Preparation method of modified biomass char adsorbent applied to 30B carbon tube mercury test

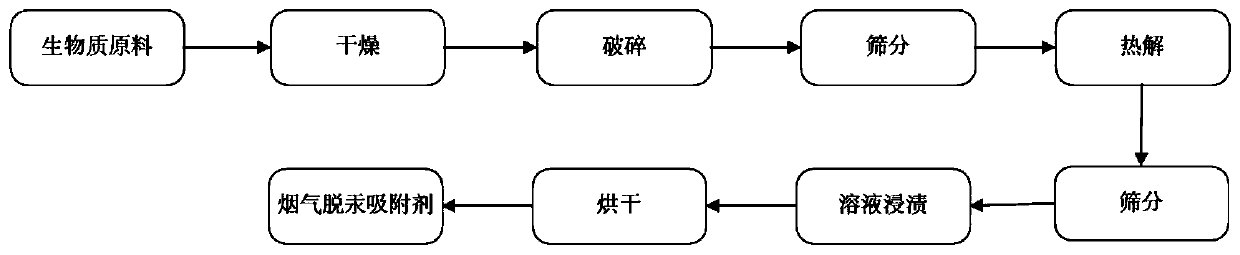

A technology of biomass coke and testing method, applied in separation methods, chemical instruments and methods, and other chemical processes, etc., can solve the problems of poor biomass coke adsorption capacity, low adsorption efficiency, and high cost, and achieve multi-polarity Chemical utilization and solving the effect of low adsorbent efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Use a crusher to crush the original biomass, and use the corresponding standard sieve to obtain samples within the range of 100-150 mesh; put the samples to be processed into a crucible, and place them in a muffle furnace for pyrolysis at 500°C for 10 minutes; weigh Add 100ml of 1% NH to 5g of biomass coke sample 4 In the Br solution, the magnetic stirrer was used to continuously stir for 12 h, and the stirred solution was left to stand at room temperature for 24 h. Wash the mixed solution with deionized water until the filtrate is neutral, dry the modified biomass coke obtained after filtering off the clear solution at 40°C, and store it in a reagent bottle to obtain modified biomass coke Mercury removal agent.

Embodiment 2

[0028] Use a crusher to crush the raw biomass, and use the corresponding standard sieve to sieve to obtain samples within the range of 100-150 mesh; put the samples to be processed into a crucible, and place them in a muffle furnace for pyrolysis at 600°C for 10 minutes; weigh Add 100ml of 1% NH to 5g of biomass coke sample 4 In the Br solution, the magnetic stirrer was used to continuously stir for 12 h, and the stirred solution was left to stand at room temperature for 24 h. Wash the mixed solution with deionized water until the filtrate is neutral, dry the modified biomass coke obtained after filtering off the clear solution at 40°C, and store it in a reagent bottle to obtain modified biomass coke Mercury removal agent.

Embodiment 3

[0030] Use a crusher to crush the original biomass, and use the corresponding standard sieve to obtain samples within the range of 100-150 mesh; put the samples to be processed into a crucible, and place them in a muffle furnace for pyrolysis at 500°C for 15 minutes; weigh Add 100ml of 2% NH to 5g of biomass coke sample 4 In the Br solution, the magnetic stirrer was used to continuously stir for 15 h, and the stirred solution was left to stand at room temperature for 24 h. Wash the mixed solution with deionized water until the filtrate is neutral, dry the modified biomass coke obtained after filtering off the clear solution at 50°C, and store it in a reagent bottle to obtain modified biomass coke Mercury removal agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com