Novel process of acetylene purification and waste acid regeneration

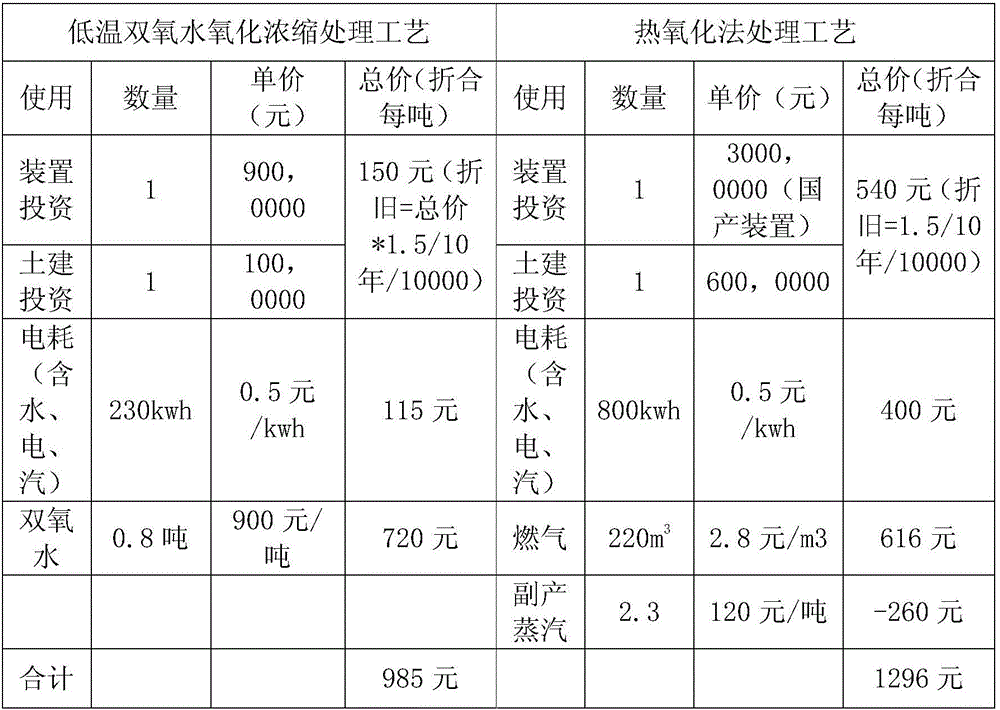

An acetylene cleaning and new process technology, applied in sulfur trioxide/sulfuric acid, inorganic chemistry, non-metallic elements, etc., to achieve the effect of reducing investment costs and operating costs, and reducing equipment use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

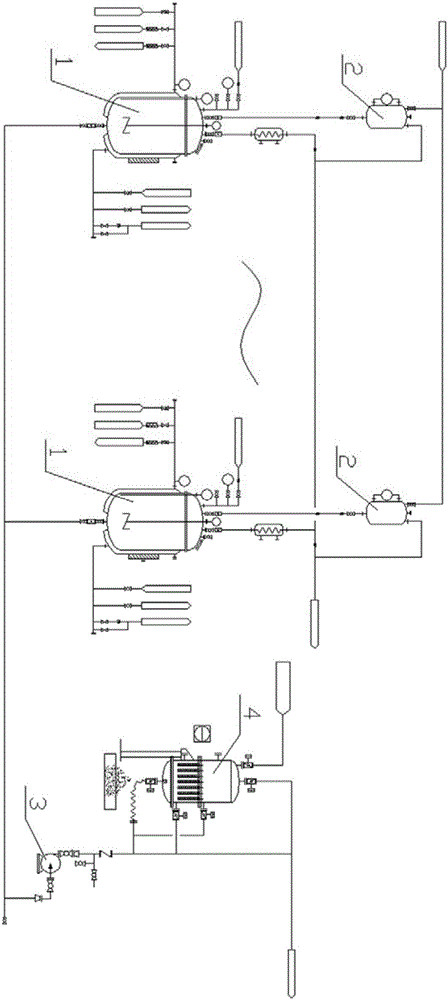

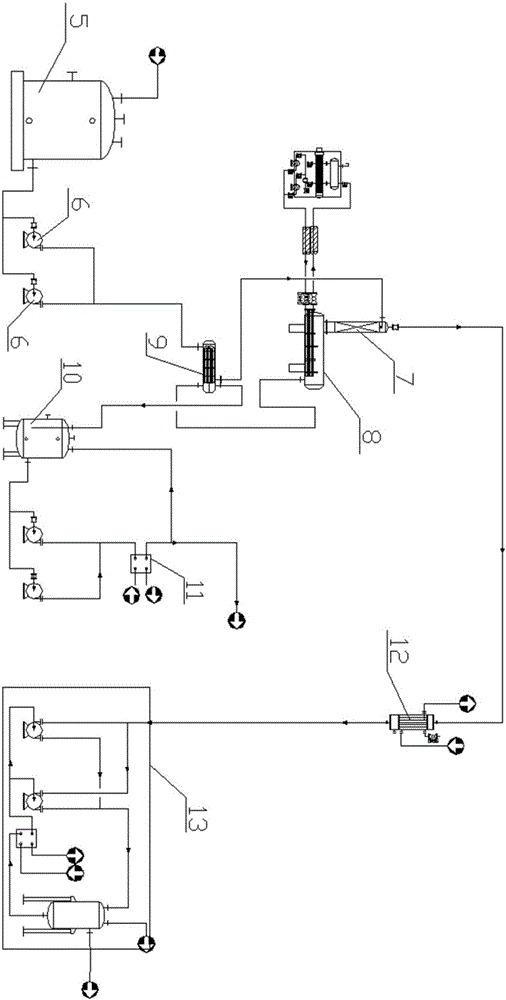

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection of the present invention is not limited thereto.

[0036] refer to figure 1 , figure 2 , a new process for regeneration of acetylene cleaning waste acid, comprising a low-temperature oxidation section and a vacuum concentration section, the low-temperature oxidation section includes the following steps:

[0037] (1) Add acetylene-clean waste acid (black, COD is 400,000 ppm) into reactor 1, open the steam valve, and heat up to 80°C;

[0038] (2) Add a non-metallic oxide carbon-based catalyst in the reactor 1, the amount of which is 0.2% of the total mass, and stir at 80° C. for 1.5 hours;

[0039] (3) Add a certain amount of hydrogen peroxide in the hydrogen peroxide metering tank 2, open the connecting valve of the metering tank and the reactor and drip hydrogen peroxide, the hydrogen peroxide dripping amount is 0.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com