Surface processing method of carbon fabric

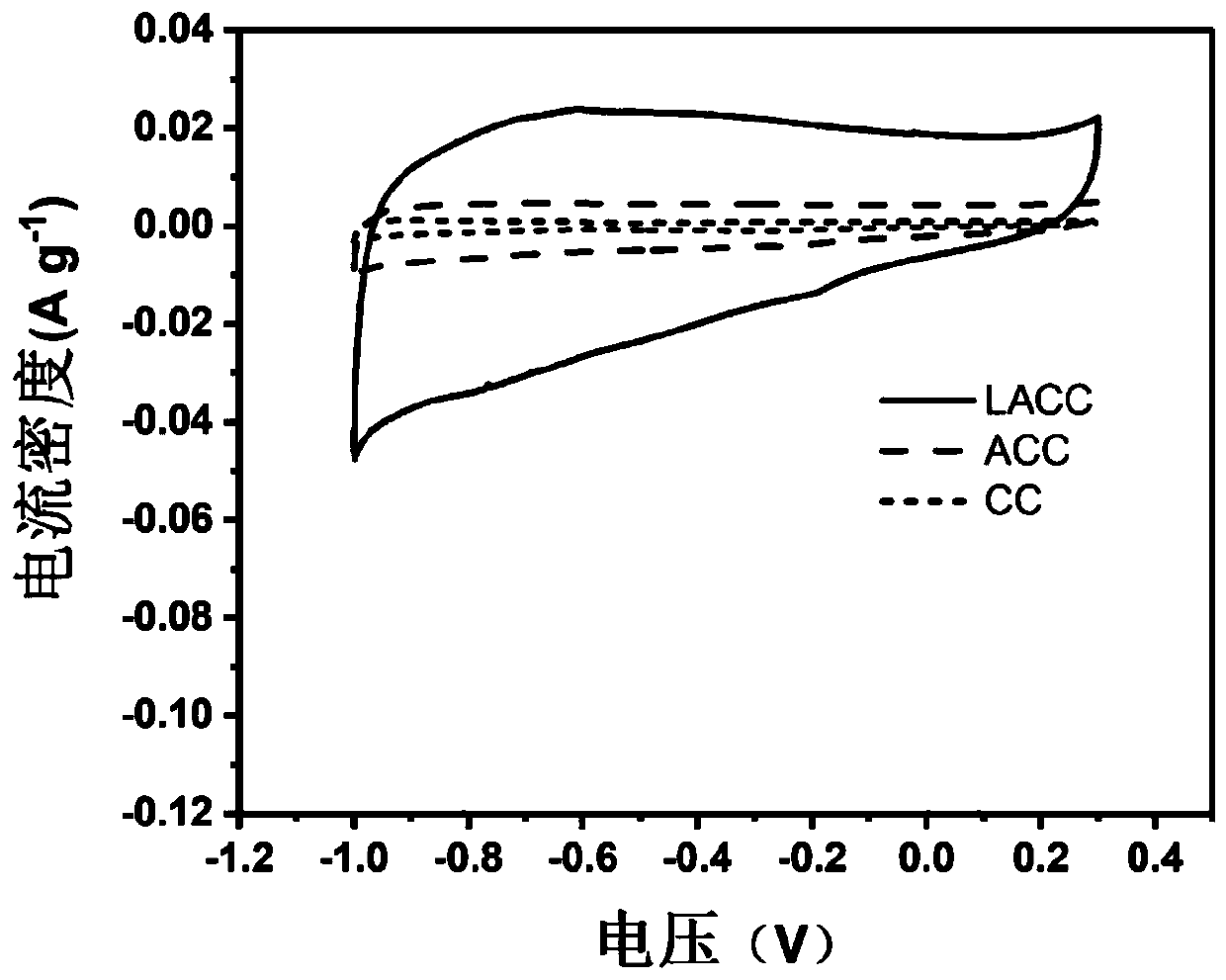

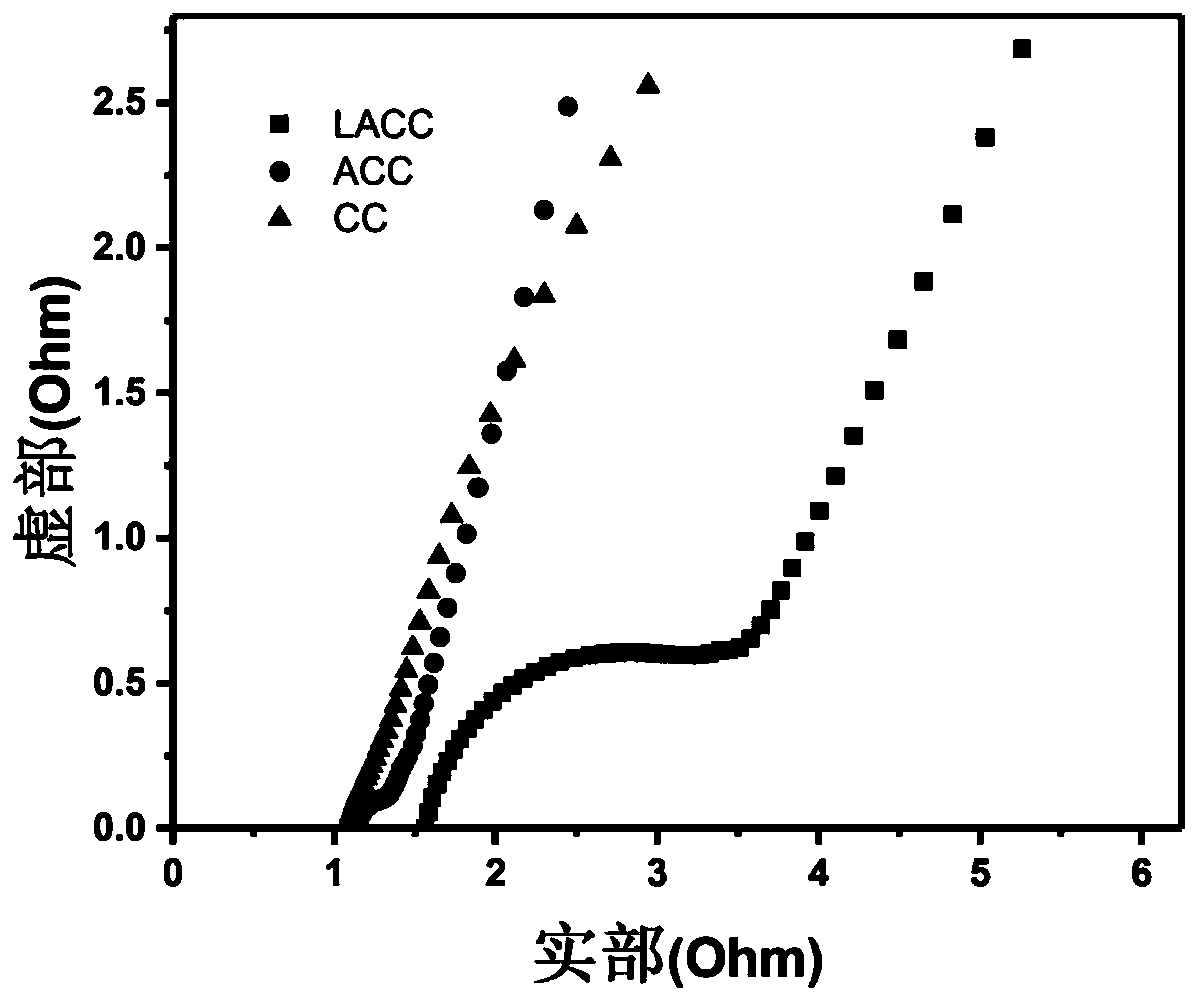

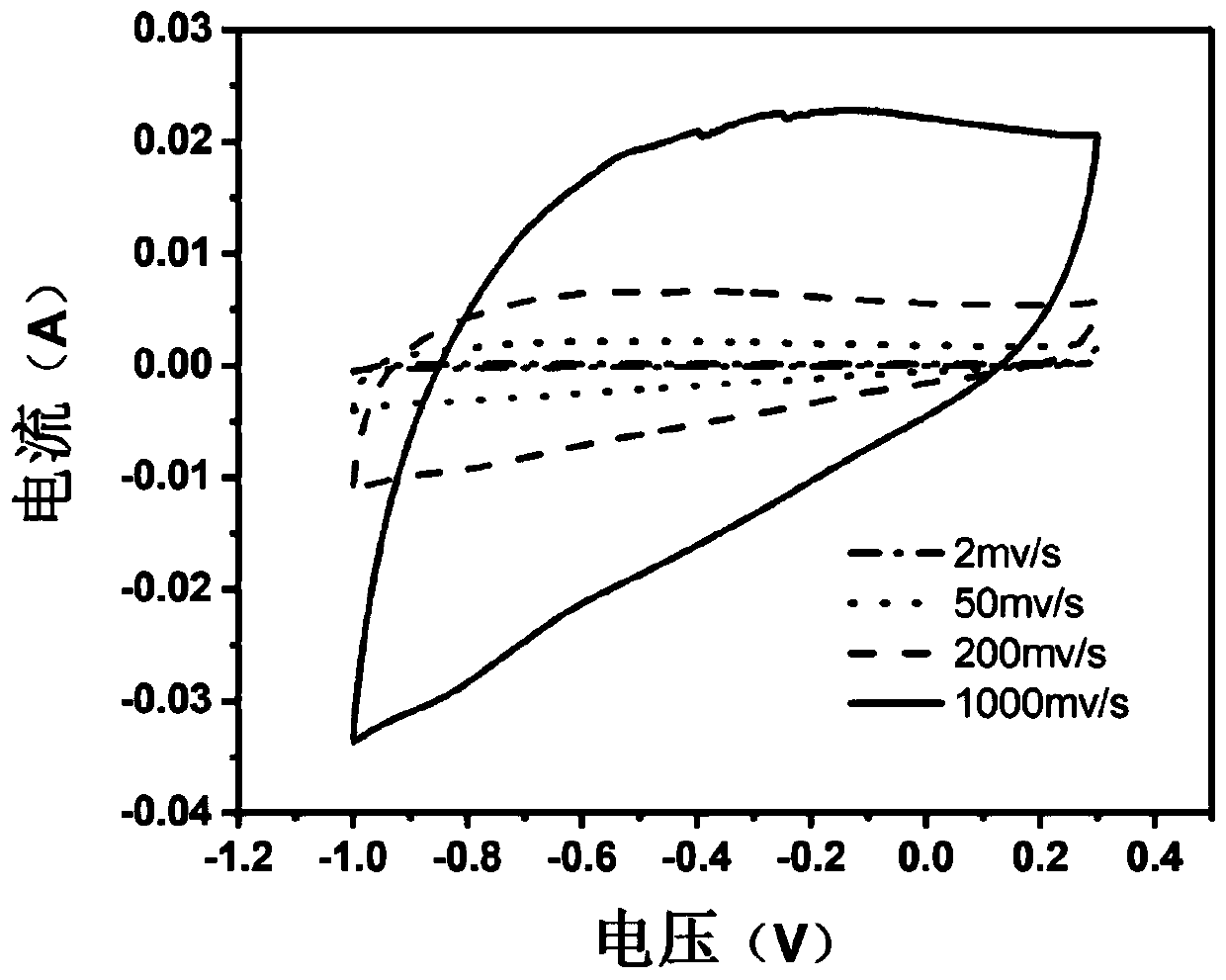

A technology of surface treatment and carbon cloth, which is applied in the field of communication, can solve the problems of not being able to meet the needs of supercapacitor electrodes and the improvement of the electrochemical performance of carbon cloth, and achieve the effects of enriching surface pore structure, improving surface activity, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for surface treatment of carbon cloth, the operation steps are as follows:

[0039] Liquid phase oxidation treatment: 1×1em 2 The carbon is placed in a beaker filled with 20ml of concentrated sulfuric acid (concentration 95%) and 20ml of concentrated nitric acid (concentration 68%), soaked for 5min, and rinsed repeatedly with deionized water after soaking until the washing liquid is neutral. Dry;

[0040] Electrodeposition treatment: Take 20ml of concentrated sulfuric acid (concentration 95%) and concentrated nitric acid (concentration 65%) 20ml in a 50ml beaker and seal the mouth of the cup with plastic wrap for later use, and clamp the carbon cloth after liquid phase oxidation treatment on the electrode clamp, and fix the calomel electrode and platinum electrode on the support frame of the iron stand, place the above-mentioned beaker containing the solution directly under the support frame, slowly lower the support frame until the front end of the electrode ...

Embodiment 2

[0043] A method for surface treatment of carbon cloth, the operation steps are as follows:

[0044] Liquid phase oxidation treatment: 1×1Gm 2 The carbon is arranged in a beaker filled with 20ml of concentrated sulfuric acid (concentration 95%) and 20ml of concentrated nitric acid (concentration 68%), soaked for 15min, rinsed repeatedly with deionized water after soaking until the washing liquid is neutral, and baked Dry;

[0045]Electrodeposition treatment: Take 20ml of concentrated sulfuric acid (concentration 95%) and 20ml concentrated nitric acid (concentration 66%) in a 50ml beaker and seal the mouth of the cup with plastic wrap for later use, and clamp the carbon cloth after liquid phase oxidation treatment on the electrode clamp, and fix the calomel electrode and platinum electrode on the support frame of the iron stand, place the above-mentioned beaker containing the solution directly under the support frame, slowly lower the support frame until the front end of the el...

Embodiment 3

[0048] A method for surface treatment of carbon cloth, the operation steps are as follows:

[0049] Liquid phase oxidation treatment: 1×1cm 2 The carbon is arranged in a beaker filled with 20ml of concentrated sulfuric acid (concentration 95%) and 20ml of concentrated nitric acid (concentration 68%), soaked for 10min, and rinsed repeatedly with deionized water after soaking until the washing liquid is neutral. Dry;

[0050] Electrodeposition treatment: Take 20ml of concentrated sulfuric acid (concentration 96%) and 20ml of concentrated nitric acid (concentration 67%) in a 50ml beaker, seal the mouth of the cup with plastic wrap for later use, and clamp the carbon cloth after liquid phase oxidation treatment on the electrode clamp, and fix the calomel electrode and platinum electrode on the support frame of the iron stand, place the above-mentioned beaker containing the solution directly under the support frame, slowly lower the support frame until the front end of the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com