Antibacterial tooth implant and preparation method thereof

A dental implant and implant technology, applied in the field of antibacterial dental implants and their preparation, can solve the problem that dental implants are difficult to achieve durable antibacterial, and achieve the effects of rich surface pore structure, increased load capacity, and increased surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

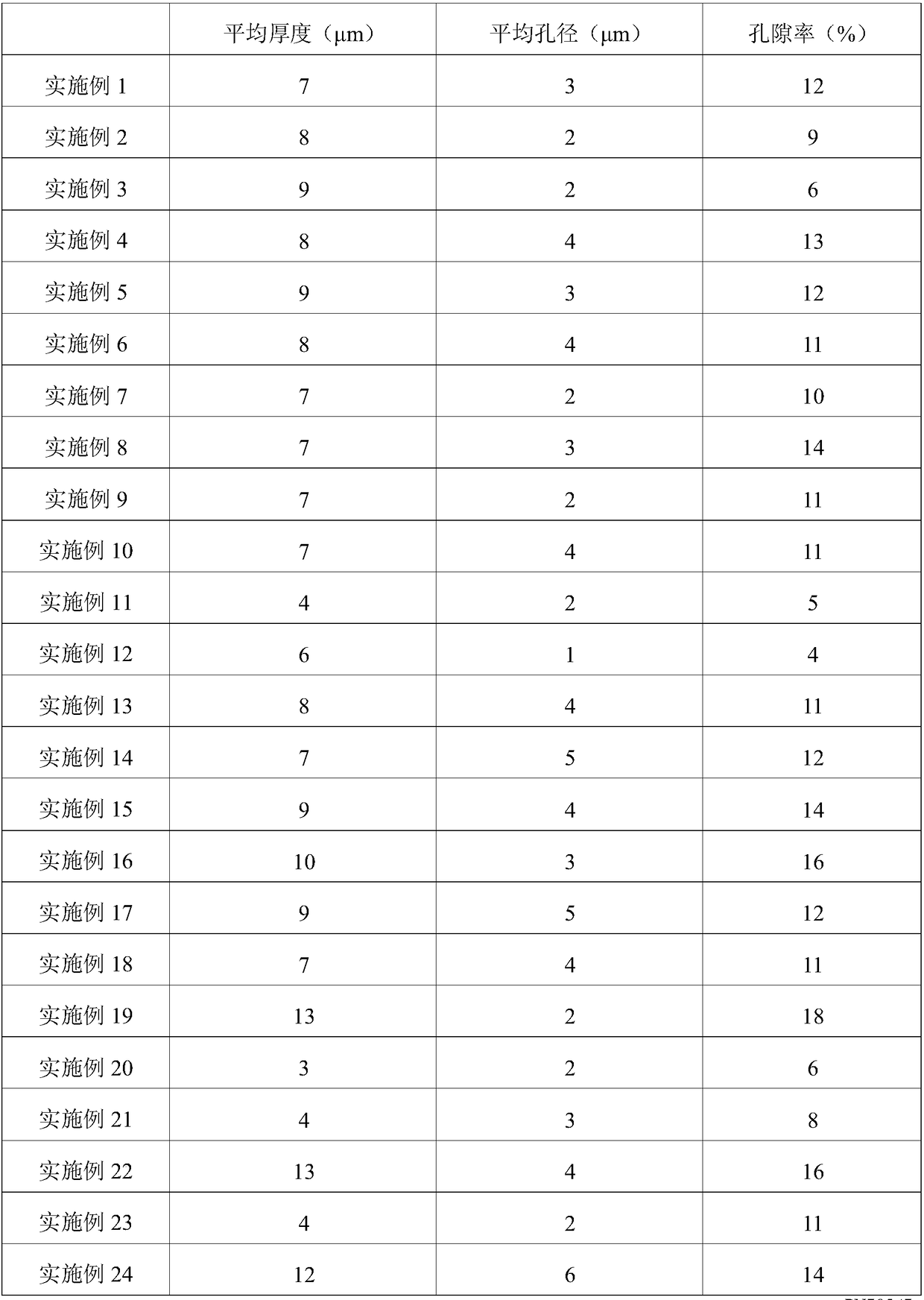

[0029] In another typical embodiment of the present application, a method for preparing an antibacterial dental implant is provided, the preparation method comprising: step S1, performing micro-arc oxidation on the dental implant body to growing a micro-arc oxidation film layer; step S2, performing plasma immersion ion implantation on the dental implant body that has undergone micro-arc oxidation, so as to load nanometer antibacterial functional materials on the micro-arc oxidation film layer.

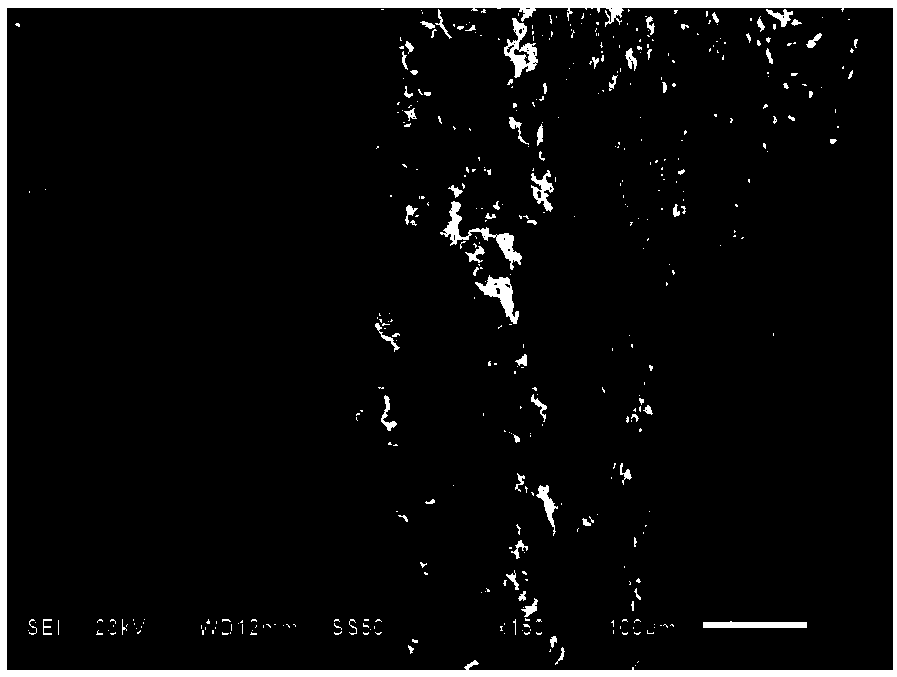

[0030]The micro-arc oxidation film layer is grown in situ on the dental implant body by the micro-arc oxidation technology, and the fitting degree of the micro-arc oxidation film layer and the dental implant body is high and relatively firm; and the surface pore structure of the dental implant body is made It is richer, and there are many crater-like pore structures in it, so it can not only increase the surface roughness of the dental implant body, but also greatly improve the surface ...

Embodiment 1

[0042] Dental implant body: Medical pure titanium prepared by forging technology is selected as the dental implant body.

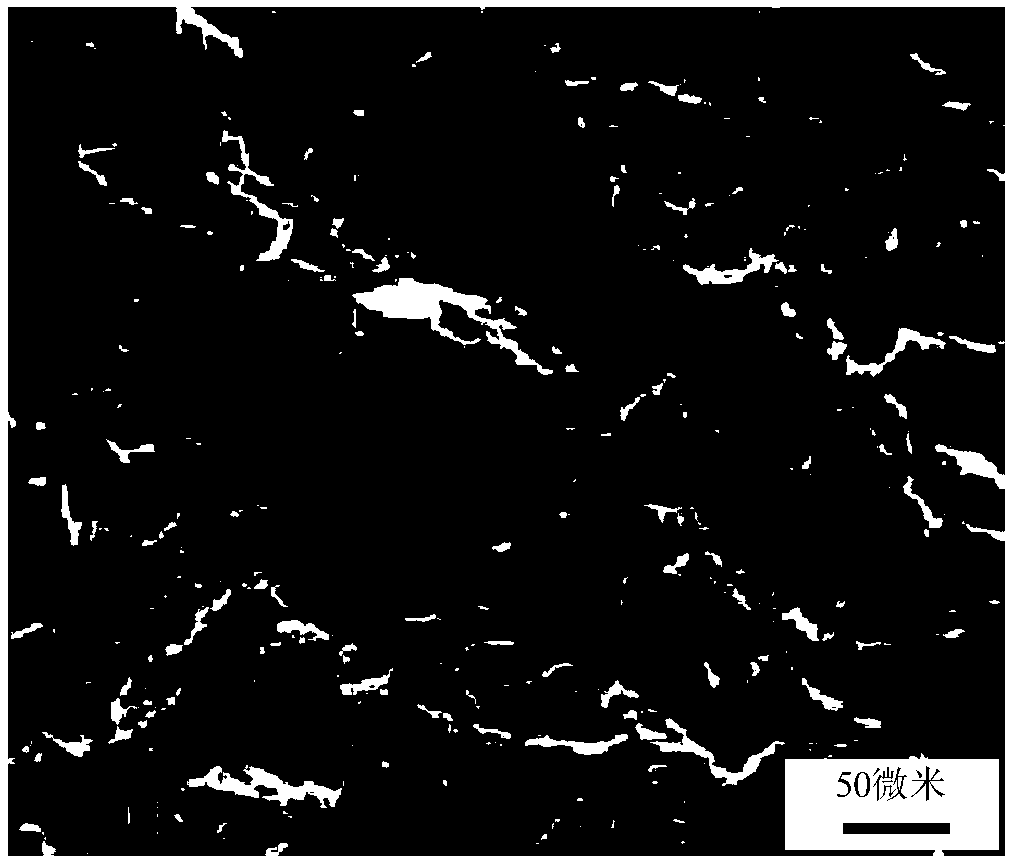

[0043] Sandblasting treatment: The dental implant body is subjected to strong sandblasting treatment, the abrasive is SiC, the particle size of the abrasive is 150μm, the sandblasting distance is 12cm, the compressed air pressure is 8bar, and the injection time is 30s. The surface obtained after sandblasting Morphology, observed by scanning electron microscope, the appearance is as follows figure 1 shown. The body of the dental implant after sandblasting was thoroughly ultrasonically cleaned with acetone and deionized water for 20 minutes in sequence, and dried for later use.

[0044] Micro-arc oxidation electrolyte preparation: Dissolve calcium acetate and sodium dihydrogen phosphate in deionized water, mix the reagents evenly, and prepare an electrolyte, in which the concentration of calcium acetate is 0.01mol / L, and the concentration of sodium dihydrog...

Embodiment 2

[0048] Preparation of the dental implant body: the Ti-6Al-4V dental implant body was manufactured by additive manufacturing electron beam melting technology.

[0049] Sandblasting treatment: The dental implant body is subjected to strong sandblasting treatment, the abrasive is SiC, the particle size of the abrasive is 300 μm, the sandblasting distance is 12cm, the compressed air pressure is 8bar, and the injection time is 30s. The body of the dental implant after sandblasting was thoroughly ultrasonically cleaned with acetone and deionized water for 20 minutes in sequence, and dried for later use.

[0050] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com