Ferric salt-doped Spiro-OMeTAD hole transport layer and solar cell comprising hole transport layer

A hole transport layer and solar cell technology, applied in the field of solar cells, can solve the problems of expensive dopant doping and low mobility of organic hole transport layers, achieve good device performance, improve charge transport properties, and dope low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

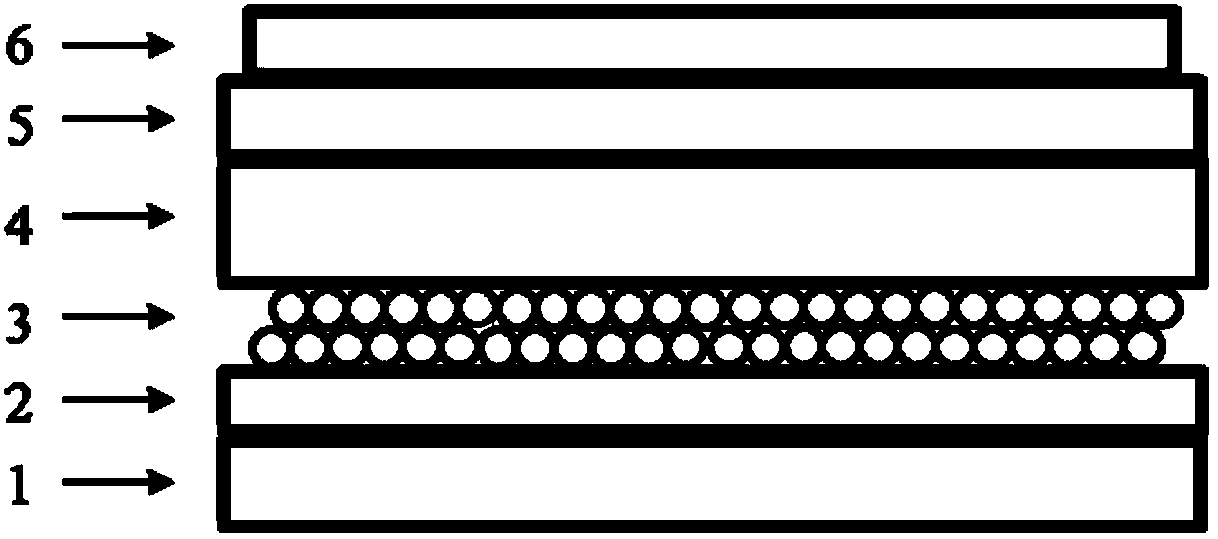

[0054] The preparation method of the perovskite solar cell described in any one of the above-mentioned, is characterized in that, comprises the following steps:

[0055] 1) ultrasonically clean the conductive substrate with water, acetone, and absolute ethanol in sequence, and dry it;

[0056] 2) Treat the cleaned conductive substrate with ultraviolet ozone for 10-20 minutes, put TiCl 4 - In hydrochloric acid aqueous solution, hydrolyze at 67-73°C, wash with water after hydrolysis, and burn at 430-480°C for 25-35min to obtain the electron transport layer;

[0057] 3) TiO with a mass ratio of 1:5 to 7 2 Spin-coat the surface of the electron transport layer with absolute ethanol solution, the spin-coating speed is 3500-4500rpm, and the time is 15-25s; then perform annealing treatment at 95-105°C, 8-12min, 430-480°C, 25-35min , and then cooled naturally to obtain a mesoporous layer;

[0058] 4) FAI, PbI 2 , MABr, PbBr 2 , CsI is dissolved in the mixed solution of DMF and DMS...

Embodiment 1

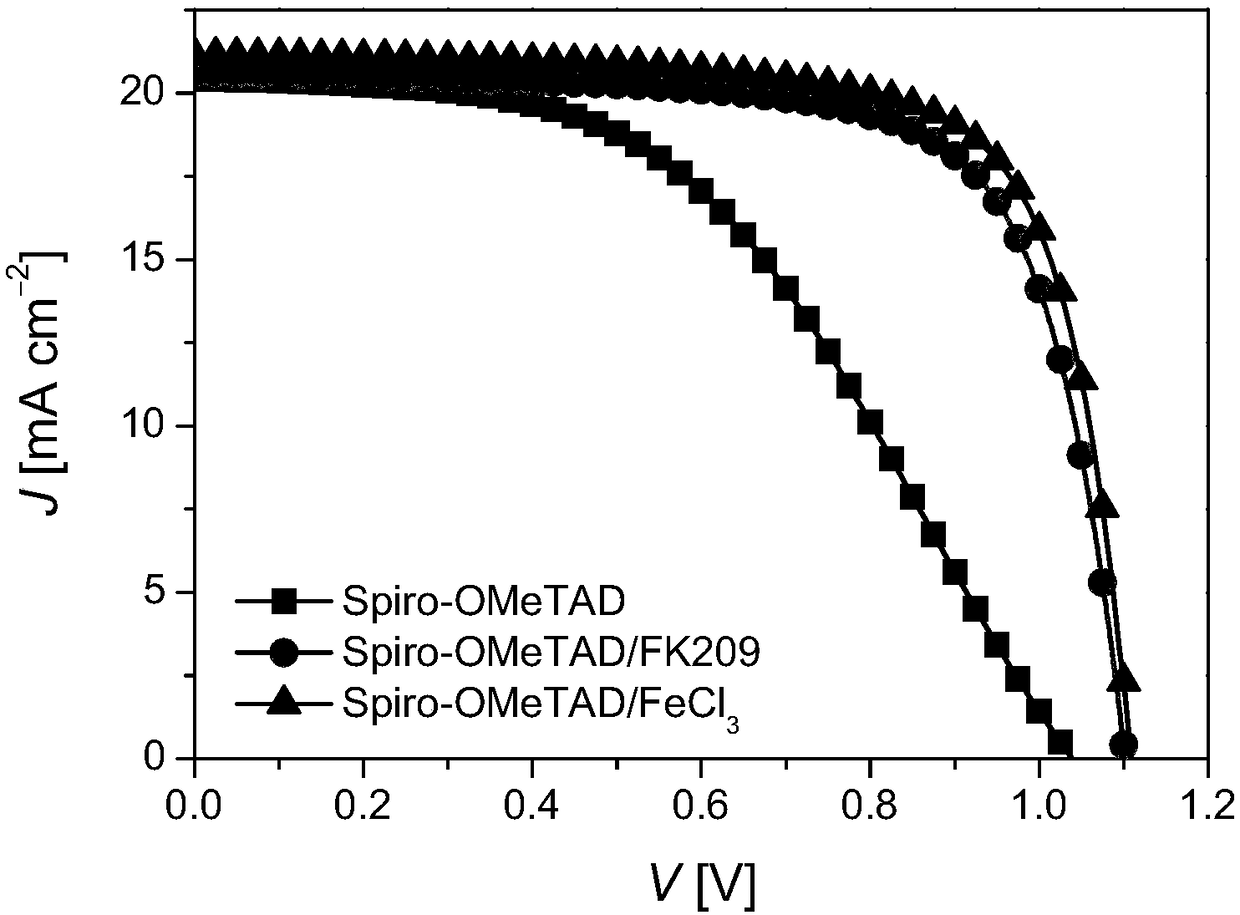

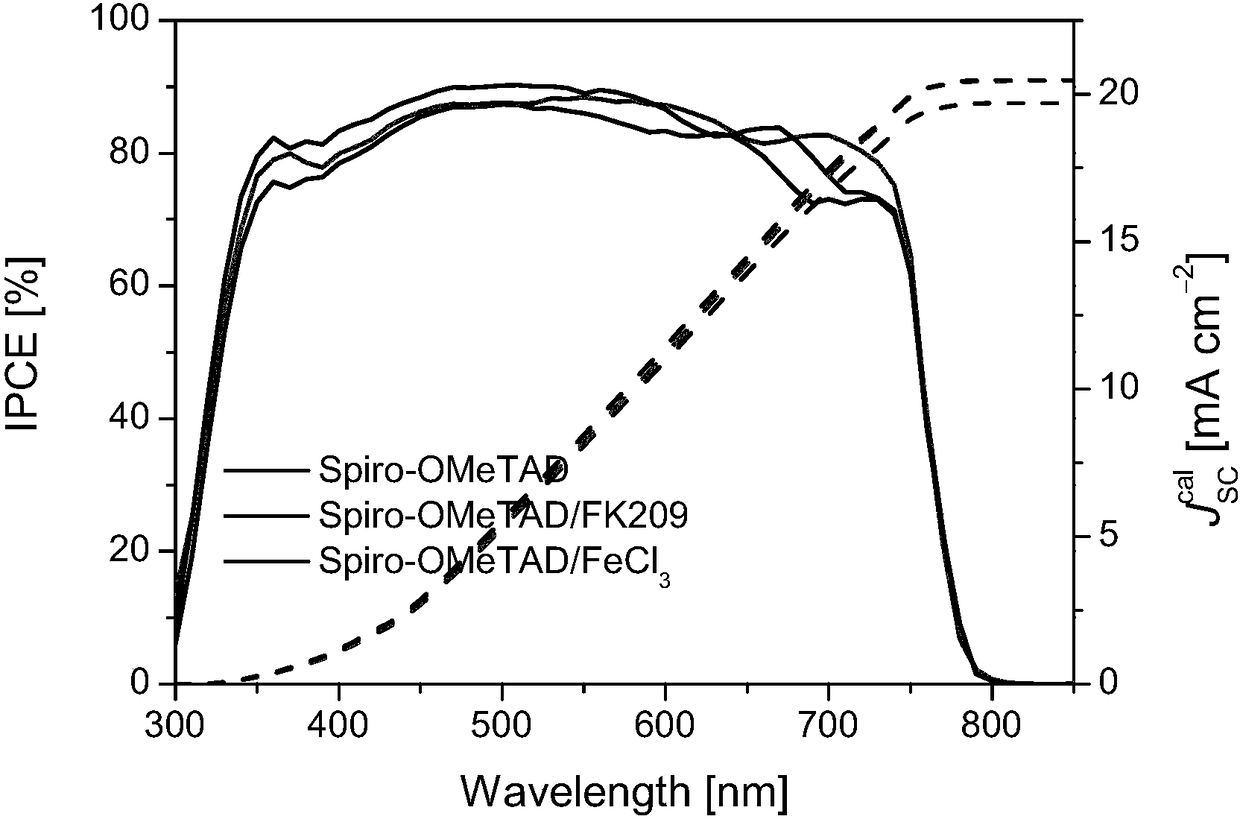

[0062] Embodiment 1 a kind of FeCl-containing 3 Solar cells with hole-transport layer doped with Spiro-OMeTAD

[0063] (1) Substrate cleaning: Clean the FTO glass with a detergent and rinse it with water. After there is no obvious dirt, put it into a sealed cleaning tank, pour in an aqueous solution of detergent, and ultrasonically clean it for 10 minutes, then use ultrapure water, acetone, Absolute ethanol, followed by ultrasonic cleaning. Blow dry with dry air when finished.

[0064] (2) Electron transport layer preparation: the cleaned substrate was treated in ultraviolet-ozone for 15 minutes. Dense TiO 2 The layer is prepared by a hydrothermal method, that is, the substrate that has been treated with ozone is soaked in an aqueous solution of titanium tetrachloride and sealed at 70° C. for 90 minutes for hydrolysis. After completion, take it out, rinse it with ultrapure water, blow dry, cut it into the required size and burn it at 450°C for 30 minutes, then lower it to ...

Embodiment 2

[0074] Embodiment 2 a kind of FeCl-containing 3 Solar cells with hole-transport layer doped with Spiro-OMeTAD

[0075] (1) Substrate cleaning: Clean the FTO glass with a detergent and rinse it with water. After there is no obvious dirt, put it into a sealed cleaning tank, pour in an aqueous solution of detergent, and ultrasonically clean it for 10 minutes, then use ultrapure water, acetone, Absolute ethanol, followed by ultrasonic cleaning. Blow dry with dry air when finished.

[0076] (2) Electron transport layer preparation: the cleaned substrate was treated in ultraviolet-ozone for 20 minutes. Dense TiO 2 The layer was prepared by a hydrothermal method, that is, the substrate that had been treated with ozone was soaked in an aqueous solution of titanium tetrachloride and sealed at 67°C for 100 minutes for hydrolysis. After completion, take it out, rinse it with ultrapure water, blow dry, cut it into the required size and burn it at 430°C for 35 minutes, then lower it to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com