Patents

Literature

104results about How to "Improve surface porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Small intestinal submucosa (SIS) soft tissue repair patch and preparation method thereof

InactiveCN102462561AImprove surface porosityImprove biological activityProsthesisTissue repairSoft tissue.FNA

The invention relates to a method for preparing a small intestinal submucosa (SIS) soft tissue repair patch, and the soft tissue repair patch prepared by the method. The invention also relates to application of the soft tissue repair path to tissue repair.

Owner:BEIJING MED ZENITH MEDICAL SCI CORP LTD

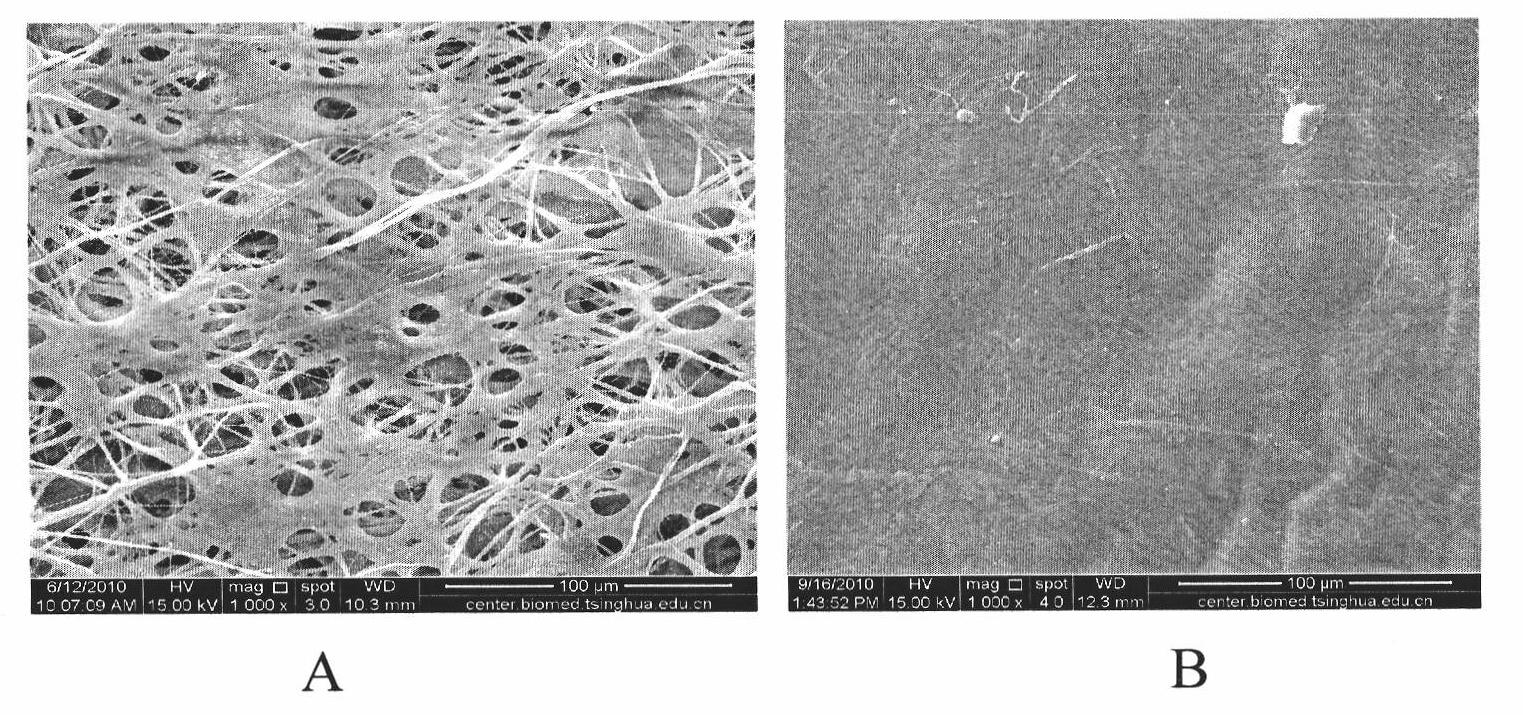

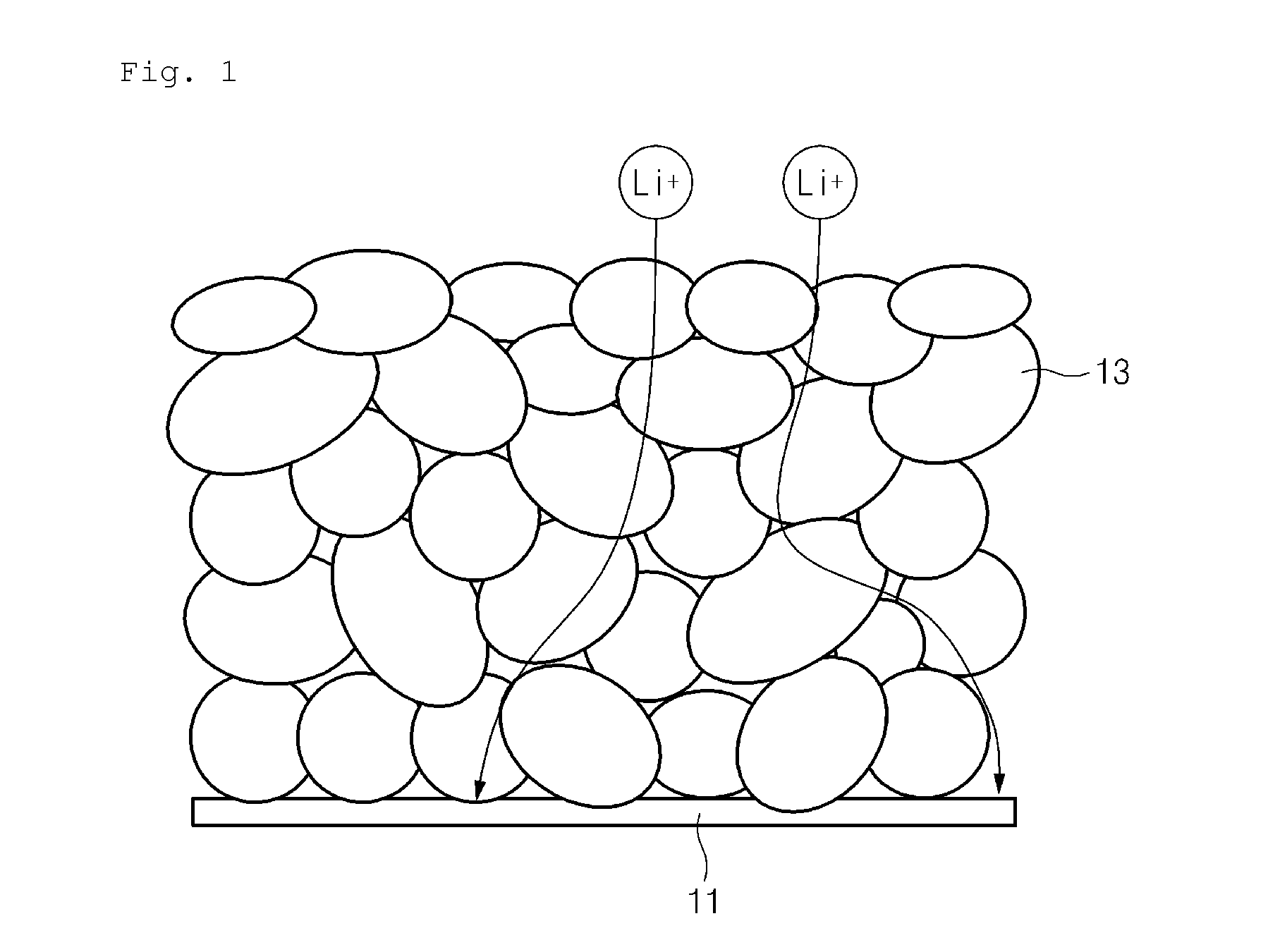

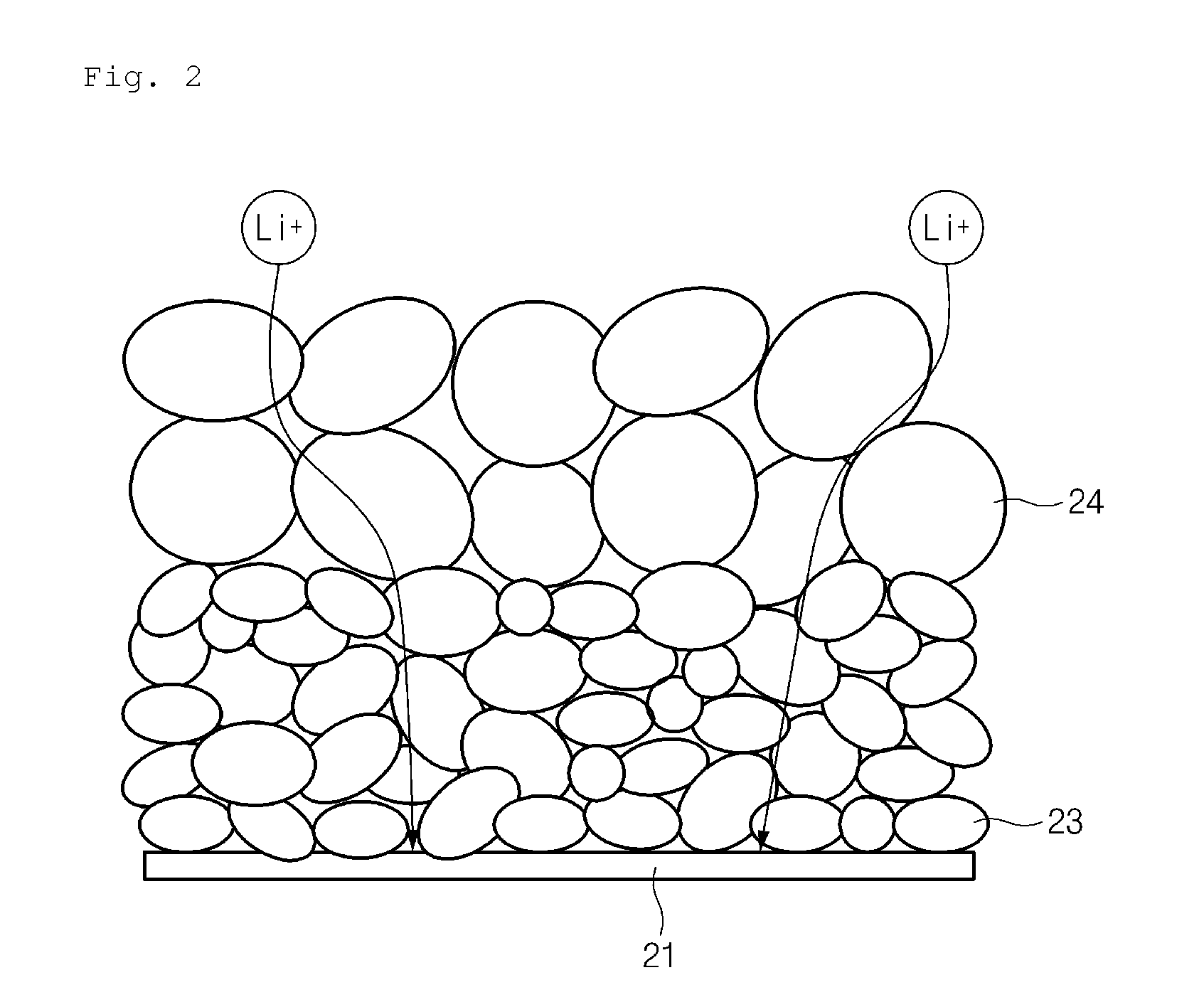

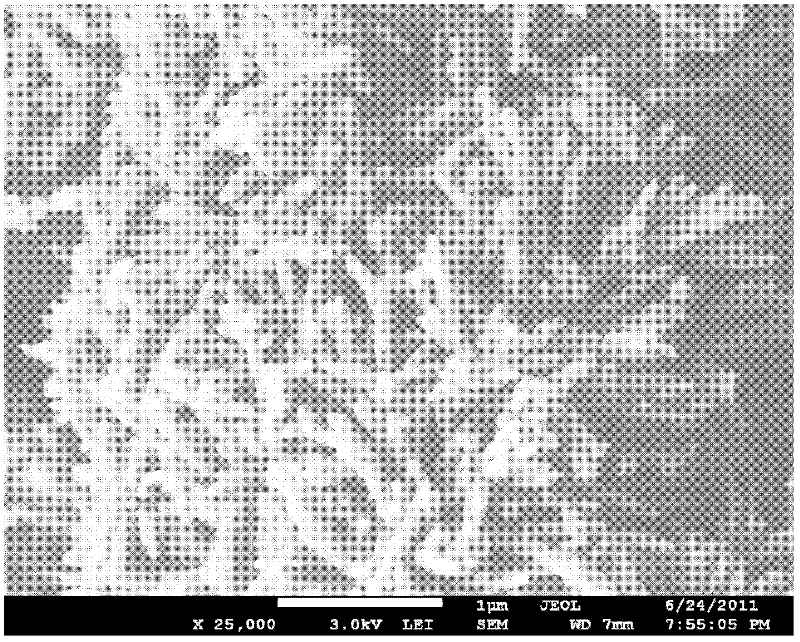

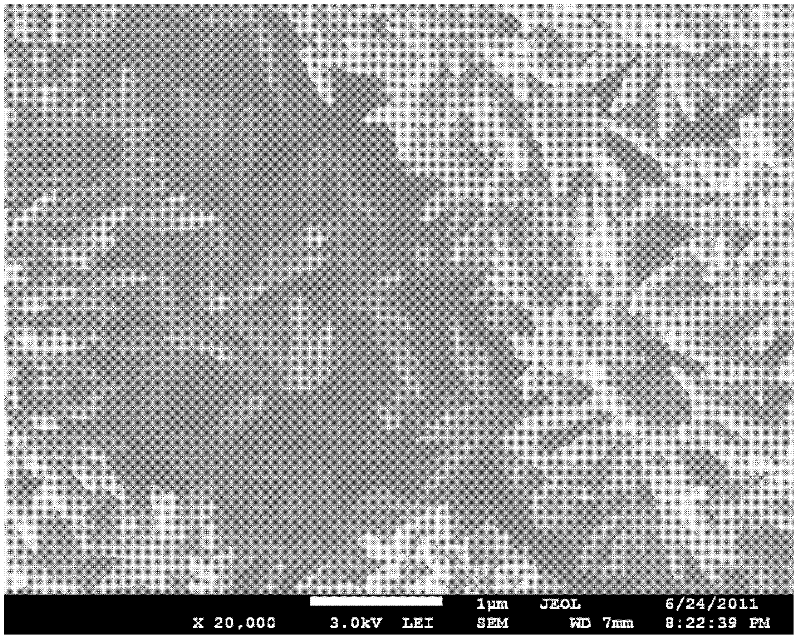

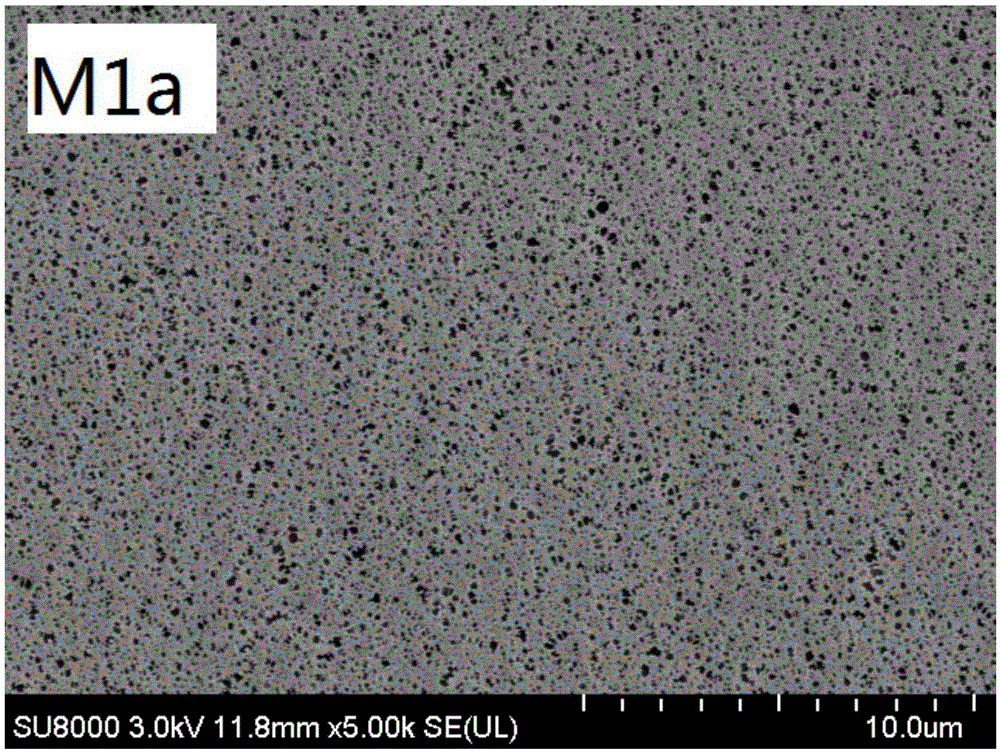

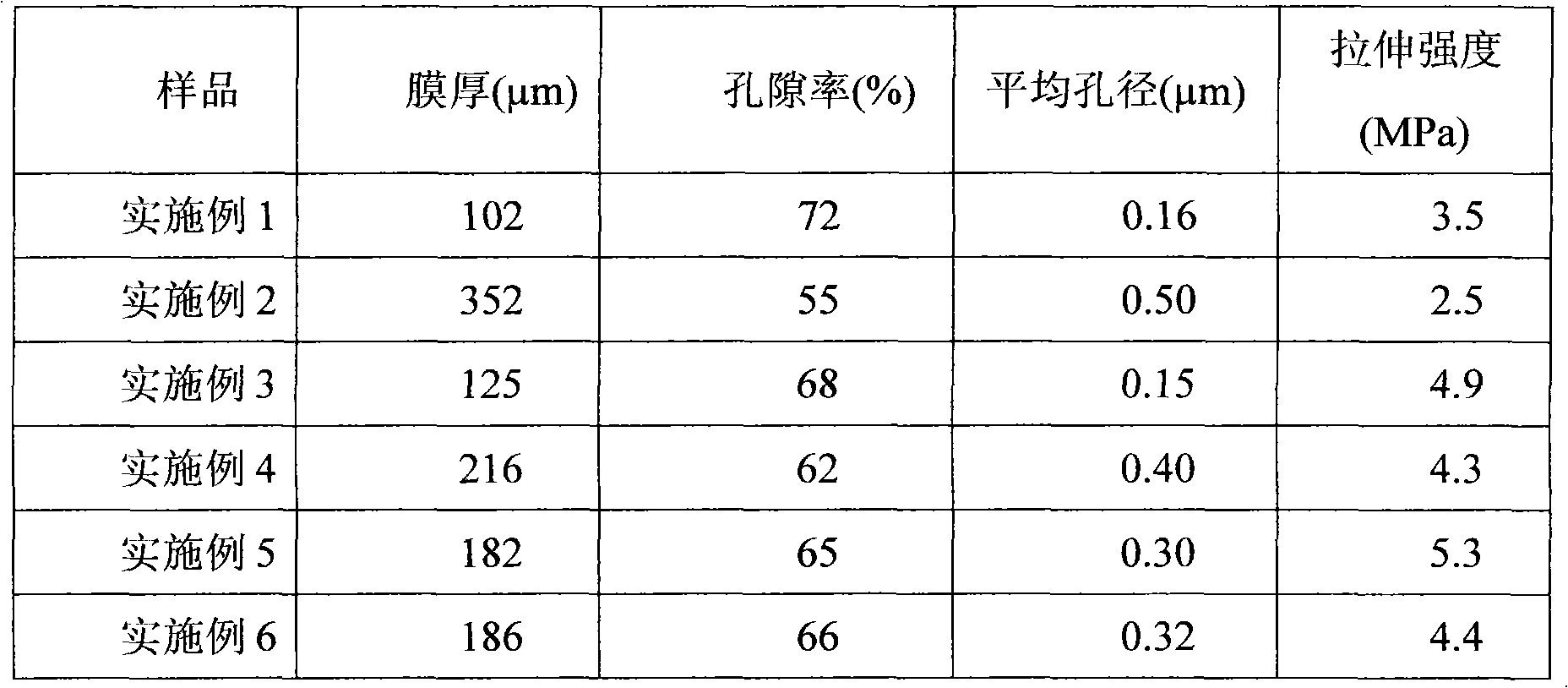

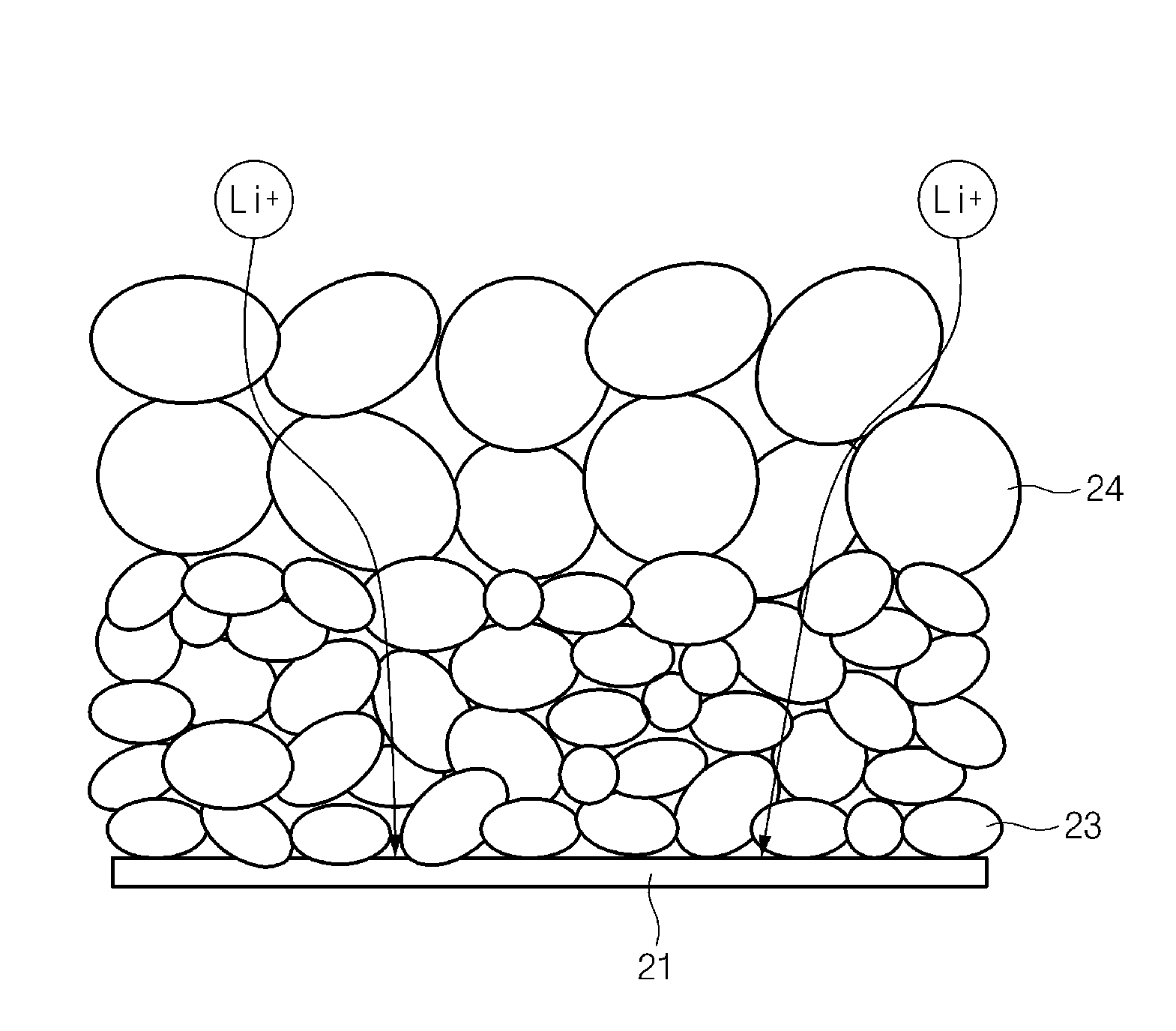

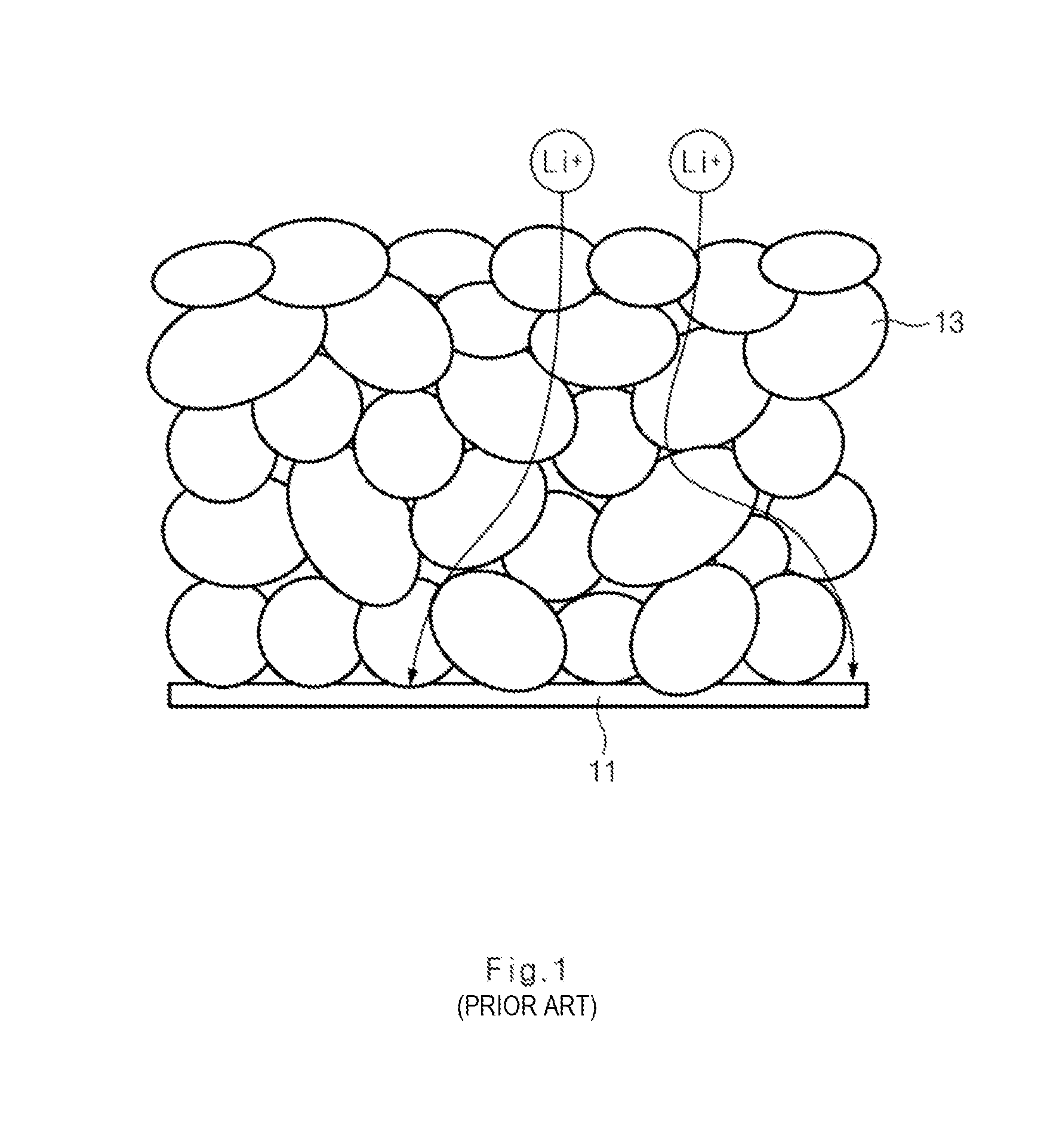

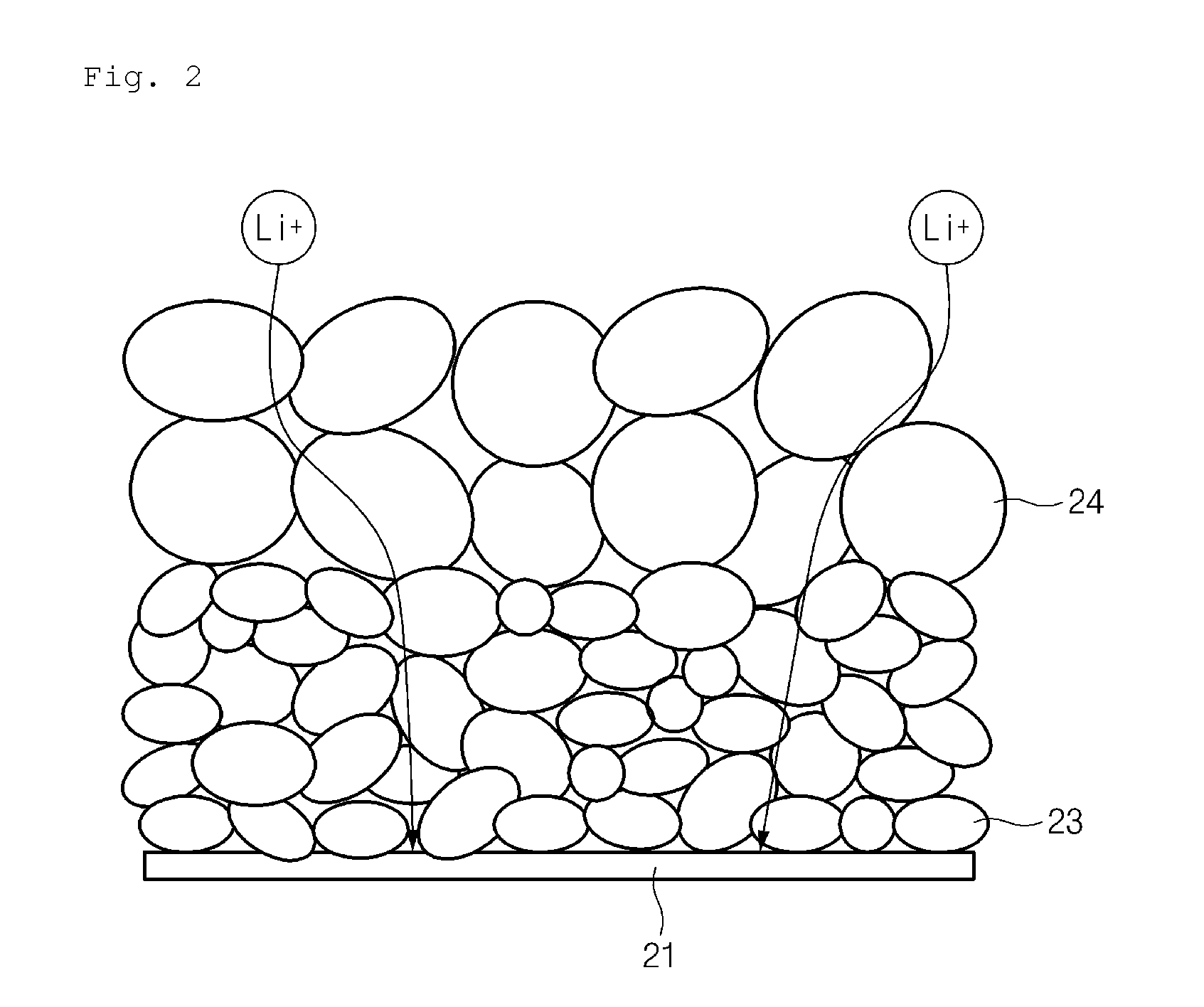

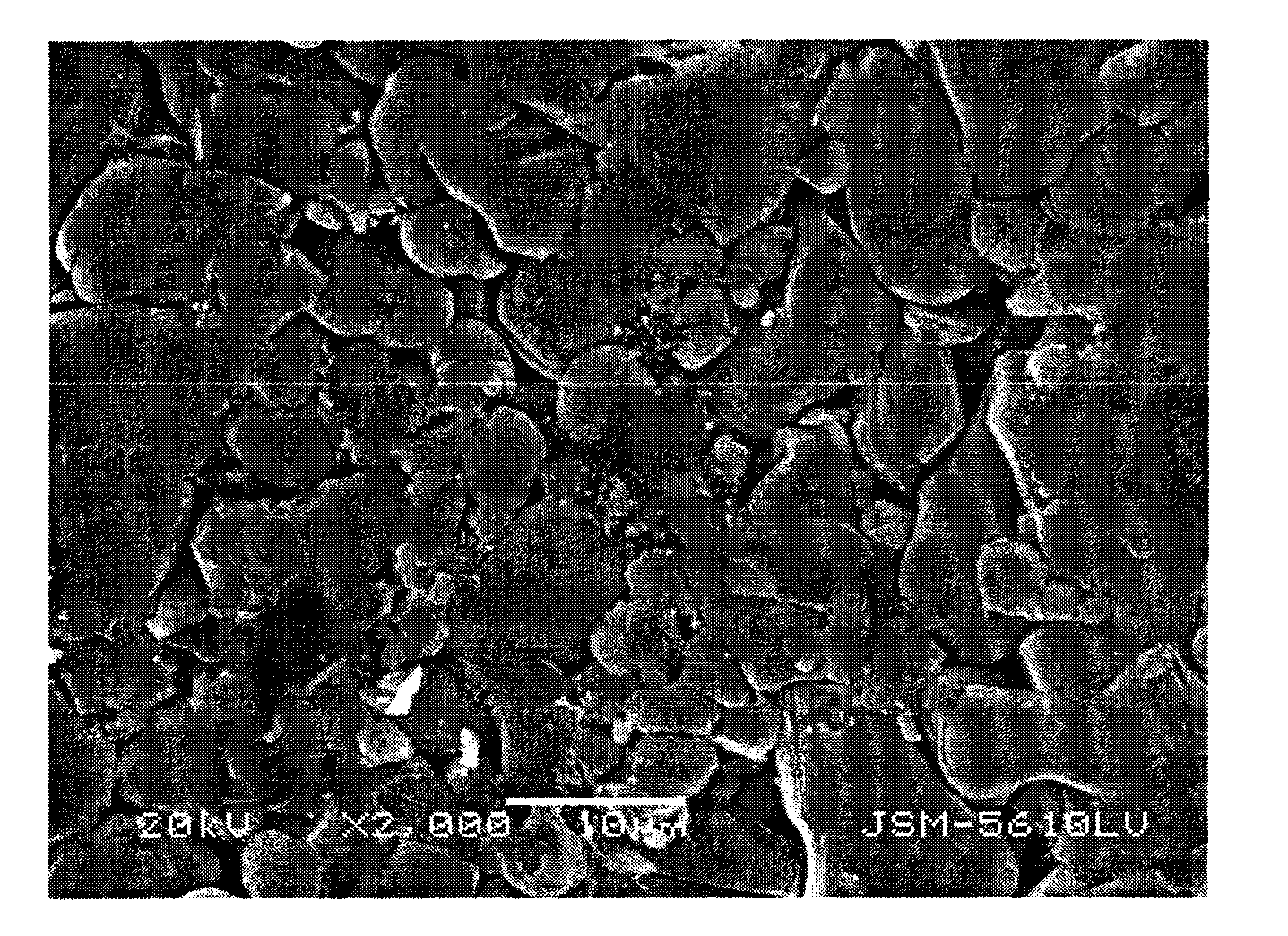

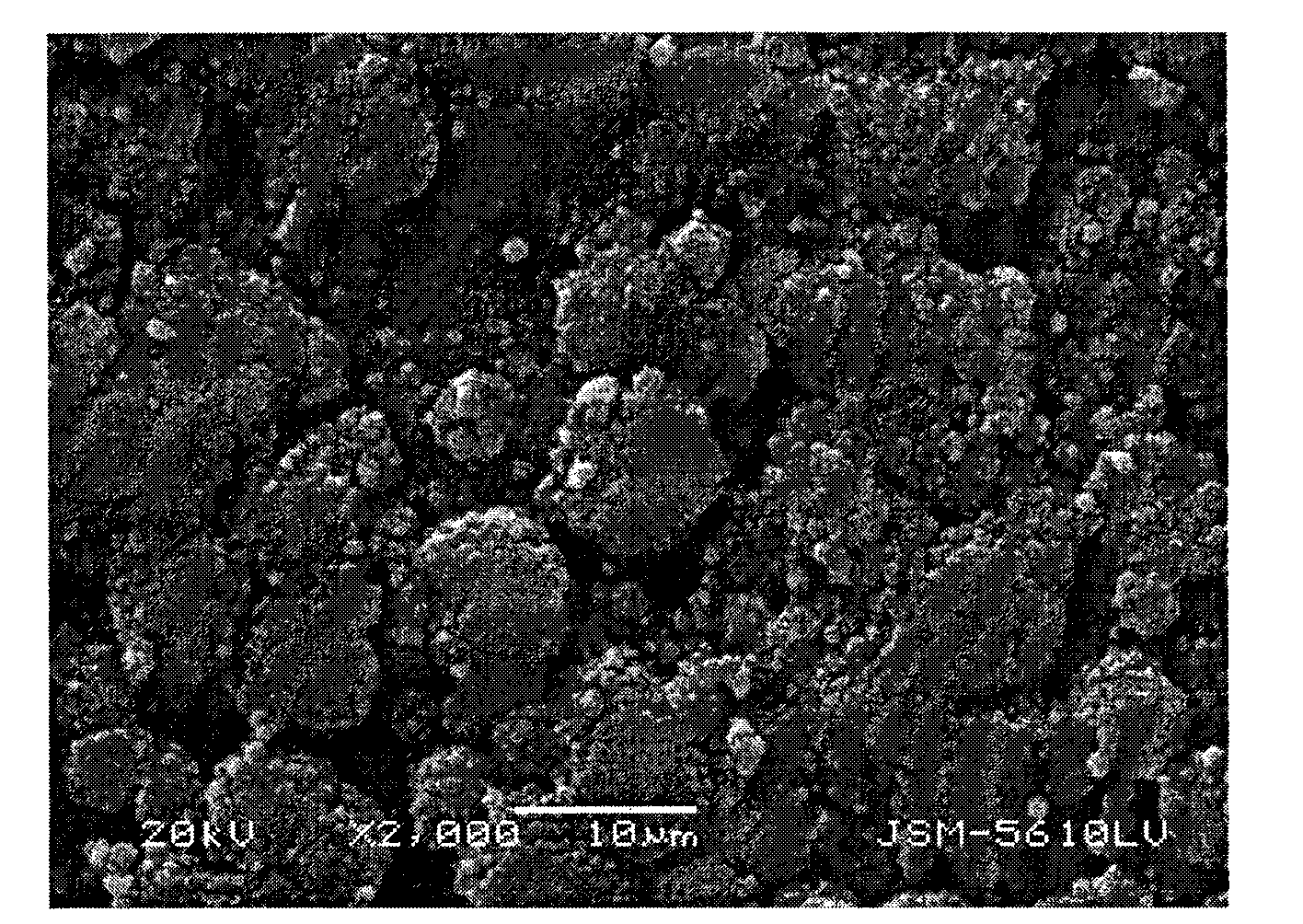

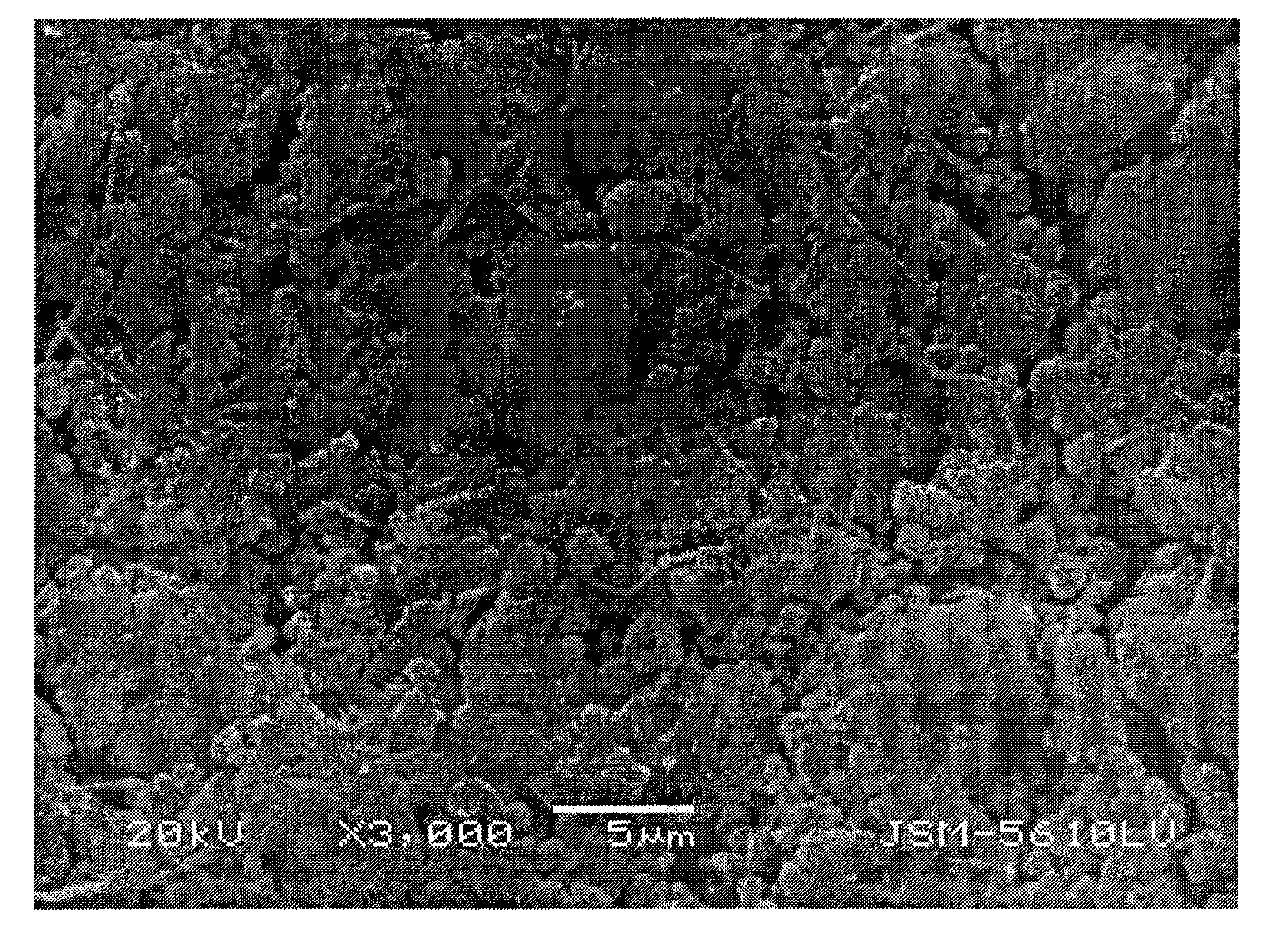

Anode for lithium secondary battery and lithium secondary battery including the same

ActiveUS20140287316A1Improve surface porosityIncreased ion mobilityElectrode rolling/calenderingLine/current collector detailsPorosityLithium

Provided is an anode for a lithium secondary battery composed of a multi-layered structure including an electrode current collector, a first anode active material layer including a first anode active material formed on the electrode current collector, and a second anode active material layer including a second anode active material having relatively lower press density and relatively larger average particle diameter than the first anode active material.Since an anode according to an embodiment of the present invention may include a multi-layered active material layer including two kinds of anode active materials having different press densities and average particle diameters on an electrode current collector, porosity of the surface of the electrode may be improved even after a press process to improve ion mobility into the electrode. Thus, charge characteristics and cycle life of a lithium secondary battery may be improved.

Owner:LG ENERGY SOLUTION LTD

Method for preparing rose calcium carbonate from low-grade limestone

InactiveCN102502749AFull flowImprove mass transfer efficiencyCalcium/strontium/barium carbonatesChemical industryPorosityHigh surface

The invention discloses a method for preparing rose calcium carbonate from low-grade limestone, which comprises the following steps: 1) proportionally calcining low-grade limestone and blind coal to prepare calcium oxide; 2) screening under vibrations to remove coal ash and lime powder, thereby obtaining lumpy lime; 3) adding water to slake the lumpy lime, removing impurities by hydrocyclone and vibration screening to obtain fine emulsion slurry, adding a whitener, and aging to obtain the Ca(OH)2 prime slurry; 4) after regulating the temperature and concentration of the Ca(OH)2 prime slurry, adding a crystal form control agent, carrying out bubbling carbonation reaction, and adding a dispersant; when the pH value of the slurry is lower than or equal to 7, stopping carbonation to obtain a cured slurry; and 5) after the cured slurry is thickened, dehydrating to obtain the rose calcium carbonate. Compared with common light calcium carbonate, the rose calcium carbonate disclosed by the invention has the advantages of higher crystal completeness, high surface porosity, high light scattering coefficient and stronger covering power; and the invention is applicable to the industries of paper making, rubber, plastics and paint.

Owner:福建省万旗非金属材料有限公司

Two-dimensional/one-dimensional heterogeneous nanochannel film and preparation method and application thereof

ActiveCN110170253AImprove energy conversion effectImprove throughputSemi-permeable membranesComposite filmRoom temperature

The invention provides a preparation method of a two-dimensional / one-dimensional heterogeneous nanochannel film. The method is characterized by comprising the following steps that step 1, graphene oxide is dissolved in an aqueous piperazine solution, and ultrasonic treatment is performed at the room temperature to obtain a uniformly dispersed first solution; step 2, the first solution is added dropwise to the upper layer of a porous aluminum oxide film, and after the solvent is evaporated at the room temperature, a first composite film with a graphene oxide film layer and a porous aluminum oxide film layer is obtained; step 3, a benzenetricarbonyl trichloride solution is added dropwise to the upper surface of the graphene oxide film layer of the first composite film, and drying is carriedout to obtain the two-dimensional / one-dimensional heterogeneous nanochannel film. The invention provides the two-dimensional / one-dimensional heterogeneous nanochannel film prepared by using the methodand application of the two-dimensional / one-dimensional heterogeneous nanochannel film in salt difference energy conversion.

Owner:FUDAN UNIV

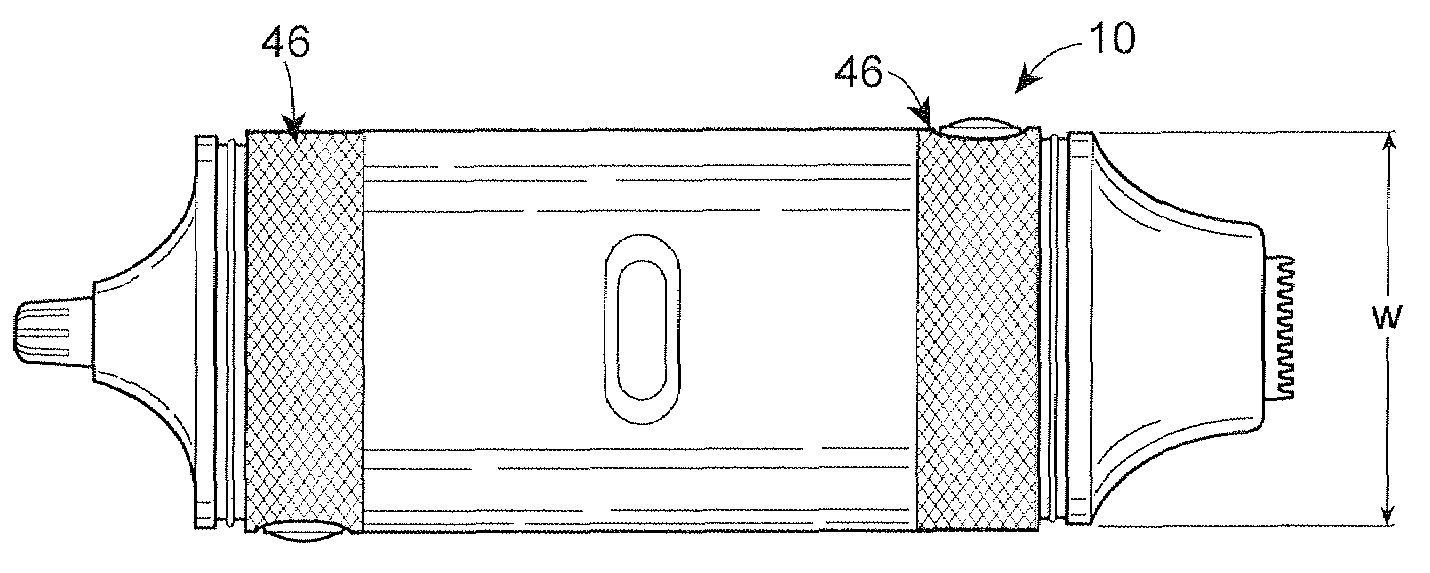

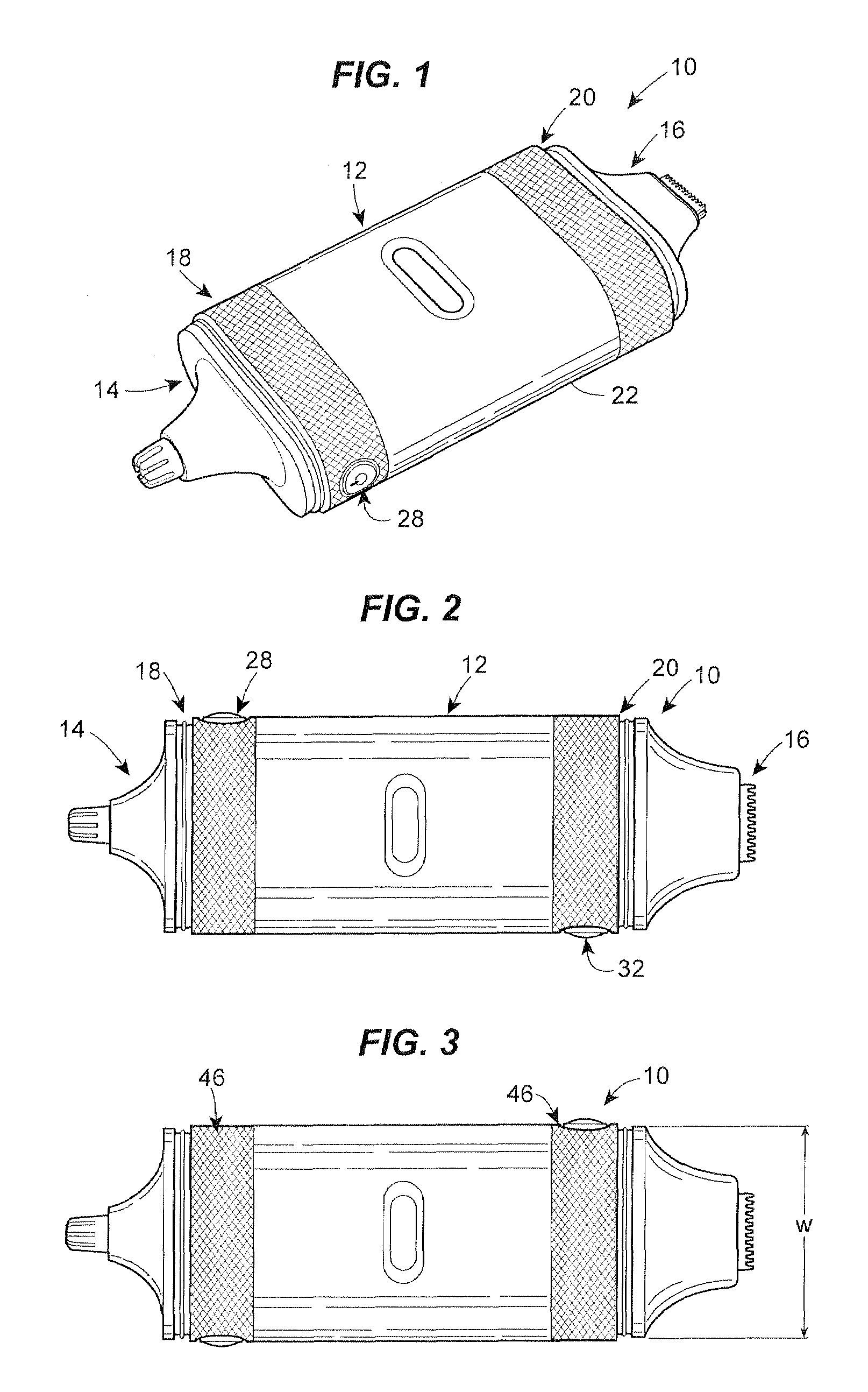

Dual-action hair trimmer

InactiveUS20090165303A1Reduce equipment footprintSave bathroom vanity counter-spaceMetal working apparatusPorosityDual action

An electric hair-trimming device includes a body having two opposite ends, two trimming heads mounted to the two opposite ends of the body, and two endcaps that detachably couple to the two opposite ends of the body to cover the two trimming heads. The endcaps each have a generally flat end surface such that the device can be stood upright on either of the endcaps. In an example embodiment, the trimming heads are provided by a nose-hair trimmer and a detail trimmer. And in another example embodiment, the nose-hair trimmer includes a high surface-porosity foil shroud.

Owner:GOODY PRODS

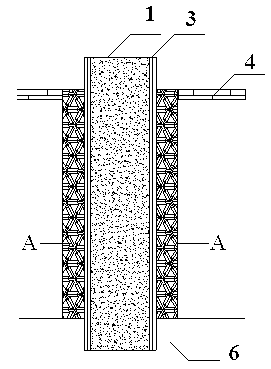

Casing draining end bearing pile for treating liquefied foundation and construction method

InactiveCN102995622AImprove bearing capacityTimely dissipation of excess pore water pressureBulkheads/pilesSoil preservationCrushed stoneEngineering

The invention discloses a casing drawing end bearing pile for treating a liquefied foundation and a construction method. The casing drawing end bearing pile for treating the liquefied foundation is that a pile body comprises an inner plastic pipe, an outer plastic pipe, a blind drain, concrete and a geotextile; a casing pile is an end bearing pile; a drilling machine is adopted and is used for drilling a hole so as to insert the outer plastic pipe which is wrapped by the geotextile into a foundation bearing course; the annular draining blind drain of which the diameter is slightly smaller than that of the outer pipe is placed on the inner side of the outer plastic pipe, so as to form a vertical draining channel; the inner plastic pipe is placed on the inner side of the annular draining blind drain; the concrete is poured into the inner plastic pipe to form the pile; and a gravel cushion layer is paved at the top of the pile along the horizontal direction, thus forming a horizontal draining channel. By adopting the casing draining end bearing pile for treating the liquefied foundation and the construction method, the bearing capacity of the pile is improved under the same amount of used concrete, the application range is wide, and the casing draining end bearing pile is applicable to the treatment of a general wear foundation and the liquefied foundation; the horizontal draining channel and the vertical draining channel are provided for foundation liquefying, and thus the possibility that the foundation is liquefied is reduced; and the casing draining end bearing pile is reasonable in structure, good in pile forming effect, low in cost and convenient to construct, and realizes the effects on foundation treatment and seismic hardening.

Owner:HOHAI UNIV

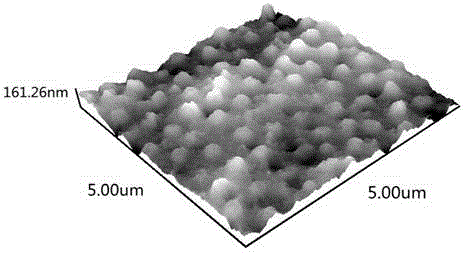

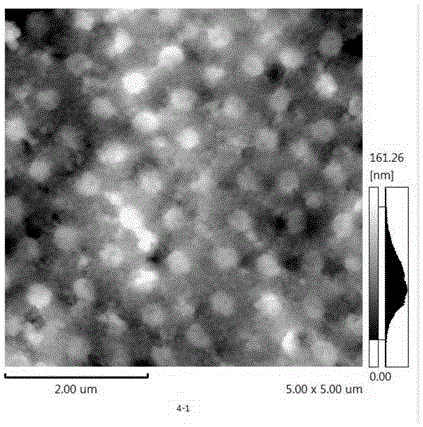

Surface functionalized carbon fiber reinforced polyether-ether-ketone dental composite material and preparation method thereof

PendingCN110201224ATightly boundChanging the composition of surface functional groupsPharmaceutical delivery mechanismTissue regenerationCarbon fibersBiocompatibility Testing

The invention provides a surface functionalized carbon fiber reinforced polyether-ether-ketone dental composite material. The surface treatment of the carbon fiber reinforced polyether-ether-ketone composite material is carried out by sulfonation and functionalization of graphene oxide to obtain a surface functionalized carbon fiber reinforced polyether-ether-ketone composite material coated witha graphene oxide functional layer, the functional layer has strong binding force to a substrate, is not easy to fall off, and can effectively change the surface geometry and surface functional group composition of the carbon fiber reinforced polyether-ether-ketone composite material, the carbon fiber reinforced polyether-ether-ketone composite material is given with a new surface topography and surface properties, the biocompatibility and osteogenicity are increased, the application in medical materials is increased, the operation method of the invention is simple and easy, the surface treatment condition is mild, and the method is suitable for large-scale promotion and application, and has high medical value.

Owner:FIRST HOSPITAL OF SHANXI MEDICAL UNIV

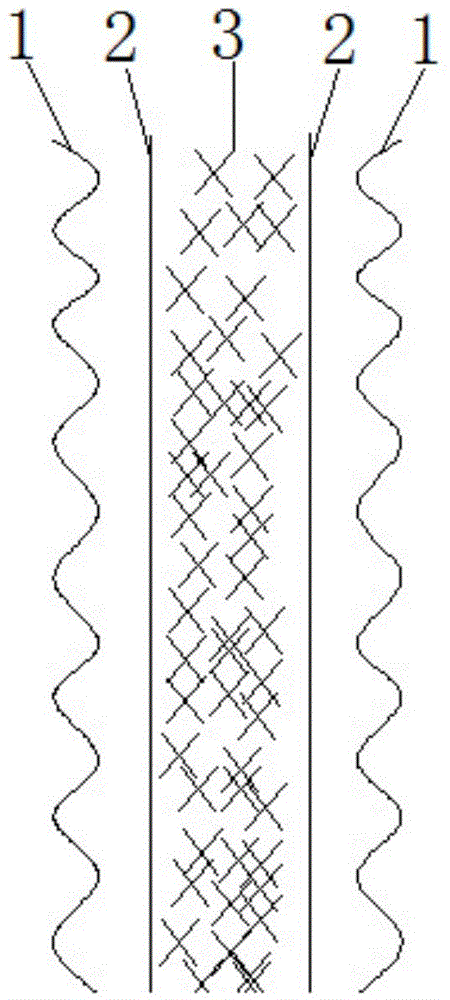

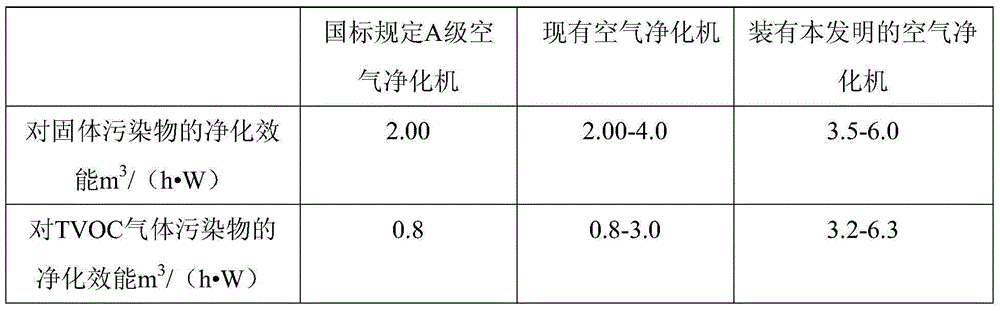

Novel filtering material for air cleaning machine, and preparation method and use thereof

ActiveCN104888532AReduce volumeImprove space utilizationCombination devicesSynthetic resin layered productsAir cleaningActive carbon

The invention belongs to the field of air cleaning, and especially relates to a novel filtering material for an air cleaning machine, and a preparation method and a use thereof. The filtering material comprises at least one melt-blown fabric filter layer subjected to surface electrostatic treatment, and an active carbon layer uniformly arranged on the at least one melt-blown fabric filter layer, and the outer side of the at least one melt-blown fabric filter layer is also provided with a polyester skeleton supporting layer. The novel filtering material is an one body formed by sequentially bonding the polyester skeleton supporting layer as a first layer, the melt-blown fabric filter layer as a second layer, the active carbon layer as a third layer, the melt-blown fabric filter layer as a fourth layer and the polyester skeleton supporting layer as a fifth layer, can realize efficient cleaning of solid pollutants and gas pollutants, and can greatly reduce the volume of the filter core of the air cleaning machine and improve the space utilization rate; and the melt-blown fabric filter layers are subjected to the surface electrostatic treatment, so the adsorption efficiency of pollutants is greatly improved under same conditions, and the air cleaning efficiency is improved.

Owner:C CLOUD FILTER

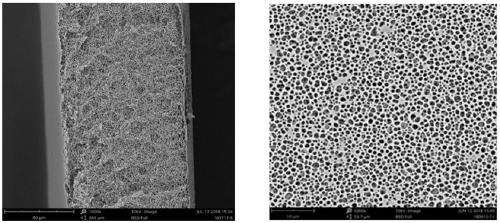

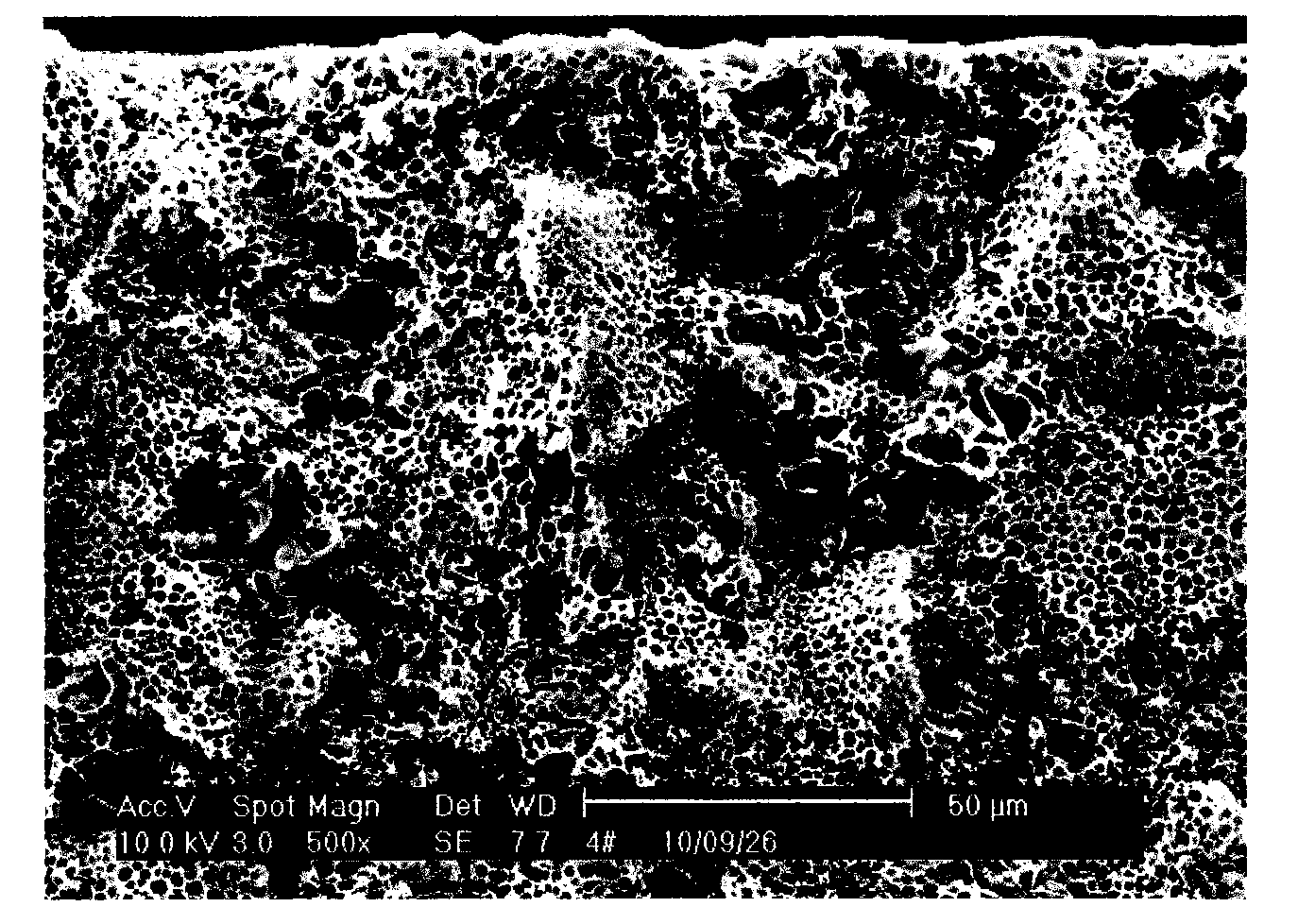

Novel hydrophobic membrane and preparation method thereof

InactiveCN105032211AImprove surface porosityNarrow pore size distributionSemi-permeable membranesOrganic solventMembrane distillation

The invention relates to a novel hydrophobic membrane and a preparation method thereof. The method comprises the following steps: dissolving 0-15wt% of a pore-forming agent and 70-80wt% of an organic solvent, uniformly mixing to obtain a mixture I, adding 8-25wt% of PVDF-CTFE copolymer powder after being subjected to drying dehumidification into the mixture I to obtain a mixture II, and stirring the mixture II for 24h or more at the constant temperature of 25-70 DEG C at the speed of 50-1400rpm until the mixture II is uniformly mixed; standing for defoaming for 12h or more at the temperature of 25-70 DEG C to form uniform film casting liquid; scraping the film casting liquid by a film scraping device to obtain a primary film; and soaking the primary film for 24h in a sol-gel bath formed by tap water, and airing in an air environment to obtain the novel hydrophobic membrane. Compared with the prior art, the novel hydrophobic membrane has a more obvious crystalline structure, a better hydrophobic performance, the narrower pore diameter distribution, and a more communicated pore structure, and can show the higher permeant flux and produced water quality in the membrane distillation application; the method has the wide application prospect in hydrophobic membrane preparation and application fields.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI +1

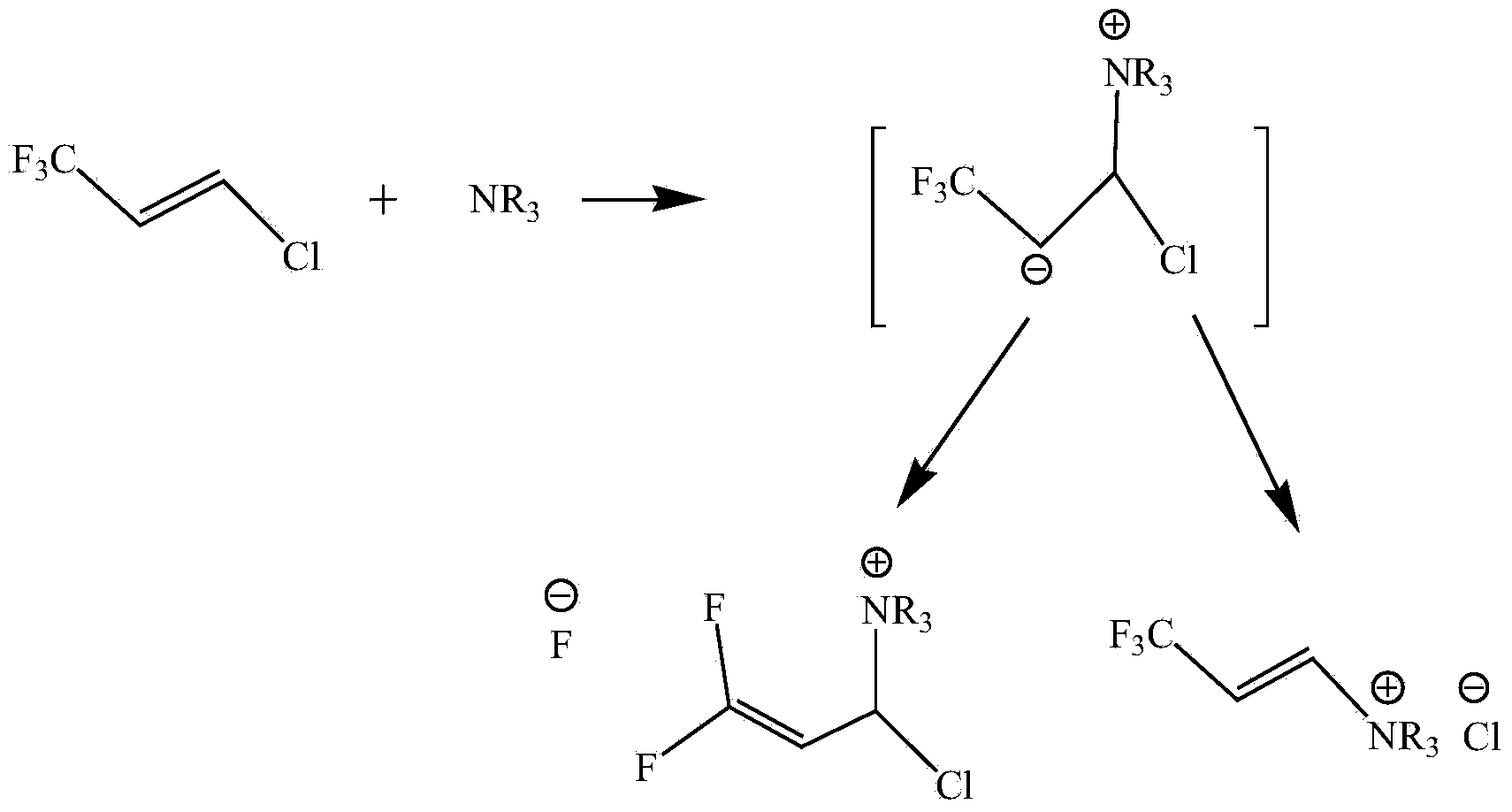

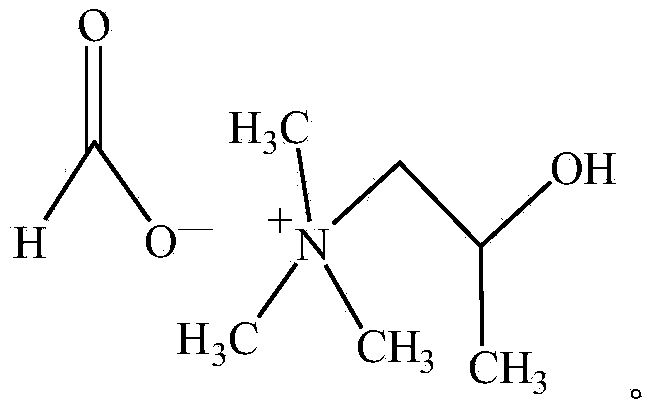

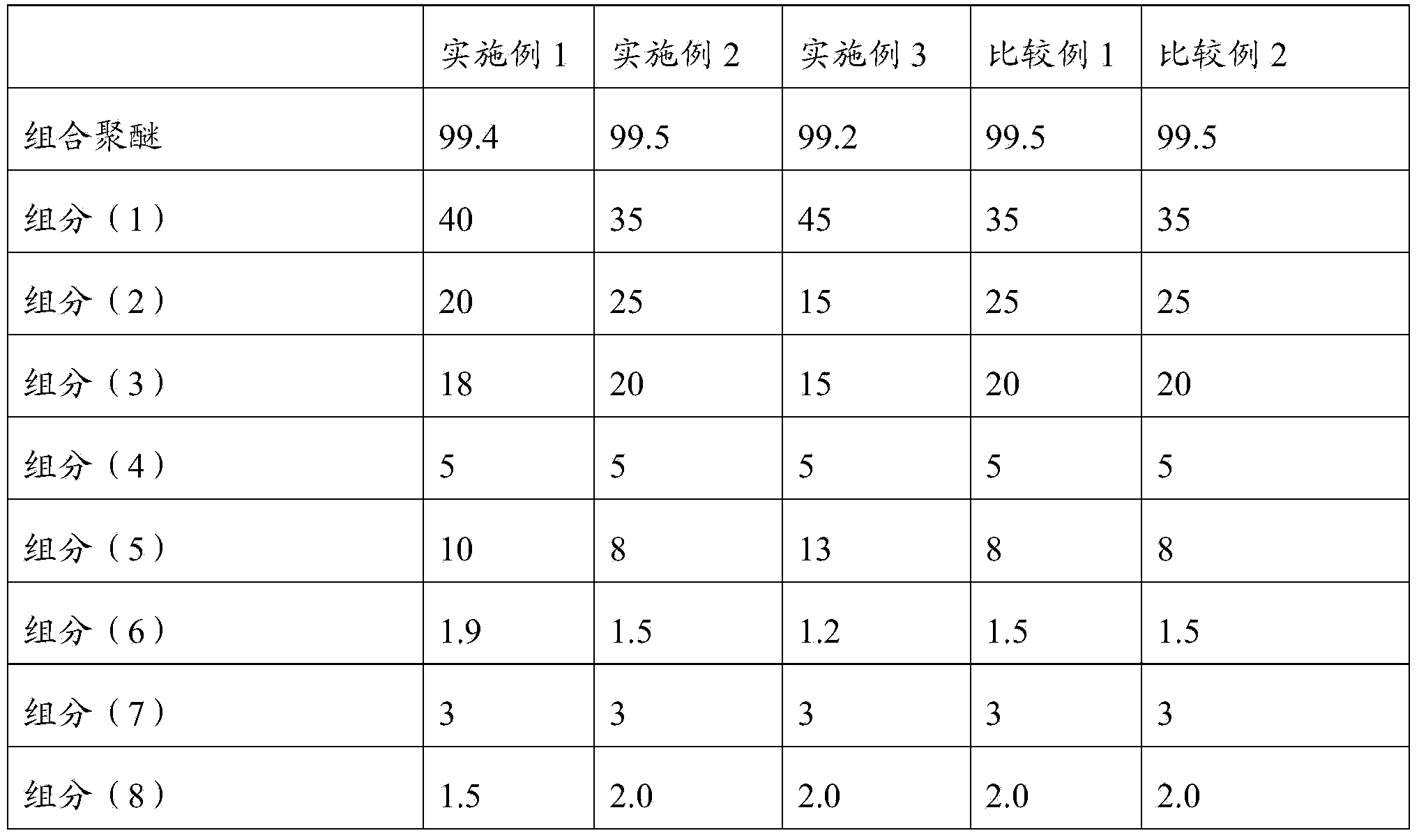

Polyurethane foaming white material and polyurethane composition

The invention discloses a polyurethane foaming white material. The polyurethane foaming white material comprises combined polyether, a foaming agent and a trimerization type catalyst, wherein the foaming agent comprises trans-1-chloro-3, 3, 3-trifluoropropene, and the trimerization type catalyst is (2-hydroxypropyl) trimethyl ammonium formate. The invention further provides a polyurethane composition. The polyurethane foaming white material has stability in storage, and after the polyurethane foaming white material is placed at room temperature for 1 month, the foaming reaction speed of the polyurethane composition and the heat conduction coefficient of foam are basically unchanged.

Owner:HEFEI HUALING CO LTD

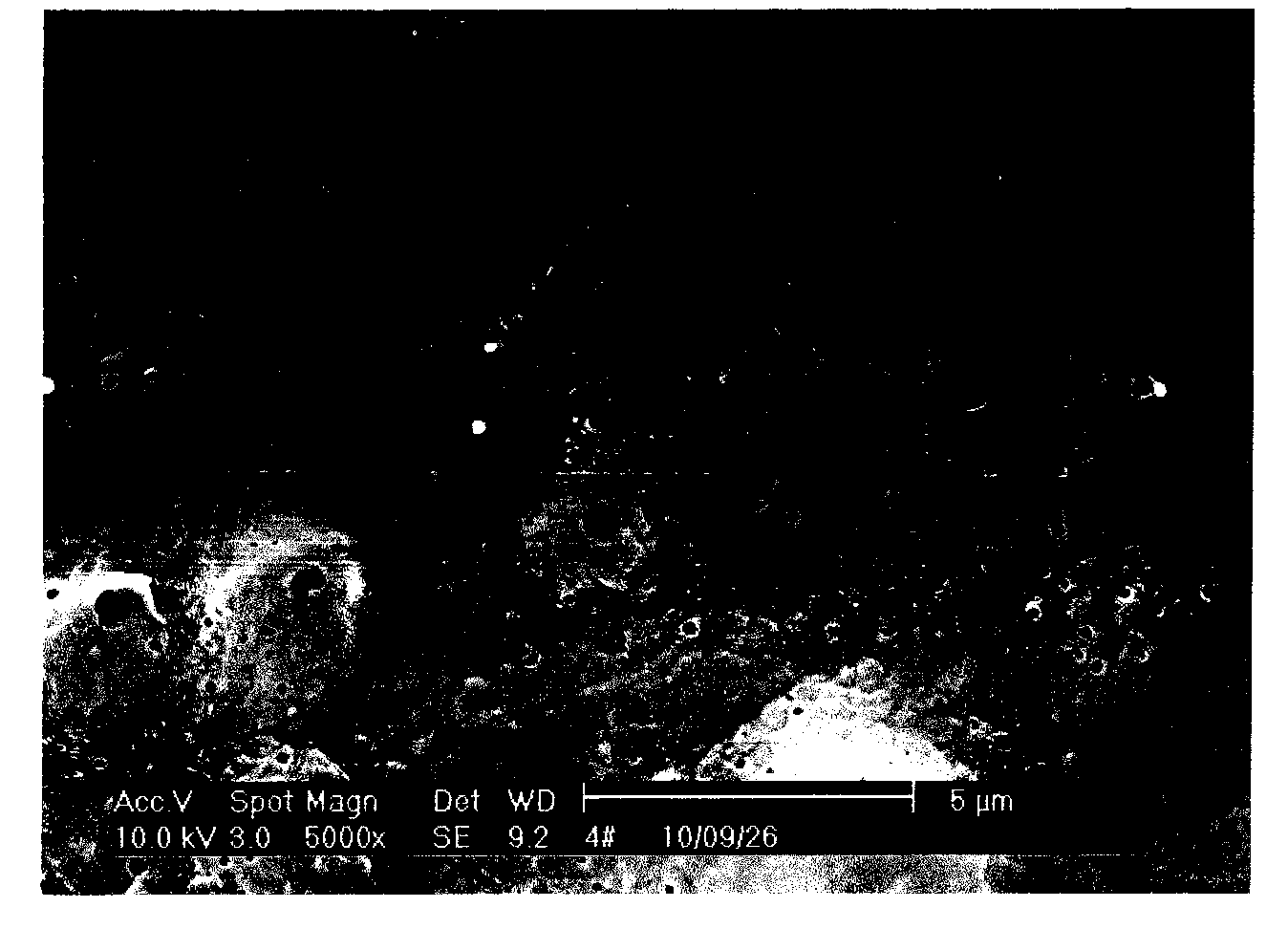

Antibacterial tooth implant and preparation method thereof

PendingCN108434517ARich surface pore structureImprove surface roughnessVacuum evaporation coatingSurface reaction electrolytic coatingPorosityPlasma electrolytic oxidation

The invention provides an antibacterial tooth implant and a preparation method of the antibacterial tooth implant. The antibacterial tooth implant comprises a tooth implant body, a micro-arc oxidationfilm layer and a nano-antibacterial function material, wherein the micro-arc oxidation film layer is arranged on the surface of the tooth implant body; the nano-antibacterial function material is loaded to the micro-arc oxidation film layer. According to the technical scheme, the micro-arc oxidation film layer is arranged on the tooth implant body, so that the surface pore structure of the toothimplant body is rich, many pore structures similar to volcanic vents exist, therefore, the surface roughness of the tooth implant body can be increased, the surface porosity is alos greatly improved,at the time, the antibacterial function material of the nano size adopting the plasma immersed ion injection method can be injected to the surface of the micro-arc oxidation film layer and also can beinjected into the pore structures of the micro-arc oxidation film layer, so that the loading amount of the nano-antibacterial function material is greatly increased, meanwhile, when bacteria enter the micropores, sterilizing can be carried out in time, so that the permanent antibacterial effect is achieved.

Owner:BEIJING AKEC MEDICAL

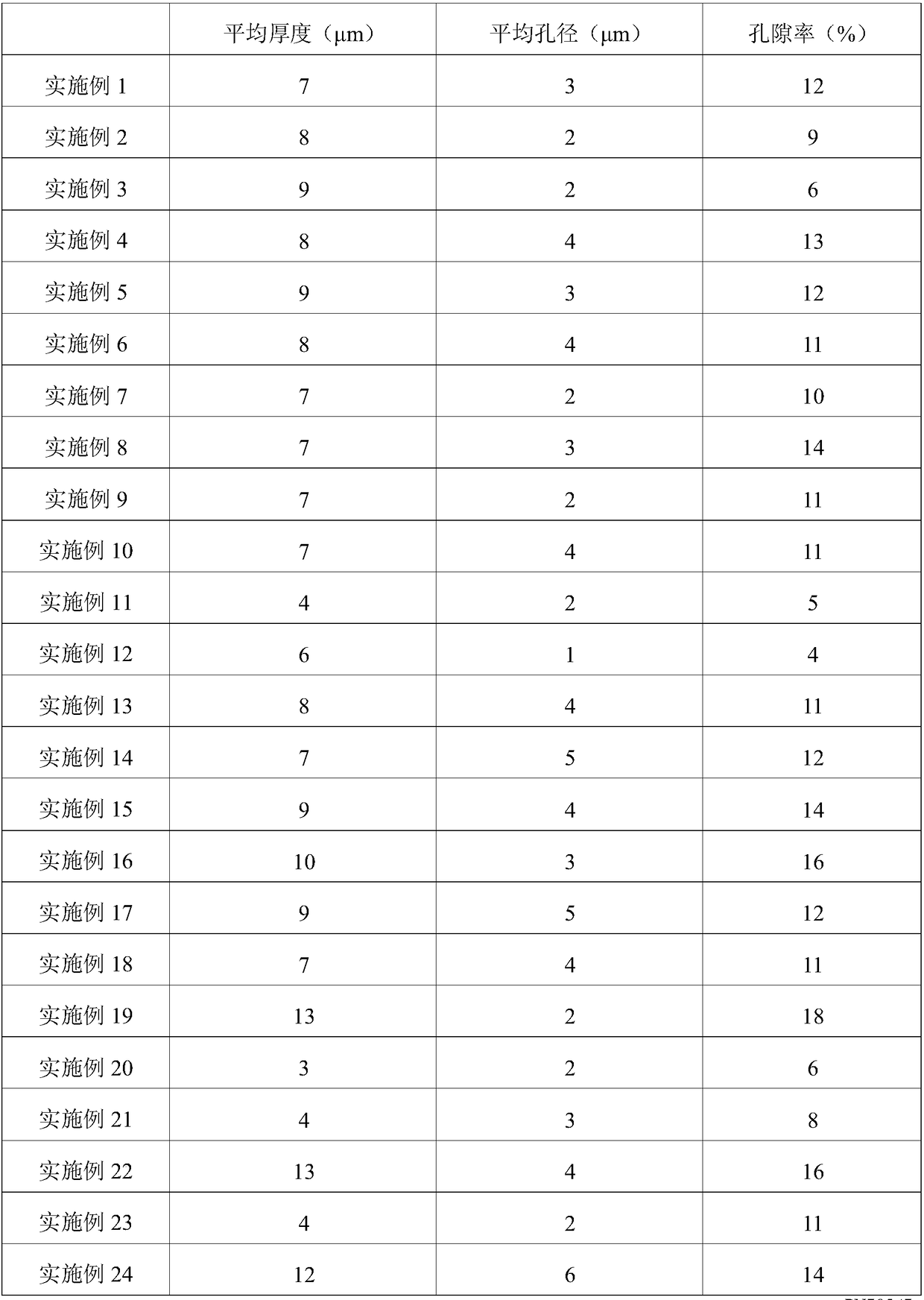

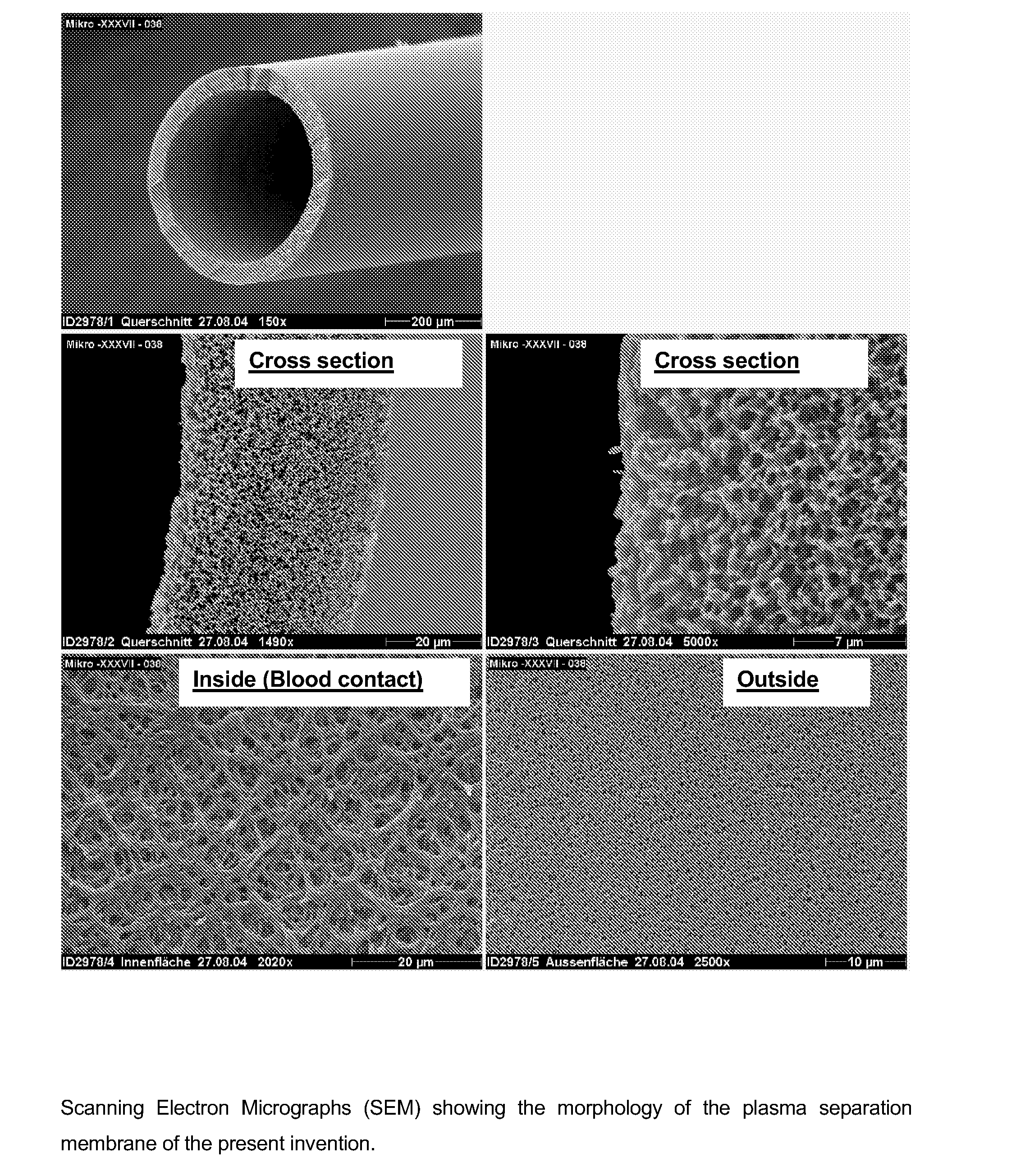

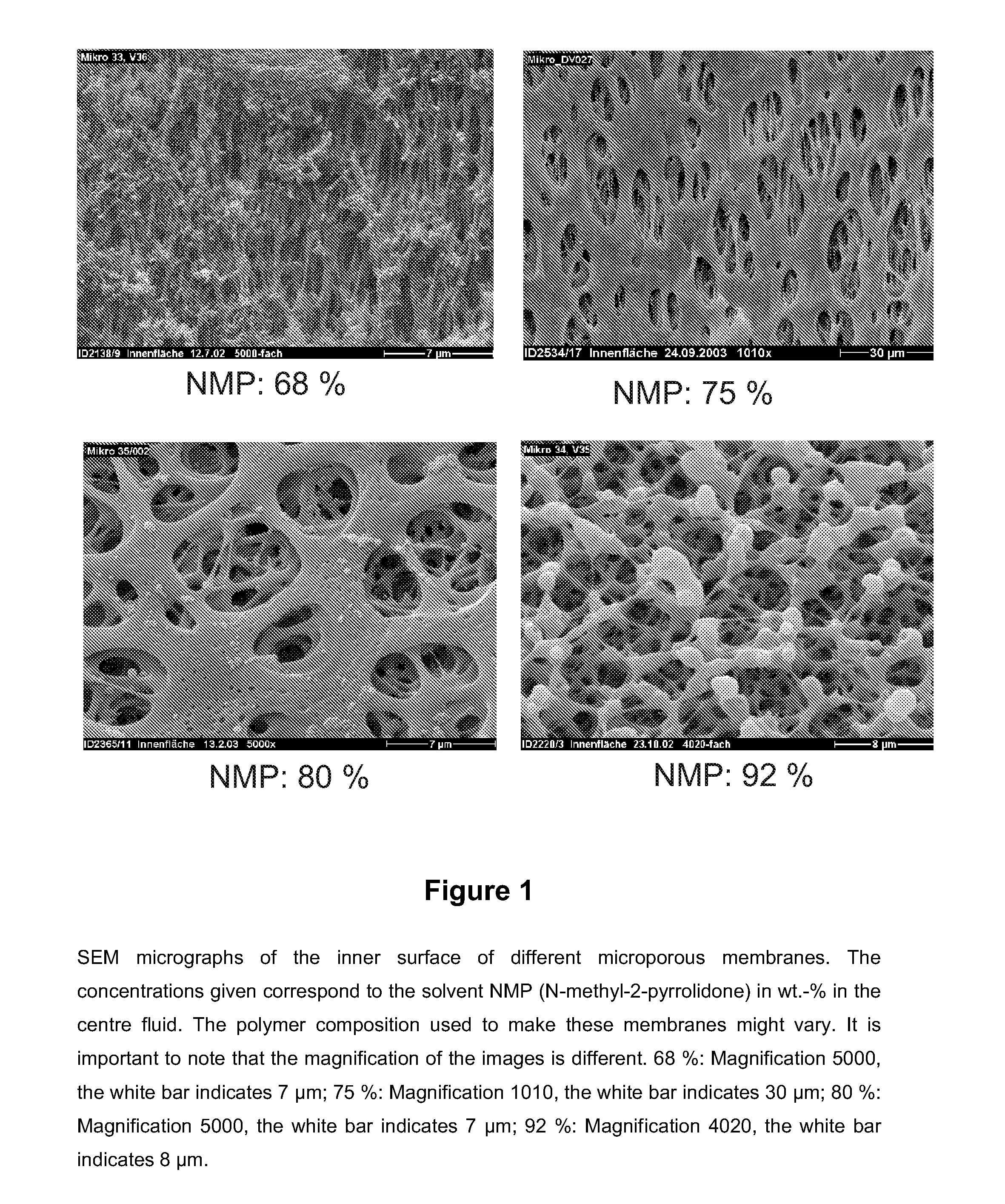

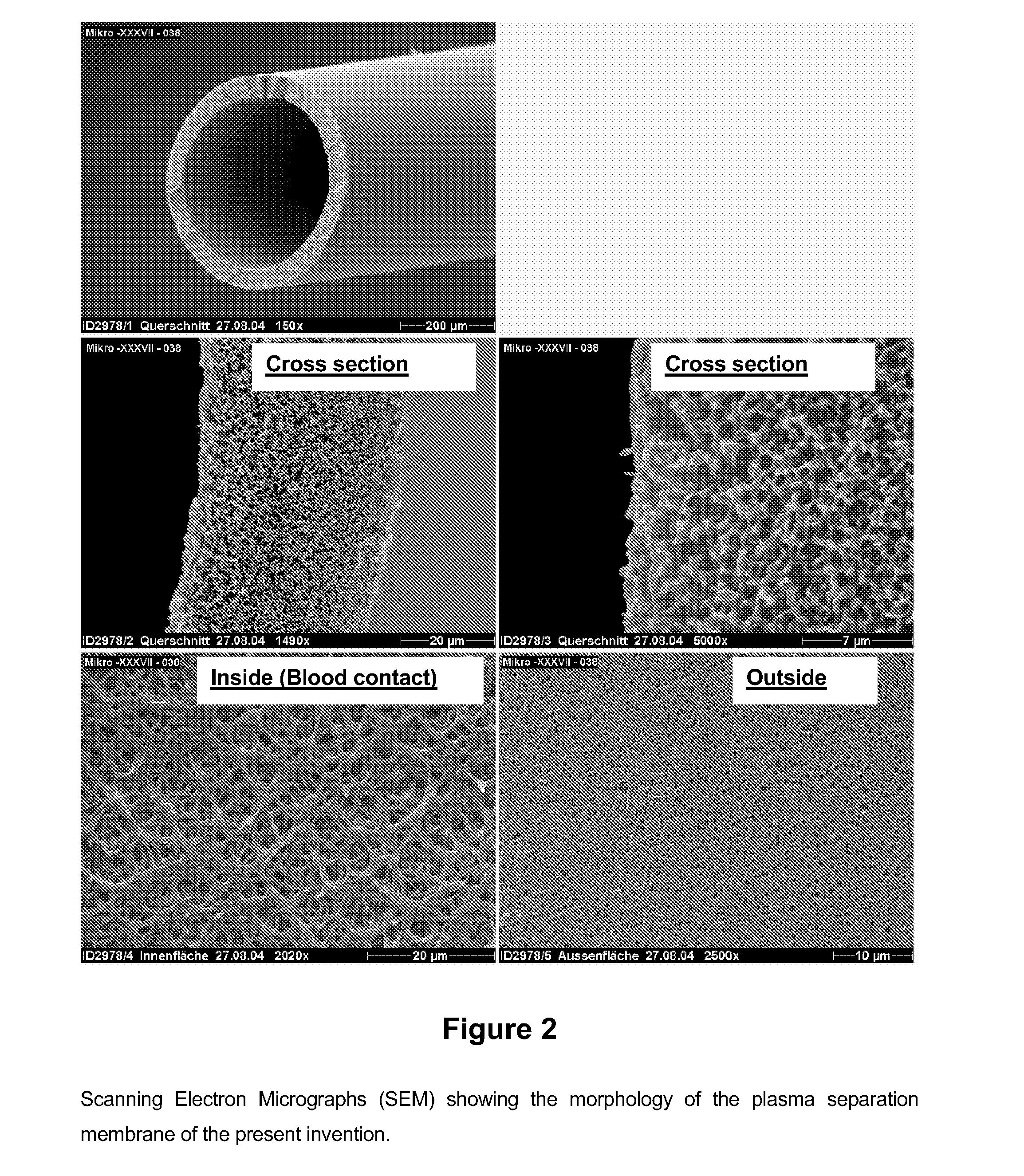

Plasma Separation Membrane

ActiveUS20100012577A1Improve surface porosityConstant sieving property and filtration behaviourLayered productsFilament/thread formingFiberHollow fibre membrane

A process for manufacturing of an asymmetric hollow fibre membrane, comprising the steps of extruding a polymer solution through the outer ring slit of a hollow fibre spinning nozzle, simultaneously extruding a centre fluid through the inner bore of the hollow fibre spinning nozzle, into a precipitation bath, whereby the polymer solution contains 10 to 26 wt-% of polysulfone (PSU), polyethersulfone (PES) or polyarylethersulfone (PAES), 8 to 15 wt-% polyvinylpyrrolidone (PVP), 55 to 75 wt-% N-alkyl-2-pyrrolidone (NAP) and 3 to 9 wt-% w ater the centre fluid contains 70 to 90 wt-% N-alkyl-2-pyrrolidone (NAP) and 10 to 30 wt-% water, and the precipitation bath contains 0 to 20 wt-% N-alkyl-2-pyrrolidone (NAP) and 80 to 100 wt-% water.

Owner:GAMBRO LUNDIA AB

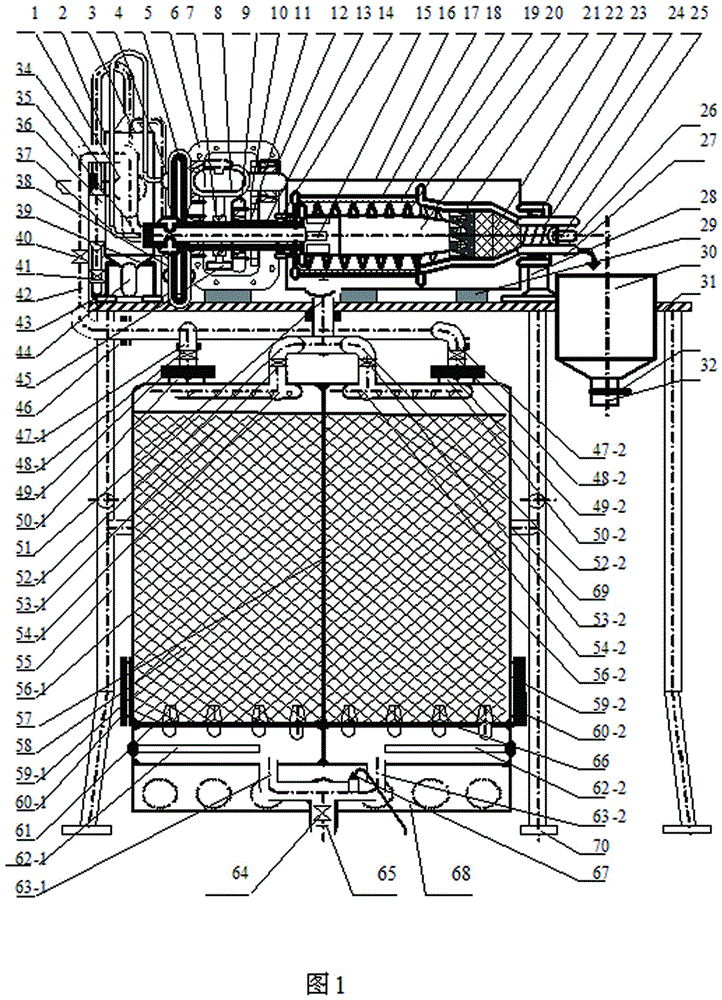

BX high-end three-dimensional integrated solid-liquid synchronous deeply sewage-treating device and manufacturing method

InactiveCN106186521ASolve the problem of synchronous deep harmless processingSolve pollutionSludge treatment by de-watering/drying/thickeningWater treatment parameter controlAutomatic controlSludge

The invention relates to a BX high-end three-dimensional integrated solid-liquid synchronous deeply sewage-treating device and a manufacturing method. The device is characterized by forming a set of complete sewage treating system device by three-dimensionally combining power transmission, double-vortex gearshift, dosing neutralizing, oil-water separation, aeration biochemical treatment, solid-liquid centrifugal separation, sweeping de-sliming, sludge wiping, overhead storage, biologic gnawing, deep physical absorption, malnutrition reduction, PH value, heavy metal (other pollutants), turbidity self-detection, cross circulation backwashing, sterilization and disinfection, water purification and draining, overhead bearing support and automatic control system. The energy consumption is low, the running cost is low and the industrial wastewater, rural sewage, municipal (other) sewage and reclaimed water are locally intensively treated nearby, so that the requirements for standard emission and resource reutilization are met; the device has obvious effects of cleaning production, capacity promotion and effect enhancement; the device has huge national benefit or public benefit at the aspects of water resource shortage, water pollution, sustainable economic development maintenance and promotion for energy saving and emission reduction.

Owner:白山市百祥环保科技开发有限公司

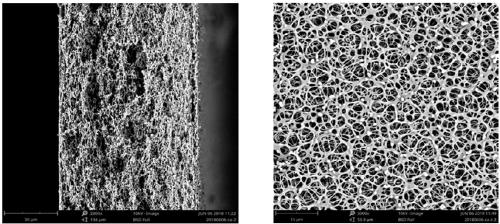

Preparation method of spongy-structure separation membrane with adjustable pore diameter and the separation membrane prepared by the preparation method

PendingCN111266016AUniform pore sizeImprove throughputSemi-permeable membranesMembranesHollow fibrePolymer science

The invention provides a preparation method of a spongy-structure separation membrane with an adjustable pore diameter and the separation membrane prepared by the preparation method. The specific preparation method comprises the following steps: (1) preparing a membrane casting solution containing polymer resin, volatile small molecules, a small molecule non-solvent, a water-soluble polymer and asolvent, fully mixing the components, stirring and dissolving at 20-100 DEG C, standing and defoaming for 2-24 hours; (2) preparing a membrane from the membrane casting solution through a flat membrane scraping machine or a hollow fiber spinning machine at room temperature, enabling a primary membrane or membrane filaments to enter a constant air humidity with the humidity of 50-100%, controllingthe retention time to be 0-300s under the temperature condition of 30-100 DEG C, and carrying out evaporation phase splitting; (3) immersing the membrane or membrane filament prepared by evaporation phase splitting into a coagulating bath to be cured into a membrane; and (4) treating the cured membrane with a post-treatment liquid. The cross section of the separation membrane prepared by the method is of a full-sponge structure, and the separation membrane has a good open pore structure, uniform pore diameter, high separation precision and large membrane flux.

Owner:广东洁科膜分离技术有限公司

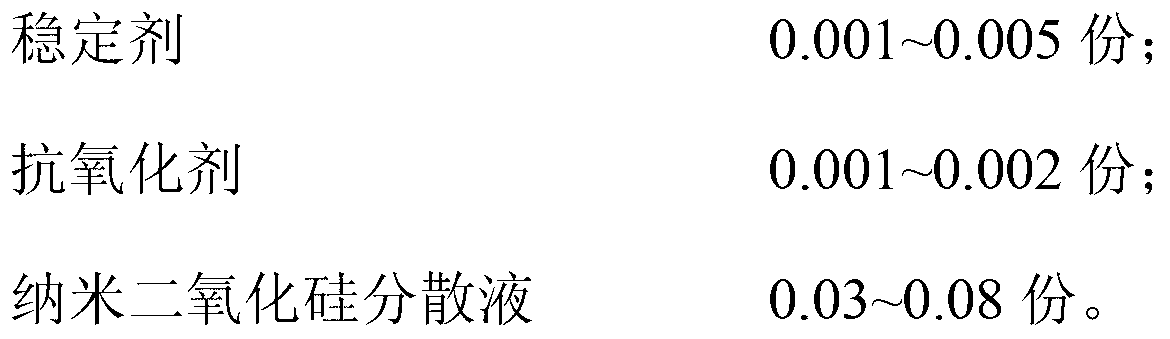

Water-based adhesive

ActiveCN103254845AImprove stabilityImprove surface porosityNon-macromolecular adhesive additivesChloroprene adhesivesChemistryAntioxidant

The invention discloses a water-based adhesive which comprises the following components in parts by mass: 0.5-0.7 parts of water-based neoprene latex, 0.3-0.5 parts of acrylic latex, 0.001-0.005 parts of stabilizing agent, 0.001-0.002 parts of antioxidant and 0.03-0.08 parts of nanosilicon dioxide dispersing liquid. The water-based adhesive is excellent in stability, and is not required to be stirred and mixed before use. Compared with the ordinary product, the adhesive power per unit solid content is improved significantly. Superior performance can be obtained by single-sided adhesive spraying under the equivalent occasion. The adhesive effect is particularly good for a base material with a high surface opening degree. The double-sided adhesive spraying contributes to ensuring the comprehensive effect under the occasion with tension, bounce and stress, adhesion can be conducted after a moment according to the different base materials, and the pressure application and adhesion can also be conducted immediately.

Owner:JIANGSU OSIC PERFORMANCE MATERIALS CO LTD

Surface treatment process for aluminum alloy sections before coloring

ActiveCN106149028AIncrease the surface friction coefficientQuality improvementSurface reaction electrolytic coatingBiological activationAlkaline etching

The invention relates to the technical field of aluminum alloy surface treatment, in particular to a surface treatment process for aluminum alloy sections before coloring. The process includes the following steps of cleaning, mechanical lapping and polishing, ultrasonic ungrease treatment, alkaline etching, primary anodic oxidation, activation, wire-drawing treatment and secondary anodic oxidation. By means of the surface treatment process before coloring, the surface friction coefficient of the aluminum alloy sections can be effectively increased, surface adhesive force is enhanced, and therefore subsequent coloring treatment can be facilitated.

Owner:ANHUI HENGXING DECORATION ENG CO LTD

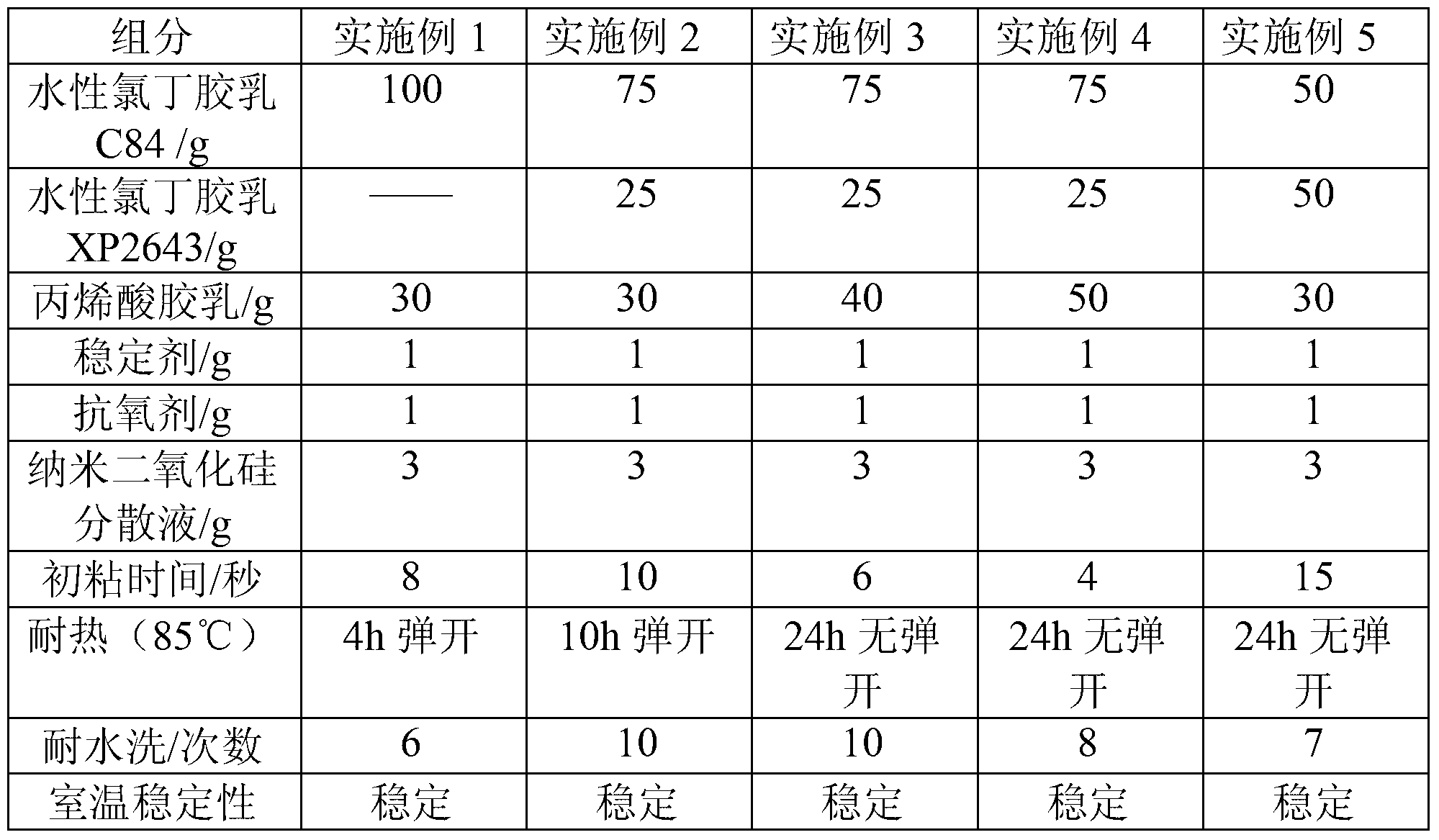

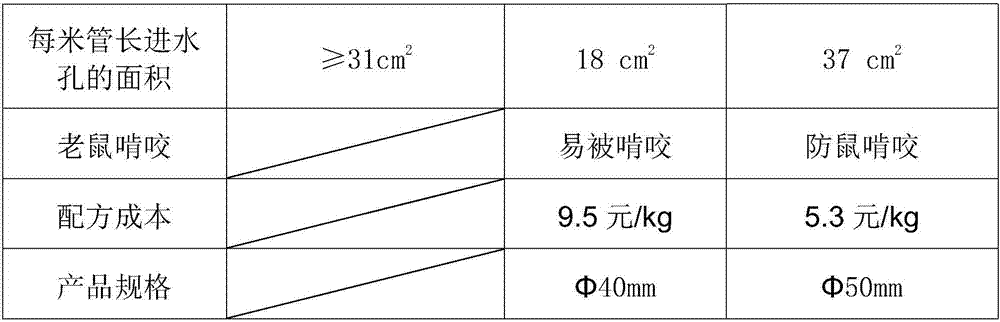

Modified PVC (Polyvinyl Chloride) corrugated pipe for concealed-pipe salt removal

The invention relates to a modified PVC (Polyvinyl Chloride) corrugated pipe for concealed-pipe salt removal. The modified PVC corrugated pipe is prepared from the following ingredients in parts by mass: 100 parts of PVC resin, 5-12 parts of plasticizer, 3-6 parts of composite stabilizer, 5-15 parts of novel PVC impact modifier ACM resin, 0.5-1.8 parts of lubricant, 0.5-1.8 parts of processing modifier and 2-20 parts of calcium carbonate. The modified PVC corrugated pipe is low in cost, high in ring stiffness, high in surface opening percent, good in compressive strength, tolerant to salt and alkali corrosion and good in salt removing effect and is mainly applied to the field of concealed-pipe salt removal.

Owner:XINJIANG TIANYE GRP +1

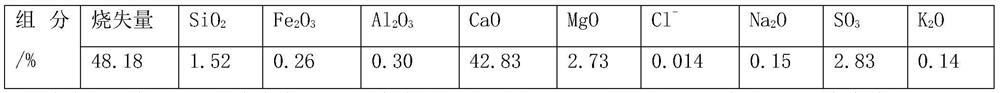

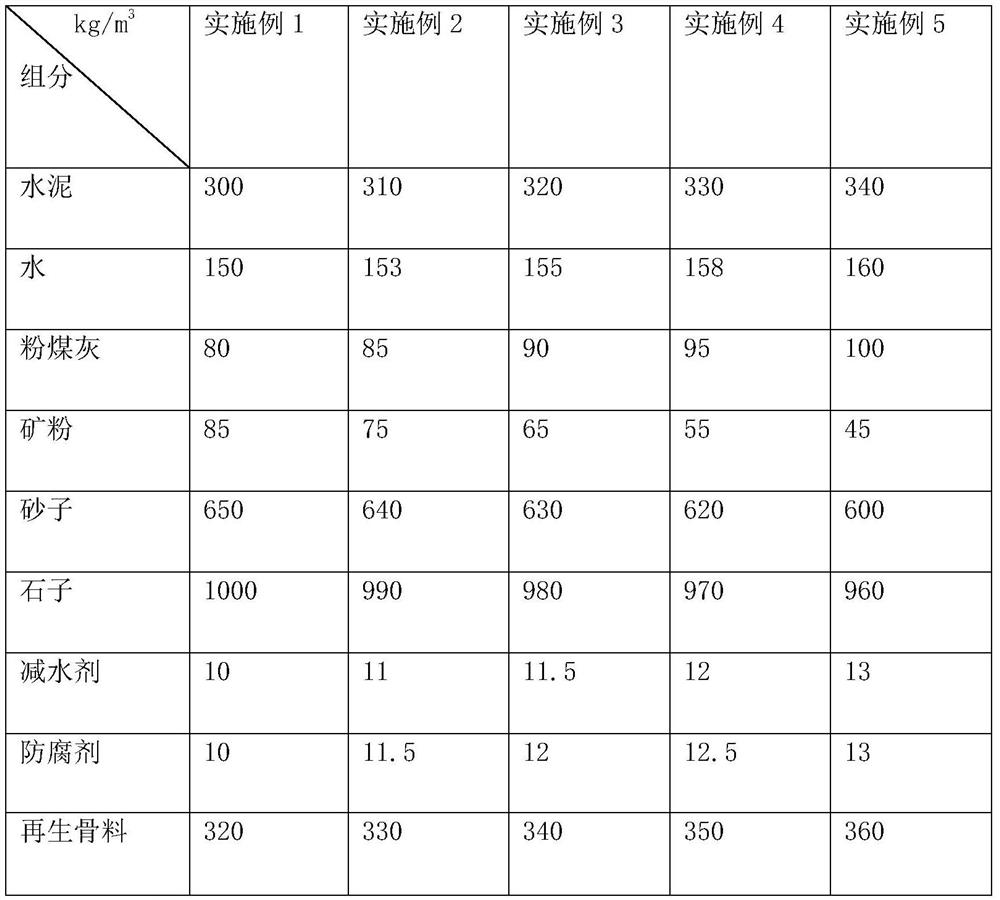

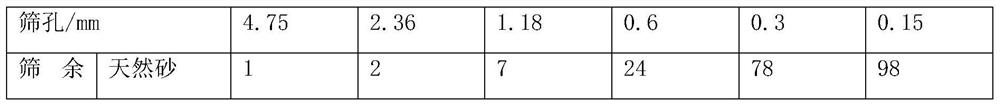

Recycled aggregate concrete and preparation method thereof

The invention relates to the field of building materials, and particularly discloses recycled aggregate concrete and a preparation method thereof. The recycled aggregate concrete is prepared from the following components in parts by weight: 300 to 340 parts of cement, 150 to 160 parts of water, 85 to 100 parts of fly ash, 65 to 85 parts of mineral powder, 600 to 650 parts of sand, 960 to 1000 parts of stones, 8 to 10 parts of a water reducing agent, 10 to 13 parts of a preservative and 320 to 360 parts of recycled aggregate, the preparation method comprises the following steps: S1, uniformly mixing the cement, the water, the fly ash and the mineral powder to obtain a premixed mixture; and S2, adding the recycled aggregate, the stones, the sand, the water reducing agent and the preservative into the premixed mixture, and uniformly mixing. The recycled aggregate concrete disclosed by the invention has the advantages of strong scouring resistance, good chloride ion corrosion resistance and excellent durability when being used for ocean engineering construction.

Owner:深圳市宝金华混凝土有限公司

Production method of microcrystalline glass-ceramic composite brick

ActiveCN104309215AImprove the decorative effectRaise the firing temperatureCeramic layered productsGlass/slag layered productsCeramic compositeBrick

The invention discloses a production method of a microcrystalline glass-ceramic composite brick. The production method comprises the following steps: (1) preparing a high-calcium raw material; (2) preparing a low-viscosity glass frit and a high-viscosity glass frit; (3) preparing powder of a green microcrystalline glass-ceramic composite brick through a conventional method; (4) preparing a microcrystalline glass-ceramic composite brick substrate from the powder of the green microcrystalline glass-ceramic composite brick prepared by the step (3) through a conventional method; (5) preparing a microcrystalline glass-ceramic composite brick; and (6) post-processing. The microcrystalline glass-ceramic composite brick prepared by the production method disclosed by the invention, through staggered distribution of crystallization regions and transparent and / or semitransparent regions, changes an original monotonous texture that has only crystallization patterns on the entire surface, and the brick is richer in pattern layering sense and better in decoration effect; the production method disclosed by the invention is lower in sintering temperature, shorter in sintering cycle, and capable of greatly reducing energy consumption, relieving emission and saving manufacturing cost; and the prepared composite brick has fewer surface pores, good anti-fouling performance and high wear resistance.

Owner:HANGZHOU NABEL CERAMIC

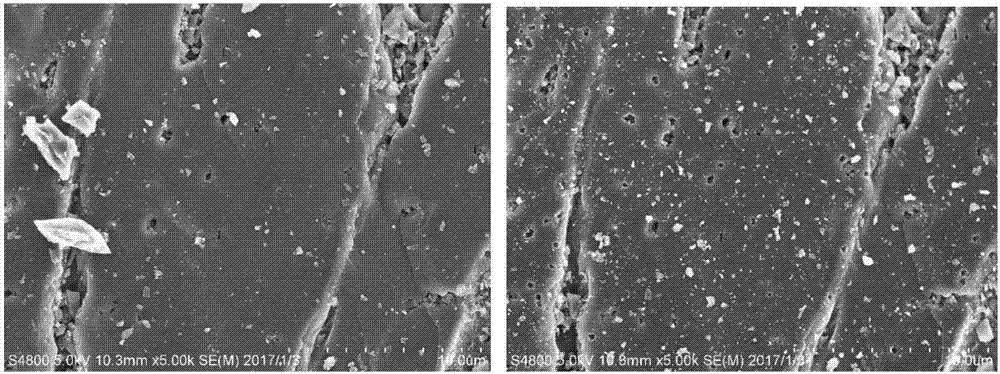

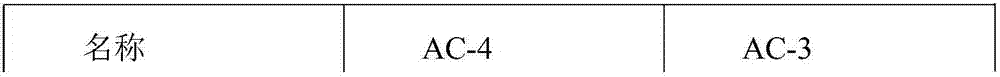

Modification method and application of activated carbon

The invention discloses a modification method and application of activated carbon. The modification method of the activated carbon comprises the following steps of S1, subjecting the activated carbon to drying treatment; S2, introducing a gas into an atmospheric-pressure low-temperature plasma device according to a gas flow rate of 1cc / min to 200cc / min, sending the activated carbon subjected to the drying treatment into the plasma device, making the activated carbon located at an ejection outlet of the low-temperature plasma device, controlling the movement speed of the ejection outlet of the plasma device to be 0mm / s to 30mm / s, and carrying out treatment for 0.5min to 30min, so as to subsequently obtain modified activated carbon. According to the modification method, the modification of the activated carbon through spark discharge is realized through a physical way; the specific surface area of the activated carbon is obviously increased; further, surface functional groups are also more abundant. The modification process is simple and convenient; the efficiency is high; further, no pollutants are generated.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

Tile for removing formaldehyde and process for preparing the same

InactiveCN101784501AImprove antifouling performanceImprove surface porosityThin material handlingClaywaresActivated carbonThermal treatment

A tile using an activated carbon, which is excellent as a formaldehyde absorbent, and a preparation process thereof are disclosed. The effect of activated carbon on absorbing formaldehyde is maximized by the activated carbon-in-core structure, in which the problem of activated carbon that is easily oxidized during a heat treatment may be overcome.

Owner:LG HAUSYS LTD

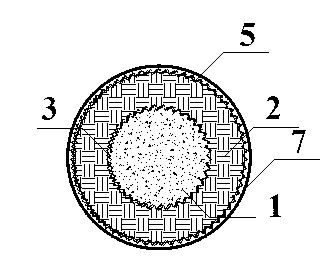

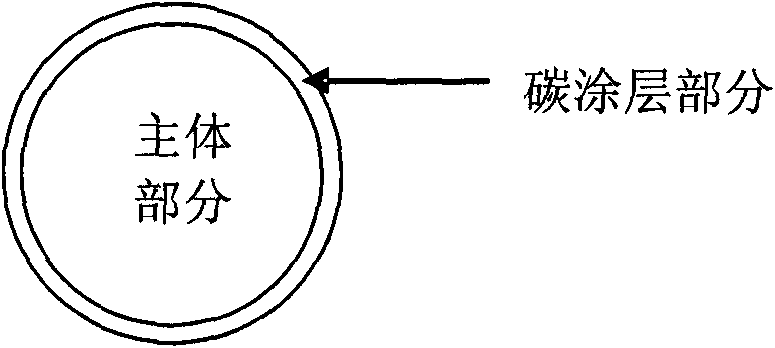

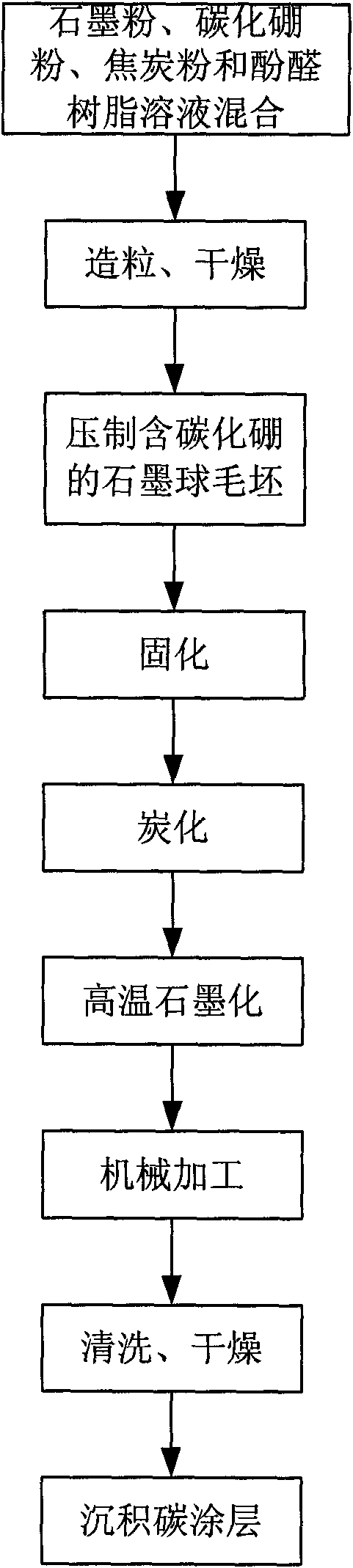

Boron-carbide-containing graphite absorber ball and preparation process thereof

InactiveCN102214488AHigh strengthHigh degree of automationNuclear energy generationReactors manufactureCarbon coatingPorosity

The invention provides a boron-carbide-containing graphite absorber ball and a preparation process thereof. The boron-carbide-containing graphite absorber ball consists of a main structure and a carbon coating attached to the surface of the main structure, wherein the main structure is boron-carbide-containing graphite which comprises the flowing components in percentage by mass: 5-50% of boron carbide and 50-95% of graphite or carbon. Coke powder is added to the formula of the boron-carbide-containing graphite absorber ball, therefore the strength of the product is improved. In the press forming process of the boron-carbide-containing graphite absorber ball, a continuous press is used for pressing and forming a ball-shaped product directly, equipment is simple, the degree of automation is high, and labor cost is low; in addition, since a coating is attached to the surface of the boron-carbide-containing graphite absorber ball disclosed by the invention, the surface porosity is reduced by more than 50%; since no coating is attached to surface of the traditional common boron-carbide-containing graphite absorber ball, the surface porosity is higher. The coating of the boron-carbide-containing graphite absorber ball provided by the invention is prepared by a chemical vapor deposition technology, has good combinability with the main structure and high carbon element content being more than 99.99999% and almost does not contain other impurity elements; the anti-moisture absorption property of the boron-carbide-containing graphite absorber ball provided by the invention is improved about 10-100 times higher than that of the traditional common boron-carbide-containing graphite absorber ball; and the wear resistance of the boron-carbide-containing graphite absorber ball provided by the invention is improved by about 2-10 times.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Preparation method of sodium alginate/L-cysteine/reduced graphene oxide magnetic hydrogel/aerogel

ActiveCN107759808AImprove performanceImprove surface porosityOther chemical processesMagnetic separationIonCvd graphene

The invention discloses a preparation method of sodium alginate / L-cysteine / reduced graphene oxide magnetic hydrogel / aerogel. The preparation method comprises the following steps: adding graphene oxide, sodium alginate, nano-iron oxide, L-cysteine and sodium bicarbonate into acidic, alkalic or neutral aqueous solution, performing ultrasonic treatment on the mixed solution and stirring the mixed solution until the mixed solution becomes uniform solution; contacting the mixed solution and divalent metal salt ion solution, so as to obtain unreduced aerogel; performing water-bath heating on the unreduced aerogel into aqueous solution, so as to obtain the sodium alginate / L-cysteine / reduced graphene oxide magnetic hydrogel; performing freeze drying on the magnetic hydrogel, so as to obtain the aerogel. The sodium alginate / L-cysteine / reduced graphene oxide magnetic hydrogel / aerogel prepared by the invention has porous and multi-networks structures and is larger in specific surface area and excellent in mechanical property, salt resistance, alkali resistance and adsorptive property, therefore, the hydrogel / aerogel is suitable for application in different fields; under the action of an external magnetic field, the material can be separated and recycled and has the application potential in more related fields.

Owner:TONGJI UNIV

Preparation method of plate polypropylene separation membrane

ActiveCN102755840AImprove permeabilityImprove surface porositySemi-permeable membranesPorosityDiluent

The invention relates to a preparation method of a plate polypropylene separation membrane. The method comprises the steps that: (1) polypropylene resin and a diluent are mixed and stirred; the mixture is stood and de-foamed, so that a membrane casting solution is obtained; (2) the membrane casting solution is cooled, so that a cured sample is obtained; (3) the cured sample is hot-pressed into a prefabricated polypropylene membrane containing the diluent; (4) the prefabricated polypropylene membrane is extracted in an extractant; (5) the extracted polypropylene membrane is fetched and dried; the extractant is removed; and the polypropylene plate separation membrane provided by the invention is obtained. The preparation method provided by the invention is simple and is easy to operate and realize. The prepared polypropylene plate separation membrane has a large amount of micropores on the surface, and has good permeability. The resistance of the membrane is low, the pore sizes of the membrane are uniform, and the porosity is relatively high. The membrane can be widely applied in fields of water treatment, membrane distillation, biology, medicine, energy, and the like. The membrane has a good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

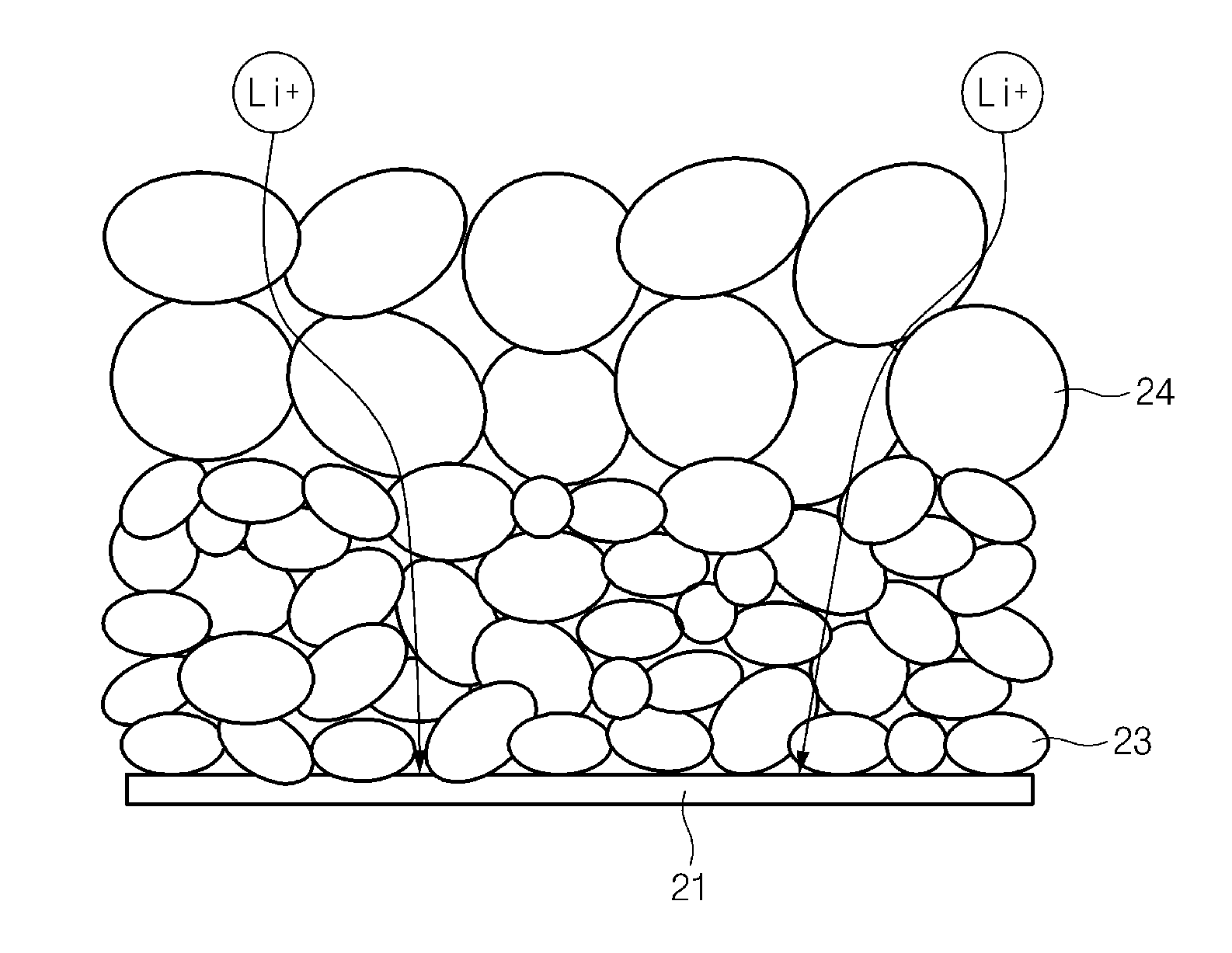

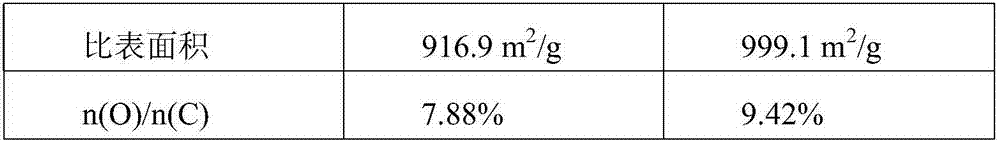

Anode for lithium secondary battery and lithium secondary battery including the same

ActiveUS9583756B2Improve surface porosityIncreased ion mobilityElectrode rolling/calenderingActive material electrodesPorosityLithium-ion battery

Provided is an anode for a lithium secondary battery composed of a multi-layered structure including an electrode current collector, a first anode active material layer including a first anode active material formed on the electrode current collector, and a second anode active material layer including a second anode active material having relatively lower press density and relatively larger average particle diameter than the first anode active material. Since an anode according to an embodiment of the present invention may include a multi-layered active material layer including two kinds of anode active materials having different press densities and average particle diameters on an electrode current collector, porosity of the surface of the electrode may be improved even after a press process to improve ion mobility into the electrode. Thus, charge characteristics and cycle life of a lithium secondary battery may be improved.

Owner:LG ENERGY SOLUTION LTD

Battery electrode, preparation method thereof and battery

ActiveCN102054979ALower internal resistanceImprove rate charge and discharge performanceElectrode carriers/collectorsLi-accumulatorsMicro nanoPower flow

The invention provides a battery electrode, a preparation method thereof, and a battery. The battery electrode comprises a current collector and an active substance layer coated on the current collector; a micro-nano particle layer is adhered to the surface of the active substance layer; the active substance layer comprises electrode active substance and electrode binder; the micro-nano particle layer comprises micro-nano dry powder particles; and the micro-nano dry powder particles comprise dry powder particles of the micro-nano electrode active substance. Interface impedance between the electrode and electrolyte is reduced and rate discharge performance of the battery is improved; a micro-nano active material reduces serious volume effect of the material; and specifically, the micro-nano particle layer may not comprise the binder preferably, so that the large-current discharge characteristic of the battery is improved further. The method is simple and is easy to implement; and the combinability between the micro-nano particle layer and the active substance layer is high, and the surface of the active substance layer is not polluted by the substances of an upper layer.

Owner:SHANGHAI BYD

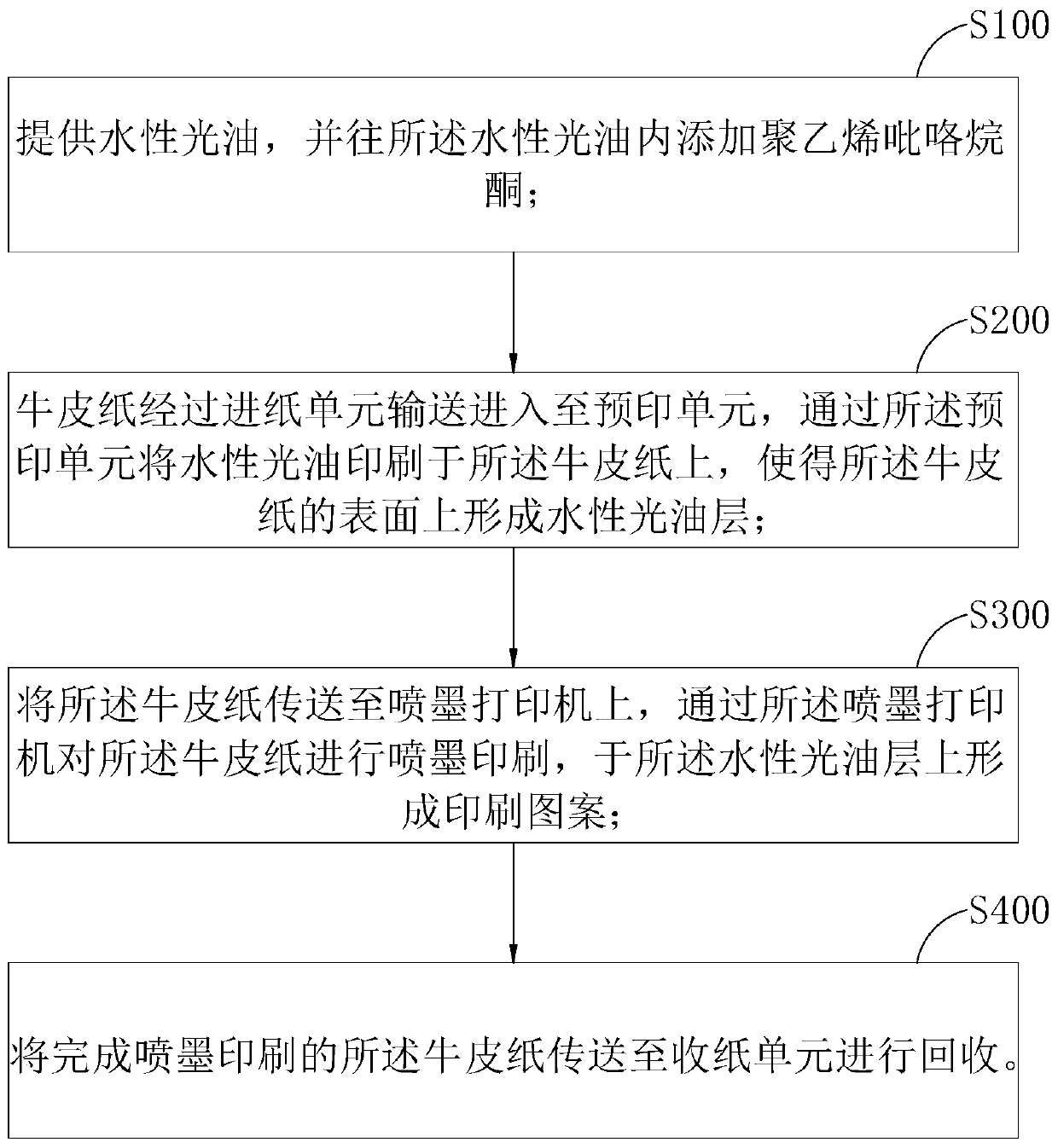

Kraft paper natural color high-definition color saturation printing method

ActiveCN110978836ALess waterproofImprove surface porosityDuplicating/marking methodsWater basedComputer printing

The invention belongs to the technical field of ink jet printing, and particularly relates to a kraft paper natural color high-definition color saturation printing method. The method comprises the following steps that S100, a water base vanishing is provided, and polyvinylpyrrolidone is added to the water base vanishing; S200, kraft paper is conveyed into a pre-printing unit passing through a paper feeding unit, the water base vanishing is printed on the kraft paper through the pre-printing unit, so that a water base vanishing layer is formed on the surface of the kraft paper; S300, the kraftpaper is conveyed to an ink-jet printer, the kraft paper is subjected to ink-jet printing through the ink-jet printer, and a printing pattern is formed on the water base vanishing layer; and S400, thekraft paper which is subjected to the ink-jet printing is conveyed to a paper collecting unit for recycling. According to the method, the high optical density and the color saturation of the ink printing can be enhanced, and the printing surface is smoother; secondly, the early-stage investment is less, and the later maintenance cost is low; in addition, and the water base vanishing layer has thecapability of increasing the waterproof capability of the kraft paper.

Owner:苏州美盈森环保科技有限公司

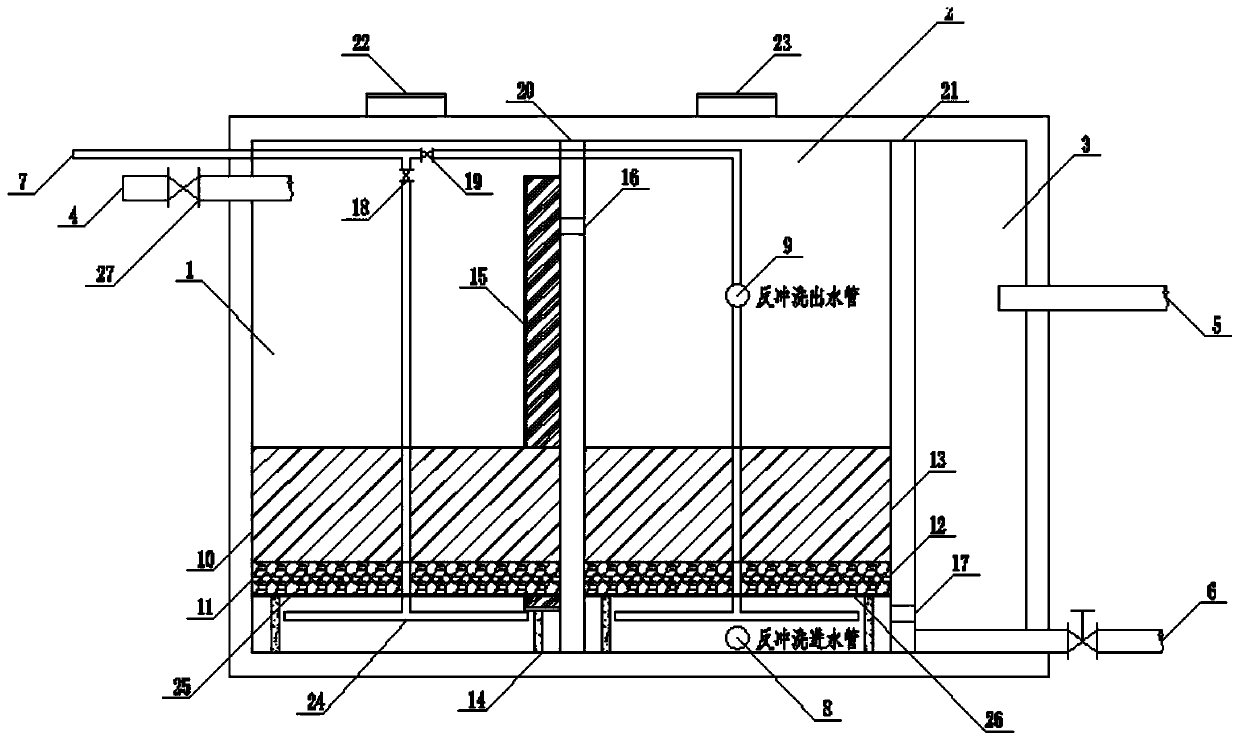

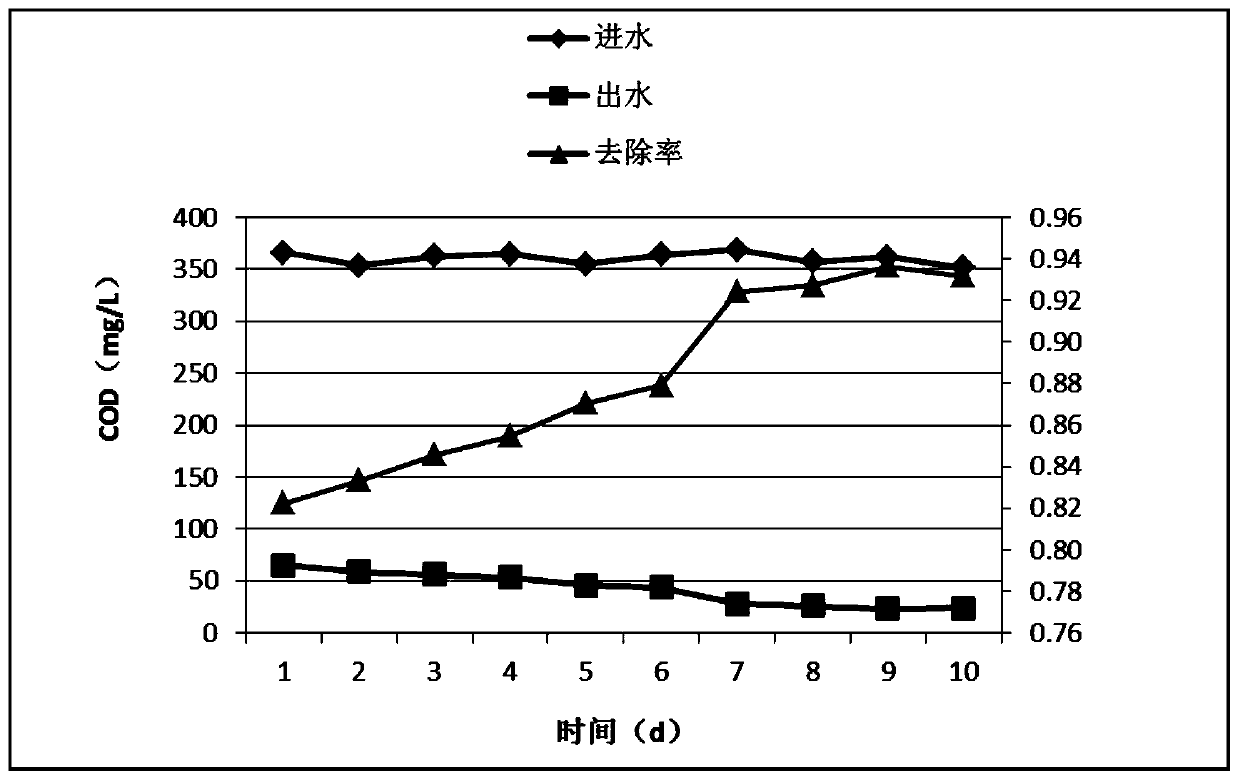

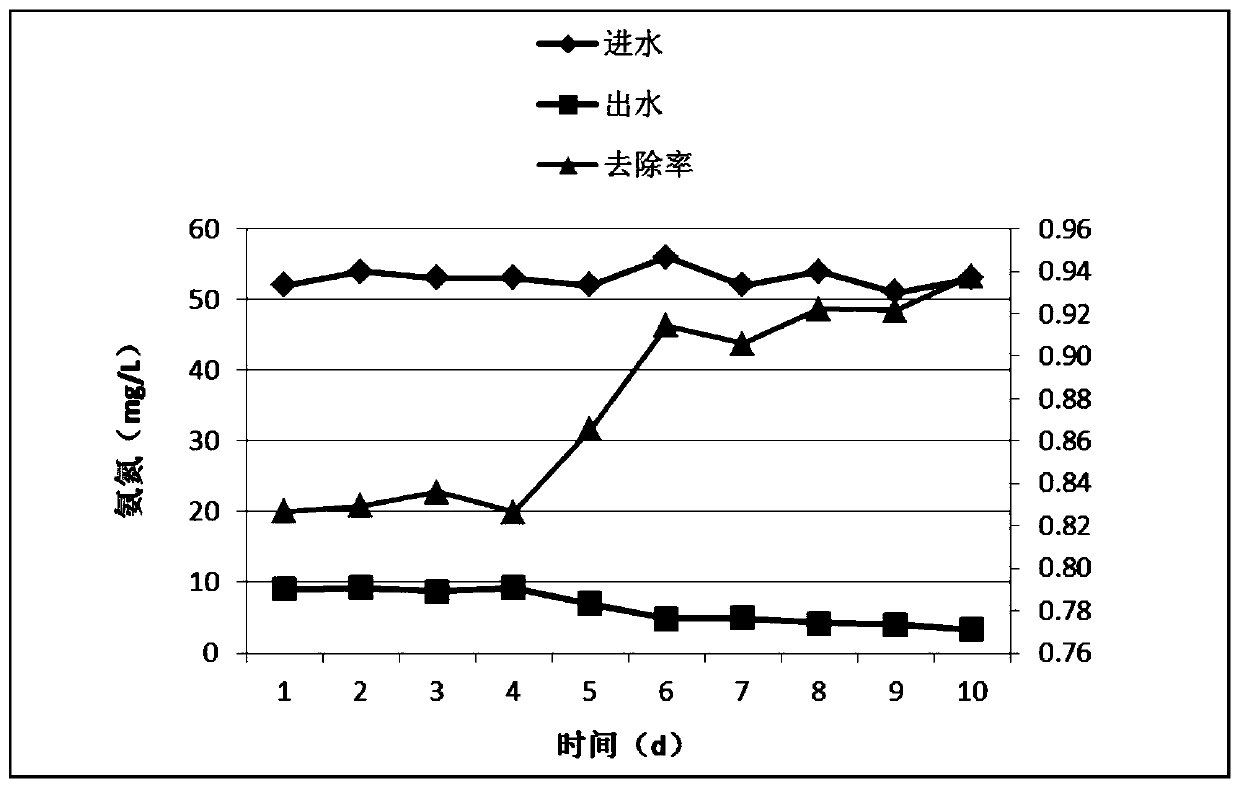

Packing coupling denitrification device and method for rural domestic sewage treatment

ActiveCN110217882AEasy to installEasy to handleBiological treatment apparatusTreatment with anaerobic digestion processesSludgeBiowarfare Agents

The invention discloses a packing coupling denitrification device and method for rural domestic sewage treatment. The device comprises an aeration tank, an iron-carbon biological denitrification tankand a sedimentation tank which communicate with one another in sequence; the aeration tank communicates with a sewage inlet pipeline; a biofilm Yulong filler and an iron-carbon filler are respectivelyarranged in the aeration tank and the iron-carbon biological denitrification tank; a flow guide plate is arranged at the communication position of the aeration tank and the iron-carbon biological denitrification tank; an air inlet main pipe separately communicates with the aeration tank and the iron-carbon biological denitrification tank and extends into the bottom of the biofilm Yulong filler and the bottom of the iron-carbon filler; the upper part of the aeration tank and the iron-carbon biological denitrification tank are respectively provided with exhaust holes; and a water outlet pipe and a sludge discharge pipe are arranged on the side wall of the sedimentation tank. Biological agents are respectively adsorbed in the aeration tank and the iron-carbon biological denitrification tankin modes of Yulong filler biofilm and iron carbon filler biofilm, so that particulate phosphorus, suspended solid (SS) and heavy-metal ion pollutants in the sewage are removed. The nitrogen and phosphorus removal effect is good, and influence of low C / N ratio on biological denitrification in a sewage treatment process is avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Polyvinylidene difluoride membrane, manufacturing method thereof, and purifying brine method thereof

InactiveCN108570155AHigh surface porosityGood salt resistanceSemi-permeable membranesMembranesSolventPolyvinylidene fluoride

A polyvinylidene difluoride membrane is provided. The polyvinylidene difluoride membrane including polyvinylidene difluoride having a melt viscosity of 35 to 60 (k poise), and the surface of the polyvinylidene difluoride membrane has a pore size of 0.1 [mu]m to 5 [mu]m. A method of manufacturing a porous polyvinylidene difluoride membrane and a method of purifying brine are also provided. The method of purifying brine includes the above-mentioned polyvinylidene difluoride membrane.

Owner:IND TECH RES INST

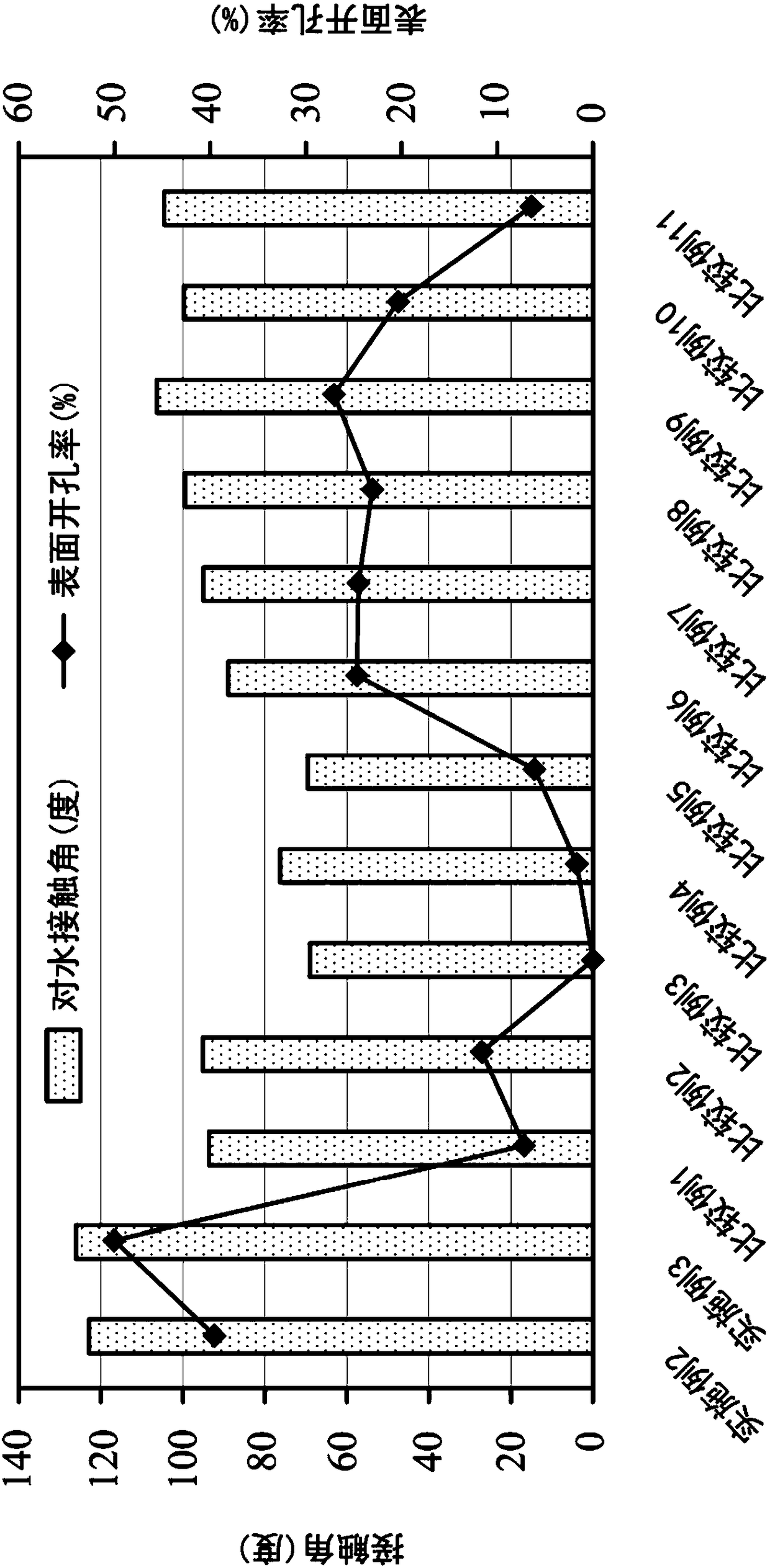

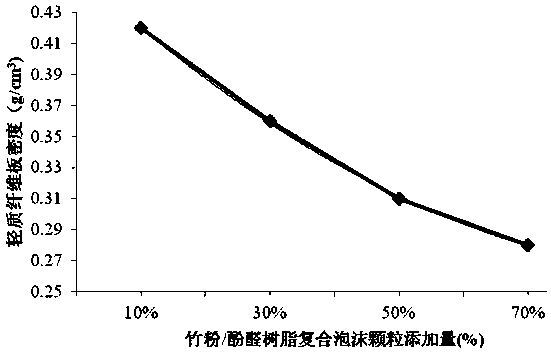

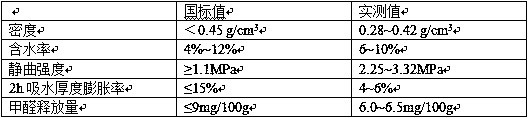

Preparation method for density-controllable light bamboo-wood-based fiber plate

ActiveCN107813397AIncrease moisture contentLow densityRadiation/waves wood treatmentWood treatment detailsFiberPorosity

The invention relates to a preparation method for a density-controllable light bamboo-wood-based fiber plate. The method comprises the steps that firstly, thermosetting phenolic resin is prepared; secondly, bamboo powder phenolic resin composite foam particles are prepared, then, fir wood fiber, paraffin and the bamboo powder phenolic resin composite foam particles are placed into a mixer, next, amodified urea-formaldehyde resin adhesive is sprayed, and paving is performed after the mixture is uniformly stirred; thirdly, the mixture is placed into a pre-presser for prepressing, and then the product is moved into a hot press to be subjected to hot-pressing treatment; and finally, the product is subjected to pressure relief, cooling, plate cutting and maintenance, and the density-controllable light bamboo-wood-based fiber plate is obtained. According to the method, bamboo powder and the phenolic resin are processed into a foam particle composite system by means of the special treatmenttechnology, and the foam particle composite system is used for replacing a part of layer structures of the fiber plate material; and the purpose of weight reduction is achieved by enhancing the porosity of the original material system, the complexity of the processing technique is effectively lowered, and the controllability of the processing technique and the regulation of the product density areimproved.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com