Flue gas combined desulfurization and denitration method

A technology for desulfurization, denitrification and flue gas, which is applied in separation methods, chemical instruments and methods, and air quality improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

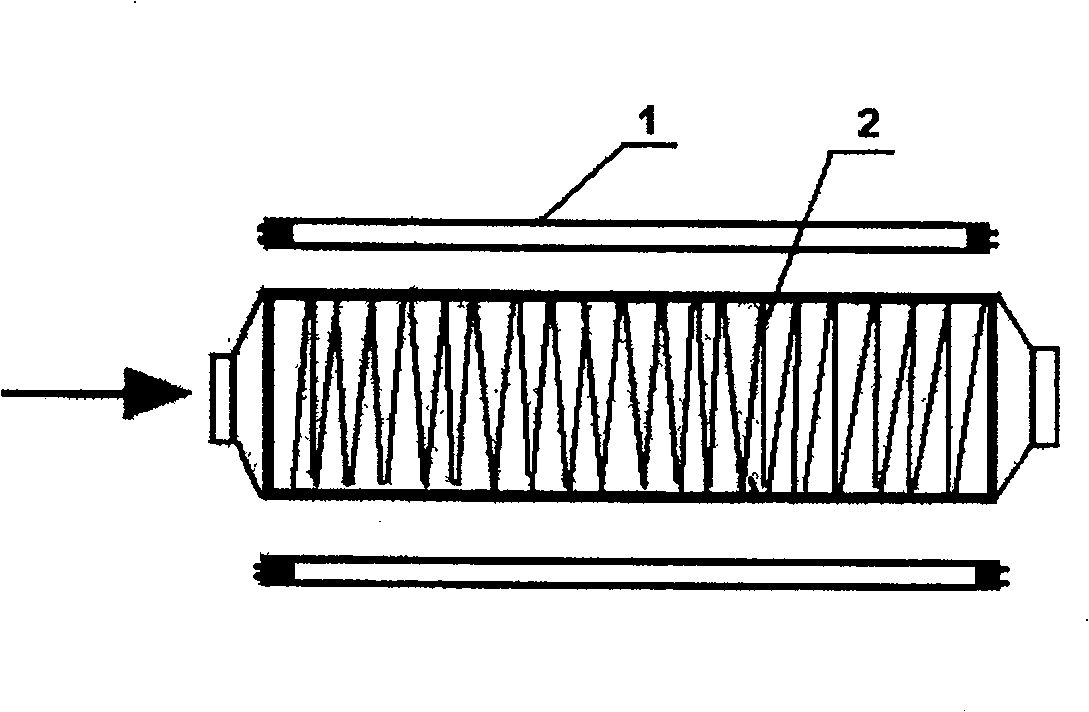

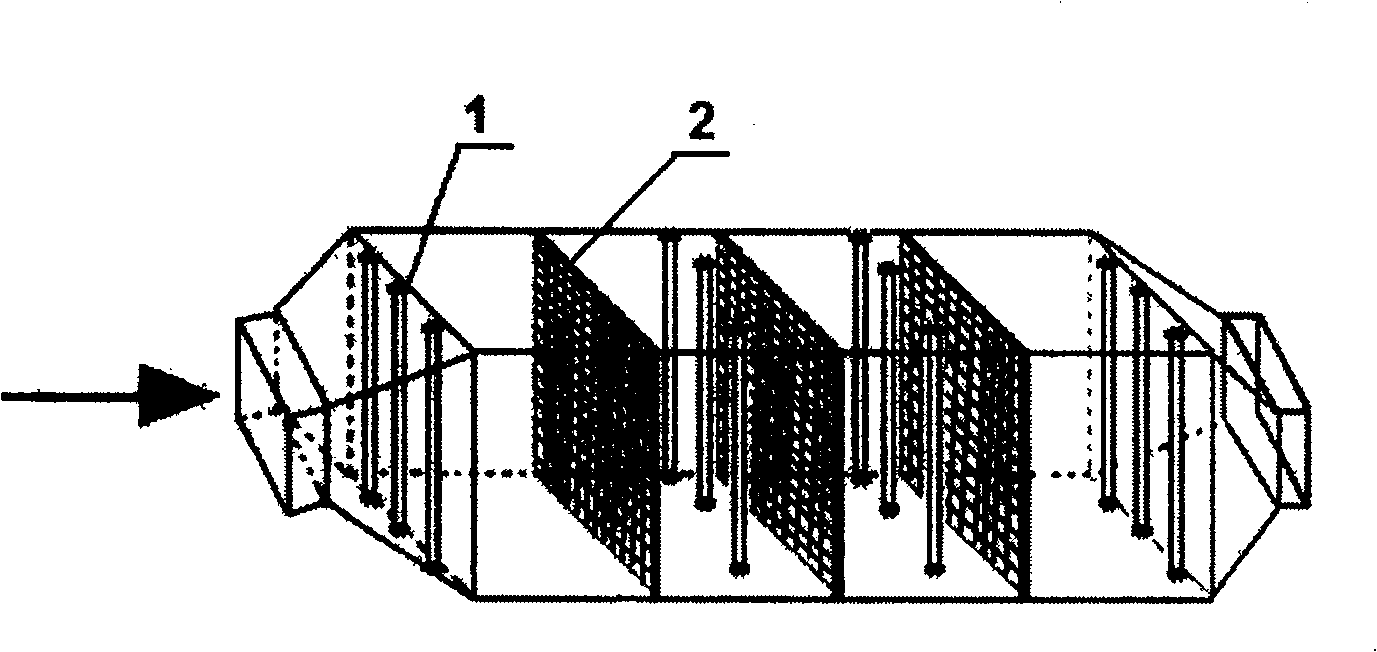

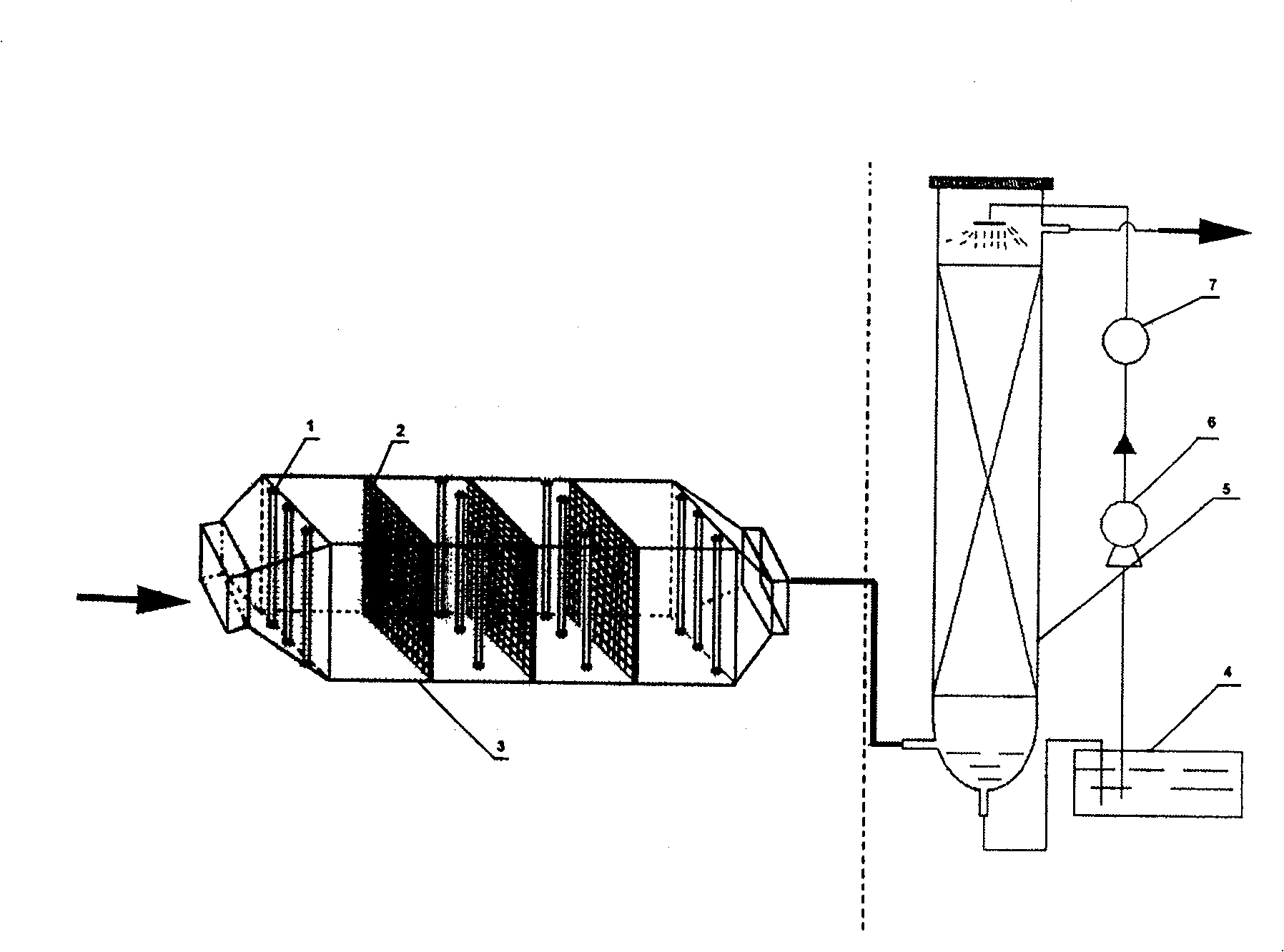

Method used

Image

Examples

Embodiment 1

[0047] Preparation of Glass Fiber Supported TiO by Coating Method 2 Immobilized catalyst, the catalyst loading is 0.7mg / cm 2 ; The loaded catalyst is stacked in the catalytic reactor. SO in the imported flue gas 2 The concentration is 1500mg / m 3 , NOx concentration is 600mg / m 3 . The sodium ion concentration of the absorption liquid is 0.1 mol / L, pH=6.0. The flue gas to be treated enters the photocatalytic reactor for photocatalytic oxidation reaction. After testing, NO in the flue gas nitrogen oxide 2 content from about 10% to more than 50%. The oxidized flue gas enters the absorption reactor and fully contacts with the absorption liquid. The test results of the discharged flue gas show that the desulfurization efficiency of 90% and the denitrification efficiency of 60% can be achieved.

Embodiment 2

[0049] Preparation of Glass Fiber Supported TiO by Coating Method 2 Immobilized catalyst, the catalyst loading is 1.0mg / cm 2 ; The loaded catalyst is stacked in the catalytic reactor. SO in the imported flue gas 2 The concentration is 1200mg / m 3 , NOx concentration is 500mg / m 3 . The sodium ion concentration of the absorption liquid is 0.1 mol / L, pH=6.0. The flue gas to be treated enters the photocatalytic reactor for photocatalytic oxidation reaction. After testing, NO in the flue gas nitrogen oxide 2 content from about 10% to more than 50%. The oxidized flue gas enters the absorption reactor and fully contacts with the absorption liquid. The test results of the discharged flue gas show that the desulfurization efficiency of 95% and the denitrification efficiency of 70% can be achieved.

Embodiment 3

[0051] Preparation of Glass Fiber Supported TiO by Coating Method 2 Immobilized catalyst, the catalyst loading is 1.5mg / cm 2 ; The loaded catalyst is stacked in the catalytic reactor. SO in the imported flue gas 2 The concentration is 1200mg / m 3 , NOx concentration is 200mg / m 3 . The sodium ion concentration of the absorption liquid is 0.1 mol / L, pH=6.0. The flue gas to be treated enters the photocatalytic reactor for photocatalytic oxidation reaction. After testing, NO in the flue gas nitrogen oxide 2 content from about 10% to more than 75%. The oxidized flue gas enters the absorption reactor and fully contacts with the absorption liquid. The test results of the discharged flue gas show that the desulfurization efficiency of 90% and the denitrification efficiency of 90% can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com