Experiment device for gas permeation around round hole

A technology of permeation experiment and gas, applied in measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of not failing to consider the effect of stress concentration of hole excavation, and achieve simple structure and test cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

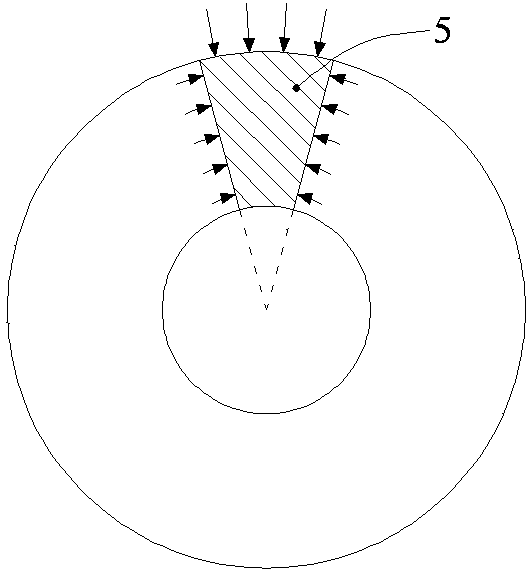

[0027] combined with figure 1 , the principle of the present invention is: the seepage law of the coal rock mass around the round hole can be considered to be axisymmetric, and a part of it (that is, the seepage test piece 5 in the present invention) can be tested to reflect the overall seepage property of the surrounding rock. The full-section experimental device can carry out large-scale experimental research.

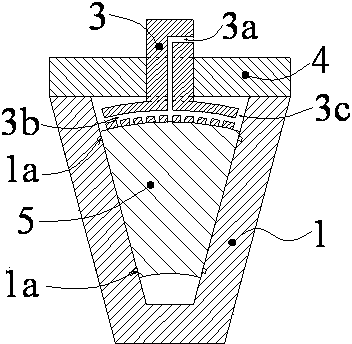

[0028] combined with figure 2 and 3 , a gas permeation experiment device around a circular hole, comprising a sealed loading box, a permeation test piece 5, an oil pressure sealing system, a gas supply system, a gas balance system and a measurement control system.

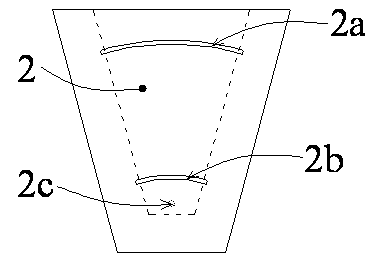

[0029] The sealed loading box includes a V-shaped groove 1, a side baffle 2, a loading pad 3, an upper cover 4 and a rubber pad.

[0030] The V-shaped groove 1 is an integral structure, including a bottom plate and two side walls, the inner surface of the side wall is at a certain inclination angle to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com