Polyurethane foaming white material and polyurethane composition

A technology of polyurethane and composition, applied in the field of rigid polyurethane foam materials, can solve the problems such as the attenuation of the foaming reaction speed of the polyurethane composition, the inability of long-term stable storage of the polyurethane foaming white material, the increase of the thermal conductivity of the foam, and the like, so as to improve the state of the pores. , The effect of improving adhesion and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

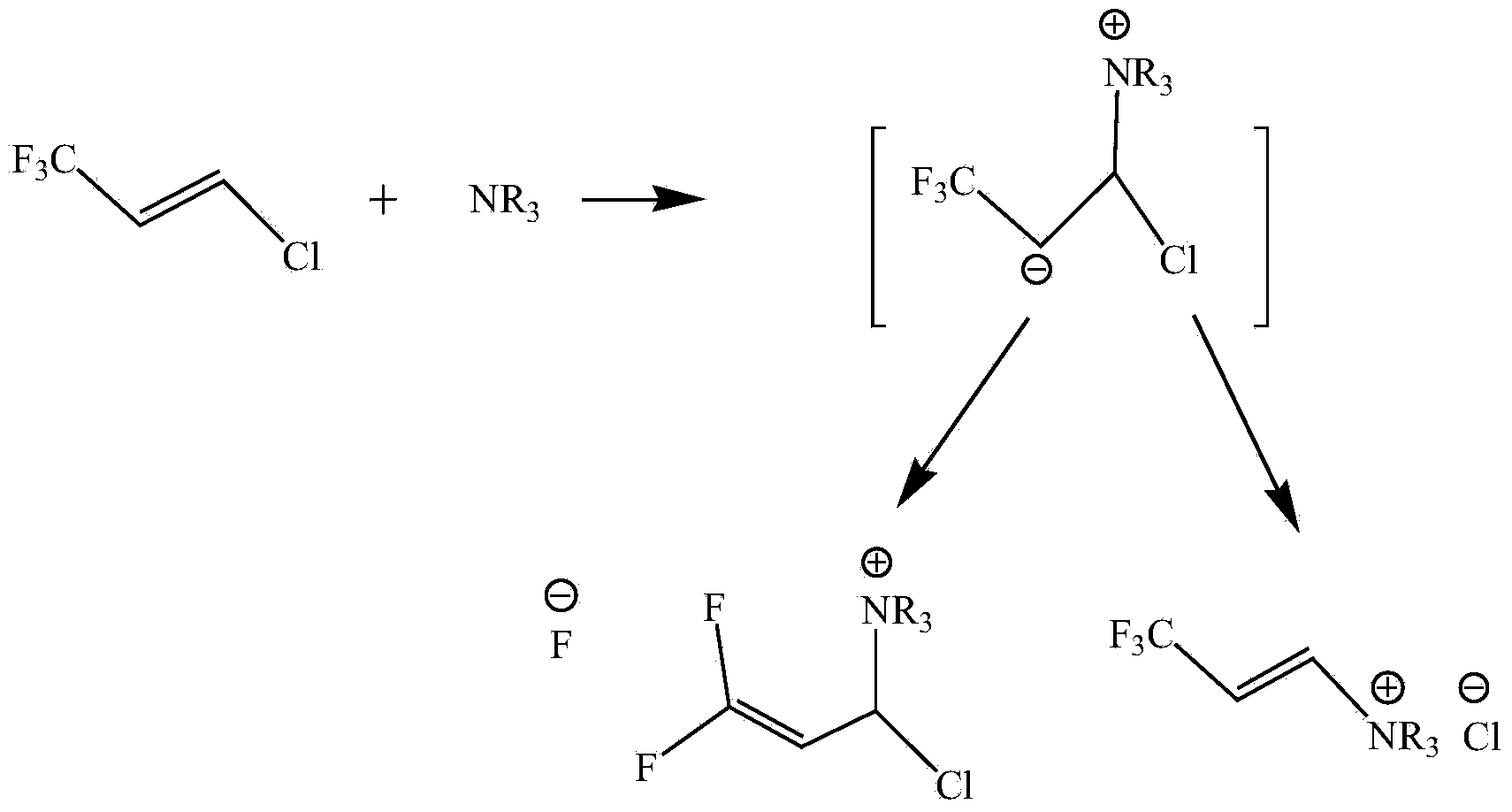

Method used

Image

Examples

Embodiment 1

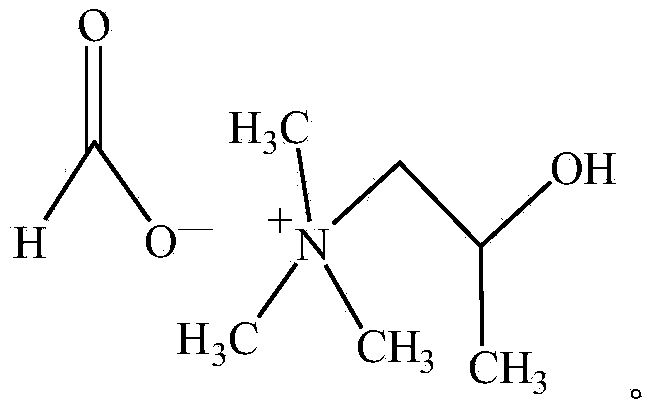

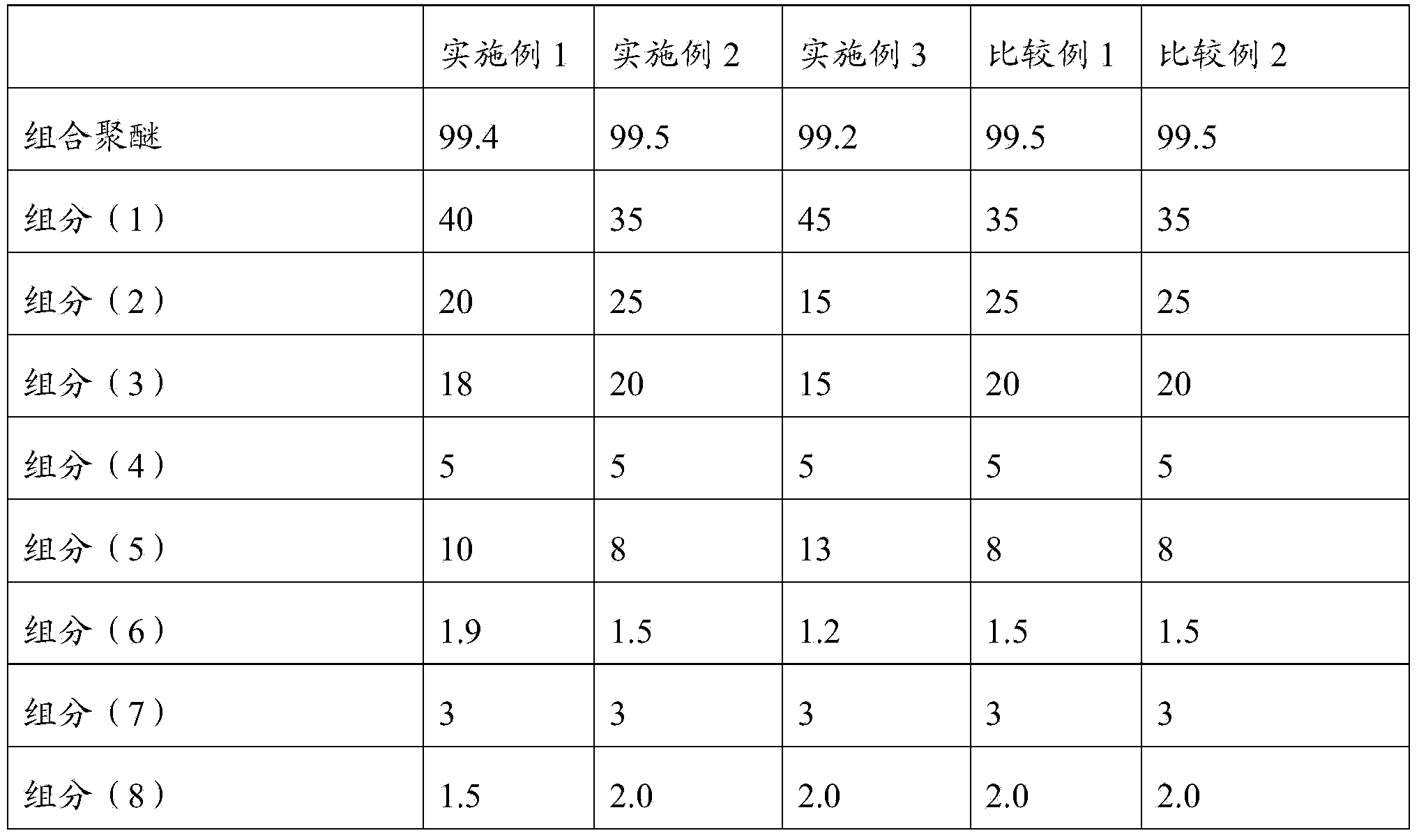

[0042] In parts by weight, mix the following components to obtain the foaming white material in the polyurethane composition: 99.4 parts of combination polyether (purchased in Ningwu Chemical Industry), 0.6 part of (2-hydroxypropyl) trimethylammonium formate (trade name for TMR-2, available from Air Products & Chemicals Inc), and 28 parts of trans-1-chloro-3,3,3-trifluoropropene (trade name LAB, available from Honeywell). The foaming black material in the polyurethane composition is: 134.4 parts of polymethylene polyphenyl polyisocyanate (trade name PM2010, purchased from Yantai Wanhua).

[0043] The above-mentioned polyurethane foaming white material and foaming black material are mixed to obtain a polyurethane composition. The mixing includes three situations: instant mixing, mixing after sealing at room temperature for 1 month, mixing after sealing at room temperature for 2 months, and foaming When the performance test is performed, the test results are shown in Table 1. ...

Embodiment 2

[0045] In parts by weight, mix the following components to obtain the foaming white material in the polyurethane composition: 99.5 parts of combined polyether (purchased in Ningwu Chemical Industry), 0.5 part of (2-hydroxypropyl) trimethylammonium formate (trade name for TMR-2, available from Air Products & Chemicals Inc), and 35 parts of trans-1-chloro-3,3,3-trifluoropropene (trade name LAB, available from Honeywell). The foaming black material in the polyurethane composition is: 137.7 parts of polymethylene polyphenyl polyisocyanate (trade name PM2010, purchased from Yantai Wanhua).

[0046] The above-mentioned polyurethane foaming white material and foaming black material are mixed to obtain a polyurethane composition. The mixing includes three situations: instant mixing, mixing after sealing at room temperature for 1 month, mixing after sealing at room temperature for 2 months, and foaming When the performance test is performed, the test results are shown in Table 1.

Embodiment 3

[0048] In parts by weight, mix the following components to obtain the foaming white material in the polyurethane composition: 99.2 parts of combination polyether (purchased in Ningwu Chemical Industry), 0.8 part of (2-hydroxypropyl) trimethylammonium formate (trade name for TMR-2, available from Air Products & Chemicals Inc), and 40 parts of trans-1-chloro-3,3,3-trifluoropropene (trade name LAB, available from Honeywell). The foaming black material in the polyurethane composition is: 141.4 parts of polymethylene polyphenyl polyisocyanate (trade name PM2010, purchased from Yantai Wanhua).

[0049] The above-mentioned polyurethane foaming white material and foaming black material are mixed to obtain a polyurethane composition. The mixing includes three situations: instant mixing, mixing after sealing at room temperature for 1 month, mixing after sealing at room temperature for 2 months, and foaming When the performance test is performed, the test results are shown in Table 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com