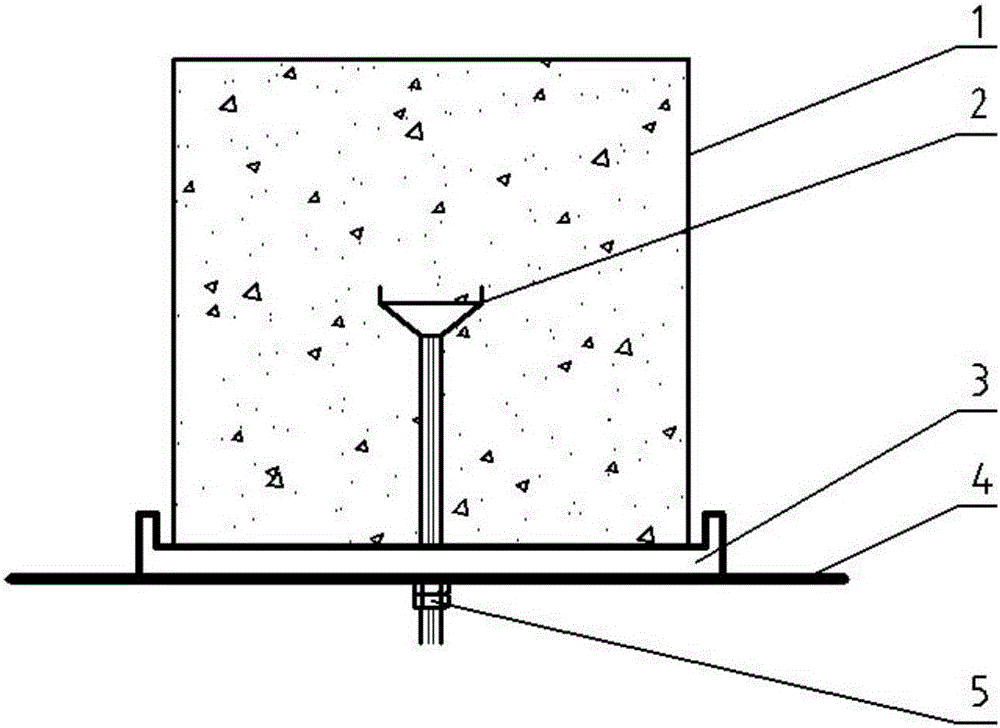

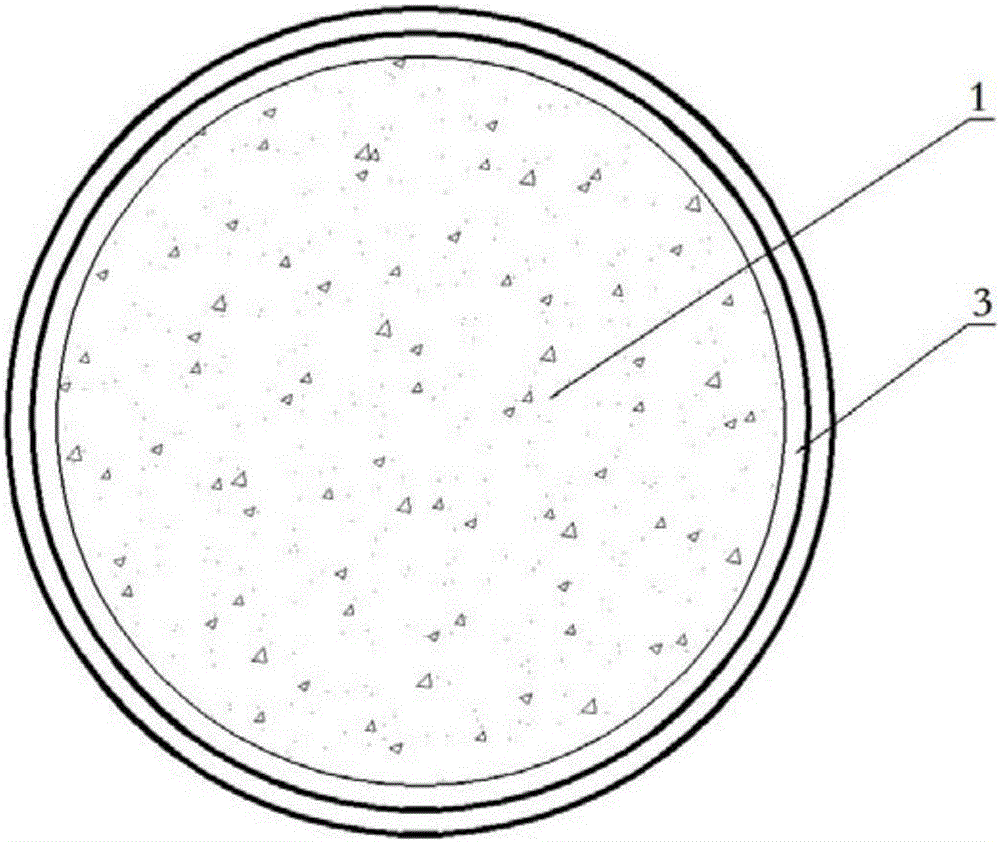

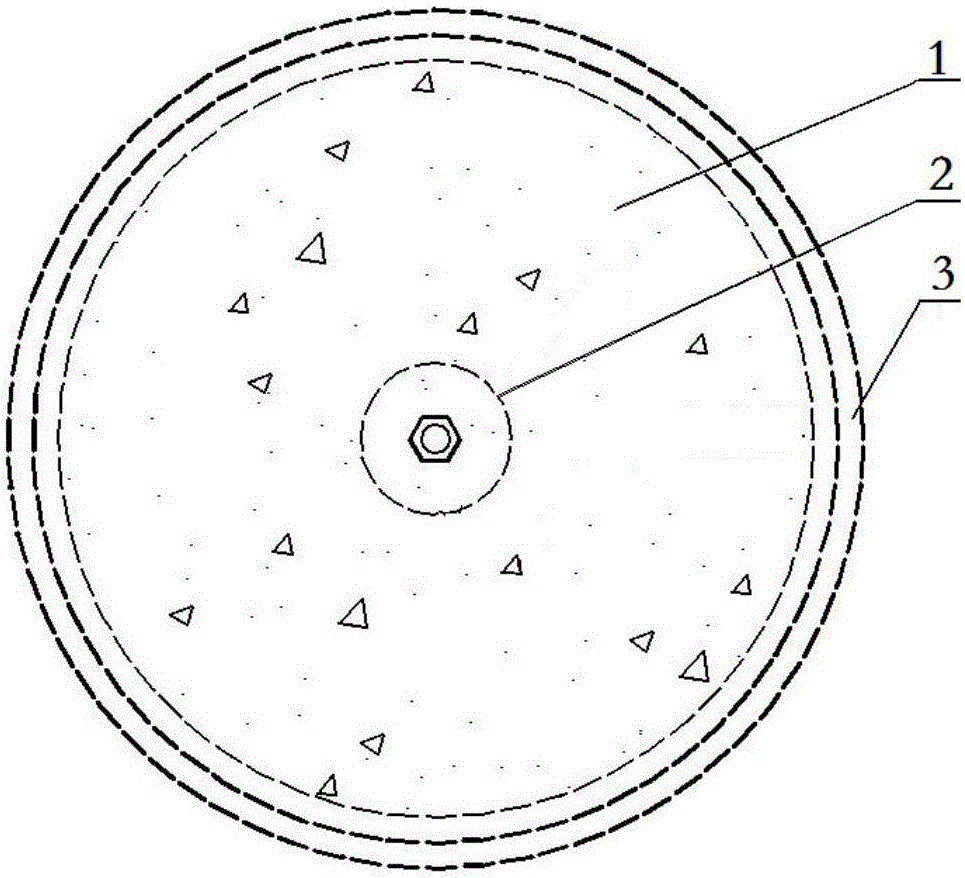

[0056] The present invention will be further described below in conjunction with accompanying drawing:

[0057] like Figure 1-7 Shown, the concrete steps of test method of the present invention are as follows:

[0058] Step 1: Test piece forming and curing

[0059] 1. Prepare the pre-embedded pressure induction pipe:

[0060] The structure of embedded pressure induction pipe 2 is as follows: Figure 4 As shown, the pre-embedded pressure induction pipe has a total length of 200 mm and is in the shape of a funnel. It is composed of a funnel opening 6 and a straight tube 7. The opening 6 and the straight tube 7 are connected by connecting bolts 10 or directly welded. The diameter φ 20mm of straight tube 7 is long 180mm, and there is a hole in the middle, aperture φ 2~4mm, is used for guiding water flow, and the outer wall of straight tube lower end 20mm place has 10mm grinding section 12, is about to grind straight tube 7 flat, is convenient to The wrench insert is fixed or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com