Pore-free aluminum alloy casting process

A casting process and aluminum alloy technology, applied in the field of casting, can solve the problems of difficult to obtain high-density castings, mixed gas, formability (poor casting performance, etc.), and achieve the effect of improving formability, reducing resistance and improving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

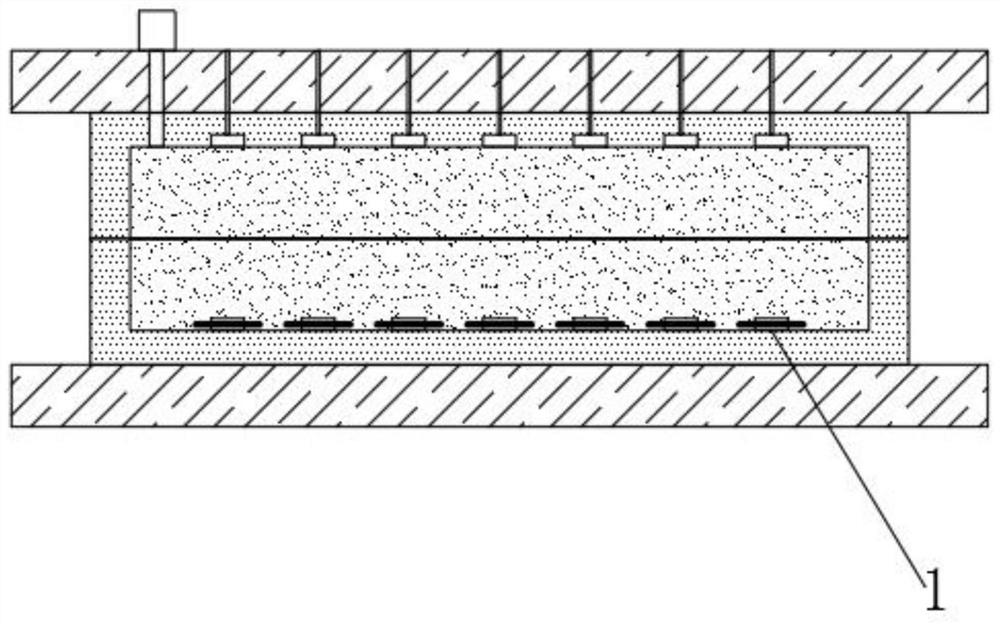

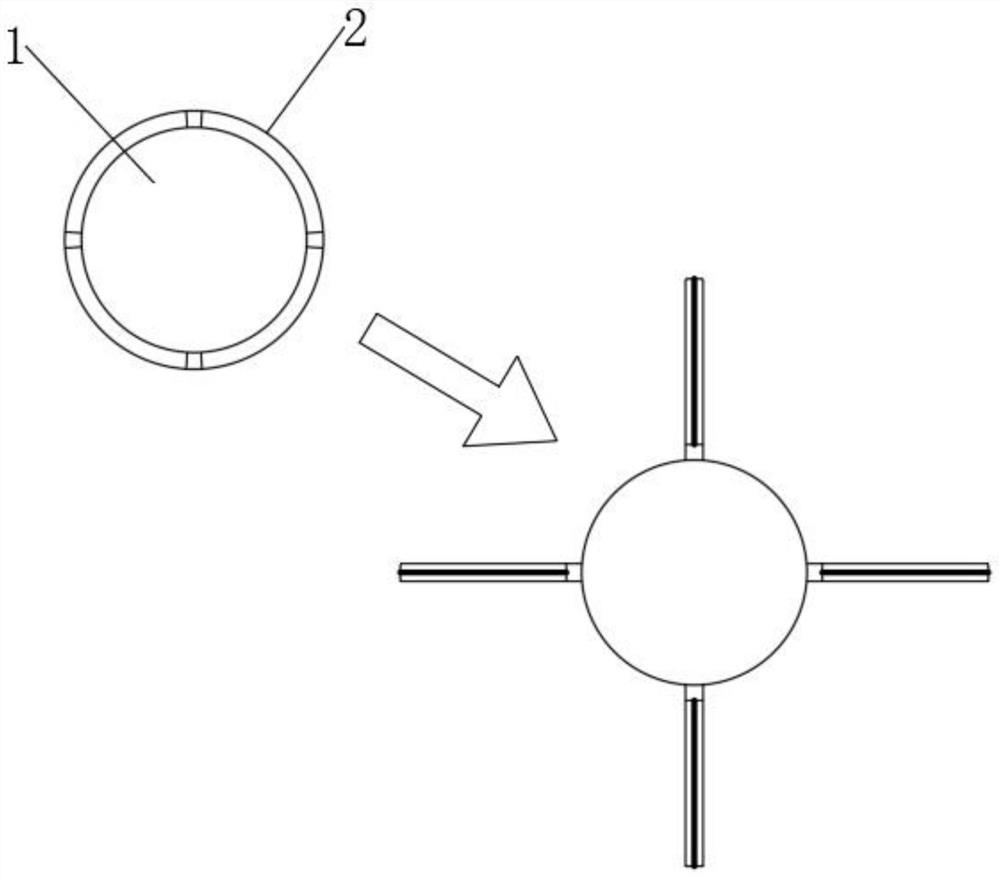

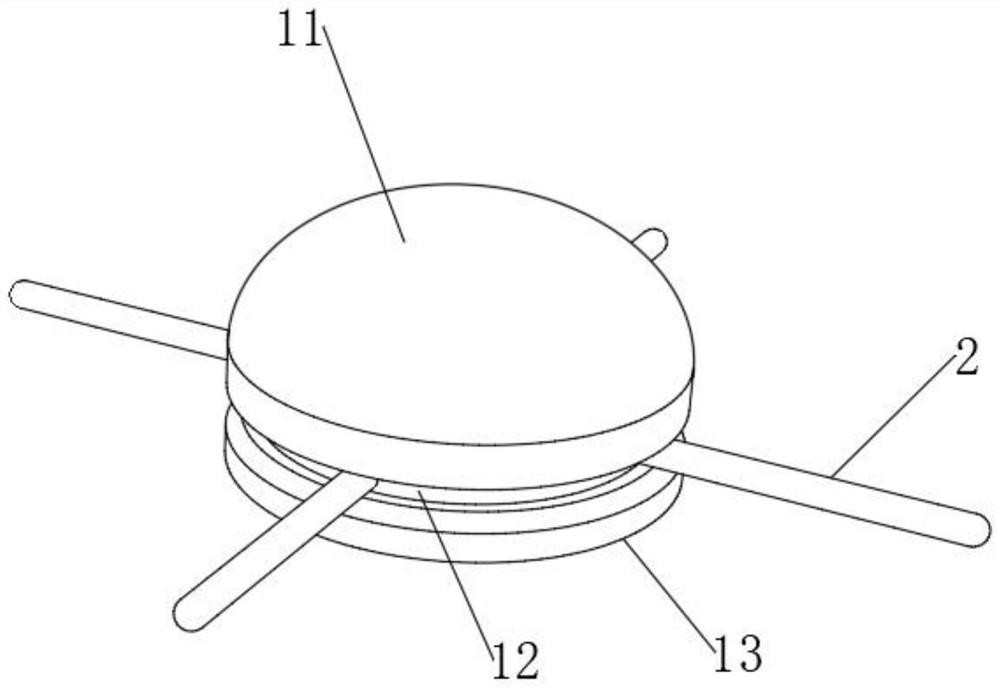

[0044]SeeFigure 1-2, A casting process of non-porous aluminum alloy, including the following steps:

[0045]S1. Take the aluminum alloy material and put it into the melting furnace for smelting. The melting temperature of the aluminum alloy material is 800°C to obtain the aluminum alloy melt;

[0046]S2. The casting mold is made in advance, and the mold is preheated to 400°C, and the aluminum alloy melt is poured. The casting temperature of the aluminum alloy melt is 700°C;

[0047]S3. Apply a magnetic field above the casting mold to force the composite degassing disc 1 in the casting mold to move upward, and to degas the aluminum alloy melt, and combine it with the holding groove reserved on the casting mold after completion;

[0048]S4. Supplement a proper amount of aluminum alloy melt and pressurize it to 0.08MPa until the aluminum alloy melt fills the casting mold cavity, then adjust the pressure to 0.06MPa to hold the pressure, and the pressure hold time is 200s to obtain a crude product;

[...

Embodiment 2

[0059]A casting process of non-porous aluminum alloy includes the following steps:

[0060]S1. Take the aluminum alloy material and put it into the melting furnace for smelting. The melting temperature of the aluminum alloy material is 900°C to obtain the aluminum alloy melt;

[0061]S2. The casting mold is made in advance, and the mold is preheated to 450°C, and the aluminum alloy melt is poured. The casting temperature of the aluminum alloy melt is 710°C;

[0062]S3. Apply a magnetic field above the casting mold to force the composite degassing disc 1 in the casting mold to move upward, and to degas the aluminum alloy melt, and combine it with the holding groove reserved on the casting mold after completion;

[0063]S4. Supplement appropriate amount of aluminum alloy melt and pressurize it to 0.09MPa until the aluminum alloy melt fills the casting mold cavity, and then adjust the pressure to 0.065MPa to hold the pressure. The pressure hold time is 250s to obtain a crude product;

[0064]S5. Open...

Embodiment 3

[0068]A casting process of non-porous aluminum alloy includes the following steps:

[0069]S1. Take the aluminum alloy material and put it into the melting furnace for melting, and the melting temperature of the aluminum alloy material is 950°C to obtain the aluminum alloy melt;

[0070]S2. The casting mold is made in advance, and the mold is preheated to 500°C, and the aluminum alloy melt is poured. The casting temperature of the aluminum alloy melt is 720°C;

[0071]S3. Apply a magnetic field above the casting mold to force the composite degassing plate 1 in the casting mold to move upwards, and degas the aluminum alloy melt, which is combined with the holding groove reserved on the casting mold after completion;

[0072]S4. Supplement an appropriate amount of aluminum alloy melt and pressurize it to 0.1MPa until the aluminum alloy melt fills the casting mold cavity, then adjust the pressure to 0.07MPa to hold the pressure, and the pressure hold time is 300s to obtain a crude product;

[0073]S5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com