Preparation method of iron-dextrin

A technology for iron dextran and dextran, which is applied in the field of preparation of iron dextran, can solve the problems of uneven molecular weight distribution of dextran raw materials, low iron and iron dextran content, serious environmental pollution, etc., and achieves easy control of process conditions, fewer processes, and reduced ion content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

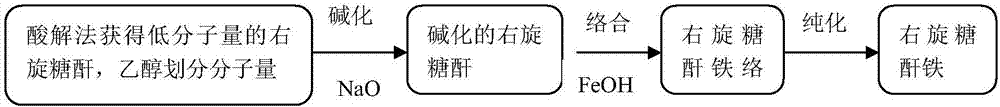

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of iron dextran in the present embodiment is as follows:

[0029] 1. Using sucrose as a substrate, synthesize high molecular weight dextran in the presence of dextran sucrase, and then add dextranase to degrade high molecular weight dextran to obtain dextran with a molecular weight of 5000-7500Da; the concentration of sucrose in the reaction system is 300mg / mL, and the dextran The concentration of invertase is 3.0U / mL, the concentration of dextranase is 3.0U / mL, the reaction temperature is 35°C, and the reaction time is 250-300min;

[0030] 2. Add 24g of low-molecular-weight dextran obtained in step 1 into a three-neck flask, add 60ml of pure water, dissolve, raise the temperature to 35°C, adjust the pH value to 5-12 with 20% (w / w) NaOH solution, and then drop Add 36ml of sodium hypochlorite mixed solution (active chlorine content is 5%) and maintain the pH value at 5-12 during the dropwise addition of sodium hypochlorite mixed solution, and perfo...

Embodiment 2

[0034] The preparation method of iron dextran in the present embodiment is as follows:

[0035] 1. Using sucrose as a substrate, synthesize high molecular weight dextran in the presence of dextran sucrase, and then add dextranase to degrade high molecular weight dextran to obtain dextran with a molecular weight of 5000-7500Da; the concentration of sucrose in the reaction system is 300mg / mL, and the dextran The concentration of sucrase is 3.0 U / mL, the concentration of dextranase is 3.0 U / mL, the reaction temperature is 35° C., and the reaction time is 250-300 min.

[0036] 2. Add 24g of low-molecular-weight dextran obtained in step 1 into a three-neck flask, add 70ml of pure water, dissolve, raise the temperature to 45°C, adjust the pH value to 5-12 with 20% (w / w) NaOH solution, and then drop Add 26ml of sodium hypochlorite mixed solution (active chlorine content is 5%) and maintain the pH value at 5-12 during the dropwise addition of sodium hypochlorite, and oxidize at 45°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com