Material for catalytic decomposition of formaldehyde and organic gas with PDT(photodynamic therapy) and preparation method of material

A technology for catalytic decomposition of organic gases, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as formaldehyde and other organic gases exceeding the standard, achieve the effects of changing water solubility, expanding application fields, and facilitating industrial operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

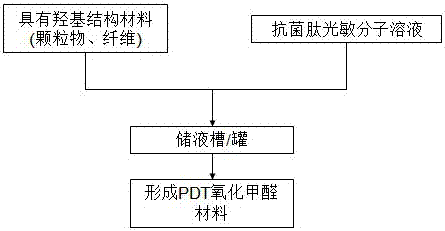

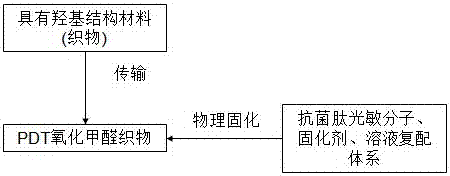

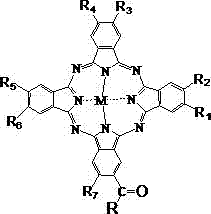

Method used

Image

Examples

Embodiment 1

[0088] In the first step, soak 1kg of activated carbon in 100ml 0.01wt% antimicrobial peptide photosensitive molecule (manufacturer: Qingdao Sunshine Power Biomedical Technology Co., Ltd.) solution, or spray 100ml 0.01wt% antimicrobial peptide photosensitive molecule solution on the surface of 1kg activated carbon, After the antimicrobial peptide photosensitive molecules are on the surface of the activated carbon, it is preferable to wash with water to remove the unadsorbed antimicrobial peptide photosensitive molecules;

[0089]The second step is to dry or dry at 50°C to obtain the PDT catalytic decomposition of formaldehyde and organic gas activated carbon particles of the present invention.

Embodiment 2

[0091] In the first step, soak 1kg ceramics in 100ml 10wt% antimicrobial peptide photosensitive molecules (manufacturer: Qingdao Sunshine Power Biomedical Technology Co., Ltd.) solution, or spray 100ml 10wt% antimicrobial peptide photosensitive molecule solution on 1kg ceramics, and the antimicrobial peptides After the photosensitive molecules arrive on the ceramic surface, it is preferable to wash with water to remove the unadsorbed antimicrobial peptide photosensitive molecules;

[0092] The second step is drying or oven-drying at 90° C. to obtain the PDT catalytic decomposition of formaldehyde and organic gas ceramic particles according to the present invention.

Embodiment 3

[0094] In the first step, soak 1kg microcrystalline cellulose in 100ml 50wt% antimicrobial peptide photosensitive molecule (Qingdao Sunshine Power Biomedical Technology Co., Ltd.) solution, or spray 100ml 50wt% antimicrobial peptide photosensitive molecule solution on 1kg microcrystalline cellulose, After the antimicrobial peptide photosensitive molecules are on the surface of the microcrystalline cellulose, it is preferable to wash with water to remove the unadsorbed antimicrobial peptide photosensitive molecules;

[0095] The second step is drying or oven-drying at 120° C. to obtain the PDT catalytic decomposition of formaldehyde and organic gas microcrystalline cellulose particles according to the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com