Amino exhaust smoke purifying method and amino exhaust smoke purifying device

An amino, purification tower technology, applied in chemical instruments and methods, fertilization devices, separation methods, etc., can solve the problems of weak acid and strong acid aerosol, and achieve reliable crystal quality, effective oxidation, safe operation and operation control. reliable results

Inactive Publication Date: 2015-06-10

SHANGHAI JIAO TONG UNIV

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved in the present invention is to disclose a novel method for purifying ammonia smoke exhaust, so as to solve the serious problem of weakly acidic and strongly acidic aerosols in the prior art, and at the same time ensure more effective control of the escape loss of ammonia , and higher ammonia feedstock utilization

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

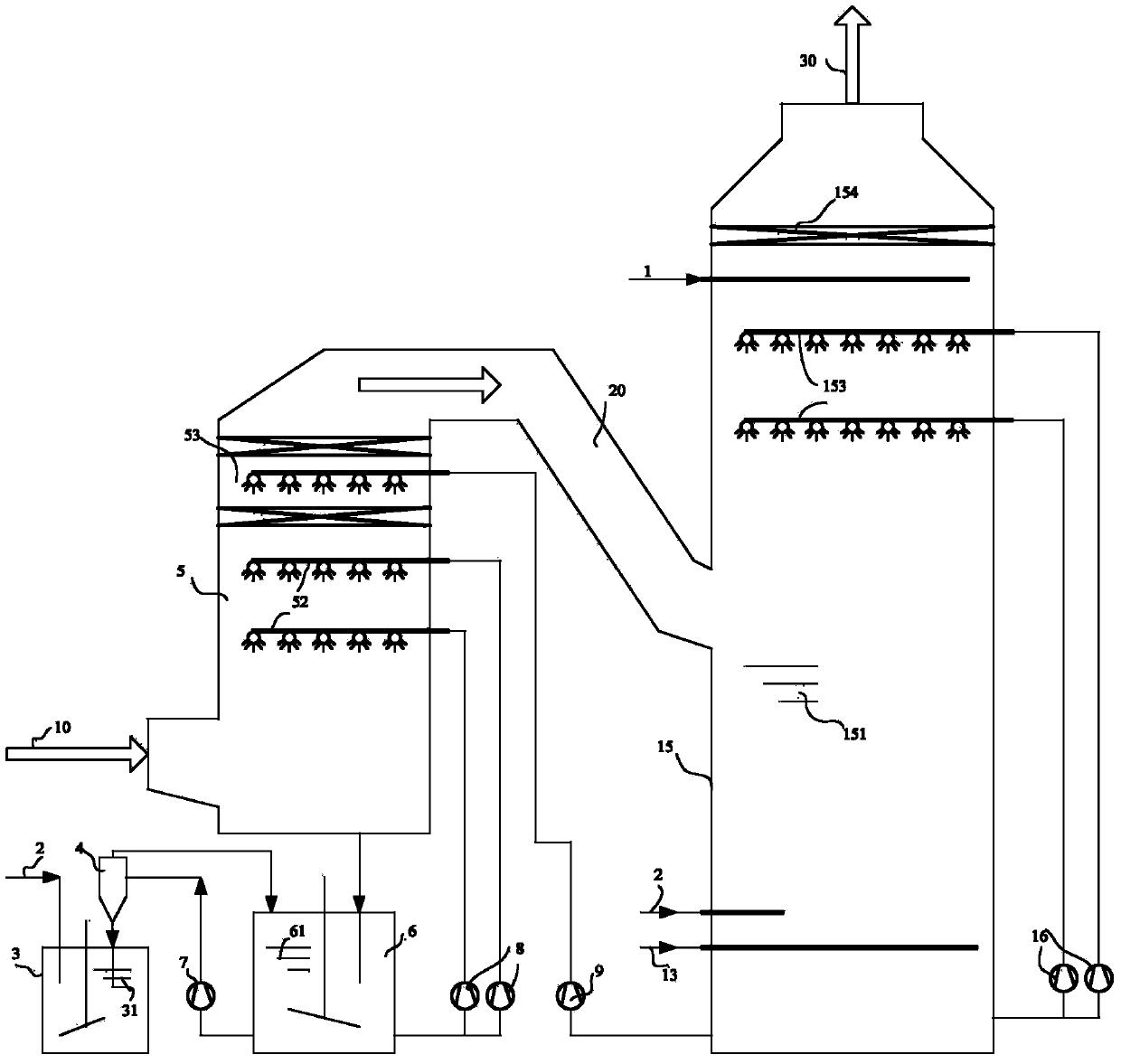

The invention relates to an amino exhaust smoke purifying method and an amino exhaust smoke purifying device, used for removing aerosol and ammonia escape. The amino exhaust smoke purifying device comprises a washing tower, a purifying tower, a washing circulation tank and a crystal growing tank; exhaust smoke enters the washing tower at first, so that the temperature of the exhaust smoke is lowered and the exhaust smoke absorbs strongly acidic gas; then, the exhaust smoke enters the subsequent purifying tower to absorb weakly acidic gas. The amino exhaust smoke purifying device is characterized in that a dilute ammonium sulphate aqueous solution is used in the purifying tower; the concentration is 5-40%; the pH is 5.3-6.3; thin serous fluid containing ammonium sulphate crystalline solids is used in the washing tower; the solid content of ammonium sulphate is less than 10%; the pH is 1.0-4.5; furthermore, the proportion of the flow of sulphur to the flow of circulation solution in the purifying tower is 50-500 (g / h) / (m3 / h); and the proportion of the flow of circulation solution in the washing tower to the flow of the exhaust smoke is 1.0-10.0 (L / h) / (Nm3 / h). Therefore, the two processes deciding formation of aerosol and ammonia escape are decoupled and controlled effectively; and thus, the whole purifying system is also more safe and reliable to operate and control.

Description

Technical field The invention relates to a purification method and device for ammonia exhaust fumes, in particular to a purification method and device for producing ammonium sulfate fertilizer by recovering sulfur oxides from flue gas using ammonia as a raw material. It belongs to the technical fields of electric power, metallurgy, environmental protection and chemical engineering, and is particularly suitable The field of smoke purification. Background technique The acidic gaseous harmful substances contained in flue gas, especially SO 2 It is the main source of acid rain. It is well known that one solution to acid rain pollution is to purify smoke. The existing exhaust gas purification method is mainly calcium-based purification with limestone as raw material. The purification product is calcium sulfate (or purified gypsum), which can be used as building materials, including gypsum board and cement additives. However, due to China's gypsum resources It is relatively abunda...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/80B01D53/50C01C1/24C05C3/00

Inventor 肖文德阎建民罗漫

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com