Controllable preparation method and application of Cu7S4-Cu9S8 heterostructure hollow cube catalyst

A heterogeneous structure, cube technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, imino compound preparation, etc., can solve the problem of low photocatalytic activity of single copper sulfide, and achieve simple and easy test method, shape Uniform appearance and low experimental cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

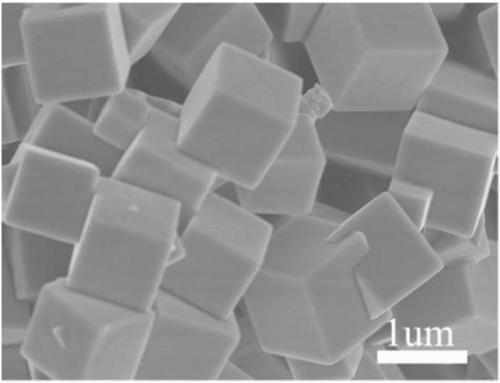

[0036] Specific embodiment one: this embodiment is a kind of Cu 7 S 4 -Cu 9 S 8 The controllable preparation method of the heterostructure hollow cube catalyst is specifically carried out as follows:

[0037] 1. Preparation of cuprous oxide cubes: first dissolve copper sulfate in disodium ethylenediaminetetraacetate solution, then add glucose, stir well, add sodium hydroxide, and stir in a water bath to obtain a precipitate. Wash the material with ethanol, then centrifuge and dry;

[0038] 2. Vulcanization: Disperse the precipitate treated in step one in water, then add sulfur source and ammonia water, mix and stir to obtain a uniform solution;

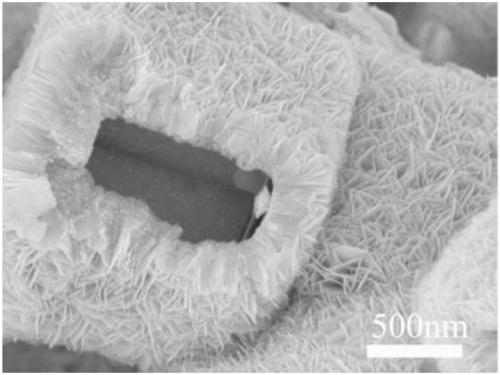

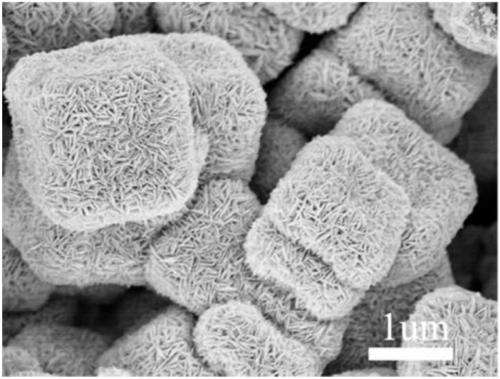

[0039] 3. The solution obtained in step 2 is subjected to mechanical stirring reaction at room temperature to obtain Cu 2 O@Cu 7 S 4 -Cu 9 S 8 cube;

[0040] 4. Separation, washing and drying: the Cu obtained in step 3 2 O@Cu 7 S 4 -Cu 9 S 8 The cube was washed with ethanol, then centrifuged and dried;

[0041] Five, except for Cu 2 O: Dispers...

specific Embodiment approach 2

[0043] Specific embodiment two: this embodiment is different from specific embodiment one in that in step two, 25-35 mg of the precipitate is dispersed into 80 mL of water. Others are the same as the first embodiment.

specific Embodiment approach 3

[0044] Specific embodiment three: this embodiment is different from specific embodiment one or two in that in step two the sulfur source is thioacetamide, the volume concentration of ammonia water is 25%, and the amount of ammonia water added is 3.5-4.5 mL. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com