Denitration catalyst

A denitration catalyst and catalyst technology, applied in the field of denitration catalysts, can solve the problems of low N2 selectivity and poor tolerance at high temperature, and achieve the effects of high NOx conversion rate, good denitration effect, and strong water resistance and SO2 resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

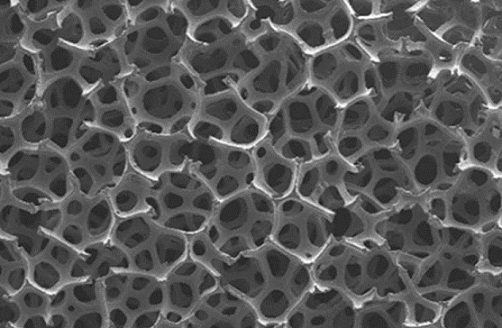

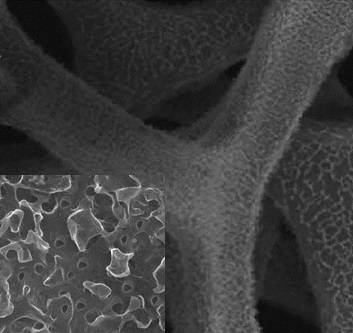

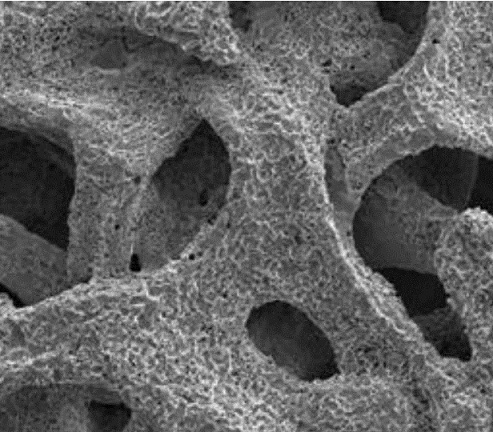

Image

Examples

Embodiment 1

[0055] A denitration catalyst prepared by the following steps:

[0056] (1) Surface cleaning pretreatment with titanium foam as the base material: Surface cleaning treatment includes the following steps:

[0057] (a) Degreasing: 25wt.% sodium silicate, 20wt.% sodium hydroxide, 5wt.% sodium carbonate, temperature 65 o C, stir and wash for 7 minutes. (b) Pickling: 30wt.% nitric acid, 3% hydrofluoric acid, room temperature, 1min.

[0058] (c) Wash with water, rinse with deionized water.

[0059] (2) Put the pretreated foamed titanium in a hydrothermal reaction kettle, use nitrogen to evacuate the oxygen in the reaction kettle, the hydrothermal reaction solution is a mixture of hydrofluoric acid and malic acid, cool naturally, wash with water, Vacuum dry.

[0060] The hydrothermal parameters: at 180 o C for 12 hours, the hydrothermal reaction solution is 1wt.% HF and 0.3wt.% malic acid aqueous solution, and the hydrothermal solution accounts for 60% of the volume of the react...

Embodiment 2

[0071] A denitration catalyst prepared by the following steps:

[0072] (1) Surface cleaning pretreatment with titanium foam as the base material: Surface cleaning treatment includes the following steps:

[0073] (a) Degreasing: 25wt.% sodium silicate, 20wt.% sodium hydroxide, 5 wt.% sodium carbonate, temperature 65 o C, stir and wash for 7 minutes. (b) Pickling: 30wt.% nitric acid, 3% hydrofluoric acid, room temperature, 2min.

[0074] (c) Wash with water, rinse with deionized water.

[0075] (2) Put the pretreated foamed titanium in a hydrothermal reaction kettle, use nitrogen to evacuate the oxygen in the reaction kettle, the hydrothermal reaction solution is a mixture of hydrofluoric acid and malic acid, cool naturally, wash with water, Vacuum dry.

[0076] The hydrothermal parameters: at 200 o C for 18 hours, the hydrothermal reaction solution was 1.25wt.% HF and 0.4wt.% malic acid aqueous solution, and the hydrothermal solution accounted for 65% of the volume of the...

Embodiment 3

[0087] A denitration catalyst prepared by the following steps:

[0088] (1) Surface cleaning pretreatment with titanium foam as the base material: Surface cleaning treatment includes the following steps:

[0089] (a) Degreasing: 25wt.% sodium silicate, 20wt.% sodium hydroxide, 5 wt.% sodium carbonate, temperature 65 o C, stir and wash for 7 minutes. (b) Pickling: 30wt.% nitric acid, 3% hydrofluoric acid, room temperature, 2min.

[0090] (c) Wash with water, rinse with deionized water.

[0091] (2) Put the pretreated foamed titanium in a hydrothermal reaction kettle, use nitrogen to evacuate the oxygen in the reaction kettle, the hydrothermal reaction solution is a mixture of hydrofluoric acid and malic acid, cool naturally, wash with water, Vacuum dry.

[0092] The hydrothermal parameters: at 200 o C for 18 hours, the hydrothermal reaction solution was 1.25wt.% HF and 0.4wt.% malic acid aqueous solution, and the hydrothermal solution accounted for 65% of the volume of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com