Fuel-lean vehicular engine exhaust gas catalyzing and purifying method

A vehicle engine and catalytic purification technology, which is applied to combustion engines, internal combustion piston engines, chemical instruments and methods, etc., can solve the problems of far-flung practical requirements, poor selectivity and high active temperature, and achieves widening the active temperature range, The effect of reducing dosage and improving NOx conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

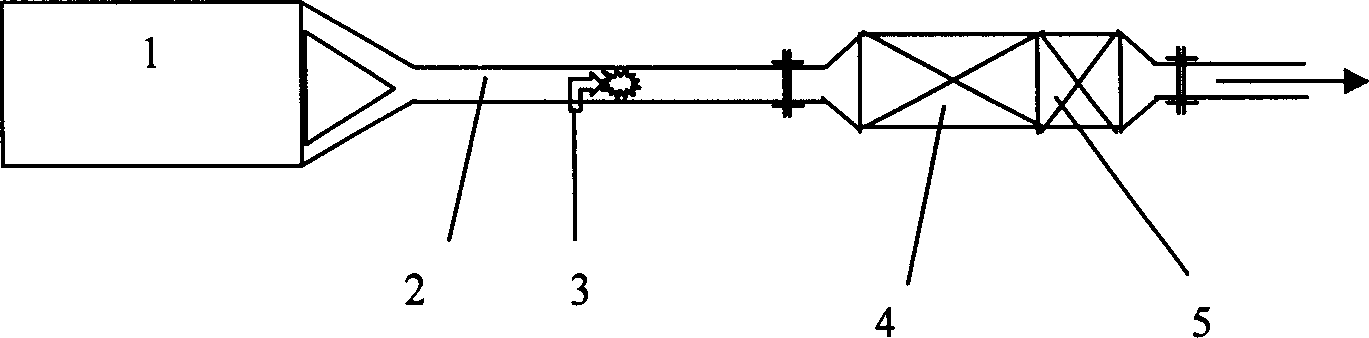

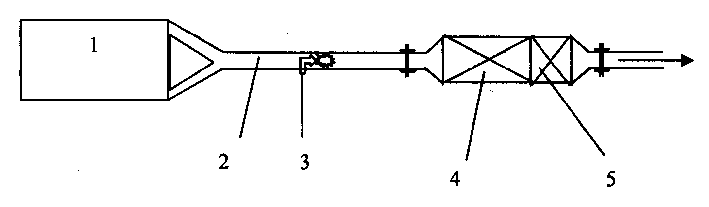

Image

Examples

Embodiment 1

[0022] Simulate lean-burn vehicle engine exhaust from 1000ppm NO, 1000ppm C 3 h 6 , 3000ppm CO, 8% O 2 , 1%H 2 O, 100ppmSO 2 and N 2 Composition, the external reducing agent is CH 3 OH, its concentration is 2200ppm. The composite catalyst consists of Ag / Al 2 o 3 and Pt / Al 2 o 3 Composed in series, the two catalysts are prepared by a sol-gel mixing method, and the weight percentages of Ag and Pt are 5% and 2% respectively. When the airspeed is 33,000h -1 , when the reaction temperature is 230-500°C, the NOx conversion rate is higher than 60%, and above about 250°C, HC and CO can be completely oxidized to CO 2 and H 2 O.

Embodiment 2

[0024] Simulate lean-burn vehicle engine exhaust from 1000ppm NO, 1000ppm C 3 h 6 , 8% O 2 , 1%H 2 O, 100ppmSO 2 and N 2 Composition, the external reducing agent is C 2 h 5 OH, its concentration is 2300ppm. The composite catalyst consists of Ag / Al 2 o 3 and Pt / Al 2 o 3 Composed in series, the two catalysts are prepared by a sol-gel mixing method, and the weight percentages of Ag and Pt are 5% and 2% respectively. When the airspeed is 33,000h -1 , when the reaction temperature is 300-550°C, the conversion rate of NOx is higher than 60%, and above about 300°C, HC can be completely oxidized.

Embodiment 3

[0026] Simulate lean-burn vehicle engine exhaust from 1000ppm NO, 600ppm C 3 h 6 , 8% O 2 , 5000ppm CO, 1% H 2 O, 100ppmSO 2 and N 2 Composition, the external reducing agent is CH 3 OH, its concentration is 3500ppm. The composite catalyst consists of Sn / Al 2 o 3 and Pt / Al 2 o 3 Composed in series, the two catalysts are prepared by a sol-gel mixing method, and the weight percentages of Sn and Pt are 5% and 2% respectively. When the airspeed is 33,000h -1 , when the reaction temperature is 200-550°C, the NOx conversion rate is higher than 60%, and above about 250°C, HC and CO can be completely oxidized to CO 2 and H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com