Aminogroup smoke exhaust purification method and device thereof

A technology for ammonia and purification towers, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as easy to occur, unsolved ammonia escape loss, large ammonia escape loss, etc., to achieve effective oxidation, operation and operation Controlling safe and reliable, crystallized quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The amino smoke exhaust purification device and method of the present invention are applied to a smoke exhaust purification process, and the treated flue gas volume is 100,000 Nm 3 / h, the sulfur dioxide content in the flue gas is 3000mg / Nm 3 , the content of sulfur trioxide is 50mg / Nm 3 , the hydrogen chloride content is 25mg / Nm 3 , NO 2 The content is 50mg / Nm 3 , NO content is 320mg / Nm 3 , the dust content is 80mg / Nm 3 , the flue gas temperature is 135°C.

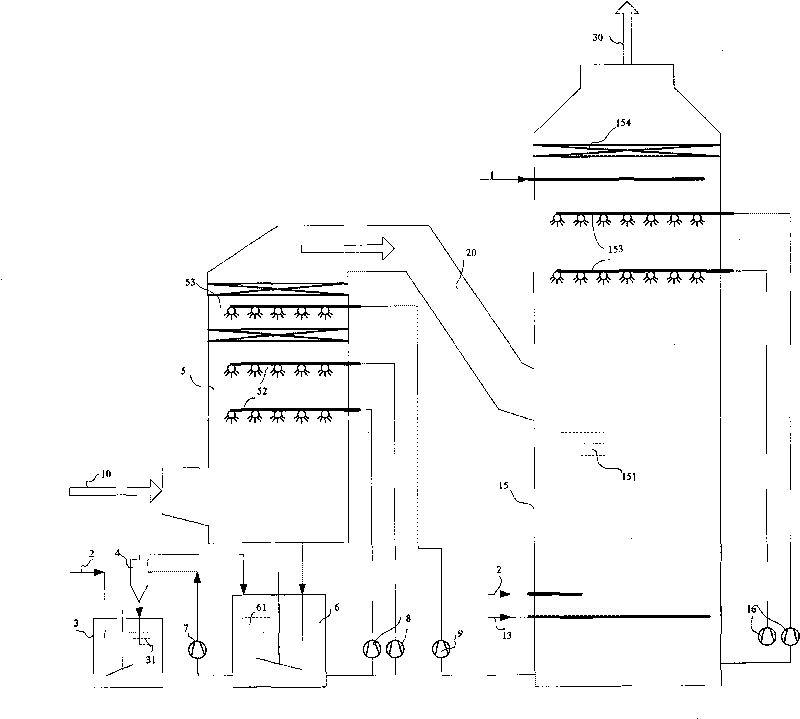

[0054] Use as attached figure 1 As shown in the amino smoke exhaust purification device of the present invention, the washing tower 5 is a vertically installed spray tower with a diameter of 3.6m, and the purification tower 15 is an inverse sulfur tower with a diameter of 3.6m. The described smoke exhaust purification method is implemented according to the following steps:

[0055] 1) The original flue gas 10 enters the washing tower 5 to cool down to 55°C, removes dust, and absorbs strong acid gases such a...

Embodiment 2

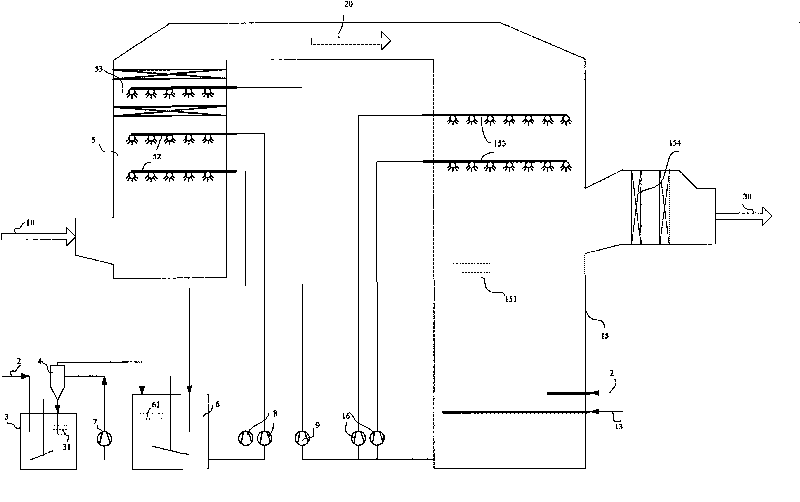

[0070] Other conditions of the flue gas are the same as in Example 1, except that the content of sulfur dioxide in the flue gas is higher, reaching 12000mg / Nm 3 , the content of sulfur trioxide reaches 150mg / Nm 3 , using the attached figure 2 The shown amino smoke exhaust purification device of the present invention, that is, the washing tower 5 is a vertically installed spray tower, and the purification tower 15 is a downstream tower, and the diameter of the two towers is 3.6m. Implementation steps are also the same as in Example 1.

[0071] In addition, the raw material ammonia 2 enters the oxidation tank at the lower part of the purification tower 15 with a flow rate of 628.5kg / h, and the oxidation air 13 also enters the oxidation tank with a flow rate of 50Nm 3 / min, the process water 1 also enters the oxidation tank with a flow rate of 4.5m 3 / h, obtain described dilute ammonium sulfate aqueous solution 151 and store in the oxidation pond of described purification tow...

Embodiment 3

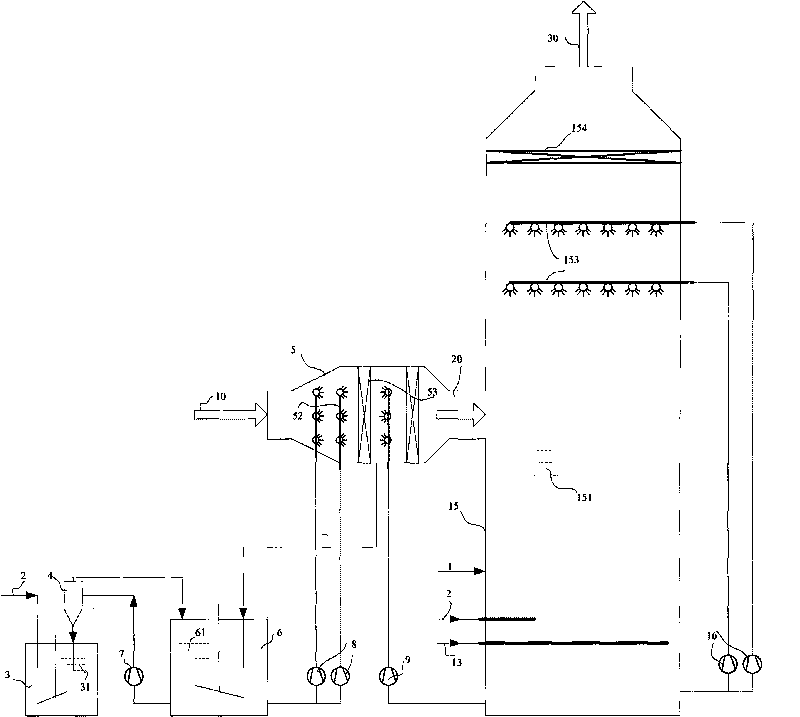

[0078] Other conditions of flue gas are identical with embodiment 1, have adopted as attached image 3 The shown amino smoke exhaust purification device of the present invention, that is, the washing tower 5 is a horizontally installed spray tower, and the purification tower 15 is a countercurrent tower with a diameter of 3.6m and a height of 35m. Moreover, the special feature of this embodiment is that the flue gas outlet on the top of the purification tower is directly connected with a straight chimney, and the height of the straight chimney is 60m. Implementation steps are the same as in Example 1.

[0079] In the present embodiment, the purification efficiency reaches 96.5%, and the ammonia escape amount in the purification exhaust gas 30 is 3.5mg / Nm 3 , the sulfur dioxide content is 98mg / Nm 3 , there is no obvious aerosol phenomenon, and the smoke plume basically disappears when the length of the smoke plume is about 100m. The effect is very obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com