Electrolytic cleaning device for cold-rolled strip steel high-speed cleaning line

A technology of electrolytic cleaning and cold-rolled strip steel, which is applied in the electrolysis process and electrolysis components, etc., can solve the problems that the current density is not directly proportional to the degreasing speed, the production line speed is low, small bubbles, etc., so as to avoid hydrogen embrittlement and poor quality Affected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

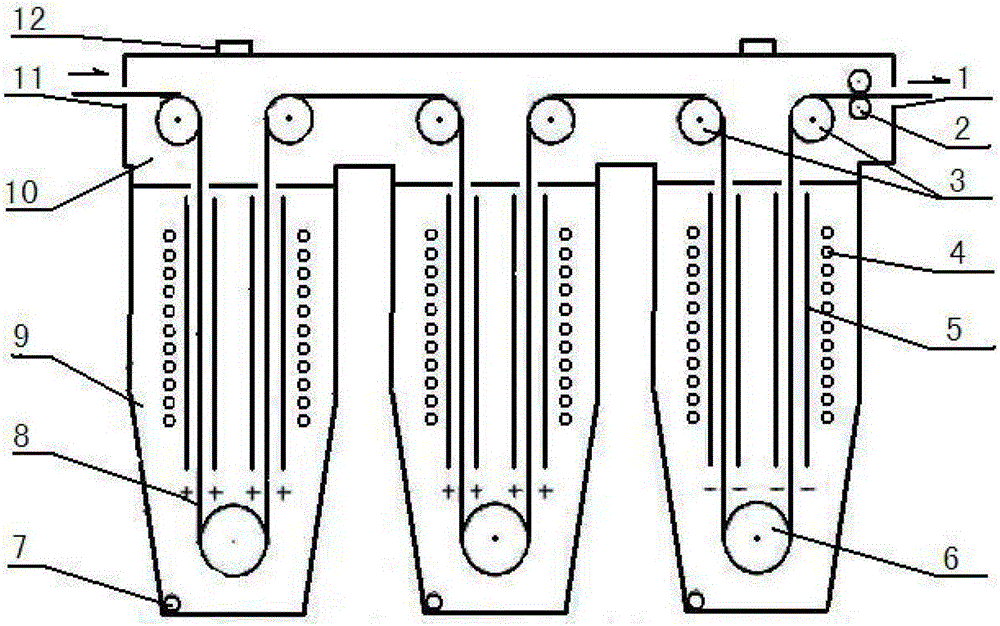

[0017] The components in the figure are numbered as follows: strip steel outlet 1, squeeze roller 2, steering roller 3, high pressure spray pipe 4, electrode plate 5, sinking roller 6, electrolyte outlet 7, strip steel 8, electrolytic tank 9, transition tank 10 , Strip inlet 11, steam discharge port 12.

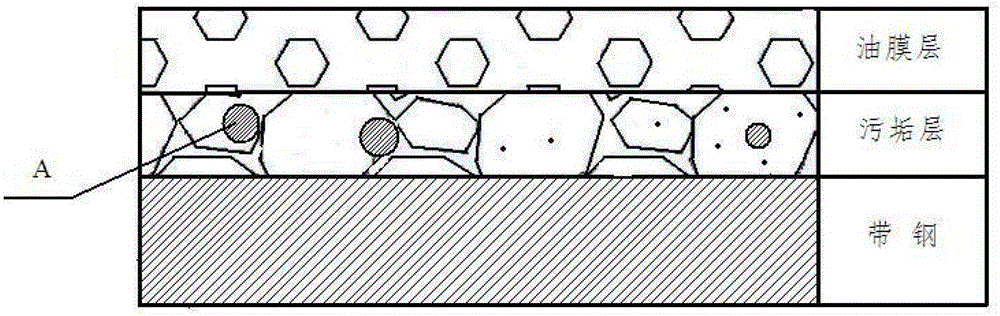

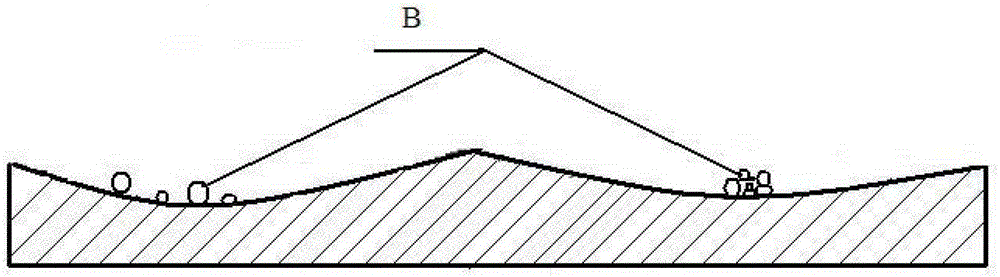

[0018] Aiming at the problems caused by the high-speed cleaning of strip steel, the present invention proposes the following solutions: (1) More than two electrolytic cells are arranged side by side, and the strip steel passes through multiple electrolytic cells continuously, which solves the short residence time of the strip steel in the electrode plate The problem. (2) Decompose the electrolytic cell of the prior art into upper and lower parts, the lower part is a structure of multiple single electrolytic cells, and the electrode plate is installed in the single electrolytic cell, which is convenient for processing, transportation and maintenance. The electrolytic cell of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com