Method for extracting xylan from woody fiber material

A lignocellulosic material and a lignofiber technology, applied in the field of xylan extraction, can solve the problems of high production cost, dark product color, light product color and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

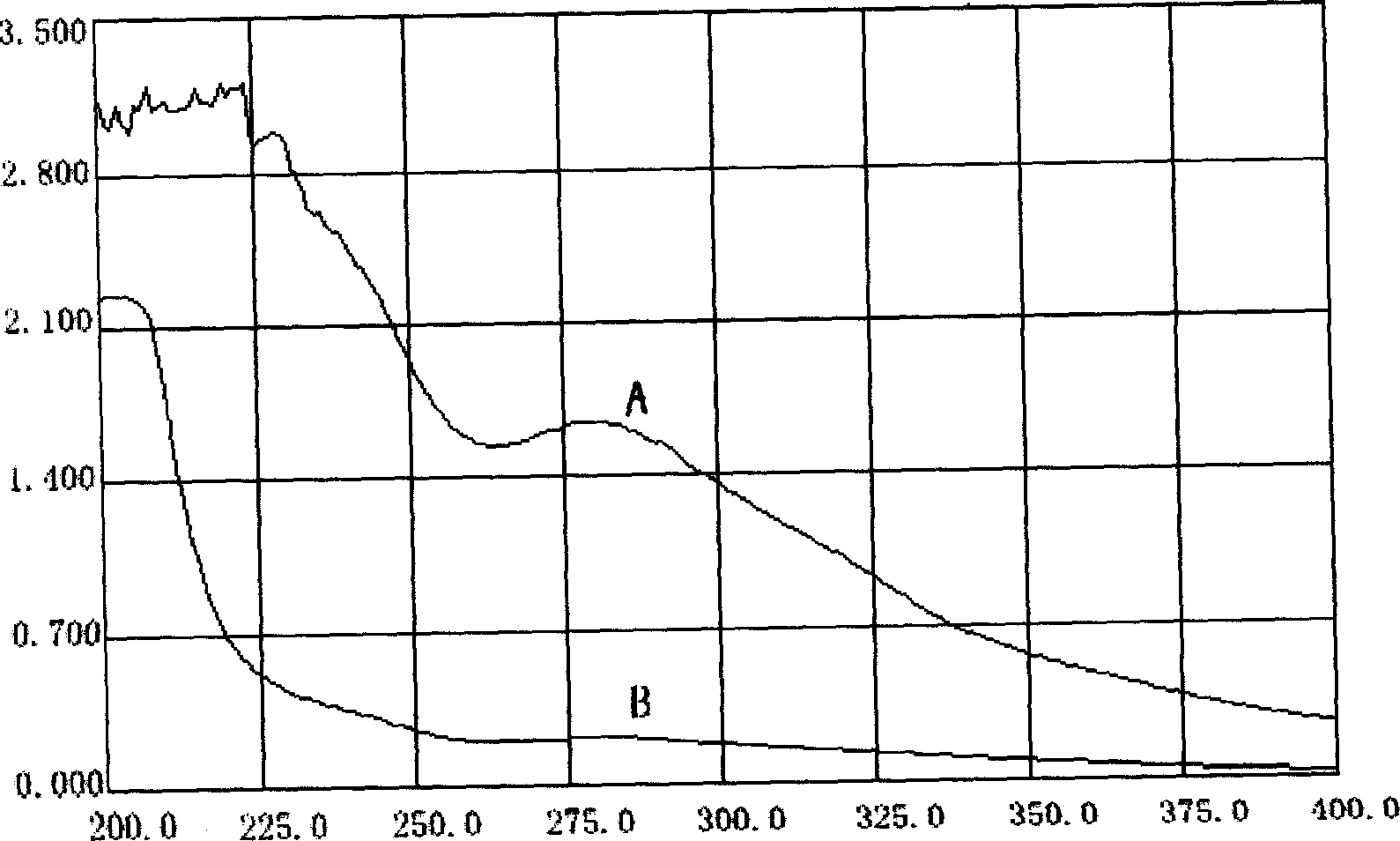

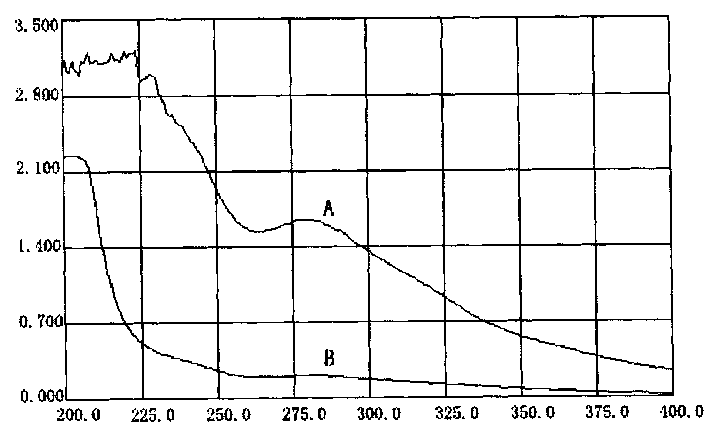

Image

Examples

Embodiment 1

[0027] Dry 100g of bagasse, add 2% sodium hydroxide, 400ml of 1% hydrogen peroxide solution, mix well in a conical flask, place at 28°C for 10 hours, then heat in a 750W microwave oven for 4 minutes, squeeze out 200ml of the solution, and use Wash once. Combine the two extraction solutions, neutralize to pH8 with hydrochloric acid, remove the precipitate by centrifugation, concentrate the supernatant in vacuum at 70°C to 100 ml, neutralize to pH4.5 with hydrochloric acid, add 300 ml of 95% ethanol, and centrifuge The precipitate was collected and dried to obtain 35 grams of off-white bagasse xylan. That is, the yield of product to material bagasse is 35%.

Embodiment 2

[0029]As the contrast of embodiment 1, do not add hydrogen peroxide in the sodium hydroxide solution of the present embodiment, and material ratio, as bagasse consumption, sodium hydroxide consumption etc., are all with embodiment 1. If treated by microwave, the extract is concentrated, precipitated with ethanol, and dried to obtain 15 grams of dark brown xylan product. Without microwave treatment, only 4 g of dark brown xylan product was obtained. That is, under the condition of the same amount of alkali used, the yield of xylan products obtained by a single alkali extraction process is only 1 / 9 of the present invention; only the extraction process of alkali-microwave is used, and the yield is not as high as that of the present invention. 50%, and they are all far less than the light color of the product of the present invention.

Embodiment 3

[0031] The raw material is corncobs instead, and other processing conditions are the same as in Example 1. Obtain off-white corncob xylan product 45 grams. That is, adopt corncob as raw material, the yield of product will be higher than bagasse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com