Cylindrical heating rod test section filled with inert gas and air gap sealing method

A technology of inert gas and test section, which is applied in the sealing of the engine, the method of container discharge, the shape of the heating element, etc., to solve the difficulty of air gap sealing, solve the air gap pressure maintenance, and ensure the effect of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

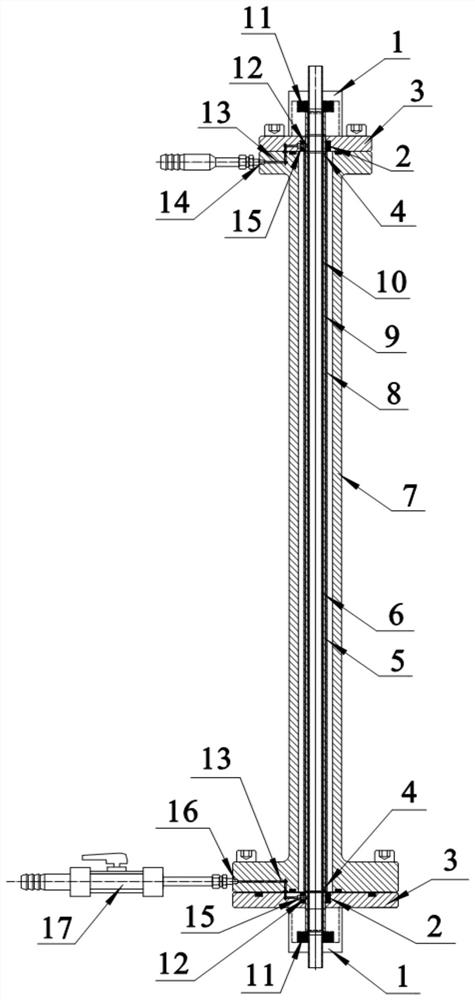

[0016] The present invention is described in detail below in conjunction with accompanying drawing:

[0017] Such as figure 1 As shown, a cylindrical heating rod test section filled with inert gas includes a test section composed of an outer casing 7, an outer surface 8, a heating block 9 and an inner surface 10 arranged coaxially from the outside to the inside, The two ends of the test section are fixed in radial size and air gap sealed by the outer sealing ring 2 and the inner sealing ring 11, and are axially fixed by the flange 3 and the gland 1. The annular air gap between the outer surface 8 and the heating block 9 is the outer air gap 5 , and the annular air gap between the inner surface 10 and the heating block 9 is the inner air gap 6 .

[0018] Such as figure 1 As shown, the inner edges of the outer surface 8 and the two ends of the heating block 9 are provided with certain chamfers; the outer sealing ring 2 and the inner sealing ring 11 are ring gaskets specially m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com