Shaft run-through position sealed structure of pedestal type sliding bearing structured motor

A technology of seat type sliding bearing and sliding bearing, which is used in electrical components, electromechanical devices, electric components, etc., can solve problems such as difficulty in sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

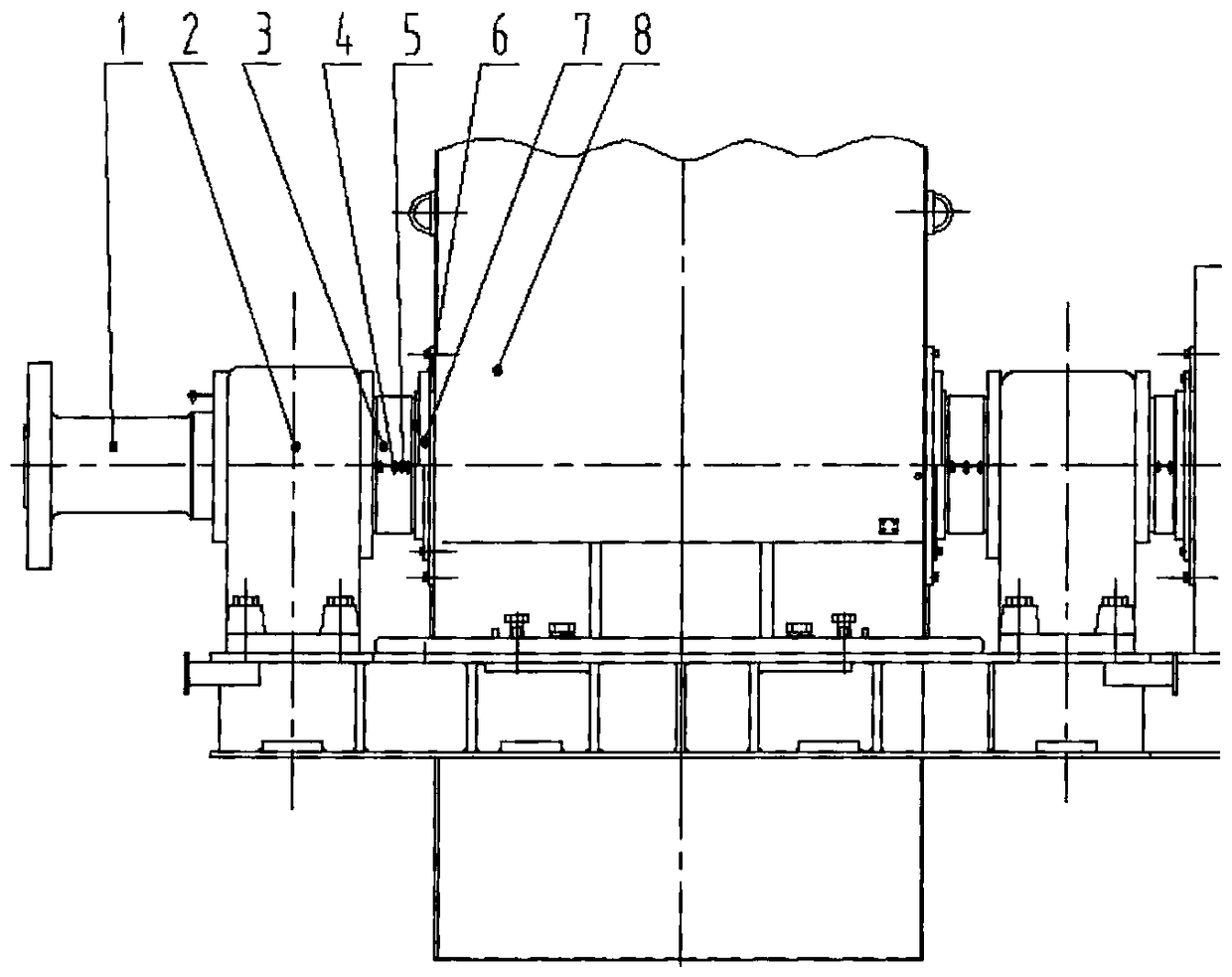

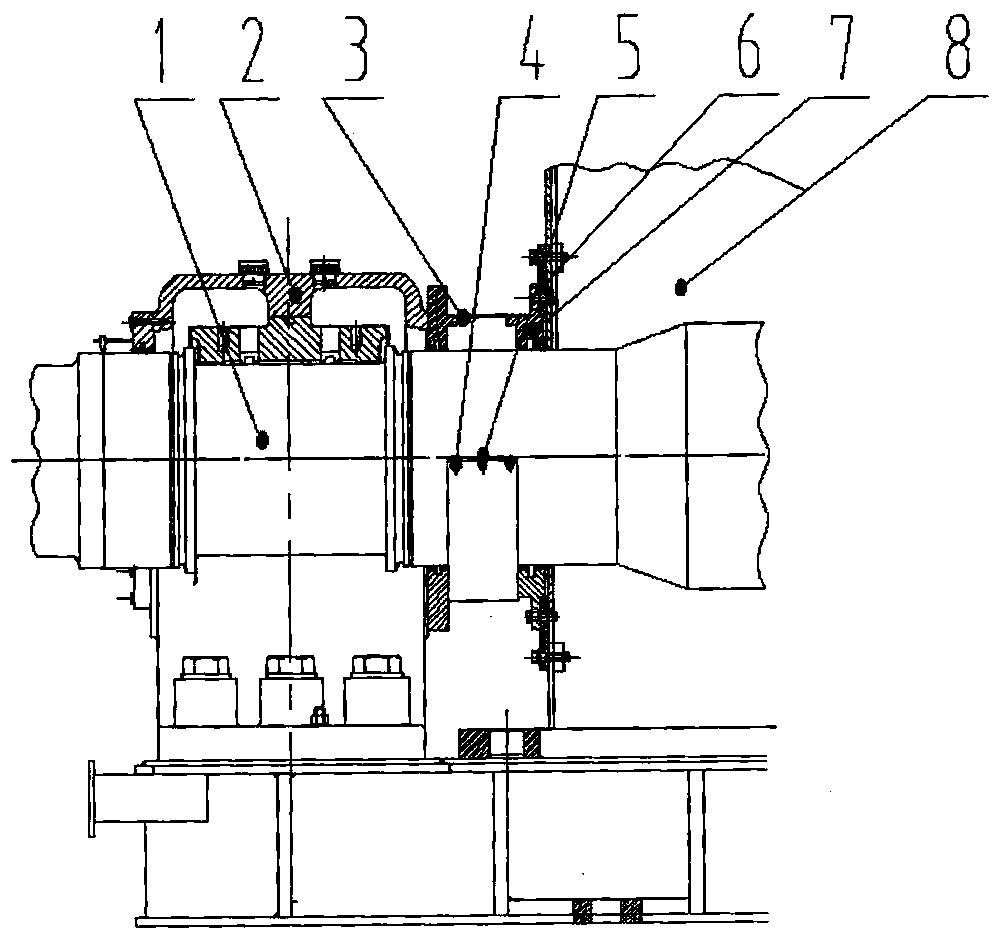

[0008] Specific embodiments: The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. A sealing structure at the penetration of the motor shaft with a seat type sliding bearing structure consists of: shaft 1, seat type sliding bearing 2, pressure plate 3, bolt connector 4, Gasket 5, sealing plate 6, sealing cover 7, machine base 8 constitute. The shaft 1 is installed in the machine base 8, the seat type sliding bearing 2 is installed on the shaft 1, the upper and lower pressure plates 3 are installed between the machine base 8 and the seat type sliding bearing 2 through the bolt connection 4, and the upper and lower pressure plates 3 A gasket 5 is installed between them, a sealing plate 6 is installed on the machine base 8 through bolts, and a sealing cover 7 is mounted on the sealing plate 6 .

[0009] Due to the adoption of this sealing structure, the sealing structure at the penetration of the seat type sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com