Self-excited oscillation annular jet stirring system

A technology of annular jet and stirring system, which is applied in chemical/physical/physical-chemical fixed reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve problems such as difficult sealing of motor shafts, and achieve a solution to the problem of sealing Difficulty, improve stirring efficiency, improve the effect of increasing mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

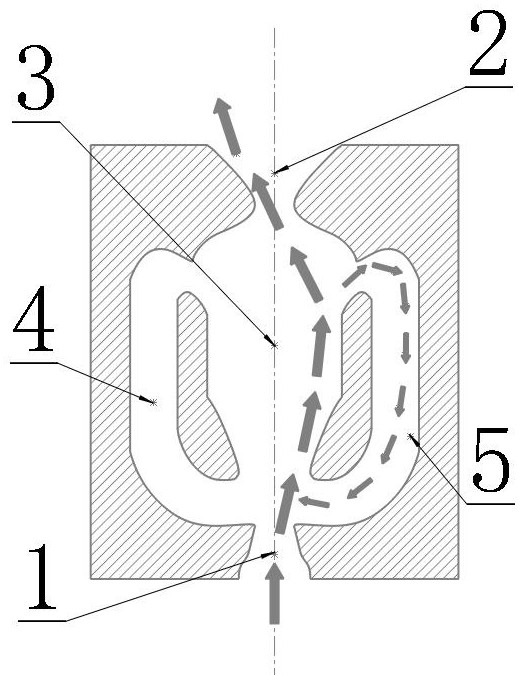

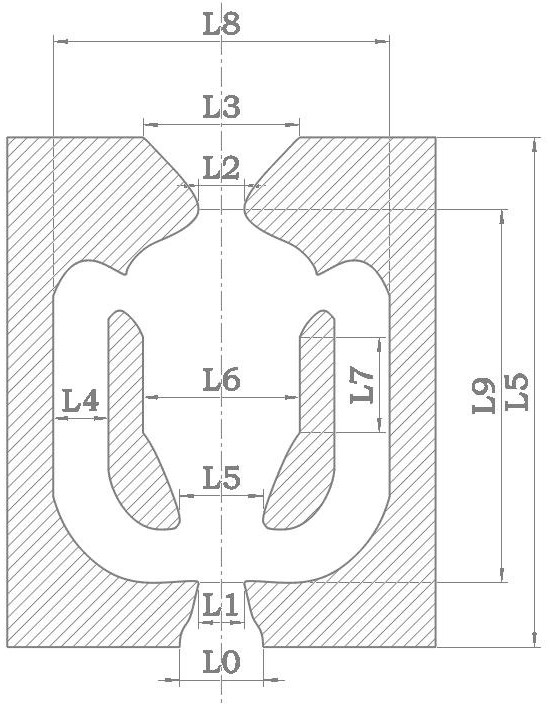

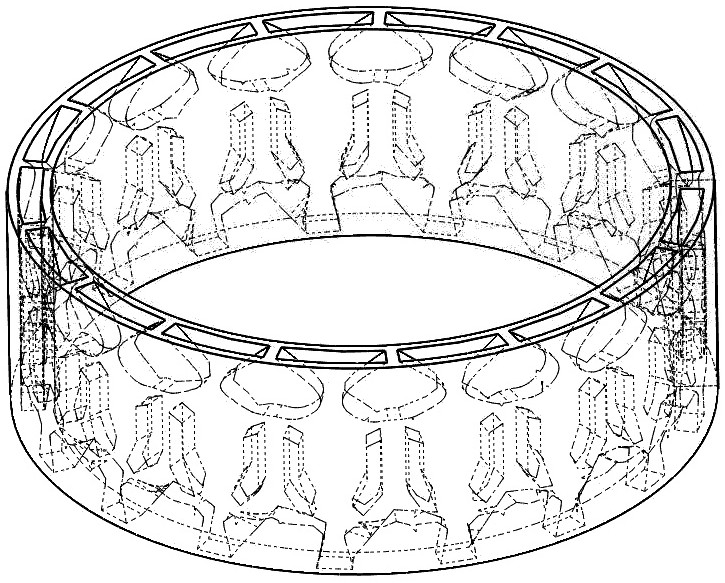

[0036] Oscillating jet unit ( figure 1 ) is a self-excited oscillating annular jet stirring device ( image 3 ) basic unit, including a main chamber 3 and interconnected water outlet 2 and water inlet 1; main chamber 3 and corresponding left feedback channel 4 and right feedback channel connection 5. For the size parameters of the oscillating jet unit, see figure 2 . The water inlet is roughly an isosceles trapezoid with a ratio of upper and lower bases (L1:L0) of 1:3 to 2:3, and the angle between the two waists is 60°. The water outlet is an approximately isosceles trapezoid with a bottom-to-bottom ratio (L2:L3) of 1:5-2:5. The isosceles trapezoid is connected to the main chamber 3, and the angle between the two sides is 90°. The ratio of the length L9 of the main chamber from the connection of the water inlet 1 to the connection of the water outlet 2 to the size of the water inlet L0 is 4:1-6:1. The ratio of the width of the main chamber where the section size remains c...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is that, as Figure 8 As shown, the structure of the basic unit of jet oscillation in Embodiment 2 remains unchanged, but the annular cylinder formed by several basic units in Embodiment 1 is changed into a conical surface. This change requires each basic unit to form a certain curved arc and form a closed loop. As a result, the jets of each basic unit sweep clockwise and counterclockwise alternately on the cone surface, which enhances the intensity of the large-scale jet movement in the middle area. At the same time, the sweeping jet cone surface and the inner wall cylinder of the stirred tank maintain an appropriate space interval, which is beneficial to the inner circulation of the large-scale jet movement inside the stirred tank. It also further enhances the applicability.

[0044] In conjunction with the first embodiment, the principles of the present invention are explained as follows:

[0045] The flow princi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com