Method for recycling heavy metal nickel from chemical nickel-plating waste water

An electroless nickel plating and heavy metal technology, applied in chemical instruments and methods, metallurgical wastewater treatment, optics, etc., can solve the problem that hypophosphorous wastewater and nickel-containing wastewater cannot be treated at the same time, and achieve the effect of easy application and economic application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Take the electroless nickel-plating cleaning wastewater containing hypophosphorous and heavy metal nickel, and use cation exchange resin to adsorb and enrich the heavy metal nickel in the electroless nickel-plating cleaning wastewater to obtain hypophosphorous-containing wastewater;

[0032] 2) Using concentrated hydrochloric acid solution to elute and regenerate the cation exchange resin to obtain a regenerated solution containing nickel ions and chloride ions;

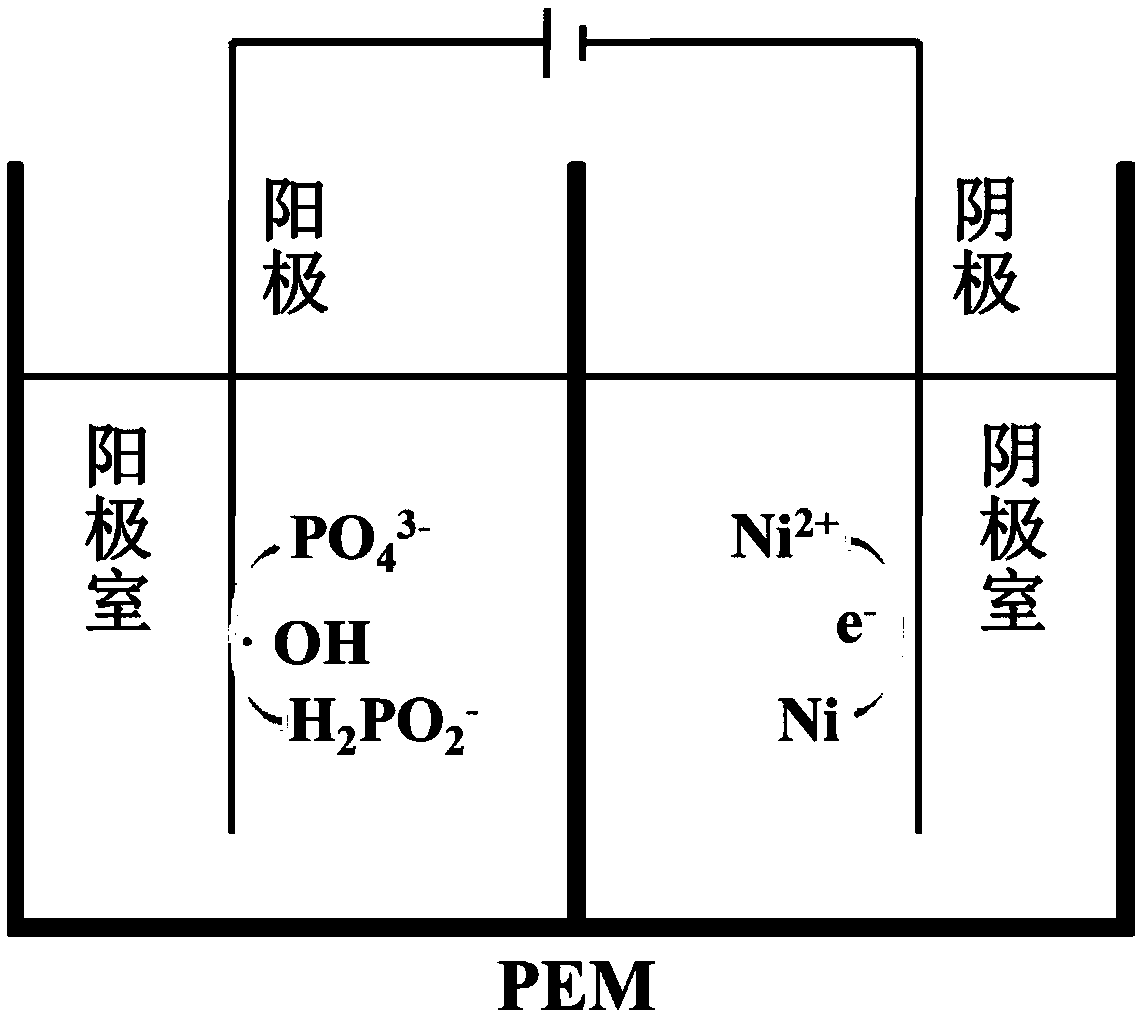

[0033] 3) Such as figure 1 As shown, it is a schematic structural diagram of a dual-chamber electrochemical reactor according to an embodiment of the present invention. Add hypophosphorous waste water to the anode chamber of the double-chamber electrochemical reactor, and add a regenerating solution containing nickel ions and chloride ions to the cathode chamber of the double-chamber electrochemical reactor; The high-performance titanium ruthenium mesh is used as the anode, the titanium sheet is used as the cath...

Embodiment 2

[0040] 1) Take the electroless nickel-plating cleaning wastewater containing hypophosphorous and heavy metal nickel, and use cation exchange resin to adsorb and enrich the heavy metal nickel in the electroless nickel-plating cleaning wastewater to obtain hypophosphorous-containing wastewater;

[0041] 2) Using concentrated hydrochloric acid solution to elute and regenerate the cation exchange resin to obtain a regenerated solution containing nickel ions and chloride ions;

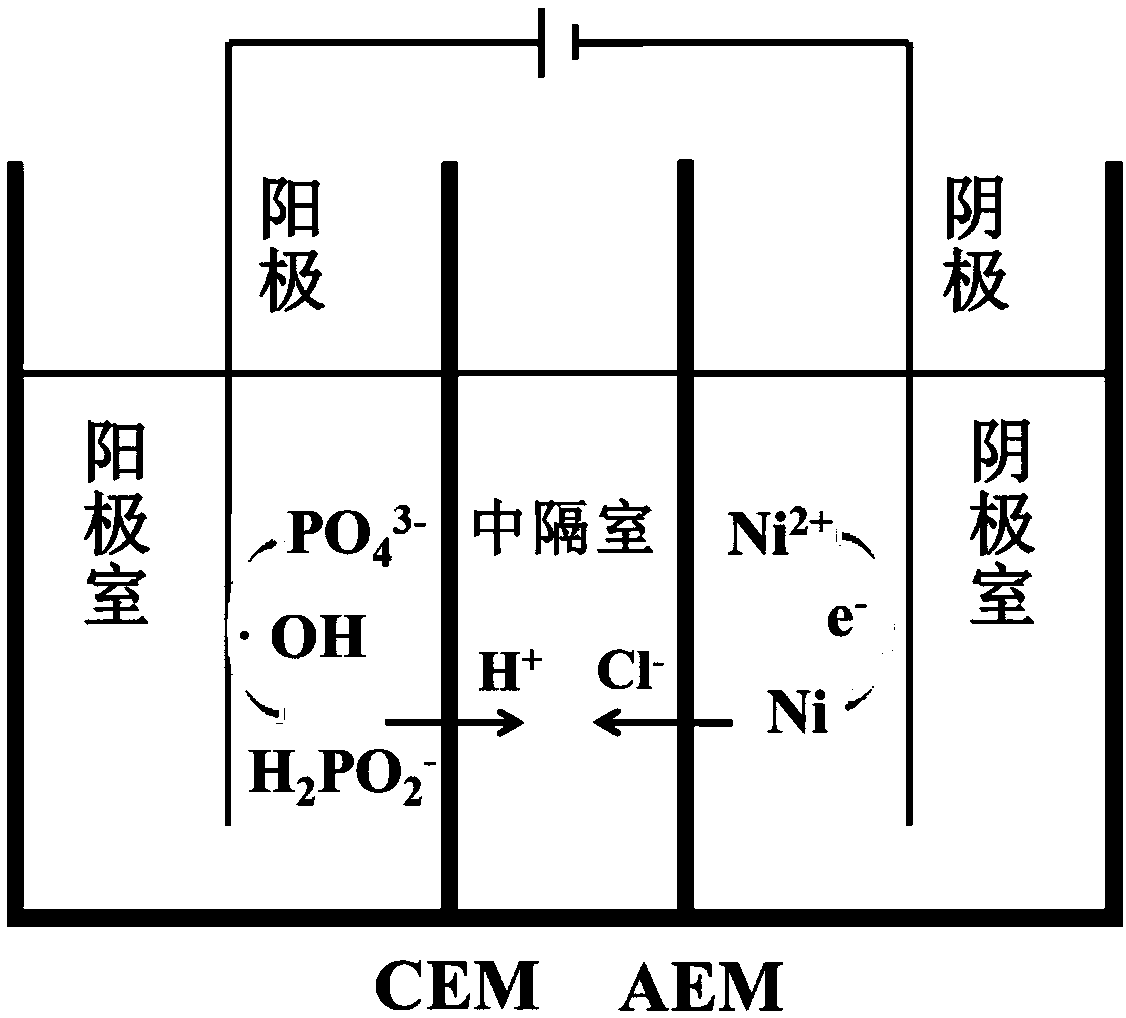

[0042] 3) Such as figure 2 As shown, it is a schematic structural diagram of a three-compartment electrochemical reactor according to an embodiment of the present invention. Add hypophosphorous waste water to the anode chamber of the three-chamber electrochemical reactor, add a regenerating solution containing nickel ions and chloride ions to the cathode chamber of the three-chamber electrochemical reactor, and add to the three-chamber electrochemical reactor Add 0.1mol / L hydrochloric acid solution to the compa...

Embodiment 3

[0047] 1) Take the electroless nickel-plating cleaning wastewater containing hypophosphorous and heavy metal nickel, and use cation exchange resin to adsorb and enrich the heavy metal nickel in the electroless nickel-plating cleaning wastewater to obtain hypophosphorous-containing wastewater;

[0048] 2) The cation exchange resin is eluted and regenerated with a concentrated sulfuric acid solution to obtain a regeneration solution containing nickel ions and sulfate ions;

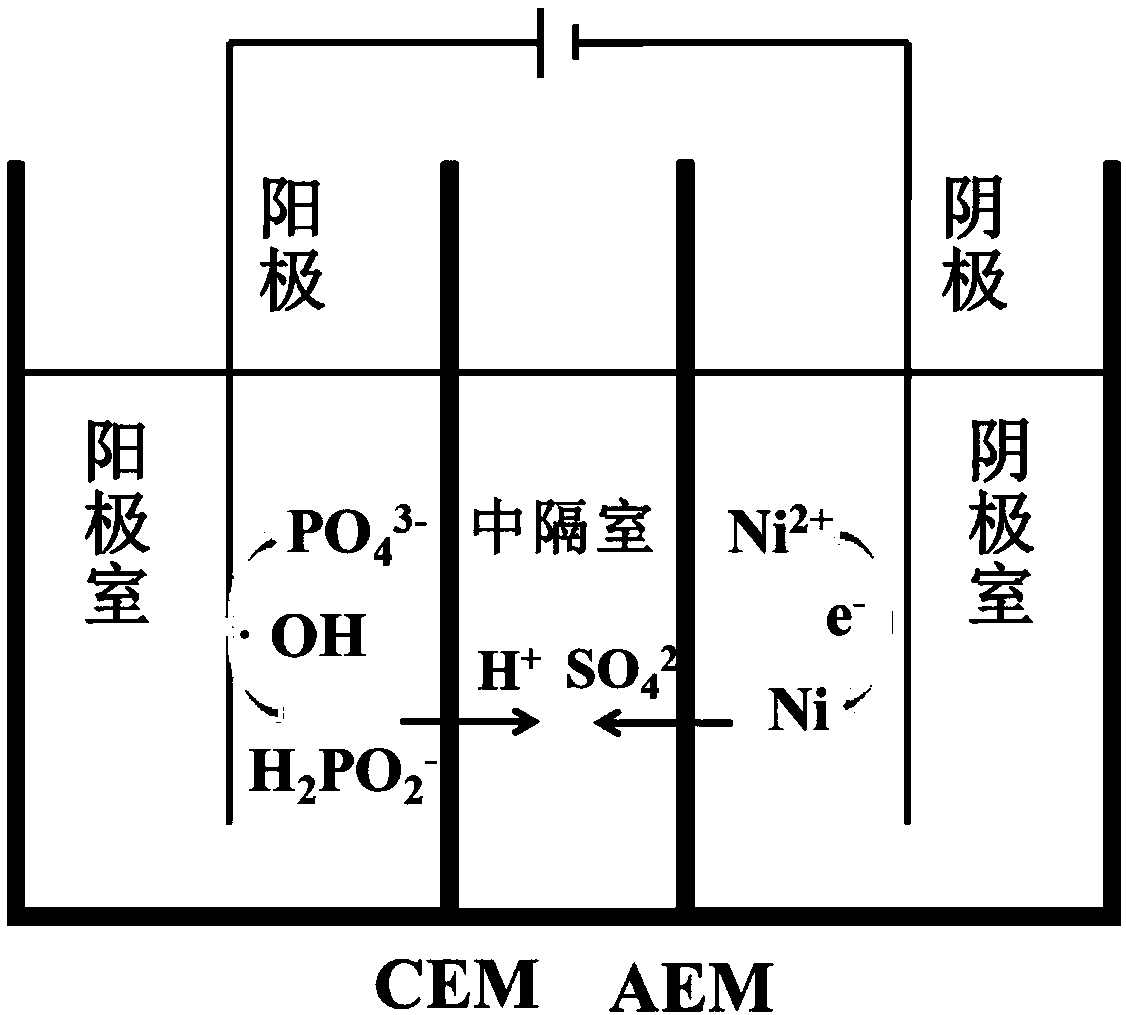

[0049] 3) Such as image 3 As shown, it is a schematic structural diagram of a three-compartment electrochemical reactor according to an embodiment of the present invention. Add hypophosphorous waste water to the anode chamber of the three-chamber electrochemical reactor, add a regenerating solution containing nickel ions and sulfate ions to the cathode chamber of the three-chamber electrochemical reactor, Add 0.02mol / L sulfuric acid solution to the middle compartment; use the highly efficient and stable rutheni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com