Patents

Literature

142results about How to "Effective oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting xylan from woody fiber material

A process for extracting xylan from wooden fibre material features that under the catalysis of microwave, the alkali solution containing hydrogen peroxide in directly sued to treat raw material for performing extraction of xylane and bleaching it at same time. Its advantages are high speed, less consumption of alkali, and high extracting rate. The resultant xylan solution can be deposited in organic solvent or superfilted and dried to obtain light-color xylan product.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

Production of polymerized ferric-aluminum chloride composite coagulating agent

InactiveCN101074128AReduce manufacturing costLow costWater/sewage treatment by flocculation/precipitationPhosphateChlorate salt

Production of inorganic polymer coagulating agent is carried out by controlling Fe2+ concentration between 75-90g / L in hydrochloric acid pickling effluent, taking it as ferric source, taking calcium aluminate powder as aluminum source with Al2O3 content 47-56 wt%, putting two kinds of raw material into reactor in proportion of calcium aluminate powder: hydrochloric acid pickling effluent=0.05-0.10, reacting while agitating at 50-80 degree for 1-3 hrs, adding into minor chlorate oxidant and phosphate stabilizer, heating, reacting while agitating, and cooling to room temperature to obtain final product. It's simple and can be used for domestic sewage and industrial effluent treatment.

Owner:SHANGHAI UNIV

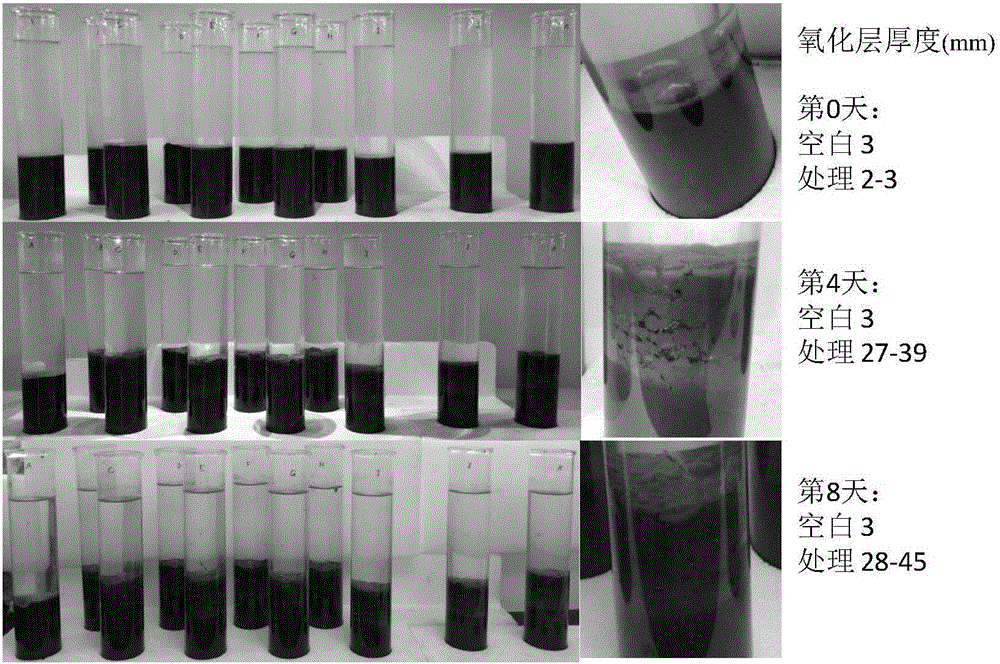

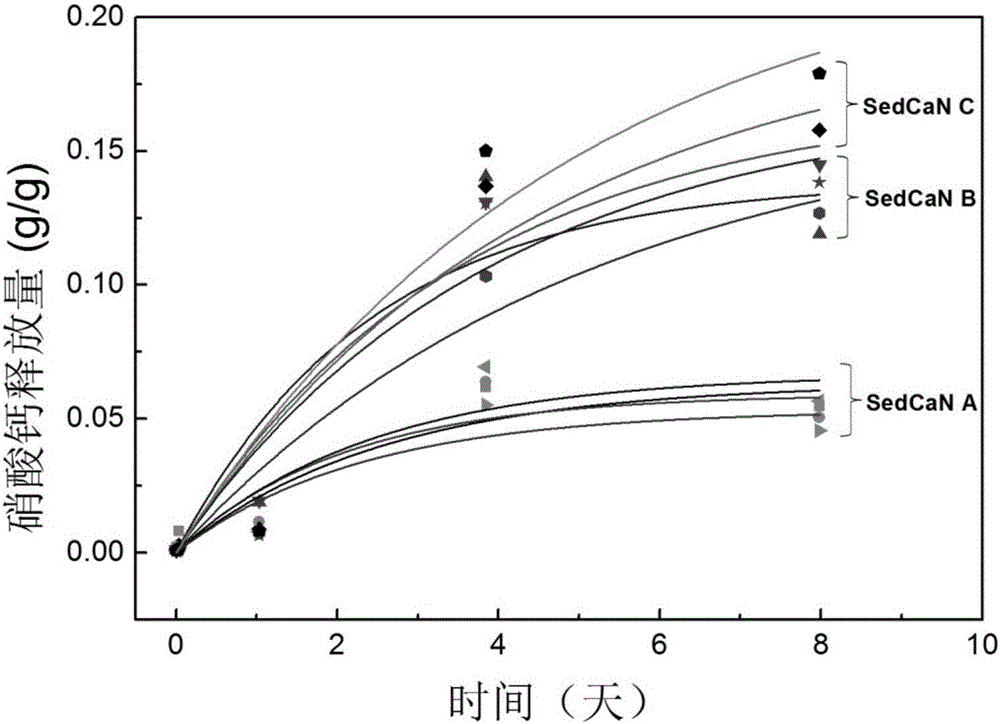

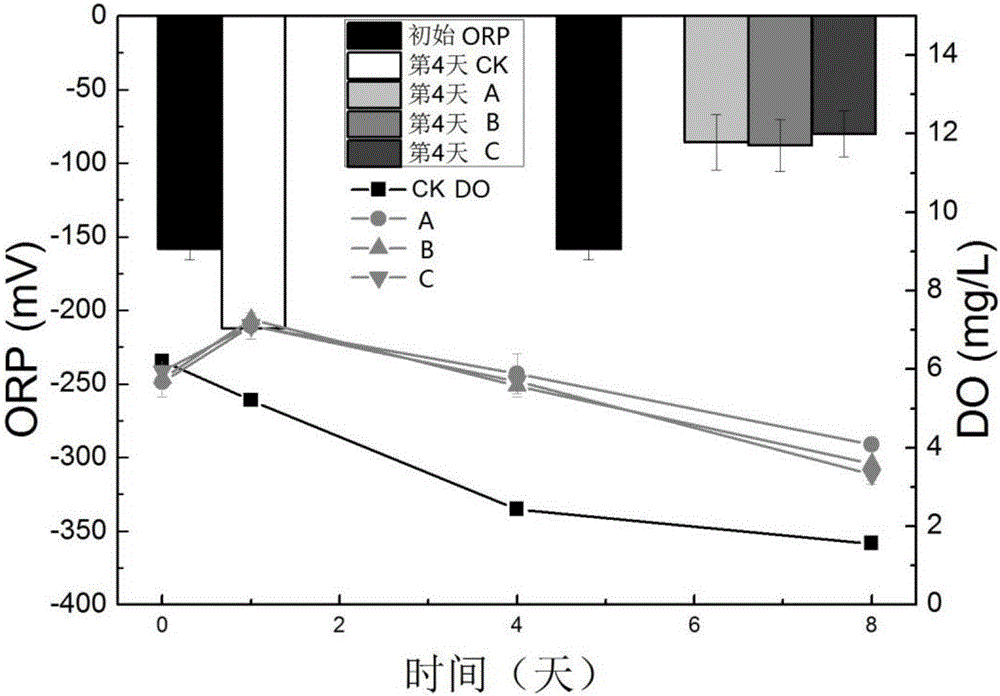

Environment-friendly calcium nitrate slow-release granule for remedying bottom mud of black and odorous river and preparation method of environment-friendly calcium nitrate slow-release granule

ActiveCN105800899AInvalid releaseEffective oxidationSludge treatment by oxidationContaminated waterways/lakes/ponds/rivers treatmentActivated carbonAlcohol

The invention discloses an environment-friendly calcium nitrate slow-release granule for remedying bottom mud of a black and odorous river and a preparation method of the environment-friendly calcium nitrate slow-release granule. The environment-friendly calcium nitrate slow-release granule for remedying bottom mud of the black and odorous river takes the bottom mud as a remediation agent additive; firstly, a great amount of denitrification bacteria are enriched through denitrification modification, secondly, activated carbon is added, and together with polyving alcohol and sodium alginate as slow-release agents and sodium alginate as a coating material, the calcium nitrate slow-release granule can be prepared. The environment-friendly calcium nitrate slow-release granule is capable of effectively eliminating black and odorous pollution of the bottom mud, has characteristics of high efficiency and environment-friendliness, and has a great significance for city environment protection.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

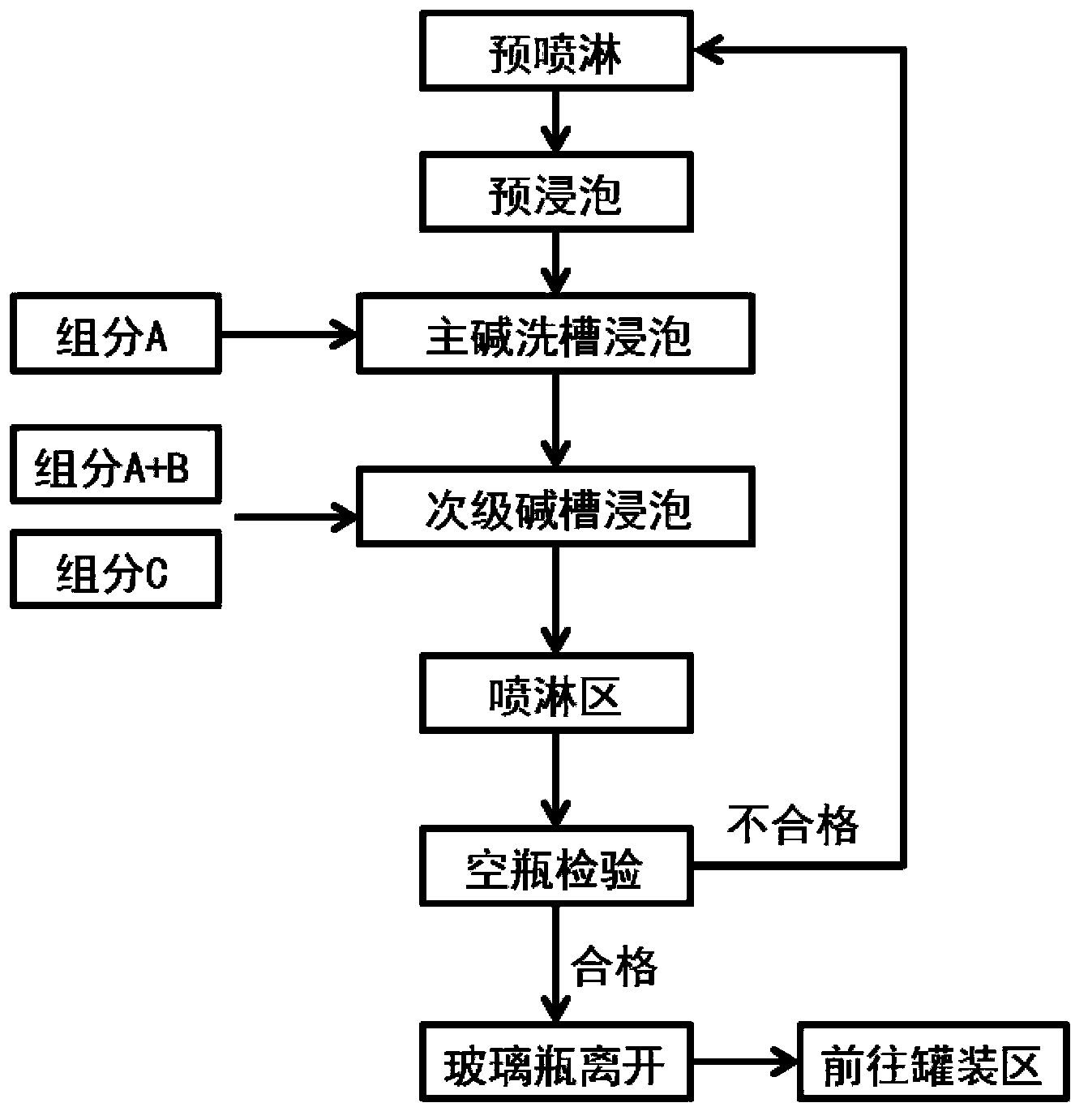

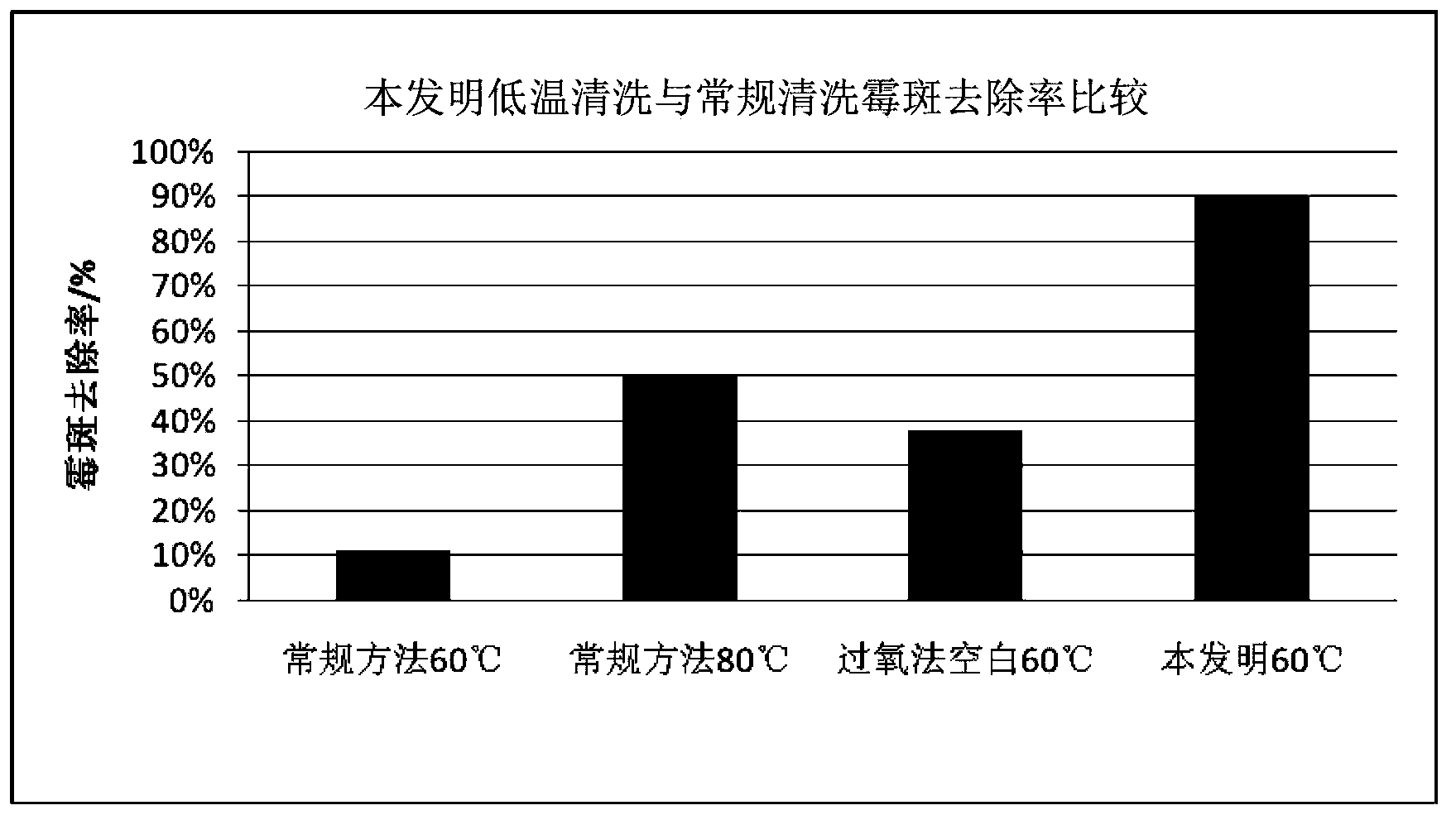

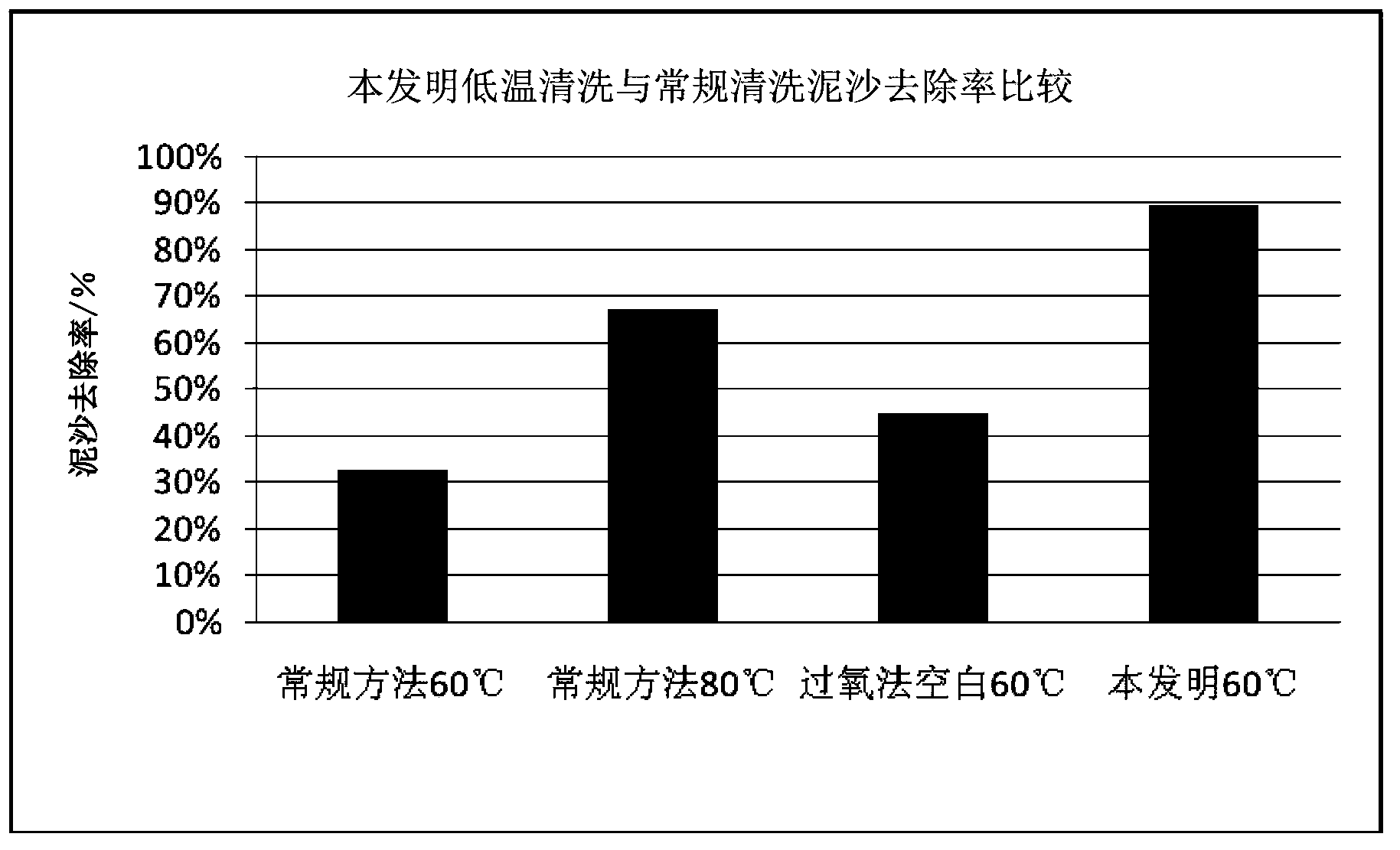

Cleaning additive and cleaning method adopting the cleaning additive

InactiveCN103849498AImprove solubilityLess corrosiveNon-ionic surface-active compoundsNon-surface-active detergent compositionsOrganic phosphorusBottle

The invention discloses a cleaning additive for glass bottles and a cleaning method of the glass bottles. The cleaning method and the cleaning additive are used for glass bottle cleaning by a primary alkaline bath and a secondary alkaline bath. The cleaning additive comprises a component A, a component B and a component C, wherein the component A comprises an organic phosphorus chelating agent, the component B comprises peroxide, the component C comprises a defoaming agent, the component A is added into the primary alkaline bath, the component B is selectively added into the primary alkaline bath, the component A and the component B are added into the secondary alkaline bath, and the component C is selectively added into the primary alkaline bath or the secondary alkaline bath. Based on the weight of alkaline solution in the primary alkaline bath or the secondary alkaline bath where the component is added, the adding amount of the component A is 0.05-5%, the adding amount of the component B is 0.1-0.5%, and the adding amount of the component C is 0-0.5%. The alkaline solution in the primary alkaline bath and the secondary alkaline bath is sodium hydroxide solution having a concentration of 1.5-3%. The cleaning additive and the cleaning method can achieve stable and good cleaning effects at a relatively low temperature that is usually 50-70 DEG C.

Owner:ECOLAB USA INC

Process for preparing nitric oxide adsorbent with high adsorption capacity

ActiveCN101693192AImprove adsorption capacityIncrease the number ofOther chemical processesSorbentCerium

A process for preparing nitric oxide adsorbent with high adsorption capacity belongs to the technical field of material preparation and waste gas treatment and comprises steps of utilizing manganese element ( or cobalt element ) and cerium element as main catalytic oxidation components, utilizing activated carbon as an NOx adsorbing component, obtaining activated carbon materials carrying the manganese element (or cobalt element) and the cerium element, and then obtaining an adsorbent material which can effectively oxidize NO into NO2 and adsorb NO2 at a low temperature by firing of inert gas. NOx adsorption capacity (by NO2) of the adsorbent material can reach over 30mg / g, therefore, the process for preparing nitric oxide adsorbent with high adsorption capacity has fine application prospect in operation of sintering smoke and gas denitration.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Alkylbenzene photooxidizing process with oxygen to prepare aromatic aldehyde and aromatic acid

ActiveCN1810754AEffective oxidationEasy to oxidizeOrganic compound preparationCarbonyl compound preparationBenzenePhotosensitizer

The present invention belongs to the field of preparation of aromatic aldehyde and aromatic acid, and is especially alkyl benzene photooxidizing process with oxygen to prepare aromatic aldehyde and aromatic acid. Alkyl benzene is oxidized effectively into corresponding aldehyde and acid with oxygen or air in mild condition in the presence of common photosensitizer and under irradiation of ultraviolet ray or visible light. During oxidation, the reaction time is controlled to obtain high yield of aldehyde and acid.

Owner:INST OF CHEM CHINESE ACAD OF SCI

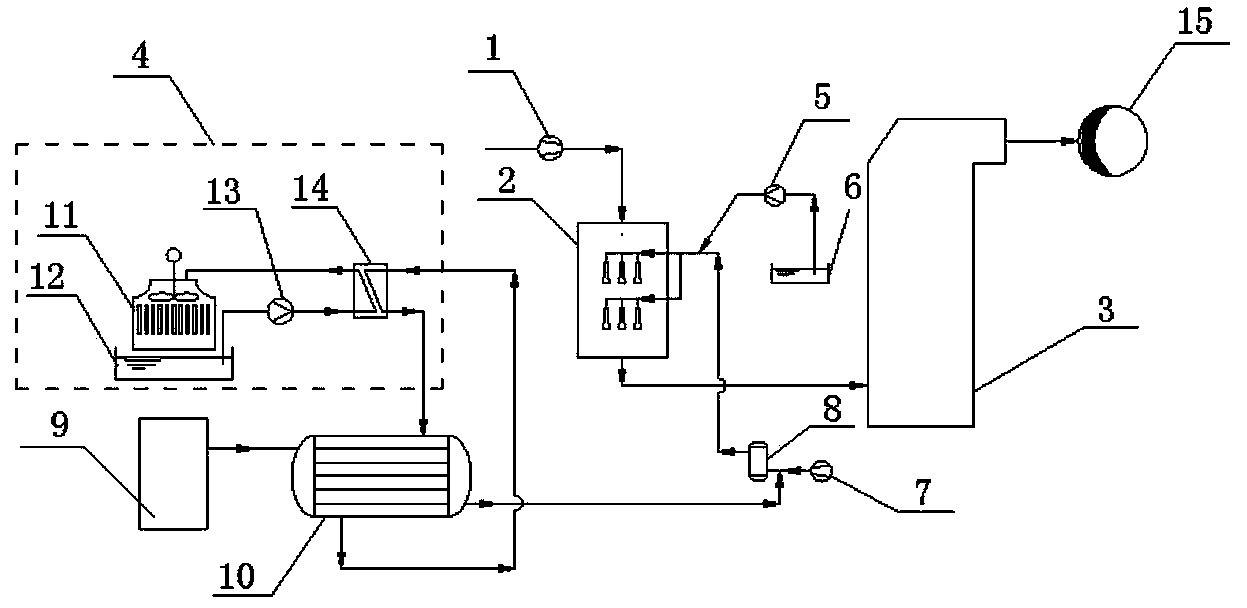

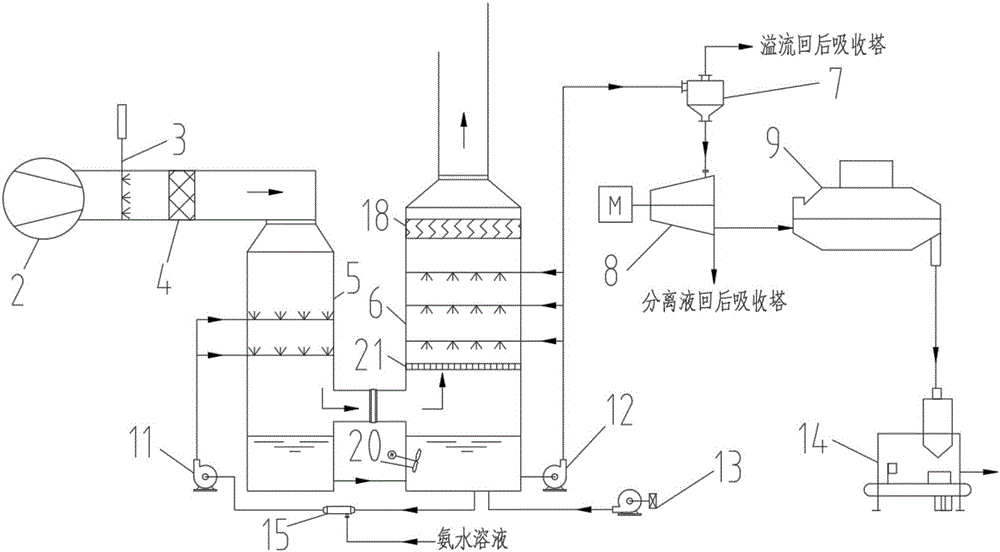

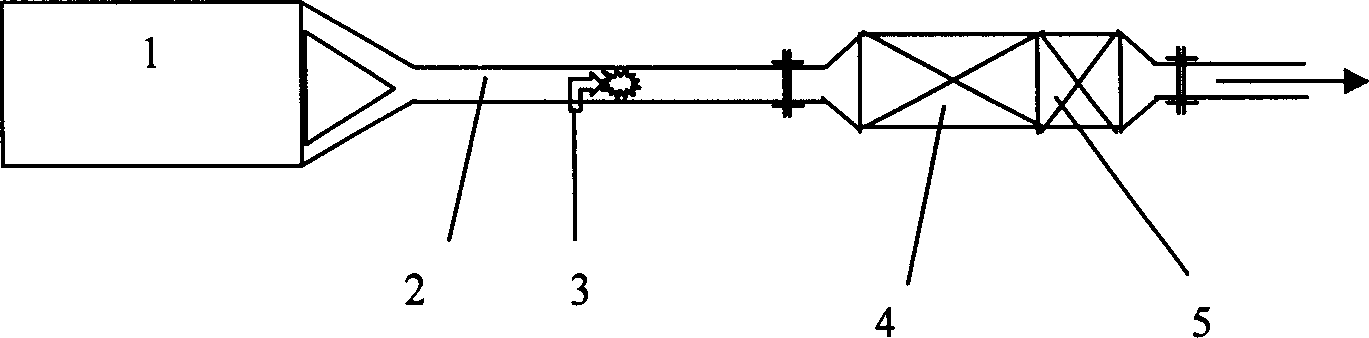

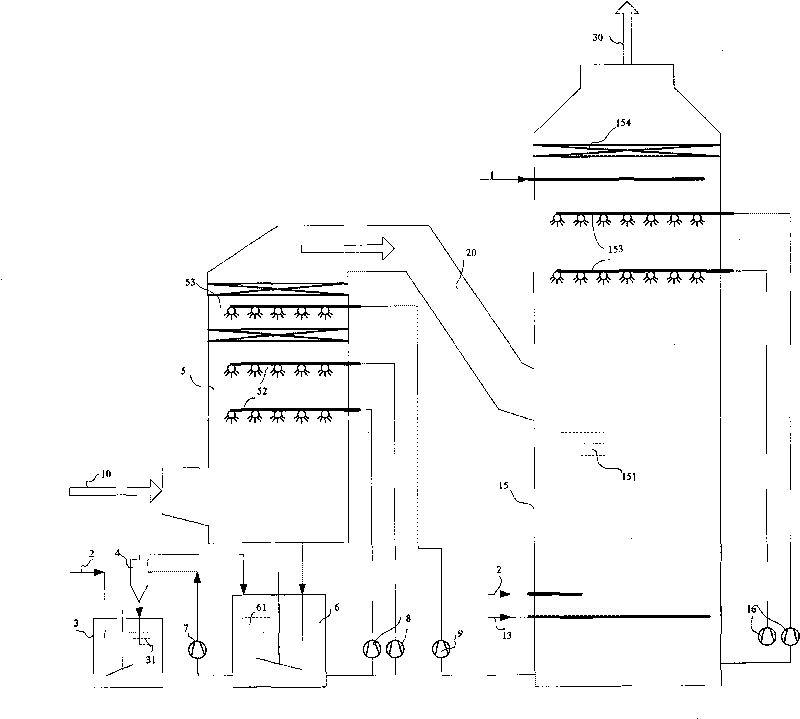

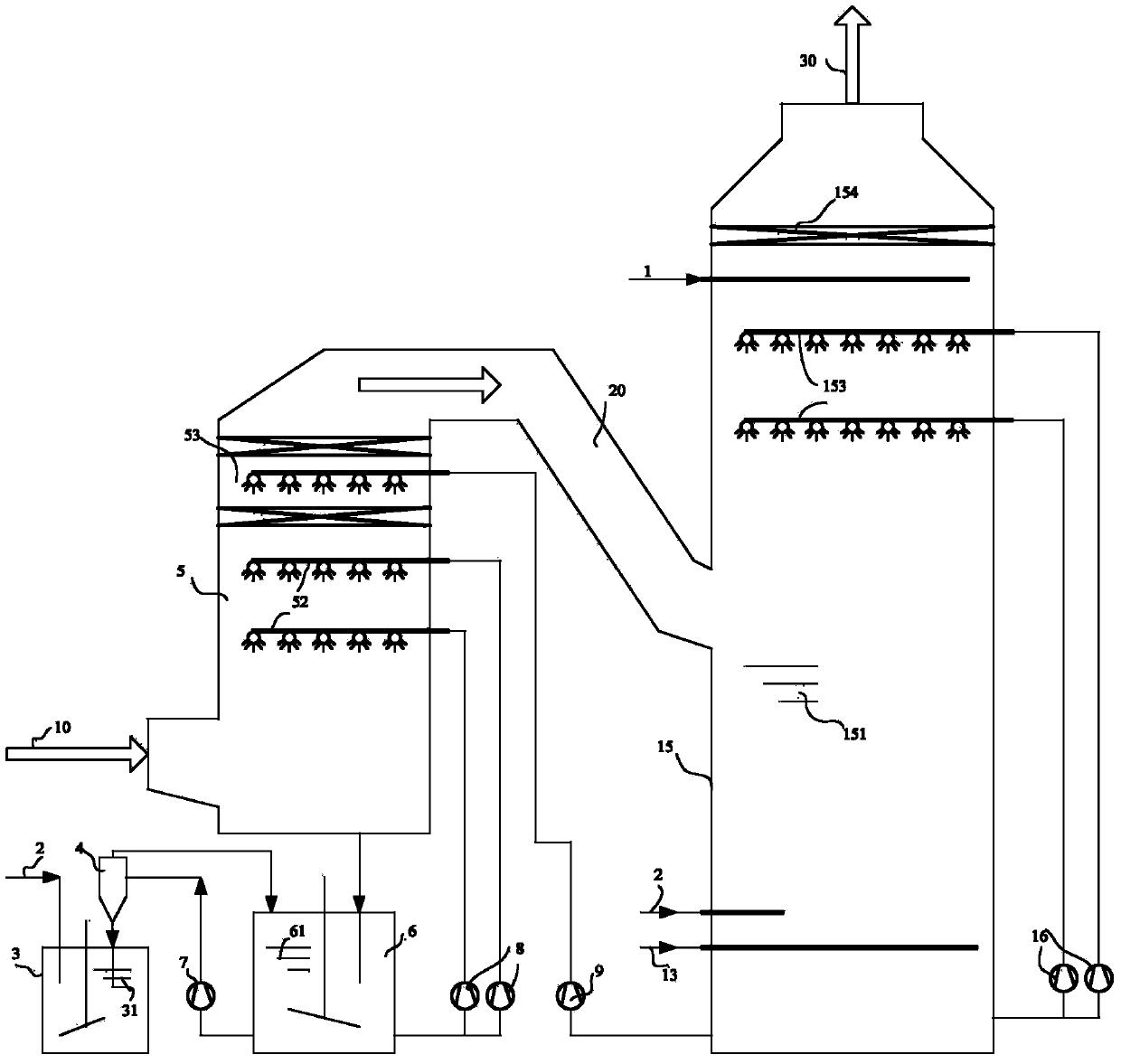

Treatment method for removing nitrogen oxides by virtue of ozone function

InactiveCN104128079AEffective oxidationImprove oxidation efficiencyDispersed particle separationOzone generatorFlue gas

The invention relates to a treatment method for removing nitrogen oxides by virtue of an ozone function. The method comprises the following steps: (1) flue gas containing the nitrogen oxides is introduced into a flue and an ozone adding distributor is additionally arranged; (2) a gas source is introduced into an ozone generator, ozone is generated and diluted and then is mixed in a mixer to obtain ozone diluted uniformly, and the ozone diluted uniformly enters the ozone adding distributor; (3) the ozone diluted uniformly and the flue gas containing the nitrogen oxides are mixed in the ozone adding distributor and are subjected to oxidation reaction, NO in waste gas is converted into high-valent nitrogen oxides and then the high-valent nitrogen oxides enter an absorption tower; and (4) the flue gas is absorbed by the absorption tower and absorption liquid and is purified to obtain tail gas, and the tail gas is exhausted from a chimney. The treatment method for removing the nitrogen oxides has the high efficiency, the low energy consumption and the convenience in use.

Owner:山西易通环保技术有限公司

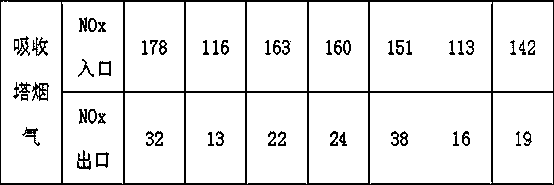

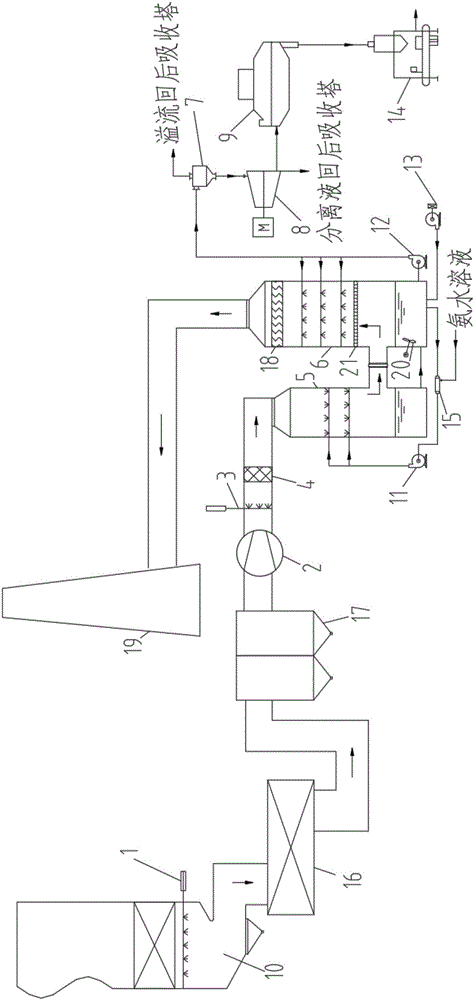

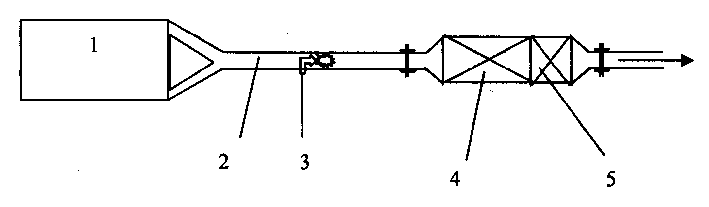

Desulfurization and denitration technology and system by ozone oxidation double-tower ammonia method

ActiveCN106166434AHigh process integrationReduce resistanceDispersed particle separationAir preheaterFlue gas

The invention relates to a desulfurization and denitration system by an ozone oxidation double-tower ammonia method. The desulfurization and denitration system sequentially comprises a hydrogen peroxide spraying device, a draught fan, an ozone spraying device, a flue gas mixing device, a front adsorption tower, a rear adsorption tower, a cyclone separator, a centrifugal separator and a drier, wherein the hydrogen peroxide spraying device is arranged at an outlet of a boiler coal economizer, the outlet of the boiler coal economizer is connected to the draught fan through an air preheater and a dust remover and is connected to the front adsorption tower; the ozone spraying device is mounted in front of an inlet flue of the front adsorption tower; and the flue gas mixing device is arranged between the ozone spraying device and the inlet flue of the front adsorption tower. The desulfurization and denitration system disclosed by the invention has the beneficial effects that the integration degree of a technology is high, the desulfurization and the denitration are integrated, the double-tower structure are stable in properties, the desulfurization efficiency and the denitration efficiency are high, the source of an adsorption tower machine is reliable, the added value of by-products is high, little secondary pollution exists, and the operation cost is low.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

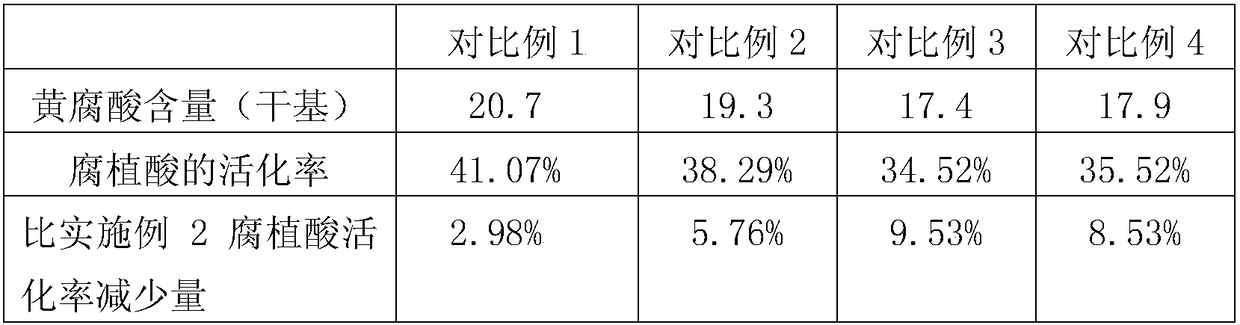

Method for preparing fulvic acid salt by using composite photocatalyst to activate low-rank coal

ActiveCN108129524AImprove alkali extraction efficiencyEffective oxidationOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHydrogenSalt solution

The invention provides a method for preparing fulvic acid salt by using a composite photocatalyst to activate low-rank coal. The method comprises the following steps of uniformly mixing the low-rank coal powder and water, adding alkaline to adjust the pH (potential of hydrogen) value to 8 to 11, stirring for 1 to 2h, adding an oxidant, reacting for 1 to 3h at the temperature of 25 to 55 DEG C, andseparating solid and liquid, so as to obtain a humic acid salt solution; adding the composite photocatalyst, stirring to react for 2 to 6h under the condition of ultraviolet radiation, separating solid and liquid, taking the solution and evaporating, so as to obtain the solid fulvic acid salt product. The method has the advantages that the production technology is simple, the green and environment-friendly effects are realized, the production cost is low, the activating rate of the humic acid in the low-rank coal is high, and the yield rate of the fulvic acid salt prepared by the low-rank coal is obviously improved.

Owner:QUJING NORMAL UNIV +2

Leather cleaning agent

InactiveCN102876478AReduce oxidationEffective oxidationOrganic detergent compounding agentsNon-ionic surface-active compoundsSurface-active agentsBenzene

Disclosed is a leather cleaning agent which comprises components of, by mass, 5-25 parts of a surface active agent, 2-5 parts of an emulsifying agent, 2-4 parts of mineral oil, 0.2-1.8 parts of an antioxidant, 0.2-0.6 part of a polyurethane resin and 20-35 parts of water. The surface active agent is fatty alcohol-polyoxyethylene ether or linear alkyl benzene sulphonic acid or a mixture of the fatty alcohol-polyoxyethylene ether and the linear alkyl benzene sulphonic acid. The emulsifying agent is sorbitan monolaurate or oil-based sodium amino acid. The antioxidant is tertiary butyl cresol or butylated hydroxytoluene. The leather cleaning agent is free of stearate and good in decontamination effect; simultaneously, the antioxidant is added, so that oxidation of leather is reduced, a protective film is formed on the surface of the leather, waterproofness and decontamination are effectively achieved, and the leather is kept clean all the time; and the leather can be kept soft, glossy and bright if the leather cleaning agent is regularly used.

Owner:SUZHOU GULI BIOTECH

Fuel-lean vehicular engine exhaust gas catalyzing and purifying method

InactiveCN1454702AHigh NOx ConversionWide active temperature rangeInternal combustion piston enginesDispersed particle separationExhaust gasProduct gas

The invention is catalyst purifying method for tails discharged by fuel-lean car engine. The invention provides a method which applies to fuel-lean car engine, reduces NOx in tails efficiently in wide temperature range, and oxidizes HC and CO. The method includes following steps: sprays carbinol or alcohol into discharging pipe, and makes it blend with the engine tails; the mixed gas is transmitted to front grade catalyzing reaction bed which is loaded with transition metal oxide catalyst and the back grade catalyzing reaction bed which is loaded with laden noble metal catalyst, realizes the purification of NOx, HC and CO with high efficiency, and finally discharges normal gas. The invention can spread the range of NOx reduction active temperature.

Owner:TSINGHUA UNIV

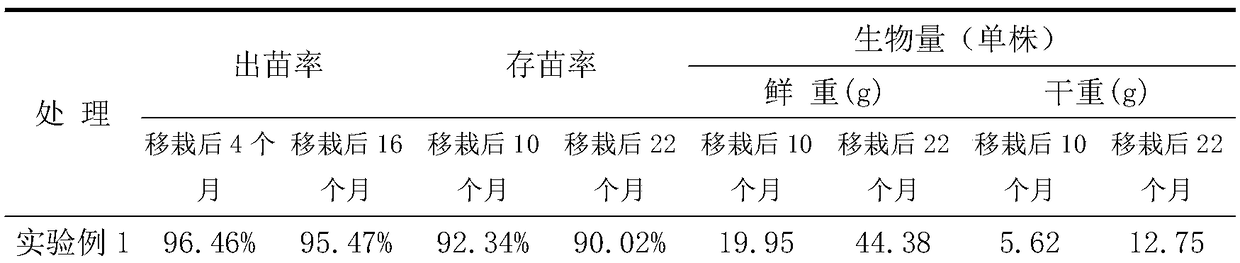

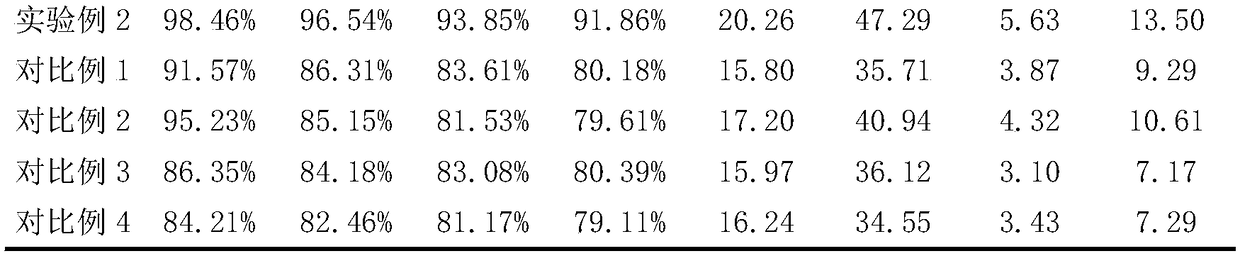

Method for improving continuous cropping soil of panax notoginseng

InactiveCN109168398AImproved soilPrevention of Soilborne DiseasesSoil-working methodsSurvival rateBacteria

The invention discloses a method for improving the continuous cropping soil of panax notoginseng, which comprises the following steps: (1) installing a drip irrigation device; (2) fumigating and disinfecting soil with dazomet; (3) disinfecting soil with chlorine dioxide; and (4) adding a compound microbial fertilizer. As a fumigant for the continuous cropping soil of panax notoginseng, dazomet cankill fungi, bacteria, insects and other organisms in the soil and is low-toxicity and safe. Chlorine dioxide can kill bacterial propagules, bacterial spores, fungi, mycobacteria and viruses, and bacteria will not develop resistance to chlorine dioxide. The compound microbial fertilizer can improve the yield of panax notoginseng, improve the quality of panax notoginseng, reduce the use of chemicalfertilizer, lower the cost, improve the soil and protect the ecological environment. By using the method, the seedling emergence rate of panax notoginseng seeds in the continuous cropping soil can bemore than 95%, the seedling survival rate can be more than 90%, and the disease incidence can be reduced.

Owner:云南天士力三七药业有限公司 +1

Aminogroup smoke exhaust purification method and device thereof

InactiveCN101703879AEffective oxidationReliable crystal qualityDispersed particle separationAmmonium sulfateSmoke

An aminogroup smoke exhaust purification method and a device thereof relate to a method and a device for eliminating aerosol and ammonia escape, wherein a purification device comprises a washing tower, a purifying tower, a washing circulation tank and a crystal growth tank. Exhaust smoke enters the washing tower for temperature reduction and strong acidic gas absorption firstly, and then enters a subsequent purifying tower for weak acidic gas absorption. The method and the device have the following characteristics: dilute aqueous solution of ammonium sulfate with concentration of 5-40% and pH of 5.3-6.3 is used in the purifying tower; dilute slurry containing ammonium sulfate crystalline solid is used in the washing tower, wherein ammonium sulfate solid content is less than 10% and pH thereof is 1.0- 4.5; in addition, the ratio of the flow rate of sulfur to the flow rate of circulating fluid in the purifying tower is 50-500 (g / h) / (m3 / h), and the ratio of the flow rate of the circulating fluid in the washing tower to the flow rate of the exhaust smoke is 1.0-10.0 (l / h) / (Nm3 / h). Therefore, two processes deciding aerosol formation and ammonia escape are effectively decoupled and controlled, and the operation and control of the whole purification system are safer and more reliable.

Owner:王建敏

Micro-electrolytic treatment process for treating acrylic fiber wastewater

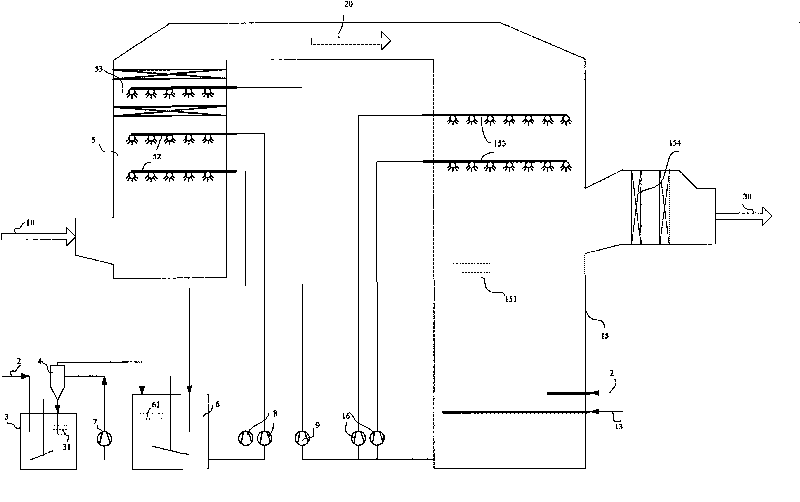

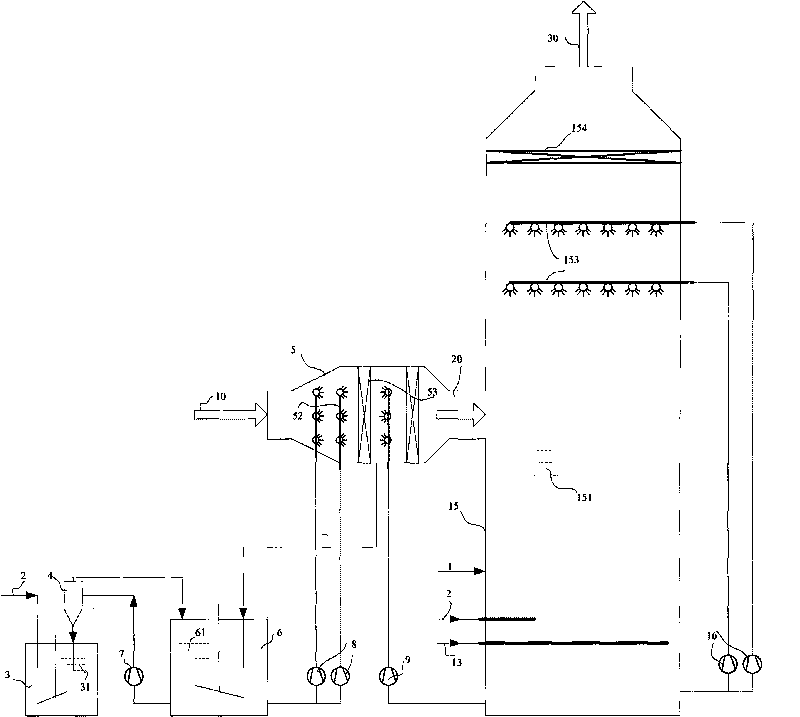

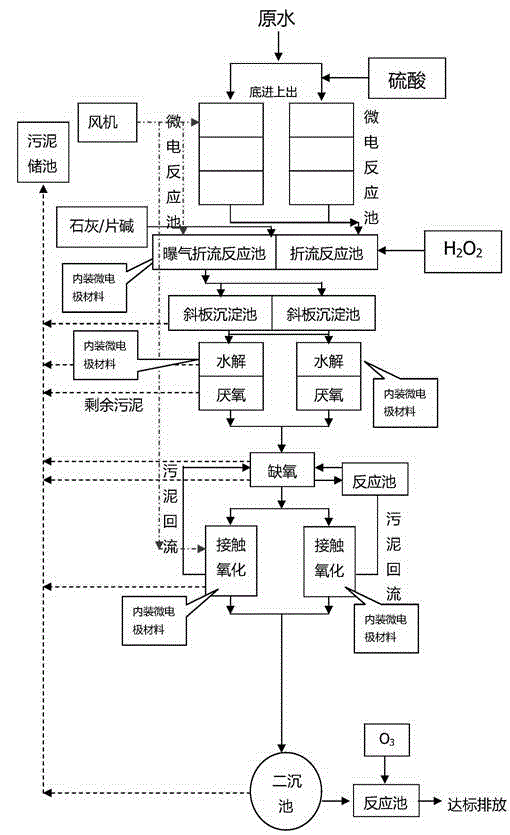

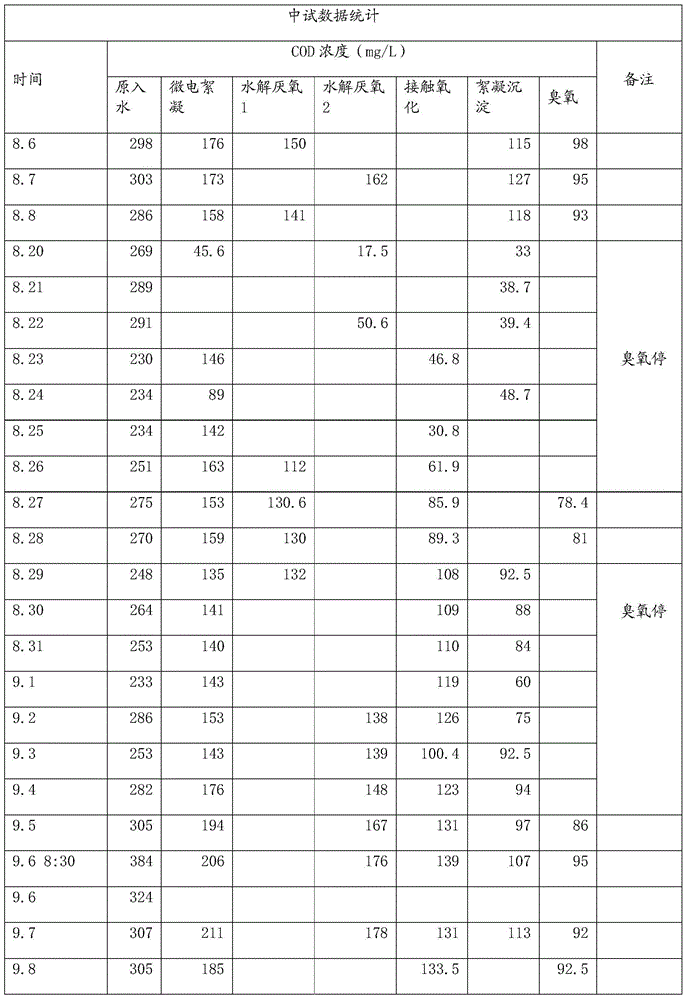

ActiveCN104926046AEffective oxidationReduce loadWater/sewage treatmentMultistage water/sewage treatmentFenton reagentCatalytic oxidation

The invention discloses a micro-electrolytic treatment process for treating acrylic fiber wastewater. The process comprises the following treatment steps of: (1) adjusting the pH value of the wastewater to be acidic, preferably pH being equal to 3-5; (2) treating the wastewater which is adjusted to be acidic in a micro-electrolytic reaction tank containing an acidic microelectrode; (3) adding hydrogen peroxide into the effluent of the micro-electrolytic reaction tank for carrying out Fenton oxidizing reaction; (4) adding lime and / or flake caustic into the water subjected to Fenton oxidizing reaction for neutralization, adjusting the pH value to 8-10 and aerating and stirring the mixture, and carrying out air stripping to remove most of ammonia nitrogen; (5) carrying out sedimentation treatment on the neutralized effluent so as to precipitate the suspended solid; and (6) carrying out biochemical treatment on the precipitated effluent. According to the process method disclosed by the invention, a Fenton reagent is formed by adding hydrogen peroxide into ferrous sulfate generated by micro-electrolytic reaction skillfully, so that various organic matters in the wastewater are effectively removed; moreover, in hydrolytic treatment, anaerobic treatment and catalytic oxidation treatment, the difficulty of carrying out biochemical treatment is further reduced by using a micro-electrolytic material, so that the sludge load is reduced.

Owner:广东灵捷制造化工有限公司

Ferric salt-doped Spiro-OMeTAD hole transport layer and solar cell comprising hole transport layer

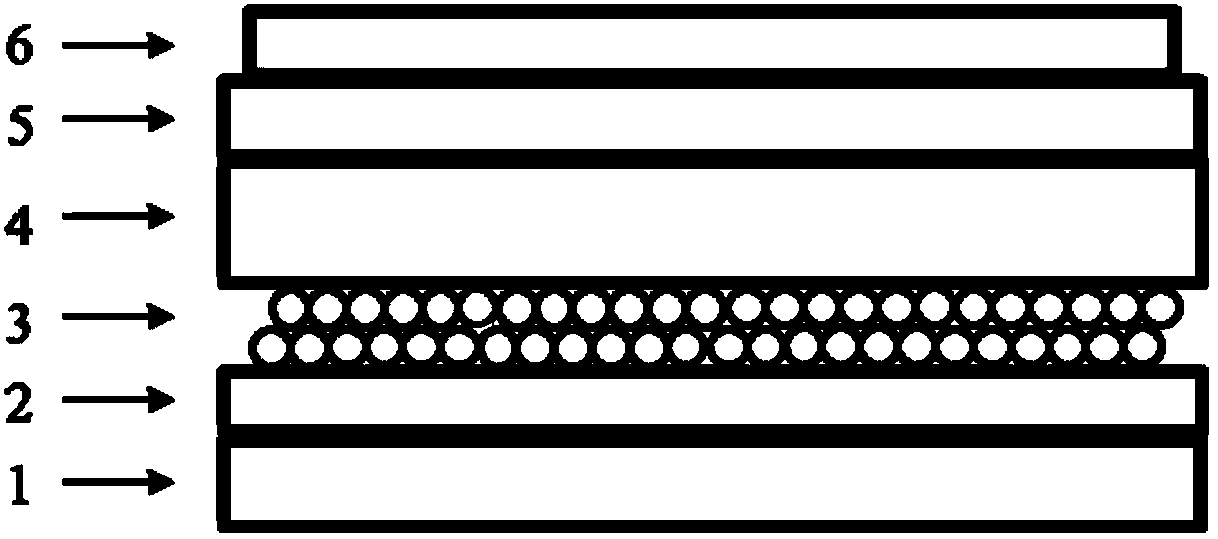

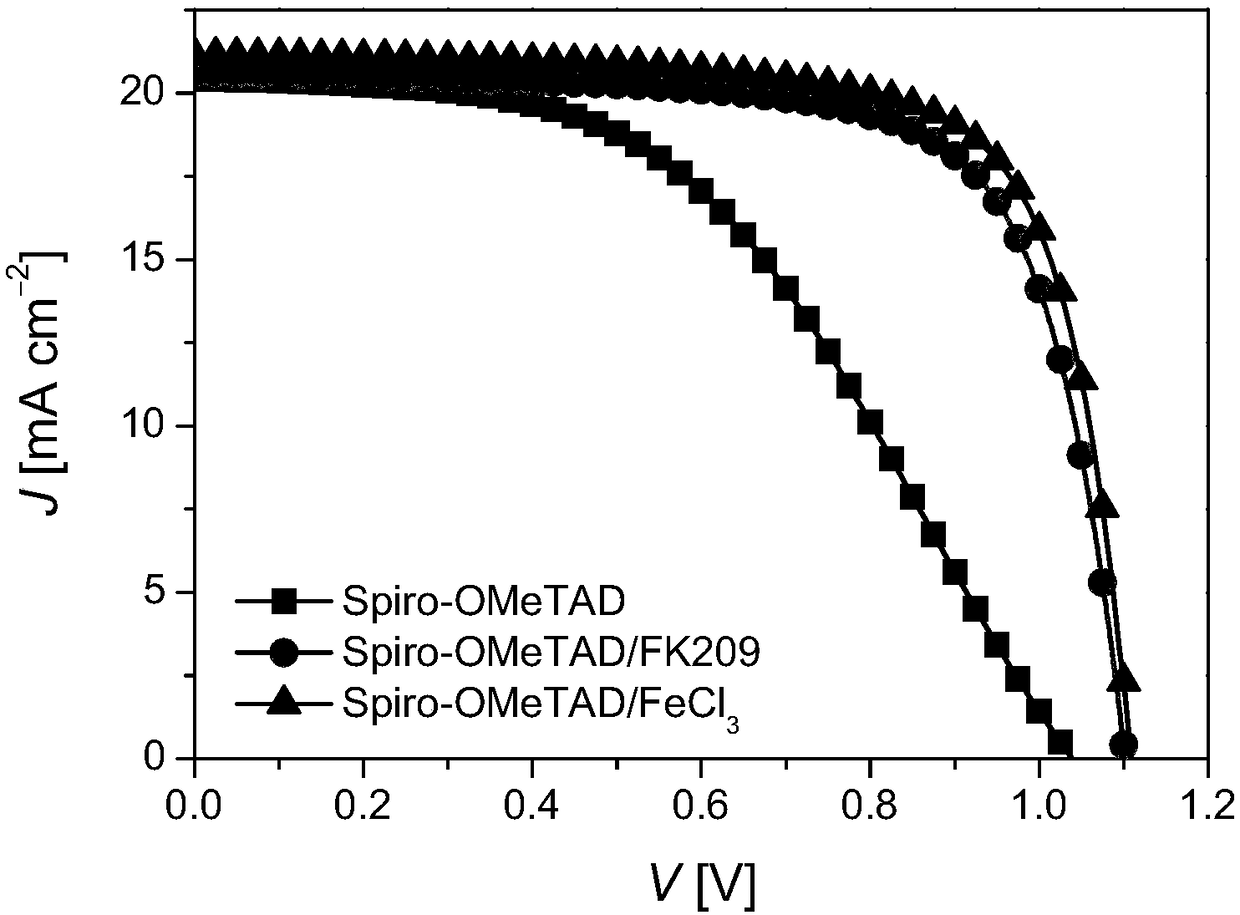

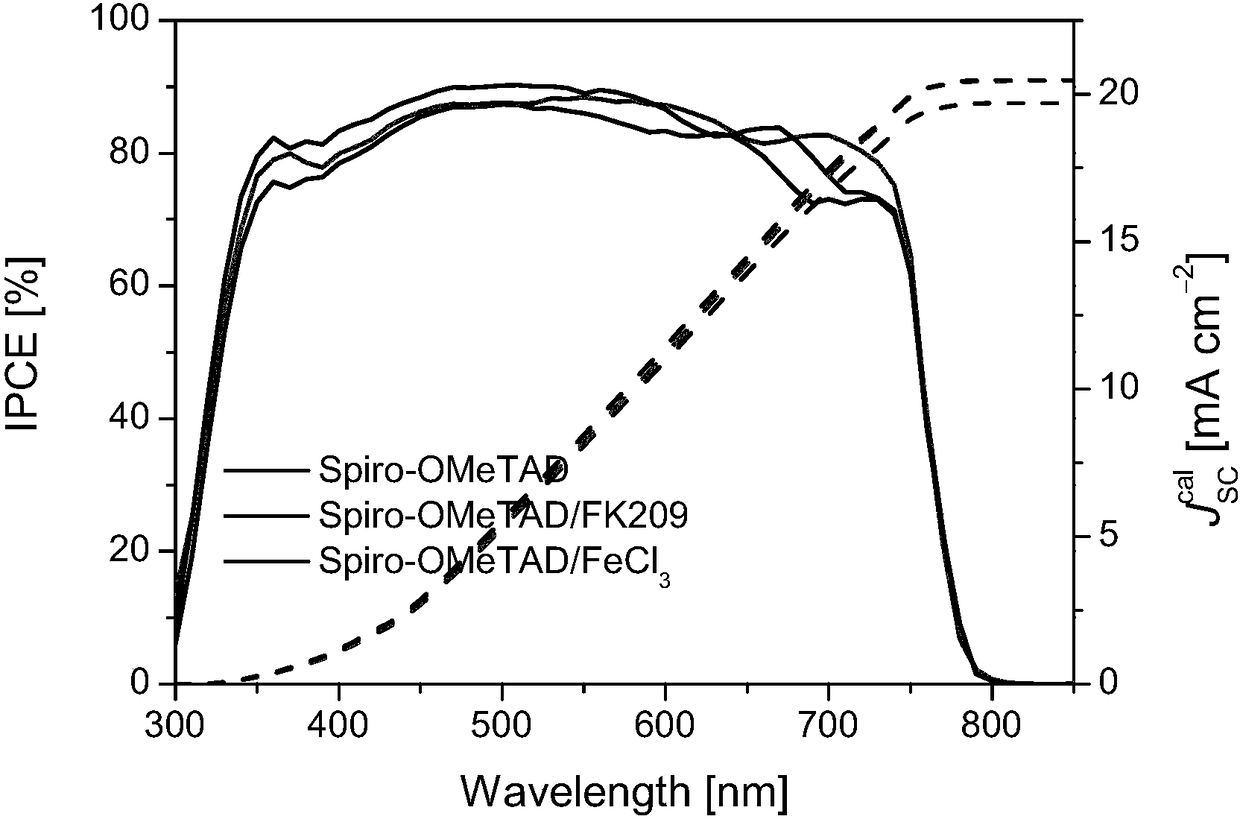

ActiveCN108288675AEffective oxidationLower HOMO levelSolid-state devicesSemiconductor/solid-state device manufacturingDopantTransport layer

The invention discloses a ferric salt-doped Spiro-OMeTAD hole transport layer and a solar cell comprising the hole transport layer. The solar cell comprises a conductive substrate, an electron transport layer, a mesoporous layer, a perovskite layer, a FeCl<3>-doped Spiro-OMeTAD hole transport layer and a metal electrode from the bottom up in sequence. The hole transport layer is obtained by dropwise adding a FeCl<3> solution to an Spiro-OMeTAD solution, and performing spin coating on the perovskite layer with the mixed solution. By adopting FeCl<3> as a dopant to dope the Spiro-OMeTAD, the energy conversion efficiency of the perovskite solar cell can be greatly improved, and the efficiency of a device which adopts the hole transport material can reach 17.2%.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Production method of germinated rice

InactiveCN102599435ASimple production processEasy to implementFood preparationOzone generatorPesticide residue

The invention relates to the technical field of food processing, one of grain deep processing, in particular to a production method of germinated rice. The production method has the following advantages: more particularly, germination of unhusked rice is directly accelerated to prepare germinated unhusked rice and then the germinated unhusked rice is processed into the finished product, namely germinated rice; in the implementation process, the unhusked rice is soaked and sterilized in ozone water solution prepared by an ozone generator and a gas-liquid mixing pump, so that the pesticides on the surface of the unhusked rice can be effectively oxidized, the pesticide residues can be reduced and the quality of the germinated rice product can be guaranteed; after being soaked in cold water and warm water alternately, the unhusked rice is put in the environment with temperature being 30-33 DEG C and relative humidity being 85-90% to undergo germination acceleration to prepare the germinated unhusked rice; the germinated unhusked rice is processed into the germinated rice after being dried in the low temperature state; the comprehensive nutritive indexes of the germinated rice product produced by the method greatly exceed the comprehensive nutritive indexes of the common rice; the germinated rice product has magical effect on improving sub-health of modern people; and the product has low production cost, good effects and good prospect.

Owner:何寒

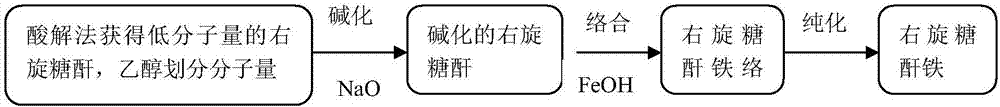

Preparation method of iron-dextrin

ActiveCN107201387AUniform molecular weight distributionHigh quality raw materialFermentationSolubilityIron dextran

The invention discloses a preparation method of iron-dextrin. The preparation method comprises the following steps: preparing low molecular weight dextran through bi-enzyme (dextransucrase-dextranase) synergy, and then oxidizing dextran by taking sodium hypochlorite mixed liquor as an oxidizing agent, so as to obtain an oxidation-type dextran; simultaneously titrating and complexing with weak base and acid-base to prepare iron-dextrin and curing iron-dextrin under the conditions of high temperature and high pH value, so as to obtain cured iron-dextrin; filtering unreacted dextran and micromolecule iron-dextrin and ions therein with biological membranes with different molecular weights, so as to obtain purified iron-dextrin. The iron-dextrin prepared by the invention is uniform in distribution of the molecular weight, high in stability and less in content of impurities. Various indexes of iron-dextrin synthesized by the method conform to the requirements of Chinese pharmacopoeia, and the solubility of iron-dextrin is very good.

Owner:HEFEI UNIV OF TECH

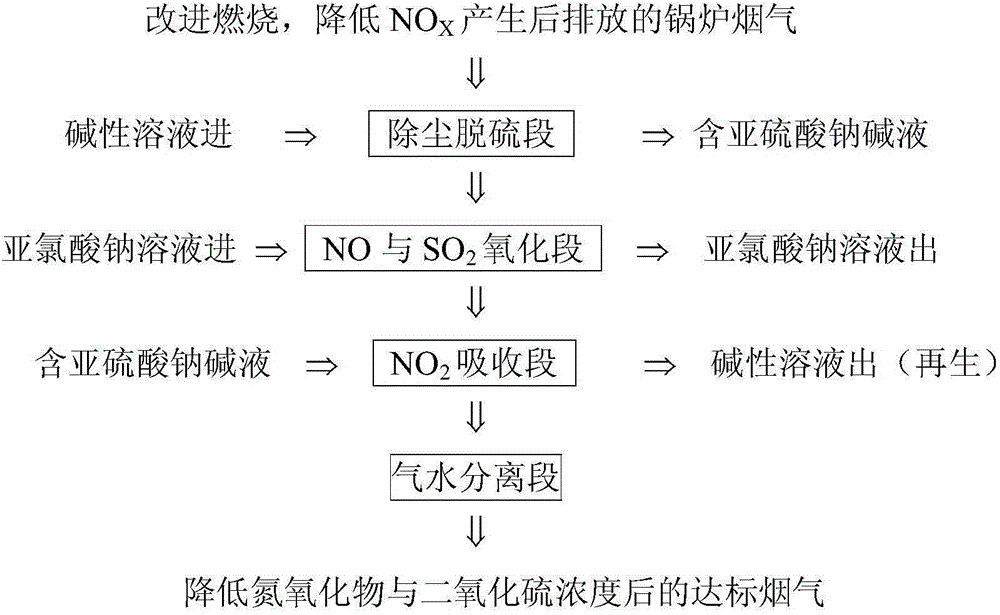

Method for reducing nitrogen oxides in flue gas of medium and small sized industrial coal burning boiler through combination with wet-method sulfur removing technology

InactiveCN104801160ALess investment in equipment transformationLow running costDispersed particle separationChemistryEnvironmental standard

The invention provides a method for reducing nitrogen oxides in flue gas of a medium and small sized industrial coal burning boiler through a wet-method sulfur removing technology. The method comprises the following steps: conducting dust removing and primary sulfur removing on flue gas generated by the coal burning boiler; collecting alkali liquor comprising sulfur removing product sodium sulfite of primary desulfuration according to a dual-alkali method; conducting oxidation treatment on the pretreated flue gas to integrally oxidize NO and residuary sulfur dioxide in the pretreated flue gas; utilizing the oxidized flue gas to get in contact with an alkali liquor, thereby removing nitrogen dioxide and sulfur oxide generated after oxidation in the oxidized flue gas to obtain purified flue gas; conducting gas-water separation to discharge flue gas which meets the environmental standard. Compared with the conventional dry-process flue gas denitration technology, the method provided by the invention has the advantages that desulfurization and denitrification can be simultaneously realized only by additionally arranging an oxidation reactor section in a conventional dual-alkali method absorbing system, so that the economic performance is very high.

Owner:BEIJING YANJING BREWERY

Novel process of acetylene purification and waste acid regeneration

ActiveCN105923610AEffective oxidationReduce pollutionSulfur-trioxide/sulfuric-acidOrganic matterImpurity

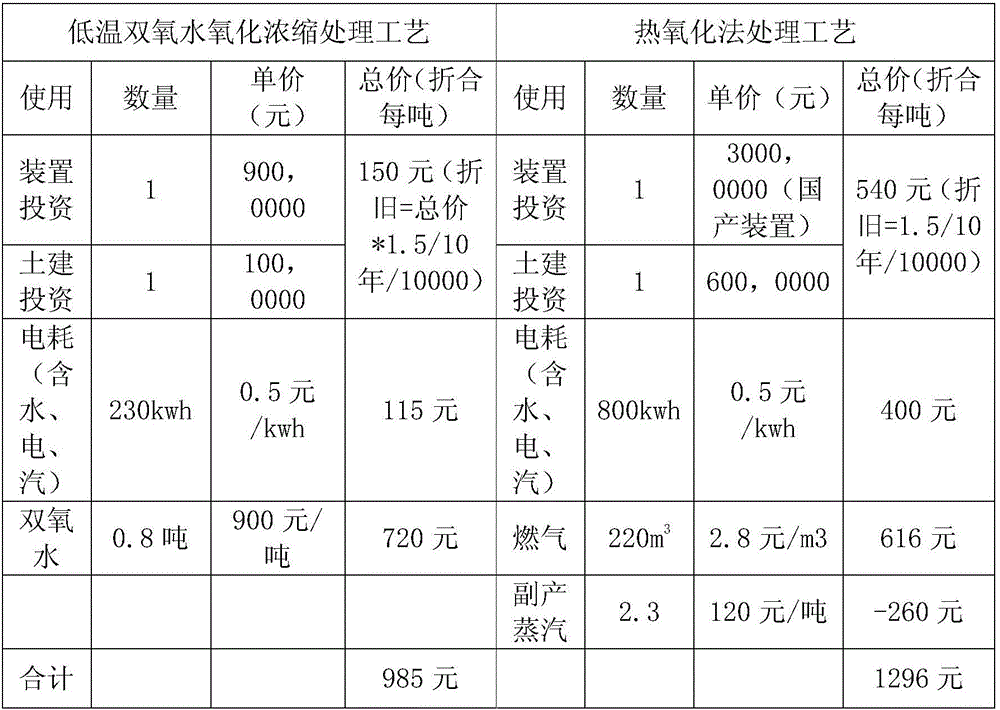

The invention relates to a novel process of acetylene purification and waste acid regeneration. The novel process of acetylene purification and waste acid regeneration comprises a low-temperature oxidation working section and a vacuum concentration working section. Catalyzing is conducted through a catalyst; oxidization is conducted through hydrogen peroxide; organic matter in waste acid can be effectively and completely oxidized; oxidized waste acid is subjected to vacuum concentration, and after being concentrated, the oxidized waste acid can be directly used for the acetylene purification process; the catalyst added in the oxidization process can be regenerated and recycled; no hazardous wastes are generated in the whole process; the oxidation products are carbon dioxide and water; no other impurities are taken in. According to the novel process of acetylene purification and waste acid regeneration, the waste acid recycling regeneration process can be engineering-oriented and can be directly reused for vitriol used in the acetylene purification procedure, and the problem of tri-waste discharge is solved.

Owner:HANGZHOU ZHONGHAO TECH

Material for catalytic decomposition of formaldehyde and organic gas with PDT(photodynamic therapy) and preparation method of material

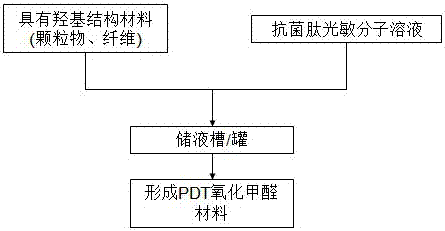

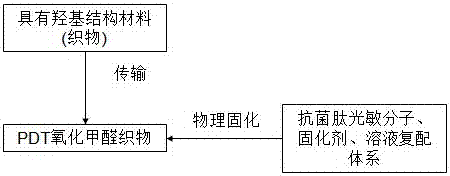

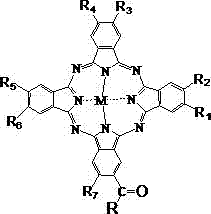

ActiveCN107233923ARealize industrial productionEffective oxidationGas treatmentAntifouling/underwater paintsPhotodynamic therapyCatalytic decomposition

The invention relates to a material for catalytic decomposition of formaldehyde and organic gas with PDT(photodynamic therapy). The material is prepared from antimicrobial peptidephotosensitive molecules and a material with hydroxyl on the surface in one or two of a chemical bonding mode and a physical curing mode. A preparation method of thematerial adopts a simple process and mild reaction conditions and is suitable for industrial production, a final PDT material product with function of catalytic decompositionformaldehyde and organic gas can be applied to preparation of an organic gas purification coating, domestic air purification and industrial air purification.

Owner:SUNDYNAMIC TECH

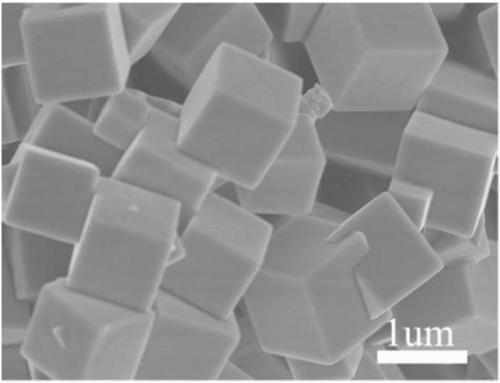

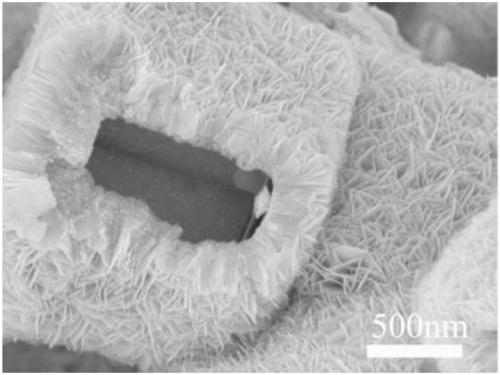

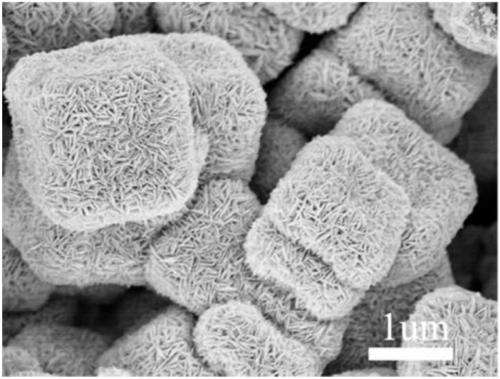

Controllable preparation method and application of Cu7S4-Cu9S8 heterostructure hollow cube catalyst

ActiveCN109465017AThe test method is simpleReduce experiment costPhysical/chemical process catalystsImino compound preparationAmmonium hydroxideChemistry

The invention relates to a controllable preparation method and the application of a Cu7S4-Cu9S8 heterostructure hollow cube catalyst. The invention relates to the field of a catalyst, and particularlyrelates to a controllable preparation method and the application of the Cu7S4-Cu9S8 heterostructure hollow cube catalyst. The invention aims to solve the technical problem of low photocatalytic activity of conventional single copper sulphide. The method comprises the following steps: preparing a cuprous oxide cube by using copper sulfate as a copper source; carrying out stirring at the room temperature in aqueous solution containing ammonium hydroxide by using the cuprous oxide cube as a sacrifice template and using thioacetamide as a sulfur source to prepare Cu2O@Cu7S4-Cu9S8 cube, then removing Cu2O, and carrying out centrifugation, washing and drying to prepare the Cu7S4-Cu9S8 heterostructure hollow cube catalyst. The controllable preparation method has the advantages of simple process,low cost, low environment pollution and simple required equipment. The Cu7S4-Cu9S8 heterostructure hollow cube catalyst prepared by the controllable preparation method, as a catalyst, is applied to oxidize benzylamine into imine under the action of visible light.

Owner:HEILONGJIANG UNIV

Method for preparing nanometer amorphous low-neodymium complex phase neodymium iron boron

The invention discloses a method for preparing nanometer amorphous low-neodymium complex phase neodymium iron boron. According to the method, low-neodymium magnetic phase and nanometer neodymium-rich phase are prepared separately, the prepared low-neodymium magnetic phase alloy powder is in crystal state and is dipped in mineral oil for oxidation protection, the prepared nanometer neodymium-enriched phase alloy powder is amorphous and is not easy to oxidize; the manner can effectively protect the low-neodymium magnetic phase and nanometer neodymium-enriched phase from being deoxidized, so that the content of rare earth is not increased in burdening; furthermore, the method is convenient to realize the purpose of manipulating and controlling micro tissue structure so as to prepare the nanometer low-neodymium complex phase neodymium iron boron, the material cost of neodymium iron boron is greatly lowered, the remanence and energy product of the neodymium iron boron are improved, and the coercivity of the magnet is relatively higher. The method also can regulate the property of the product by the mixing proportion of the low-neodymium magnetic phase powder and nanometer neodymium-rich phase powder, so as to produce different specifications of products and produce different products more conveniently.

Owner:宁波金科磁业有限公司

Environment-friendly compounded denitrification agent and denitrification method

InactiveCN105668810AImprove denitrification effectHigh concentration of ammonia nitrogenWater treatment compoundsWater contaminantsHigh concentrationCompound a

The invention discloses an environment-friendly compounded denitrification agent and a denitrification method, and belongs to the technical field of wastewater denitrification. The environment-friendly compounded denitrification agent is formed by compounding a green surfactant, ethylene glycol deaminase, ferrate and organic carboxylic acid in a certain ratio, wherein the surfactant accounts for 30-70%; ethylene glycol deaminase accounts for 10-20%; ferrate accounts for 5-10%; organic carboxylic acid accounts for 5-30%; hydrogen peroxide accounts for 5-30%. 2-8mg / L of the compounded denitrification agent in the ratio is added into ammonia-nitrogen wastewater, meanwhile the pH value of wastewater is adjusted to 7.0-10.5, and a stage aeration method is adopted for aeration blowoff based on concentration of residual ammonia-nitrogen in wastewater. The environment-friendly compounded denitrification agent is applicable to treatment on high-concentration ammonia-nitrogen and organic nitrogen wastewater, the ammonia-nitrogen concentration of wastewater can be reduced to be less than 0.3mg / L, and the environment-friendly compounded denitrification agent has the advantages that the compounded denitrification agent is environment-friendly, is small in use amount, high in denitrification efficiency and the like.

Owner:NANJING UNIV

Production method of instant Chaozhou beef balls

ActiveCN103431440AExtended shelf lifeGood stickiness and moisturizing effectFood preparationNutrientNutrition

The invention discloses a production method of instant Chaozhou beef balls, which comprises the following production steps: (1) selecting fresh qualified thick flank, removing fascia and fat, (2) grinding the beef with a meat grinder, adding auxiliary materials, and mixing evenly to form beef ball paste, (3) extruding the beef ball paste into semifinished beef balls, (4) grinding wheat tissue protein, then sieving with a 325-mesh sieve to prepare wheat tissue protein powder, intensively mixing the semifinished beef balls and the wheat tissue protein powder, (5) putting 1kg semifinished beef balls in a microwave oven with the output power of 600-800W for curing and shaping, allowing the heating time to be 3-5min, and (6) performing conventional vacuum package and sterilization on the semifinished beef balls to obtain products. The beef balls prepared by the method are nutrient-rich, delicious, succulent, long in shelf life, good in taste and elastic.

Owner:广东真美食品股份有限公司

Treatment method of cyanide-containing electroplating comprehensive wastewater

ActiveCN104402144AStrong oxidation abilityEffective oxidationWater treatment compoundsSpecific water treatment objectivesCombined methodWater quality

The invention discloses a treatment method of cyanide-containing electroplating comprehensive wastewater, which comprises the following steps: (1) taking the cyanide-containing electroplating comprehensive wastewater, adding alkaline liquor, regulating pH (potential of hydrogen) to 8.0-12.0, adding cationic PAM (polyacrylamide), standing for precipitation, taking a supernate for analysis to determine the cyanide concentration, (2) adding the alkaline liquor to the supernate to regulate the pH to 10-14, (3) adding a sodium hypochlorite solution, stirring for reaction, standing for precipitation after the reaction, and taking a supernate, (4) adding concentrated sulfuric acid, regulate the pH to 6.5-7.0, (5) adding the sodium hypochlorite solution, stirring for reaction to form reaction liquid, and (6) adding a ferrate solution into the reaction liquid, stirring, standing for reaction, and filtering to obtain treated wastewater. The method solves the problems that a thiocyanogen compound cannot be removed by a two-step alkaline chlorination method and a sodium pyrosulfite air oxidation-sodium hypochlorite combined method, and the water becomes black when sodium hypochlorite is fed excessively during treatment.

Owner:HUAQIAO UNIVERSITY

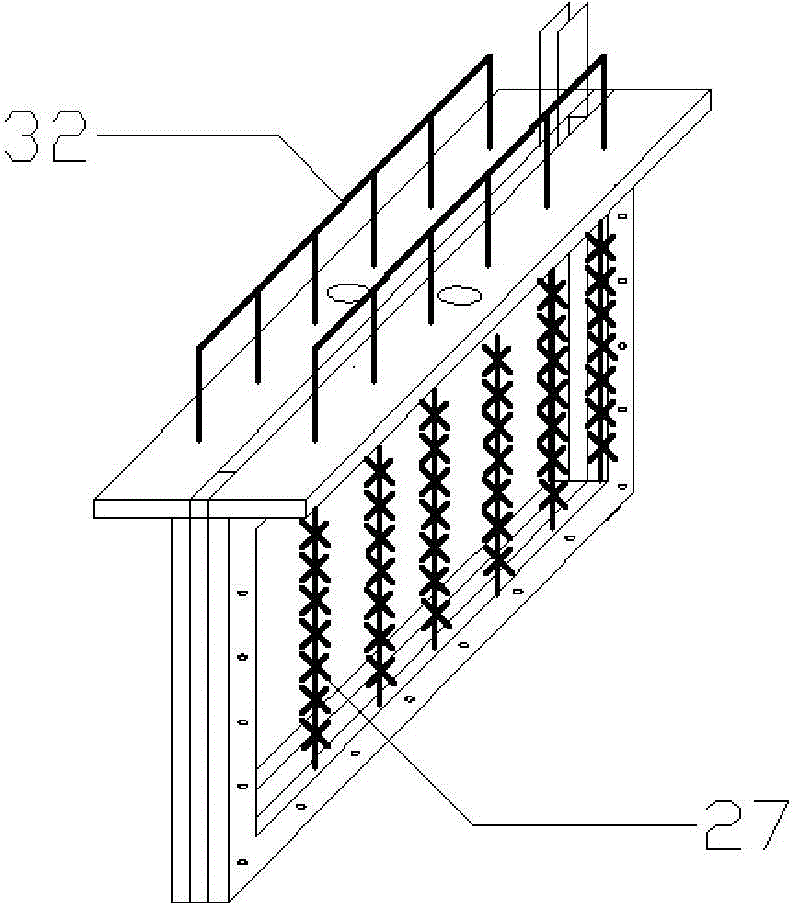

Stack baffling type microbial fuel cell and method for treating waste water and achieving zero energy consumption by using stack baffling type microbial fuel cell

ActiveCN104466216AEffective adhesionGood effectFuel cell auxillariesBiochemical fuel cellsFiberMicrobial fuel cell

The invention relates to a stack baffling type microbial fuel cell and a method for treating waste water and achieving the zero energy consumption by using the stack baffling type microbial fuel cell, relates to a microbial fuel cell and a method for treating the waste water, and aims at solving the problems that a traditional device for treating the waste water has the huge energy consumption and can not be used for effectively recovering energy and the waste water treated by the traditional device can not reach the standard. The stack baffling type microbial fuel cell comprises an open reaction tank body, a biological fuel cell, a water inlet, a water outlet, an insertion opening, a water intake, a water storage tank, a water pump, a high-level water tank, a liquid flowmeter and a sealing cover plate. The method for treating the waste water comprises the following steps that the waste water enters the high-level water tank from the water storage tank by being pumped through the water pump, and the waste water inside the high-level water tank flows into the water inlet of the stack baffling type microbial fuel cell under the action of gravity; the liquid flowmeter controls the flow velocity of the waste water entering the water inlet; the waste water is degraded through microbes attached to anodes of multiple carbon fiber brushes. According to the invention, the stack baffling type microbial fuel cell can be obtained, and the zero energy consumption of beer waste water treatment can be achieved.

Owner:HARBIN INST OF TECH

Amino exhaust smoke purifying method and amino exhaust smoke purifying device

InactiveCN104689705AEffective oxidationReliable crystal qualityDispersed particle separationAmmonium sulfatesAmmonium sulfateSmoke

The invention relates to an amino exhaust smoke purifying method and an amino exhaust smoke purifying device, used for removing aerosol and ammonia escape. The amino exhaust smoke purifying device comprises a washing tower, a purifying tower, a washing circulation tank and a crystal growing tank; exhaust smoke enters the washing tower at first, so that the temperature of the exhaust smoke is lowered and the exhaust smoke absorbs strongly acidic gas; then, the exhaust smoke enters the subsequent purifying tower to absorb weakly acidic gas. The amino exhaust smoke purifying device is characterized in that a dilute ammonium sulphate aqueous solution is used in the purifying tower; the concentration is 5-40%; the pH is 5.3-6.3; thin serous fluid containing ammonium sulphate crystalline solids is used in the washing tower; the solid content of ammonium sulphate is less than 10%; the pH is 1.0-4.5; furthermore, the proportion of the flow of sulphur to the flow of circulation solution in the purifying tower is 50-500 (g / h) / (m3 / h); and the proportion of the flow of circulation solution in the washing tower to the flow of the exhaust smoke is 1.0-10.0 (L / h) / (Nm3 / h). Therefore, the two processes deciding formation of aerosol and ammonia escape are decoupled and controlled effectively; and thus, the whole purifying system is also more safe and reliable to operate and control.

Owner:SHANGHAI JIAO TONG UNIV

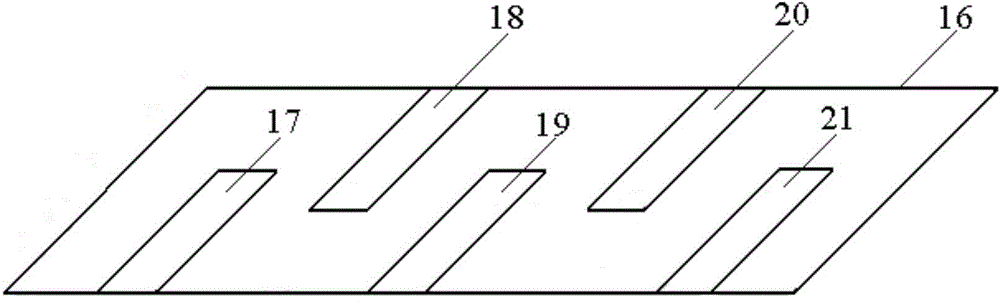

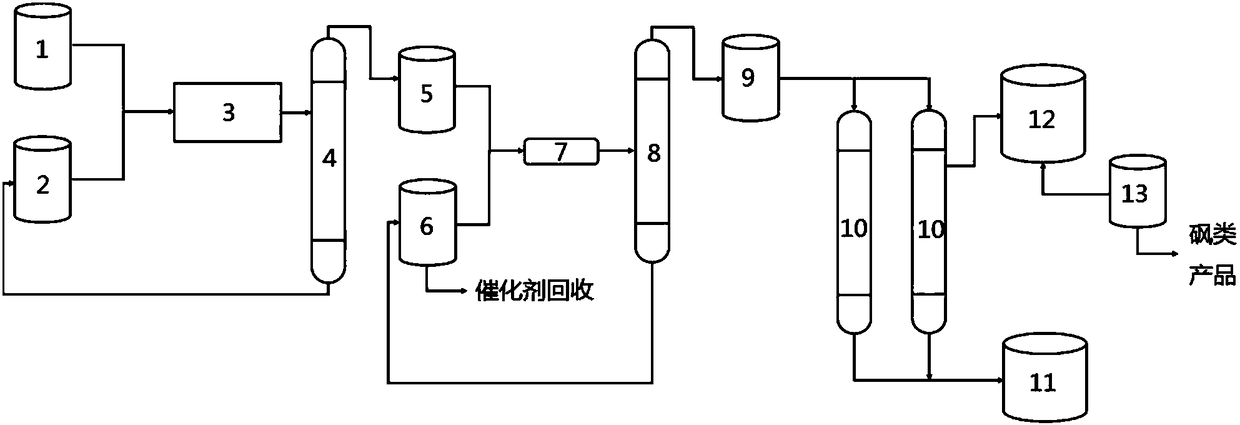

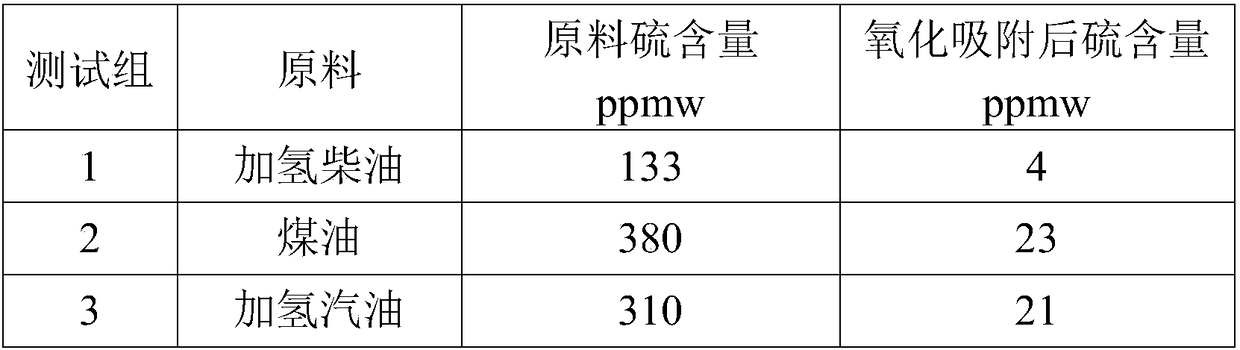

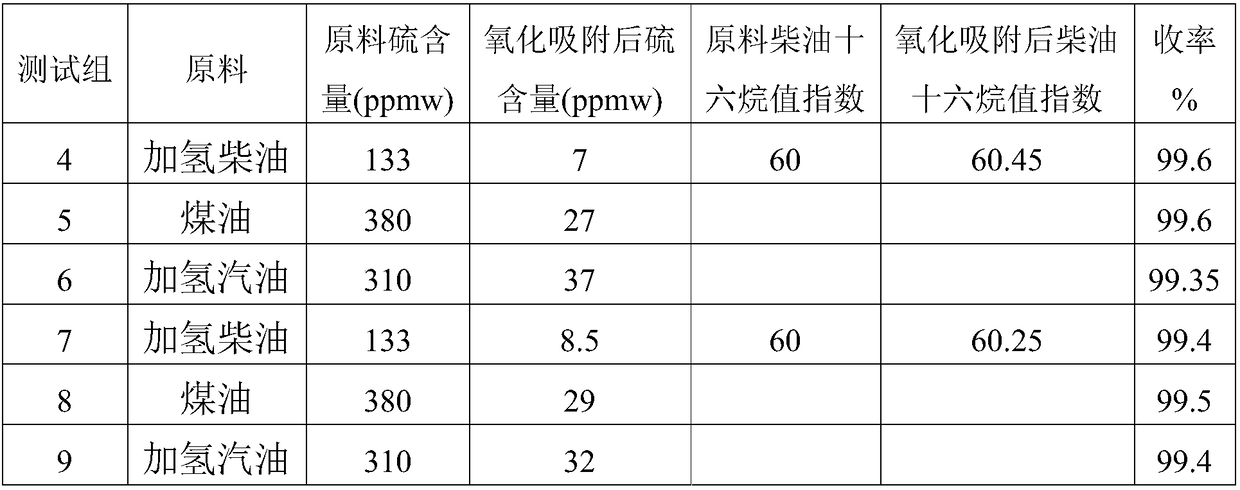

Fuel oxidation adsorption desulfurization technology and device thereof

ActiveCN108264932AEffective oxidationPromote oxidation reactionTreatment with plural serial refining stagesHydrodesulfurizationSorbent

The invention relates to a fuel oxidation adsorption desulfurization technology and a device thereof. A fuel and a water-soluble oxidant are subjected to an oxidation desulfurization reaction in an interface mass transfer enhanced reactor in the presence of a catalyst in order to oxidize most sulfur-containing compounds into sulfone products. The reaction products undergo oil-water separation, thesulfone products are removed by selective adsorption to achieve the purpose of desulfurization, and an adsorbent and the catalyst can be recycled. The technology can realize ultra-deep desulfurization of the fuel under mild conditions, and the octane number and the cetane number of the fuel before and after desulfurization are not significantly changed. The technology has the advantages of cleanprocess, high desulfurization efficiency, and suitableness for large-scale industrial production. The technology can be combined with an existing hydrodesulfurization technology to produce a clean fuel that meets national V sulfur index requirements. The method has the characteristics of simple and clean process, high desulfurization rate, no significant loss of the octane number or the cetane number, and easiness in industrial application.

Owner:DALIAN UNIV OF TECH +1

Preparation method of high-concentration evenly-dispersed carbon nano tube suspension liquid

ActiveCN106276850AEffective oxidationEffective surface modificationMaterial nanotechnologyHigh concentrationModified carbon

The invention belongs to the technical field of carbon nano tube surface modification and particularly relates to a preparation method of high-concentration evenly-dispersed carbon nano tube suspension liquid. The method includes the steps that firstly, to-be-modified carbon nano tubes are mixed with a concentrated sulfuric acid and concentrated nitric acid mixed acid solution according to the proportion of 1 g:(20-50) ml, the mixture is heated to 80-100 DEG C and then subjected to reflux condensation for 6-8 hours for surface modification, the mixture is naturally cooled and then washed with deionized water for dilution, the modified carbon nano tubes are centrifugally separated out, finally, water is added, the material is prepared into suspension liquid, the pH is adjusted to range from 7 to 12, and the carbon nano tube suspension liquid with the mass fraction being about 10% is obtained. The suspension liquid prepared through the method is high in concentration and even in dispersion, does not contain excessive organic surfactant, and does not settle after still standing for 3 months.

Owner:湖北迪洁膜科技有限责任公司

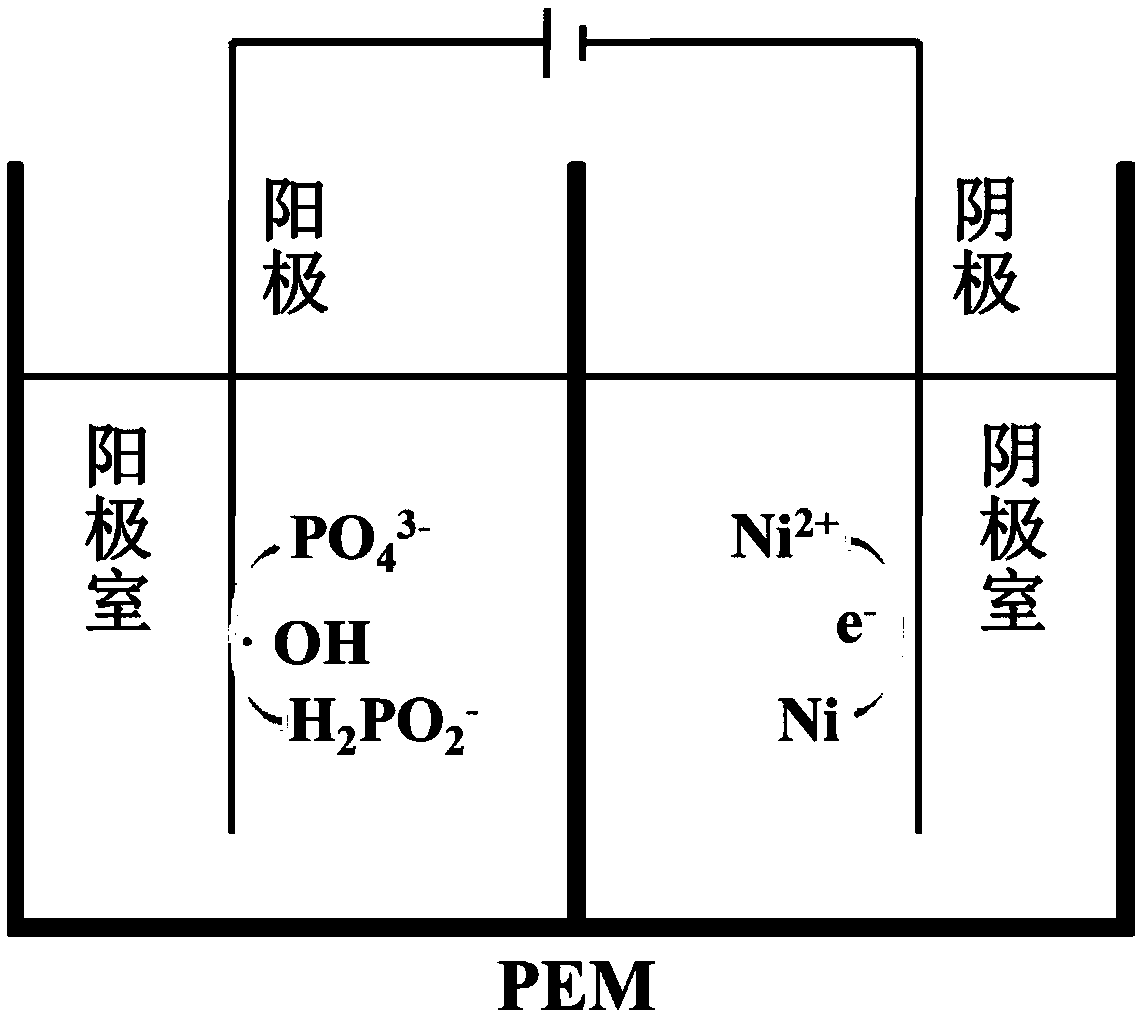

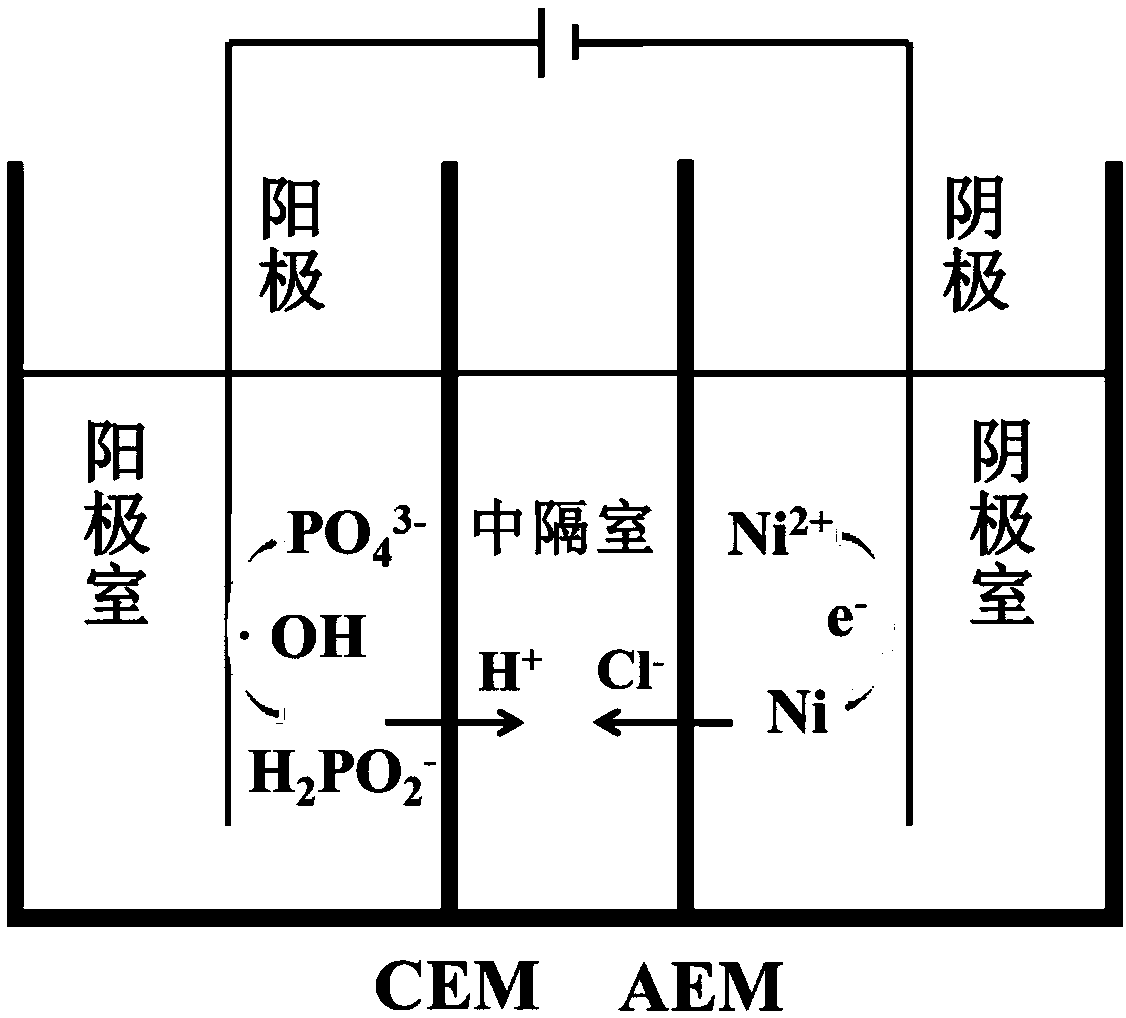

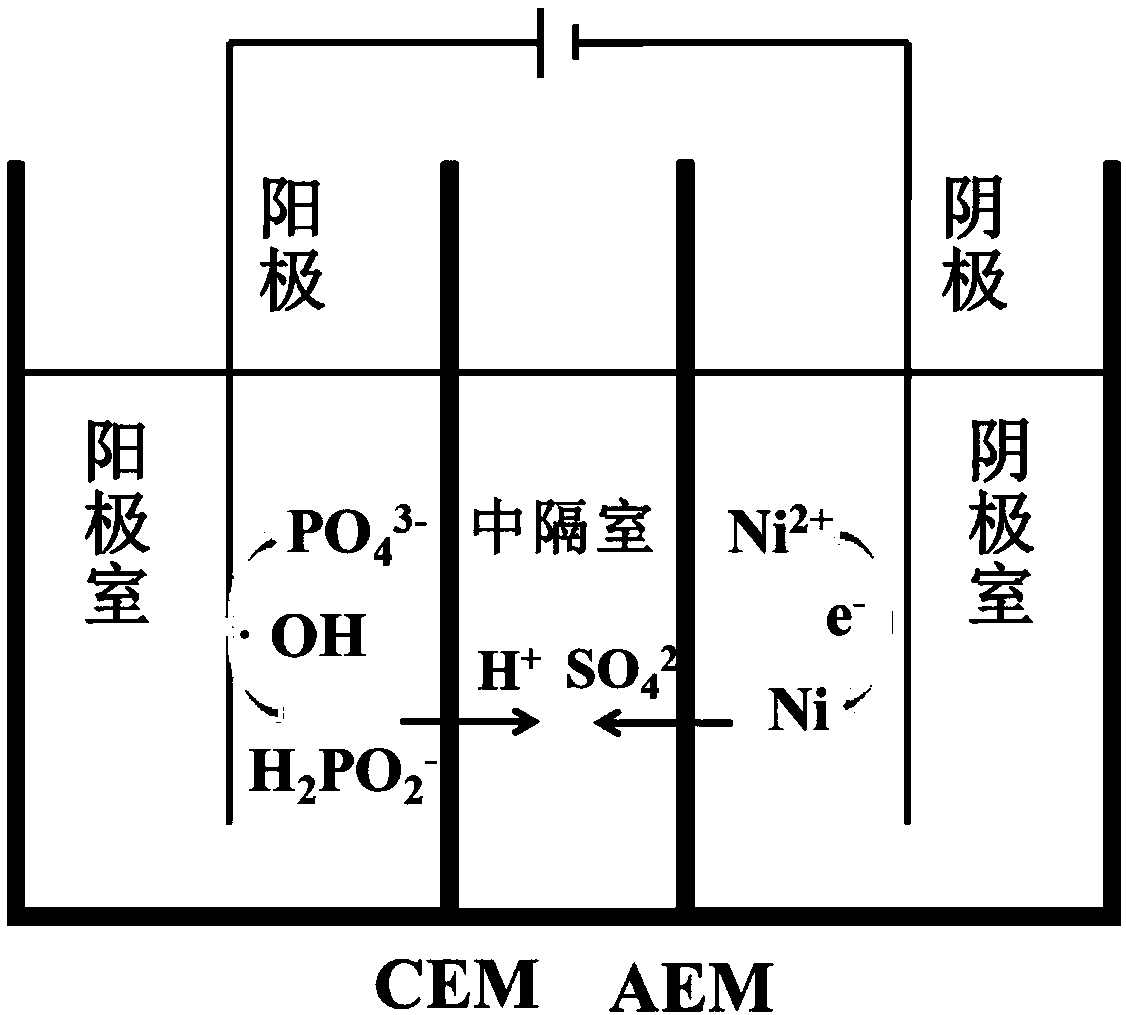

Method for recycling heavy metal nickel from chemical nickel-plating waste water

InactiveCN108658320AEffective oxidationPhotography auxillary processesWater contaminantsHigh concentrationCatalytic oxidation

The invention discloses a method for recycling heavy metal nickel from chemical nickel-plating waste water. The method comprises the following steps: adsorbing the heavy metal nickel which is enrichedin chemical nickel-plating cleaning waste water through ion exchange resin to obtain waste water which contains hypophosphorus; carrying out elution and regeneration on the ion exchange resin to obtain regenerated liquid which contains nickel ions; and carrying out electrochemical catalytic oxidation on the waste water which contains the hypophosphorus, and carrying out electroreduction on the regenerated liquid which contains the nickel ions so as to recycle metallic nickel. Oxidation of the hypophosphorus and synchronous recycling of high-concentration nickel ions can be realized by an electrochemical catalytic oxidation technology, the hypophosphorus in the waste water can be effectively converted into orthophosphorus, and phosphorus is recycled by addition of a precipitator; and the heavy metal nickel can be recycled by electroreduction while the hypophosphorus is oxidized, and the method has the advantages of simplicity, high efficiency, economy and easiness in application in engineering.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com