A multi-blade airtight air valve

A multi-blade and air valve technology, applied in the direction of lift valve, valve device, engine components, etc., can solve problems such as difficult sealing, hidden leakage, and inability to achieve sealing effect, and achieve the effect of solving difficult sealing and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

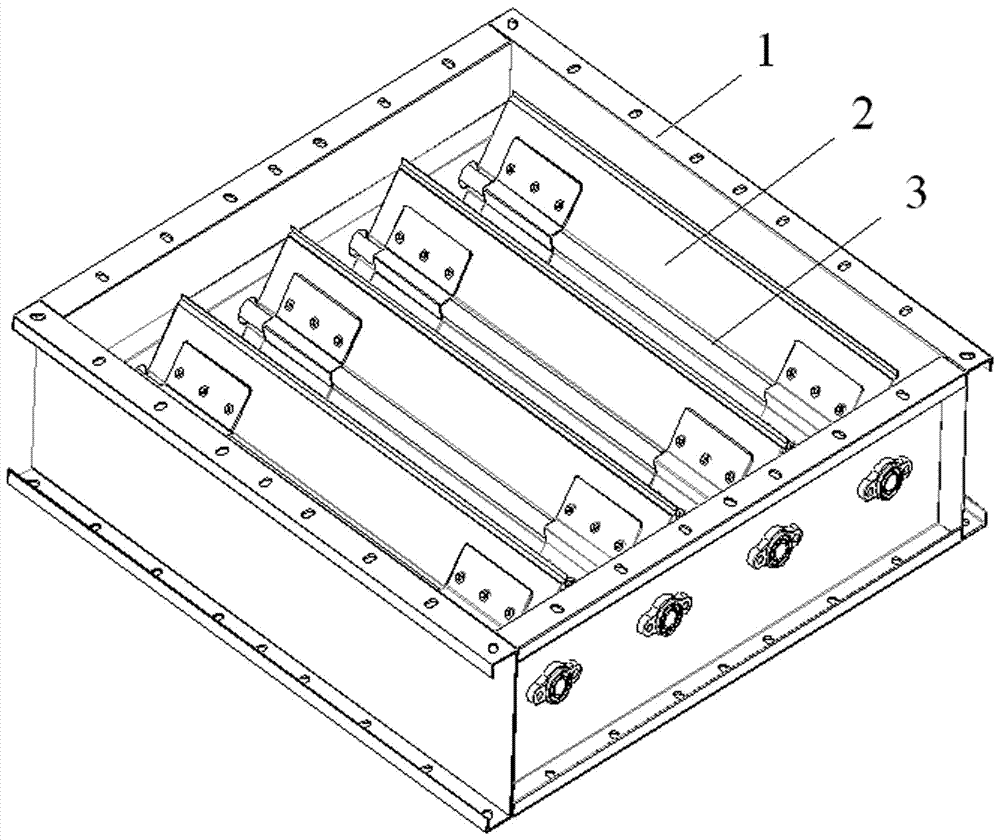

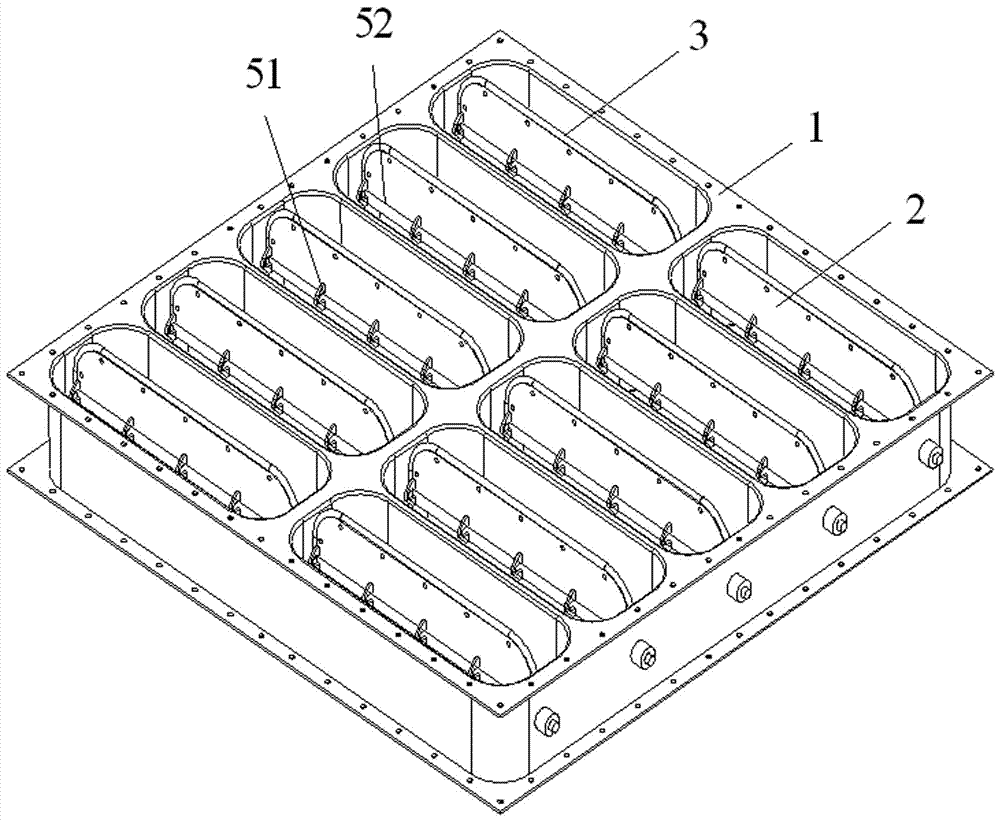

[0024] Combine the following Figure 2 ~ Figure 6 , a preferred embodiment of the present invention is described in detail.

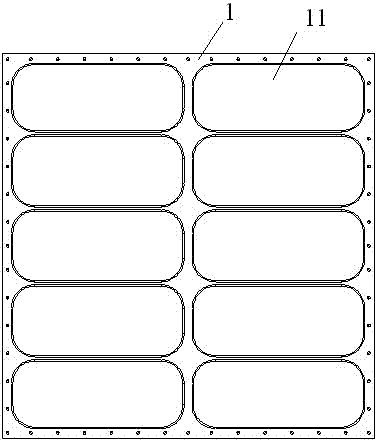

[0025] Such as figure 2 As shown, the multi-blade airtight air valve provided by the present invention includes: a square valve body 1, such as image 3 As shown, there are multiple rows of openings 11 arranged in sequence, and the end points of each opening 11 are arranged in a circular arc shape; a plurality of blades 2, each blade 2 is correspondingly arranged in each opening 11 through the first fixing assembly , and the end point of each blade 2 is arranged in an arc shape, matching the opening 11; the sealing ring 3, such as Figure 4 As shown, it is surrounded by a plurality of second fixing components on the outside of the vane 2 and is in contact with the inner wall of the square valve body 1 .

[0026] Such as Figure 5 As shown, the second fixing component includes: an upper clamping plate 41, which is covered and arranged on the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com