Novel filtering material for air cleaning machine, and preparation method and use thereof

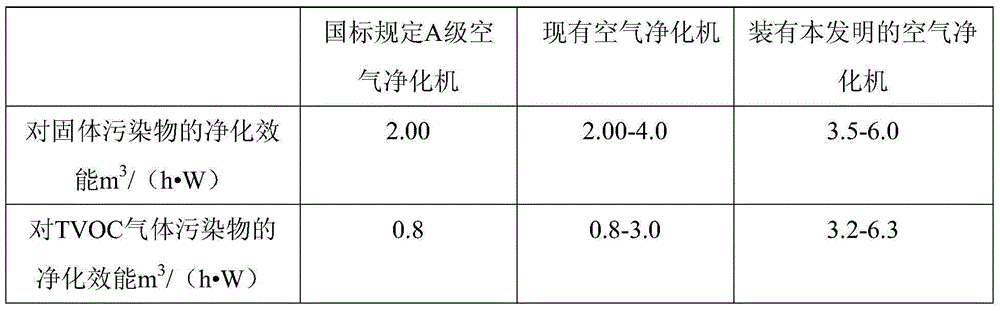

An air purifier and filter material technology, applied in the field of air purification, can solve the problems of low purification efficiency and large space occupation of air purification filter elements, and achieve the effects of improving air purification efficiency, good support, and improving polarization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

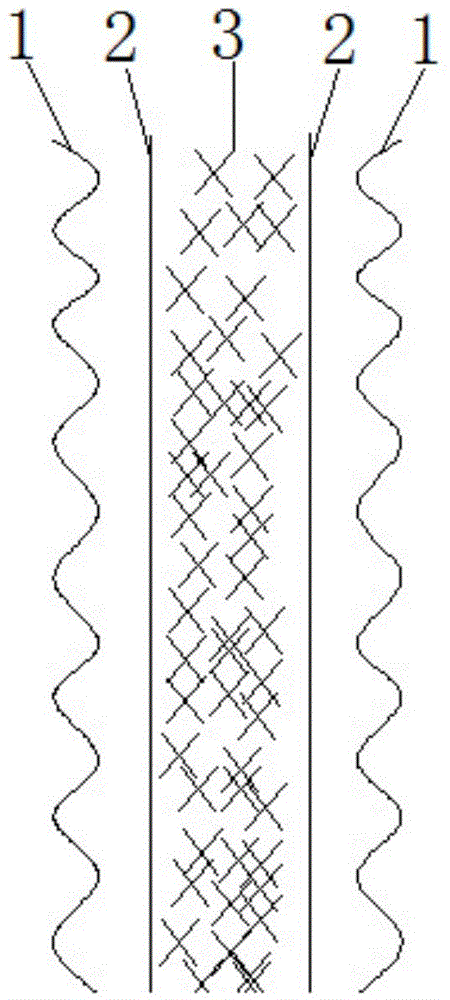

Image

Examples

Embodiment 1)

[0031] A preparation method for a novel filter material for an air purifier, comprising the following steps:

[0032](1) Pass the filter layer 2 of polypropylene melt-blown cloth through the electret plasma treatment unit, and perform surface electrostatic treatment between the front and rear rollers of the equipment. The standing current of the surface electrostatic treatment is 0.20mA and the electret peak current is 20000V. Through the unique surface line corona discharge mode of this equipment, charges are injected into the polypropylene melt-blown cloth, and the pre-embedded material doped in the filter layer 2 of the polypropylene melt-blown cloth is high-energy polarized, and the charges are fixed in the material ;

[0033] (2) Use a special water-soluble nano-adhesive to bond polypropylene meltblown cloth and polyethylene terephthalate skeleton support material, the content of the water-soluble nano-adhesive is 6g / m 2 ; and compound the two between the two rollers on ...

Embodiment 2)

[0041] A preparation method for a novel filter material for an air purifier, comprising the following steps:

[0042] (1) Pass the polyethylene terephthalate melt-blown cloth filter layer 2 through the electret plasma treatment unit, and perform surface electrostatic treatment between the front and rear rollers of the equipment. The standing current of the surface electrostatic treatment is 0.30mA electret peak-peak Electricity is 15000V. Through the unique surface line corona discharge mode of this equipment, charge is injected into the polyethylene terephthalate melt-blown cloth, and the pre-doped polyethylene terephthalate melt-blown cloth filter layer 2 The buried material conducts high-energy polarization and fixes the charge in the material;

[0043] (2) The polyethylene terephthalate melt-blown cloth and the polybutylene terephthalate skeleton support material are bonded by using a special water-soluble nano-adhesive. The water-soluble nano-adhesive The content is 7g / ...

Embodiment 3)

[0051] A preparation method for a novel filter material for an air purifier, comprising the following steps:

[0052] (1) Pass the polydicyclopentadiene melt-blown cloth filter layer 2 through the electret plasma treatment unit, and perform surface electrostatic treatment between the front and rear rollers of the equipment. The standing current of the surface electrostatic treatment is 0.35mA and the electret peak current is 30000V. Through the unique surface line corona discharge mode of the equipment, charge is injected into the polydicyclopentadiene melt-blown cloth, and the pre-embedded material doped in the filter layer 2 of the polydicyclopentadiene melt-blown cloth is high-energy polarized, and fix the charge in the material;

[0053] (2) The polydicyclopentadiene melt-blown cloth and the polyvinylidene fluoride skeleton support material are bonded with a special water-soluble nano-adhesive, and the content of the water-soluble nano-adhesive is 8g / m 2 ; and compound th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com