Wet flue gas desulfurization and denitrification combined method

A flue gas and denitrification technology, applied in separation methods, chemical instruments and methods, and air quality improvement, can solve the problems of high operating costs and large initial investment, and achieve the effects of reducing operating costs, reducing investment and increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

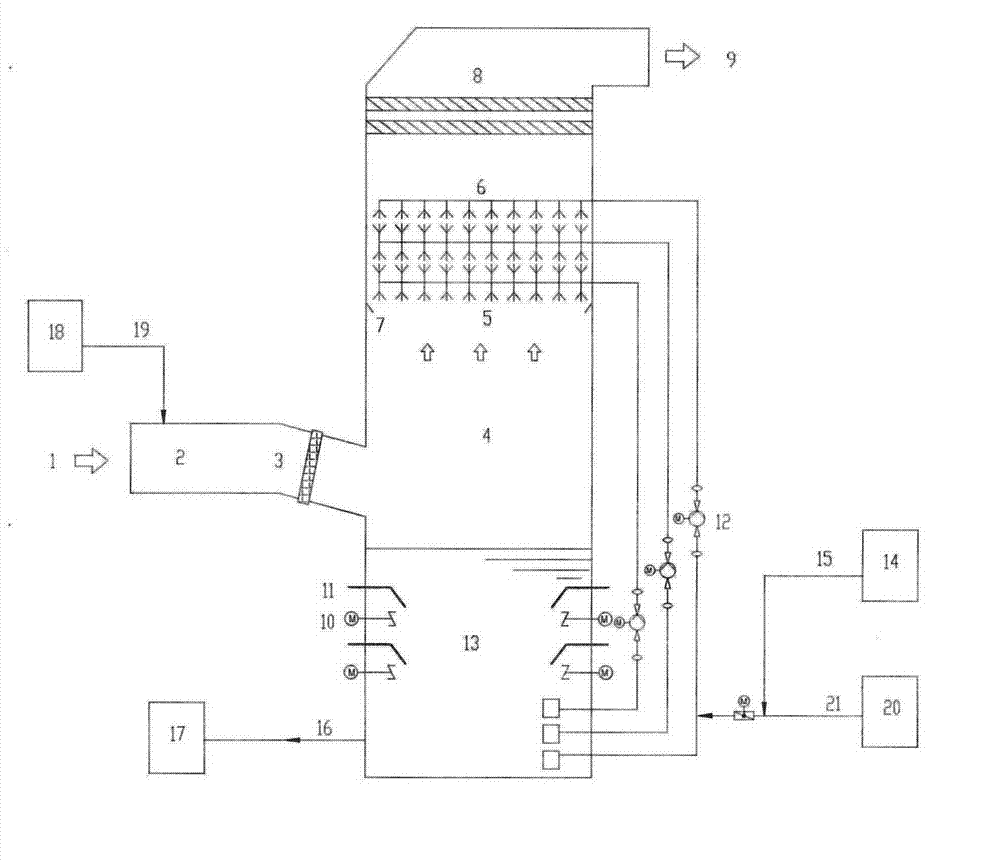

Image

Examples

Embodiment 1

[0029]The combined wet flue gas desulfurization and denitrification device implementing the method of the present invention is operated in a 3×25MW unit of a self-provided power plant in Jiangsu, and the relevant parameters are listed in Table 1.

[0030] Table 1

[0031]

[0032]

Embodiment 2

[0034] The combined wet flue gas desulfurization and denitrification device implementing the method of the present invention is operated in a 2×300MW unit of a power generation company in Northwest China, and the relevant parameters are listed in Table 2.

[0035] Table 2

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com